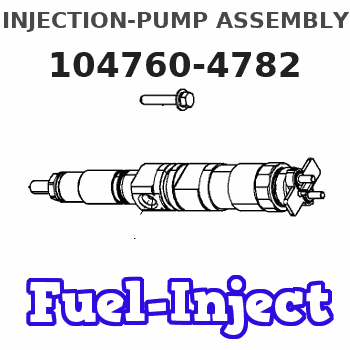

Information injection-pump assembly

BOSCH

F 01G 09W 00S

f01g09w00s

ZEXEL

104760-4782

1047604782

NISSAN-DIESEL

16700VB504

16700vb504

Rating:

Compare Prices: .

As an associate, we earn commssions on qualifying purchases through the links below

Diesel Pump Fuel Injection Pump Assembly, Compatible With ZEXEL, Compatible With NISSAN DIESEL TD42 104660-4781 NP-VE6/10F2000RNP181 16700-VB504

CHENUXO Diesel Pump Fuel Injection Pump Assembly , Compatible With ZEXEL , Compatible With NISSAN DIESEL TD42 104660-4781 NP-VE6/10F2000RNP181 16700-VB504 || Stable fuel supply: steadily extract fuel and deliver it at a certain pressure and flow rate to ensure the normal operation of the engine. || Pressure regulation: Equipped with a pressure regulator, it can automatically adjust the fuel pressure according to changes in working conditions. || Optimization design: The installation site adopts soundproof and shock-absorbing materials, further reducing the propagation of noise. || Monitoring feedback: Real time monitoring of fuel pressure, temperature, liquid level and other parameters, and feedback to the ECU.

CHENUXO Diesel Pump Fuel Injection Pump Assembly , Compatible With ZEXEL , Compatible With NISSAN DIESEL TD42 104660-4781 NP-VE6/10F2000RNP181 16700-VB504 || Stable fuel supply: steadily extract fuel and deliver it at a certain pressure and flow rate to ensure the normal operation of the engine. || Pressure regulation: Equipped with a pressure regulator, it can automatically adjust the fuel pressure according to changes in working conditions. || Optimization design: The installation site adopts soundproof and shock-absorbing materials, further reducing the propagation of noise. || Monitoring feedback: Real time monitoring of fuel pressure, temperature, liquid level and other parameters, and feedback to the ECU.

Diesel VE Pump Fuel Injection Pump Assembly 104660-4781 NP-VE6/10F2000RNP181 16700-VB504 Compatible For ZEXEL NISSAN DIESEL TD42

CFNCFJGJ [Part number] : 104660-4781 NP-VE6/10F2000RNP181 16700-VB504 || [Easy installation] : Standard interface, easy installation, plug and play, no professional skills, easy installation. || [Durable and reliable] : After multiple tests, long life, excellent quality, and stable work in extreme environments. || [Efficient and stable] : With the support of advanced technology, fuel supply is efficient and stable, ensuring the smooth flow of vehicles. || [High quality] : The use of high-quality materials and smart design, strict testing and verification, to ensure long-term stability and high reliability.

CFNCFJGJ [Part number] : 104660-4781 NP-VE6/10F2000RNP181 16700-VB504 || [Easy installation] : Standard interface, easy installation, plug and play, no professional skills, easy installation. || [Durable and reliable] : After multiple tests, long life, excellent quality, and stable work in extreme environments. || [Efficient and stable] : With the support of advanced technology, fuel supply is efficient and stable, ensuring the smooth flow of vehicles. || [High quality] : The use of high-quality materials and smart design, strict testing and verification, to ensure long-term stability and high reliability.

WBFRYEE Diesel Fuel Injection Pump 104660-4781 104760-4781 NP-VE6/10F2000RNP181 16700VB504 Compatible with Nissan

WBFRYEE Firm structure and stable || Reliability, firmness and durability || Ensure the stable operation of the engine. || Provide a stable fuel supply to ensure the normal operation of the vehicle. || Fuel pump metering unit is an important part of engine electronic gasoline injection system.

