Information injection-pump assembly

ZEXEL

104761-2010

1047612010

Rating:

Cross reference number

ZEXEL

104761-2010

1047612010

Zexel num

Bosch num

Firm num

Name

104761-2010

INJECTION-PUMP ASSEMBLY

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113orSAEJ967d

1404 Test oil ISO4113orSAEJ967d

Test oil temperature

degC

45

45

50

Nozzle

105780-0060

Bosch type code

NP-DN0SD1510

Nozzle holder

105780-2150

Opening pressure

MPa

13

13

13.3

Opening pressure

kgf/cm2

133

133

136

Injection pipe

157805-7320

Injection pipe

Inside diameter - outside diameter - length (mm) mm 2-6-450

Inside diameter - outside diameter - length (mm) mm 2-6-450

Joint assembly

157641-4720

Tube assembly

157641-4020

Transfer pump pressure

kPa

20

20

20

Transfer pump pressure

kgf/cm2

0.2

0.2

0.2

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Pump speed

r/min

600

600

600

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

33.6

33.2

34

Difference in delivery

mm3/st.

2

Basic

*

Oil temperature

degC

50

48

52

Remarks

NA

NA

Injection timing adjustment_02

Pump speed

r/min

700

700

700

Boost pressure

kPa

28

26.7

29.3

Boost pressure

mmHg

210

200

220

Average injection quantity

mm3/st.

38.6

38.2

39

Difference in delivery

mm3/st.

2

Basic

*

Oil temperature

degC

50

48

52

Remarks

CBS

CBS

Injection timing adjustment_03

Pump speed

r/min

600

600

600

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

33.6

32.7

34.5

Difference in delivery

mm3/st.

2.5

Basic

*

Oil temperature

degC

50

48

52

Injection timing adjustment_04

Pump speed

r/min

700

700

700

Boost pressure

kPa

28

26.7

29.3

Boost pressure

mmHg

210

200

220

Average injection quantity

mm3/st.

38.6

37.7

39.5

Difference in delivery

mm3/st.

2.5

Basic

*

Oil temperature

degC

50

48

52

Injection timing adjustment_05

Pump speed

r/min

1200

1200

1200

Boost pressure

kPa

66.7

65.4

68

Boost pressure

mmHg

500

490

510

Average injection quantity

mm3/st.

46

43.5

48.5

Oil temperature

degC

50

48

52

Injection timing adjustment_06

Pump speed

r/min

1800

1800

1800

Boost pressure

kPa

66.7

65.4

68

Boost pressure

mmHg

500

490

510

Average injection quantity

mm3/st.

45.7

42.7

48.7

Oil temperature

degC

50

48

52

Injection timing adjustment_07

Pump speed

r/min

2200

2200

2200

Boost pressure

kPa

66.7

65.4

68

Boost pressure

mmHg

500

490

510

Average injection quantity

mm3/st.

43.8

40.8

46.8

Oil temperature

degC

52

50

54

Injection timing adjustment_08

Pump speed

r/min

2300

2300

2300

Boost pressure

kPa

66.7

65.4

68

Boost pressure

mmHg

500

490

510

Average injection quantity

mm3/st.

43.5

40

47

Oil temperature

degC

52

50

54

Injection quantity adjustment

Pump speed

r/min

2500

2500

2500

Boost pressure

kPa

66.7

65.4

68

Boost pressure

mmHg

500

490

510

Average injection quantity

mm3/st.

20.5

19.5

21.5

Difference in delivery

mm3/st.

4.5

Basic

*

Oil temperature

degC

55

52

58

Injection quantity adjustment_02

Pump speed

r/min

2500

2500

2500

Boost pressure

kPa

66.7

65.4

68

Boost pressure

mmHg

500

490

510

Average injection quantity

mm3/st.

20.5

19

22

Difference in delivery

mm3/st.

5

Basic

*

Oil temperature

degC

55

52

58

Injection quantity adjustment_03

Pump speed

r/min

2800

2800

2800

Boost pressure

kPa

66.7

65.4

68

Boost pressure

mmHg

500

490

510

Average injection quantity

mm3/st.

