Information injection-pump assembly

ZEXEL

104761-0093

1047610093

Rating:

Cross reference number

ZEXEL

104761-0093

1047610093

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113orSAEJ967d

1404 Test oil ISO4113orSAEJ967d

Test oil temperature

degC

45

45

50

Nozzle

105000-2010

Bosch type code

NP-DN12SD12TT

Nozzle holder

105780-2080

Opening pressure

MPa

14.7

14.7

15.19

Opening pressure

kgf/cm2

150

150

155

Injection pipe

Inside diameter - outside diameter - length (mm) mm 2-6-840

Inside diameter - outside diameter - length (mm) mm 2-6-840

Transfer pump pressure

kPa

20

20

20

Transfer pump pressure

kgf/cm2

0.2

0.2

0.2

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Pump speed

r/min

1500

1500

1500

Average injection quantity

mm3/st.

45.7

45.2

46.2

Difference in delivery

mm3/st.

3

Basic

*

Injection timing adjustment_02

Pump speed

r/min

2050

2050

2050

Average injection quantity

mm3/st.

15.4

12.4

18.4

Injection timing adjustment_03

Pump speed

r/min

1800

1800

1800

Average injection quantity

mm3/st.

42.2

40.2

44.2

Injection timing adjustment_04

Pump speed

r/min

1500

1500

1500

Average injection quantity

mm3/st.

45.7

44.7

46.7

Injection timing adjustment_05

Pump speed

r/min

1000

1000

1000

Average injection quantity

mm3/st.

49.6

47.6

51.6

Injection timing adjustment_06

Pump speed

r/min

500

500

500

Average injection quantity

mm3/st.

42.3

40.3

44.3

Injection quantity adjustment

Pump speed

r/min

2050

2050

2050

Average injection quantity

mm3/st.

15.4

12.4

18.4

Basic

*

Injection quantity adjustment_02

Pump speed

r/min

2150

2150

2150

Average injection quantity

mm3/st.

6

Governor adjustment

Pump speed

r/min

300

300

300

Average injection quantity

mm3/st.

10.3

8.3

12.3

Difference in delivery

mm3/st.

2.5

Basic

*

Governor adjustment_02

Pump speed

r/min

300

300

300

Average injection quantity

mm3/st.

10.3

8.3

12.3

Governor adjustment_03

Pump speed

r/min

500

Average injection quantity

mm3/st.

0

0

0

Timer adjustment

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

65

65

Basic

*

Speed control lever angle

Pump speed

r/min

300

300

300

Average injection quantity

mm3/st.

0

0

0

Remarks

Magnet OFF

Magnet OFF

0000000901

Pump speed

r/min

1500

1500

1500

Overflow quantity

cm3/min

399.9

270

529.8

Stop lever angle

Pump speed

r/min

1500

1500

1500

Pressure

kPa

598.5

569

628

Pressure

kgf/cm2

6.1

5.8

6.4

Basic

*

Stop lever angle_02

Pump speed

r/min

500

500

500

Pressure

kPa

225.5

196

255

Pressure

kgf/cm2

2.3

2

2.6

Stop lever angle_03

Pump speed

r/min

1000

1000

1000

Pressure

kPa

411.5

382

441

Pressure

kgf/cm2

4.2

3.9

4.5

Stop lever angle_04

Pump speed

r/min

1500

1500

1500

Pressure

kPa

598.5

569

628

Pressure

kgf/cm2

6.1

5.8

6.4

Stop lever angle_05

Pump speed

r/min

1800

1800

1800

Pressure

kPa

706

677

735

Pressure

kgf/cm2

7.2

6.9

7.5

0000001101

Pump speed

r/min

1500

1500

1500

Timer stroke

mm

5.7

5.5

5.9

Basic

*

_02

Pump speed

r/min

1000

1000

1000

Timer stroke

mm

2.8

2.2

3.4

_03

Pump speed

r/min

1500

1500

1500

Timer stroke

mm

5.7

5.4

6

_04

Pump speed

r/min

1800

1800

1800

Timer stroke

mm

7.45

6.9

8

0000001201

Max. applied voltage

V

16

16

16

Test voltage

V

25

24

26

0000001501

Pump speed

r/min

1000

1000

1000

Atmospheric pressure difference

kPa

-21.9

-21.9

-21.9

Atmospheric pressure difference

mmHg

-164

-164

-164

Average injection quantity

mm3/st.

41.5

40.5

42.5

Basic

*

_02

Pump speed

r/min

1000

1000

1000

Atmospheric pressure difference

kPa

-21.9

-21.9

-21.9

Atmospheric pressure difference

mmHg

-164

-164

-164

Average injection quantity

mm3/st.

41.5

40

43

Timing setting

K dimension

mm

3.3

3.2

3.4

KF dimension

mm

5.8

5.7

5.9

MS dimension

mm

1.8

1.7

1.9

Pre-stroke

mm

0.1

0.08

0.12

Control lever angle alpha

deg.

20

16

24

Control lever angle beta

deg.

40

32

48

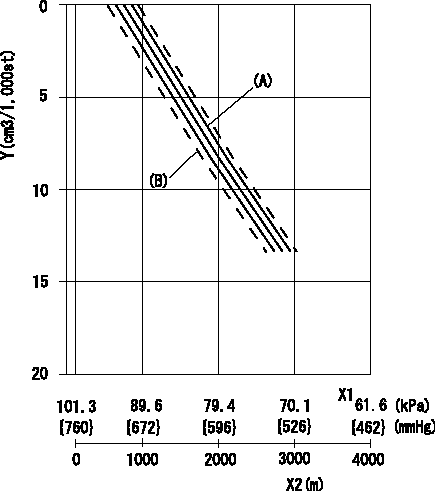

Test data Ex:

0000001501 ANEROID COMPENSATOR

ACS adjustment

Full load injection quantity at high altitudes and ACS adjusting method

1. Full load injection quantity adjustment

(1)Remove the ACS cover and remove the bellows and adjusting shim.