WBFRYEE Firm structure and stable || Reliability, firmness and durability || Ensure the stable operation of the engine. || Provide a stable fuel supply to ensure the normal operation of the vehicle. || Fuel pump metering unit is an important part of engine electronic gasoline injection system.

You can express buy:

USD 419.1

19-05-2025

19-05-2025

Diesel Fuel Injection Pump 104660-4781 104760-4781 NP-VE6/10F2000RNP181 16700VB504 For NISSAN

USD 393.14

13-05-2025

13-05-2025

Diesel Fuel Injection Pump 104660-4781 104760-4781 NP-VE6/10F2000RNP181 16700VB504 For NISSAN

Images:

USD 395.08

[31-May-2025]

USD 423.22

[31-May-2025]

USD 411

[28-Apr-2025]

USD 436.28

[30-May-2025]

Cross reference number

BOSCH

F 01G 09W 00S

f01g09w00s

ZEXEL

104760-4782

1047604782

NISSAN-DIESEL

16700VB504

16700vb504

Zexel num

Bosch num

Firm num

Name

104760-4782

F 01G 09W 00S

16700VB504 NISSAN-DIESEL

INJECTION-PUMP ASSEMBLY

TD42 * K

TD42 * K

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113orSAEJ967d

1404 Test oil ISO4113orSAEJ967d

Test oil temperature

degC

45

45

50

Nozzle

105780-0060

Bosch type code

NP-DN0SD1510

Nozzle holder

105780-2150

Opening pressure

MPa

13

13

13.3

Opening pressure

kgf/cm2

133

133

136

Injection pipe

157805-7320

Injection pipe

Inside diameter - outside diameter - length (mm) mm 2-6-450

Inside diameter - outside diameter - length (mm) mm 2-6-450

Joint assembly

157641-4720

Tube assembly

157641-4020

Transfer pump pressure

kPa

20

20

20

Transfer pump pressure

kgf/cm2

0.2

0.2

0.2

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Pump speed

r/min

1000

1000

1000

Average injection quantity

mm3/st.

45.3

44.8

45.8

Difference in delivery

mm3/st.

3.5

Basic

*

Oil temperature

degC

50

48

52

Injection timing adjustment_02

Pump speed

r/min

600

600

600

Average injection quantity

mm3/st.

43.8

41.3

46.3

Oil temperature

degC

50

48

52

Injection timing adjustment_03

Pump speed

r/min

1000

1000

1000

Average injection quantity

mm3/st.

45.3

44.3

46.3

Difference in delivery

mm3/st.

4

Basic

*

Oil temperature

degC

50

48

52

Injection timing adjustment_04

Pump speed

r/min

2000

2000

2000

Average injection quantity

mm3/st.

43.3

40.8

45.8

Oil temperature

degC

50

48

52

Injection quantity adjustment

Pump speed

r/min

2300

2300

2300

Average injection quantity

mm3/st.

17.8

15.8

19.8

Difference in delivery

mm3/st.

5

Basic

*

Oil temperature

degC

52

50

54

Injection quantity adjustment_02

Pump speed

r/min

2100

2100

2100

Average injection quantity

mm3/st.

43.1

38.6

47.6

Oil temperature

degC

52

50

54

Injection quantity adjustment_03

Pump speed

r/min

2300

2300

2300

Average injection quantity

mm3/st.

17.8

15.3

20.3

Basic

*

Oil temperature

degC

52

50

54

Injection quantity adjustment_04

Pump speed

r/min

2500

2500

2500

Average injection quantity

mm3/st.

5

Oil temperature

degC

55

52

58

Governor adjustment

Pump speed

r/min

350

350

350

Average injection quantity

mm3/st.

10.1

8.1

12.1

Difference in delivery

mm3/st.

2

Basic

*

Oil temperature

degC

48

46

50

Governor adjustment_02

Pump speed

r/min

350

350

350

Average injection quantity

mm3/st.

10.1

7.6

12.6

Difference in delivery

mm3/st.

2.5

Basic

*

Oil temperature

degC

48

46

50

Timer adjustment

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

60

50

80

Basic

*

Oil temperature

degC

48

46

50

Remarks

Full

Full

Timer adjustment_02

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

60

50

80

Oil temperature

degC

48

46

50

Remarks

Full

Full

Speed control lever angle

Pump speed

r/min

250

250

250

Average injection quantity

mm3/st.