3

Oil temperature

degC

55

52

58

Governor adjustment

Pump speed

r/min

375

375

375

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

14

13

15

Difference in delivery

mm3/st.

1.7

Basic

*

Oil temperature

degC

48

46

50

Governor adjustment_02

Pump speed

r/min

375

375

375

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

14

12

16

Difference in delivery

mm3/st.

2.2

Basic

*

Oil temperature

degC

48

46

50

Governor adjustment_03

Pump speed

r/min

800

800

800

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

5

Oil temperature

degC

50

48

52

Boost compensator adjustment

Pump speed

r/min

600

600

600

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

30.3

23.8

36.8

Oil temperature

degC

50

48

52

Lever angle (shim thickness)

mm

5.6

5.55

5.65

Boost compensator adjustment_02

Pump speed

r/min

900

900

900

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

23.9

16.9

30.9

Oil temperature

degC

50

48

52

Lever angle (shim thickness)

mm

5.6

5.55

5.65

Timer adjustment

Pump speed

r/min

100

100

100

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

40

40

Basic

*

Oil temperature

degC

48

46

50

Timer adjustment_02

Pump speed

r/min

100

100

100

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

40

40

Oil temperature

degC

48

46

50

Speed control lever angle

Pump speed

r/min

600

600

600

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

0

0

0

Oil temperature

degC

50

48

52

Remarks

Magnet OFF at full-load position

Magnet OFF at full-load position

Speed control lever angle_02

Pump speed

r/min

375

375

375

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

6

Oil temperature

degC

48

46

50

Remarks

Magnet OFF at idling position

Magnet OFF at idling position

0000000901

Pump speed

r/min

900

900

900

Boost pressure

kPa

66.7

65.4

68

Boost pressure

mmHg

500

490

510

Overflow quantity with S/T OFF

cm3/min

390

260

520

Oil temperature

degC

50

48

52

Remarks

With an O-ring

With an O-ring

Stop lever angle

Pump speed

r/min

900

900

900

Boost pressure

kPa

66.7

65.4

68

Boost pressure

mmHg

500

490

510

Pressure with S/T OFF

kPa

432

403

461

Pressure with S/T OFF

kgf/cm2

4.4

4.1

4.7

Basic

*

Oil temperature

degC

50

48

52

Stop lever angle_02

Pump speed

r/min

900

900

900

Boost pressure

kPa

66.7

65.4

68

Boost pressure

mmHg

500

490

510

Pressure with S/T ON

kPa

353

304

402

Pressure with S/T ON

kgf/cm2

3.6

3.1

4.1

Pressure with S/T OFF

kPa

431

392

470

Pressure with S/T OFF

kgf/cm2

4.4

4

4.8

Basic

*

Oil temperature

degC

50

48

52

Stop lever angle_03

Pump speed

r/min

1200

1200

1200

Boost pressure

kPa

66.7

65.4

68

Boost pressure

mmHg

500

490

510

Pressure with S/T OFF

kPa

490

451

529

Pressure with S/T OFF

kgf/cm2

5

4.6

5.4