(2)Perform all adjustments as per the adjustment standard except for ACS adjustment.

2. ACS adjustment

(1)Assemble the ACS cover, bellows and adjusting shim.

(2)At pump speed N1, adjust using a shim to obtain the decrease for the altitude shown in the table.

X1 = atmospheric pressure

X2 = altitude

Y = decrease quantity

(A) = adjustment value

(B) = test value

----------

N1=1000r/min

----------

----------

N1=1000r/min

----------

0000001801 MICROSWITCH ADJUSTMENT

Microswitch adjustment

With the clearance between the idle stopper bolt (set at the idle setting) and the control lever set at L, adjust the control lever adjusting screw so that it contacts the head of the microswitch plunger.

----------

L=3.9+-0.2mm

----------

----------

L=3.9+-0.2mm

----------

Information:

1. Remove the fuel injection lines. It is not necessary to remove the fuel transfer pump, the fuel injection pump housing and governor to remove the fuel injection pumps. 2. Remove cover (1). 3. Move the rack until tool (A) can be installed to hold the rack in the center position. The rack must be in the center position to remove the fuel injection pumps.4. Use tool (B) to remove bushing (2). 5. Install tool (C) on the bonnet and remove the fuel injection pump. 6. Remove spacer (3) from the fuel injection pump housing. Spacers (3) are the same thickness for each fuel injection pump so they can be mixed. The fuel injection pump plungers and barrels are sets and can not be mixed.Install Fuel Injection Pumps

1. Install spacer (1) in the fuel injection pump housing. 2. Move the rack until tool (A) can be installed to hold the rack in the center position. The rack must be in the center position to install the fuel injection pumps.3. Turn the camshaft until the lobe of the camshaft is down for the pump to be installed. 4. Install tool (B) on the bonnet of the fuel injection pump. Put clean oil on O-ring seal (4) and install the O-ring seal and bushing (5) over tool (B) as shown. 5. Install the fuel injection pump in the pump housing with saw cut (slot) (3) in the gear in alignment with small pin (2) in the lifter assembly and groove (7) in the barrel in alignment with large pin (6) in the pump housing.6. Push down on tool (B) and tighten bushing (5) by hand until the bushing is even with the top of the housing. If installation of the bushing can not be made this far by hand, remove it. Remove the pump, put the parts in alignment again and install the bushing again.

If installation of pump is correct, the bushing can be tightened by hand until it is even with the face of the pump housing.

7. Remove tool (B) and install tool (C) in the bushing. Use tool (C) and a torque wrench to tighten the bushing to a torque of 165 14 N m (120 10 lb. ft.).8. Remove tools (C) and (A). Install the cover on the fuel injection pump housing.9. Install the fuel injection lines. Tighten the fuel injection line nuts to a torque of 41 7 N m (30 5 lb.ft.).Disassemble Fuel Injection Pumps

start by:a) remove fuel injection pumps

Be careful when the injection pumps are disassembled. Do not damage the surfaces of the plungers, barrels and bonnets. Any scratches will cause leakage inside the fuel injection pump. The plunger and barrel for each pump are made as a set. Do not put the plunger of one pump in the barrel of another pump. If one part has wear, install a complete new pump assembly. Be careful when the plunger is put into the bore of the barrel.

1. Pull plunger (1)

1. Install spacer (1) in the fuel injection pump housing. 2. Move the rack until tool (A) can be installed to hold the rack in the center position. The rack must be in the center position to install the fuel injection pumps.3. Turn the camshaft until the lobe of the camshaft is down for the pump to be installed. 4. Install tool (B) on the bonnet of the fuel injection pump. Put clean oil on O-ring seal (4) and install the O-ring seal and bushing (5) over tool (B) as shown. 5. Install the fuel injection pump in the pump housing with saw cut (slot) (3) in the gear in alignment with small pin (2) in the lifter assembly and groove (7) in the barrel in alignment with large pin (6) in the pump housing.6. Push down on tool (B) and tighten bushing (5) by hand until the bushing is even with the top of the housing. If installation of the bushing can not be made this far by hand, remove it. Remove the pump, put the parts in alignment again and install the bushing again.

If installation of pump is correct, the bushing can be tightened by hand until it is even with the face of the pump housing.

7. Remove tool (B) and install tool (C) in the bushing. Use tool (C) and a torque wrench to tighten the bushing to a torque of 165 14 N m (120 10 lb. ft.).8. Remove tools (C) and (A). Install the cover on the fuel injection pump housing.9. Install the fuel injection lines. Tighten the fuel injection line nuts to a torque of 41 7 N m (30 5 lb.ft.).Disassemble Fuel Injection Pumps

start by:a) remove fuel injection pumps

Be careful when the injection pumps are disassembled. Do not damage the surfaces of the plungers, barrels and bonnets. Any scratches will cause leakage inside the fuel injection pump. The plunger and barrel for each pump are made as a set. Do not put the plunger of one pump in the barrel of another pump. If one part has wear, install a complete new pump assembly. Be careful when the plunger is put into the bore of the barrel.

1. Pull plunger (1)