5

Oil temperature

degC

48

46

50

Remarks

Magnet OFF at full-load position

Magnet OFF at full-load position

Speed control lever angle_02

Pump speed

r/min

350

350

350

Average injection quantity

mm3/st.

0

0

0

Oil temperature

degC

48

46

50

Remarks

Magnet OFF at idling position

Magnet OFF at idling position

0000000901

Pump speed

r/min

1000

1000

1000

Overflow quantity

cm3/min

400

270

530

Oil temperature

degC

50

48

52

Stop lever angle

Pump speed

r/min

1000

1000

1000

Pressure

kPa

422

402

442

Pressure

kgf/cm2

4.3

4.1

4.5

Basic

*

Oil temperature

degC

50

48

52

Stop lever angle_02

Pump speed

r/min

1000

1000

1000

Pressure

kPa

422

393

451

Pressure

kgf/cm2

4.3

4

4.6

Basic

*

Oil temperature

degC

50

48

52

Stop lever angle_03

Pump speed

r/min

1800

1800

1800

Pressure

kPa

686

647

725

Pressure

kgf/cm2

7

6.6

7.4

Oil temperature

degC

50

48

52

0000001101

Pump speed

r/min

1000

1000

1000

Timer stroke

mm

2.9

2.7

3.1

Basic

*

Oil temperature

degC

50

48

52

_02

Pump speed

r/min

650

650

650

Timer stroke

mm

1.2

0.7

1.7

Oil temperature

degC

50

48

52

_03

Pump speed

r/min

1000

1000

1000

Timer stroke

mm

2.9

2.6

3.2

Basic

*

Oil temperature

degC

50

48

52

_04

Pump speed

r/min

1800

1800

1800

Timer stroke

mm

6.6

6.1

7.1

Oil temperature

degC

50

48

52

_05

Pump speed

r/min

2200

2200

2200

Timer stroke

mm

8.2

7.7

8.6

Oil temperature

degC

52

50

54

0000001201

Max. applied voltage

V

8

8

8

Test voltage

V

13

12

14

0000001501

Pump speed

r/min

1000

1000

1000

Height

m

2000

2000

2000

Atmospheric pressure difference

kPa

-21.9

-23.2

-20.6

Atmospheric pressure difference

mmHg

-164

-174

-154

Average injection quantity

mm3/st.

36.8

35.3

38.3

Decrease qty

mm3/st.

8.5

8.5

8.5

Decrease rate

%

18.8

18.8

18.8

Basic

*

Oil temperature

degC

50

48

52

_02

Pump speed

r/min

1000

1000

1000

Height

m

0

0

0

Atmospheric pressure difference

kPa

0

0

0

Atmospheric pressure difference

mmHg

0

0

0

Average injection quantity

mm3/st.

45.3

44.3

46.3

Oil temperature

degC

50

48

52

_03

Pump speed

r/min

1000

1000

1000

Height

m

500

500

500

Atmospheric pressure difference

kPa

-5.9

-9.2

-2.6

Atmospheric pressure difference

mmHg

-44

-69

-19

Average injection quantity

mm3/st.

45.3

45.3

45.3

Oil temperature

degC

50

48

52

_04

Pump speed

r/min

1000

1000

1000

Height

m

2000

2000

2000

Atmospheric pressure difference

kPa

-21.9

-23.2

-20.6

Atmospheric pressure difference

mmHg

-164

-174

-154

Average injection quantity

mm3/st.

36.8

34.8

38.8

Basic

*

Oil temperature

degC

50

48

52

_05

Pump speed

r/min

1000

1000

1000

Height

m

4000

4000

4000

Atmospheric pressure difference

kPa

-39.7

-41

-38.4

Atmospheric pressure difference

mmHg

-298

-308

-288

Average injection quantity

mm3/st.