Oil temperature

degC

50

48

52

Stop lever angle_04

Pump speed

r/min

2300

2300

2300

Boost pressure

kPa

66.7

65.4

68

Boost pressure

mmHg

500

490

510

Pressure with S/T OFF

kPa

765

726

804

Pressure with S/T OFF

kgf/cm2

7.8

7.4

8.2

Oil temperature

degC

52

50

54

0000001101

Pump speed

r/min

900

900

900

Boost pressure

kPa

66.7

65.4

68

Boost pressure

mmHg

500

490

510

Timer stroke with S/T OFF

mm

3.4

3.2

3.6

Basic

*

Oil temperature

degC

50

48

52

_02

Pump speed

r/min

900

900

900

Boost pressure

kPa

66.7

65.4

68

Boost pressure

mmHg

500

490

510

Timer stroke with S/T ON

mm

1.7

1.3

2.1

Timer stroke with S/T OFF

mm

3.4

3.1

3.7

Basic

*

Oil temperature

degC

50

48

52

_03

Pump speed

r/min

1200

1200

1200

Boost pressure

kPa

66.7

65.4

68

Boost pressure

mmHg

500

490

510

Timer stroke with S/T OFF

mm

5.2

4.8

5.6

Oil temperature

degC

50

48

52

_04

Pump speed

r/min

2300

2300

2300

Boost pressure

kPa

66.7

65.4

68

Boost pressure

mmHg

500

490

510

Timer stroke with S/T OFF

mm

9.8

9.3

10.2

Oil temperature

degC

52

50

54

0000001201

Max. applied voltage

V

8

8

8

Test voltage

V

13

12

14

Timing setting

K dimension

mm

3.3

3.2

3.4

KF dimension

mm

7.22

7.12

7.32

MS dimension

mm

1.8

1.7

1.9

Control lever angle alpha

deg.

23

19

27

Control lever angle beta

deg.

42

37

47

Test data Ex:

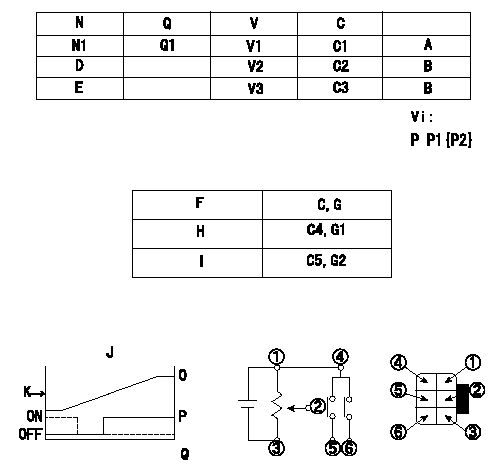

0000001801 POTENTIOMETER ADJUSTMENT

Adjustment of the potentiometer

1. Determine the position of the control lever at the adjusting point. Fix with the dummy bolt contacting the lever.

2. In the fixed position, install the potentiometer so that the output voltage is V1 (supply voltage Vi).

3. After completing potentiometer installation, remove the dummy bolt.

N:Pump speed

Q:Injection quantity

V:Output voltage

P:Boost pressure

A:Adjusting point

B:Checking point

C:Control lever angle

D:Idle lever angle

E:Full speed lever angle

F:Conversion point

G:From idle

H:ON-->OFF

I:OFF-->ON

J:Connecting diagram for the potentiometer

K:Output

O:Output when (2) and (3) connected.

P:When (4) or (6) connected: switch OFF to ON.

Q:When (4) or (6) connected: switch ON to OFF.

----------

V1=3.2+-0.03V Vi=10V

----------

N1=600r/min Q1=16.9+-1.0cm3/1,000st V1=3.2+-0.03V V2=(1.96)V V3=(8.96)V C1=-deg C2=0deg C3=42deg Vi=10V P1=0kPa P2=0mmHg C4=(1.9)deg?@ C5=(22.5++)deg G1=-V G2=-V

----------

V1=3.2+-0.03V Vi=10V

----------

N1=600r/min Q1=16.9+-1.0cm3/1,000st V1=3.2+-0.03V V2=(1.96)V V3=(8.96)V C1=-deg C2=0deg C3=42deg Vi=10V P1=0kPa P2=0mmHg C4=(1.9)deg?@ C5=(22.5++)deg G1=-V G2=-V

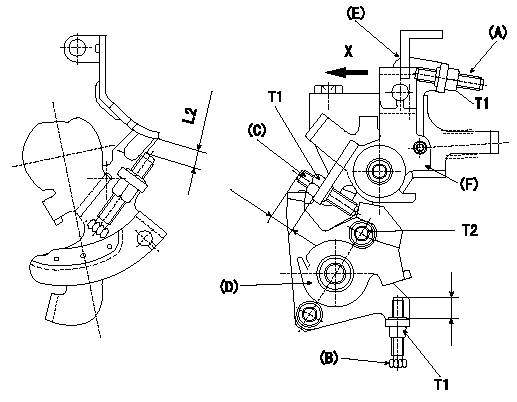

0000001901 M-CSD ADJUSTMENT

M-CSD adjustment

1. CSD adjustment

Turn the lever (D) clockwise and adjust screw (B) so that the timer piston advance angle is a (L1). Then fix using the nut.

2. With intermediate lever screw (C)'s fixing lever (D) positioned as in 1., pull the intermediate lever in direction X. After confirming that it contacts the stop position, adjust so that screw (C) contacts lever (D) and then fix using the nut.

(Intermediate lever status in 2.: full speed, indicates timer's a advance.

Confirm that the timer piston advances to b deg when the intermediate lever is returned.

3. Fast idle adjustment

Pull the intermediate lever in direction x to contact the stopper and adjust the screw (A) so that the gap between the idle set bracket and the idle screw is L2. Fix using the nut.

The gap between the control lever at the idle position and the screw (A) must be L3.

(E) control lever

(F) intermediate lever

----------

a=3deg b=0deg L1=2.5mm L2=6+-0.05mm L3=(1.7mm)

----------

T1=6~9N-m(0.6~0.9kgf-m) T2=5~7N-m(0.5~0.7kgf-m) L2=6+-0.05mm

----------

a=3deg b=0deg L1=2.5mm L2=6+-0.05mm L3=(1.7mm)

----------

T1=6~9N-m(0.6~0.9kgf-m) T2=5~7N-m(0.5~0.7kgf-m) L2=6+-0.05mm

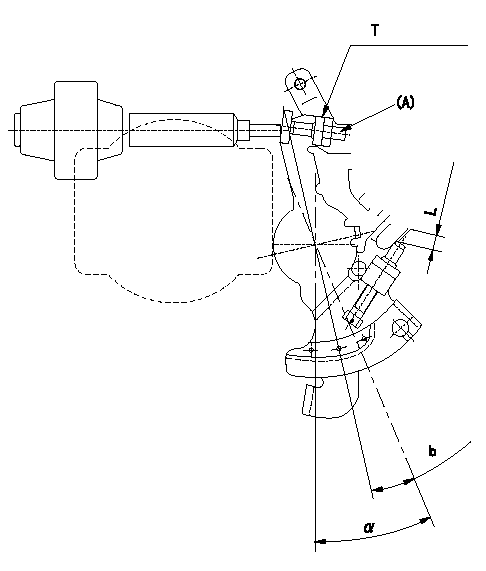

0000002001 DASHPOT ADJUSTMENT

Adjustment of the dash pot

1. Insert a block gauge L (thickness gauge) between the idle set bracket and the idle screw.

2. In the above condition, adjust so that the dashpot adjusting screw (A) contacts the pushrod. Then, fix using the nut.

Record the dashpot return time t.

a = alpha

----------

L=3.8+-0.05mm t=1.8+-0.5sec

----------

T=5.0~7.0N-m(0.5~0.7kgf-m) b=7.4deg L=3.8+-0.05mm(750r/min)

----------

L=3.8+-0.05mm t=1.8+-0.5sec

----------

T=5.0~7.0N-m(0.5~0.7kgf-m) b=7.4deg L=3.8+-0.05mm(750r/min)

Information:

1. External View

(Natural-aspirated engine)

* This photo shows the model 6D14.(Turbocharged engine)

* This photo shows the model 6D14-T.2. Major Specifications

2.1 Major Specifications

2.2 Engine Outputs Classified by Application

1. The output (SAE, gross) is corrected to standard ambient conditions based on SAE J1349.2. The continuous rated output allows 10% (one hour) overload operation.3. Engine Number And Nameplate

(1) Engine number The engine number is stamped on the position as illustrated.Example: The engine number is important in knowing the history of the engine.(2) Nameplate The nameplate is attached to the portion as illustrated.The nameplate bears the followings: 4. General Precautions For Servicing