29.8

29.8

29.8

Oil temperature

degC

50

48

52

Timing setting

K dimension

mm

3.3

3.2

3.4

KF dimension

mm

6.64

6.54

6.74

MS dimension

mm

1

0.9

1.1

Control lever angle alpha

deg.

55.5

51.5

59.5

Control lever angle beta

deg.

40

35

45

Information:

Altitude Operation

The fuel system settings and altitude limits are stamped on the engine information plate. When an engine is moved to a higher altitude, these settings must be changed by your Caterpillar dealer in order to prevent damaging the turbocharger, and to provide maximum engine efficiency. If the engine is moved to a lower altitude than that which is stamped on the engine information plate, the engine can be operated safely; however, it will deliver less than rated horsepower, and the fuel settings should be changed by your Caterpillar dealer to obtain rated horsepower.Stopping

1. Flywheel clutch operation: Quickly pull the clutch lever to the released position. For electric set operation, see the GENERATOR SET OPERATION instructions. For Woodward Governor operation, see the topic, WOODWARD GOVERNORS, Stopping the Engine. 2. Reduce engine speed to half speed. Run for 5 minutes to cool engine.3. Reduce engine speed to low idle.4. Observe the crankcase oil level while the engine is idling. Maintain the oil level between the ADD and FULL marks on the side of the dipstick stamped, CHECK WITH ENGINE RUNNING. See the LUBRICATION AND MAINTENANCE SECTION.5. Stop the engine. After Stopping Checks And Procedures

1. Fill the fuel tank. See the LUBRICATION AND MAINTENANCE SECTION: Fuel Tank Maintenance.2. Drain the raw water system if below freezing temperatures are expected; see: Draining Raw Water System.3. If below freezing temperatures are expected, allow the engine jacket water expansion tank to cool; then check the coolant for proper antifreeze protection. Add permanent-type antifreeze, if required.4. Repair any leaks, make major adjustments, tighten loose bolts, etc.5. Observe the Service Meter reading. Perform the periodic maintenance as instructed in the LUBRICATION AND MAINTENANCE CHART.

SERVICE METER

The fuel system settings and altitude limits are stamped on the engine information plate. When an engine is moved to a higher altitude, these settings must be changed by your Caterpillar dealer in order to prevent damaging the turbocharger, and to provide maximum engine efficiency. If the engine is moved to a lower altitude than that which is stamped on the engine information plate, the engine can be operated safely; however, it will deliver less than rated horsepower, and the fuel settings should be changed by your Caterpillar dealer to obtain rated horsepower.Stopping

1. Flywheel clutch operation: Quickly pull the clutch lever to the released position. For electric set operation, see the GENERATOR SET OPERATION instructions. For Woodward Governor operation, see the topic, WOODWARD GOVERNORS, Stopping the Engine. 2. Reduce engine speed to half speed. Run for 5 minutes to cool engine.3. Reduce engine speed to low idle.4. Observe the crankcase oil level while the engine is idling. Maintain the oil level between the ADD and FULL marks on the side of the dipstick stamped, CHECK WITH ENGINE RUNNING. See the LUBRICATION AND MAINTENANCE SECTION.5. Stop the engine. After Stopping Checks And Procedures

1. Fill the fuel tank. See the LUBRICATION AND MAINTENANCE SECTION: Fuel Tank Maintenance.2. Drain the raw water system if below freezing temperatures are expected; see: Draining Raw Water System.3. If below freezing temperatures are expected, allow the engine jacket water expansion tank to cool; then check the coolant for proper antifreeze protection. Add permanent-type antifreeze, if required.4. Repair any leaks, make major adjustments, tighten loose bolts, etc.5. Observe the Service Meter reading. Perform the periodic maintenance as instructed in the LUBRICATION AND MAINTENANCE CHART.

SERVICE METER

Have questions with 104760-4782?

Group cross 104760-4782 ZEXEL

Nissan

Nissan-Diesel

Nissan

Nissan-Diesel

Nissan

Nissan-Diesel

Nissan

Nissan-Diesel

Nissan

Nissan-Diesel

Nissan

Nissan-Diesel

104760-4782

F 01G 09W 00S

16700VB504

INJECTION-PUMP ASSEMBLY

TD42

TD42