Before starting the service procedures, check the vehicle for total time driven, use conditions, and user's complaints and requests to know exactly the engine conditions. Record information where necessary.To ensure you are doing correct and efficient service jobs, observe the following precautions: (1) Before performing the service procedures given in this manual, know the trouble spots and isolate the possible cause to determine whether the removal or disassembly procedure is required.(2) Select a flat surface for the service job.(3) When servicing the electrical system, be sure to disconnect the negative cable from the battery.(4) Carefully check parts for oil leaks before cleaning. After cleaning, it may become difficult to spot defective areas.(5) Ready and make the most of the special tools required for servicing. Use the right tools (specified special tools) in the right place to prevent damages to parts and personal injury.(6) Make alignment marks and keep disassembled parts neatly arranged to ensure that they are reassembled into the right positions.* Special care must be taken for assemblies involving a number of parts, similar parts, or parts identical at right- and left-hand sides to ensure correct reassembly.* For alignment and punching markings, select a position that would not mar the appearance and function.* Clearly distinguish parts to be replaced from those reused. (7) The oil seals, packings, O-rings, and other rubber parts, gaskets, and split pins must be replaced with a new one whenever they are removed. For replacement, use Mitsubishi Genuine parts. (8) Apply the specified grease to U-packings, oil seals, dust seals, and bearings before installation.(9) When work requires an assistant or two, always make sure of the safety each other. Never play with switches and levers.(10) Make sure that your shoes are free from grease and oil especially when working on a heavy item.(11) When checking or changing lubricants, wipe off grease and oil from parts immediately with a waste.(12) Special care must be taken in handling sensors and relays which are suspectible to shocks and heat.(13) Use care so that hands and fingers are not injured by sharp edges or corners of the parts.(14) Wear safety goggles whenever handling a grinder or welding machine. Wear gloves as required to ensure utmost safety.5. General Bolts And Nuts Tightening Torque Table

Unless otherwise specified, the parts and equipment of vehicle must be tightened by the following standard bolts and nuts. Tightening torques for these bolts and nuts are shown below.

(Natural-aspirated engine)

* This photo shows the model 6D14.(Turbocharged engine)

* This photo shows the model 6D14-T.2. Major Specifications

2.1 Major Specifications

2.2 Engine Outputs Classified by Application

1. The output (SAE, gross) is corrected to standard ambient conditions based on SAE J1349.2. The continuous rated output allows 10% (one hour) overload operation.3. Engine Number And Nameplate

(1) Engine number The engine number is stamped on the position as illustrated.Example: The engine number is important in knowing the history of the engine.(2) Nameplate The nameplate is attached to the portion as illustrated.The nameplate bears the followings: 4. General Precautions For Servicing

Before starting the service procedures, check the vehicle for total time driven, use conditions, and user's complaints and requests to know exactly the engine conditions. Record information where necessary.To ensure you are doing correct and efficient service jobs, observe the following precautions: (1) Before performing the service procedures given in this manual, know the trouble spots and isolate the possible cause to determine whether the removal or disassembly procedure is required.(2) Select a flat surface for the service job.(3) When servicing the electrical system, be sure to disconnect the negative cable from the battery.(4) Carefully check parts for oil leaks before cleaning. After cleaning, it may become difficult to spot defective areas.(5) Ready and make the most of the special tools required for servicing. Use the right tools (specified special tools) in the right place to prevent damages to parts and personal injury.(6) Make alignment marks and keep disassembled parts neatly arranged to ensure that they are reassembled into the right positions.* Special care must be taken for assemblies involving a number of parts, similar parts, or parts identical at right- and left-hand sides to ensure correct reassembly.* For alignment and punching markings, select a position that would not mar the appearance and function.* Clearly distinguish parts to be replaced from those reused. (7) The oil seals, packings, O-rings, and other rubber parts, gaskets, and split pins must be replaced with a new one whenever they are removed. For replacement, use Mitsubishi Genuine parts. (8) Apply the specified grease to U-packings, oil seals, dust seals, and bearings before installation.(9) When work requires an assistant or two, always make sure of the safety each other. Never play with switches and levers.(10) Make sure that your shoes are free from grease and oil especially when working on a heavy item.(11) When checking or changing lubricants, wipe off grease and oil from parts immediately with a waste.(12) Special care must be taken in handling sensors and relays which are suspectible to shocks and heat.(13) Use care so that hands and fingers are not injured by sharp edges or corners of the parts.(14) Wear safety goggles whenever handling a grinder or welding machine. Wear gloves as required to ensure utmost safety.5. General Bolts And Nuts Tightening Torque Table

Unless otherwise specified, the parts and equipment of vehicle must be tightened by the following standard bolts and nuts. Tightening torques for these bolts and nuts are shown below.

Have questions with 104761-2010?

Group cross 104761-2010 ZEXEL

104761-2010

INJECTION-PUMP ASSEMBLY