Information injection-pump assembly

ZEXEL

104760-4560

1047604560

NISSAN-DIESEL

167000Y713

167000y713

Rating:

Cross reference number

ZEXEL

104760-4560

1047604560

NISSAN-DIESEL

167000Y713

167000y713

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113orSAEJ967d

1404 Test oil ISO4113orSAEJ967d

Test oil temperature

degC

45

45

50

Nozzle

105000-2010

Bosch type code

NP-DN12SD12TT

Nozzle holder

105780-2080

Opening pressure

MPa

14.7

14.7

15.19

Opening pressure

kgf/cm2

150

150

155

Injection pipe

Inside diameter - outside diameter - length (mm) mm 2-6-840

Inside diameter - outside diameter - length (mm) mm 2-6-840

Transfer pump pressure

kPa

20

20

20

Transfer pump pressure

kgf/cm2

0.2

0.2

0.2

Direction of rotation (viewed from drive side)

Right R

Right R

(Solenoid timer adjustment condition)

OFF

Injection timing adjustment

Pump speed

r/min

1000

1000

1000

Average injection quantity

mm3/st.

48.9

48.4

49.4

Difference in delivery

mm3/st.

3.5

Basic

*

Oil temperature

degC

50

48

52

Injection timing adjustment_02

Pump speed

r/min

600

600

600

Average injection quantity

mm3/st.

49.1

47.1

51.1

Oil temperature

degC

50

48

52

Injection timing adjustment_03

Pump speed

r/min

1000

1000

1000

Average injection quantity

mm3/st.

48.9

47.9

49.9

Difference in delivery

mm3/st.

4

Basic

*

Oil temperature

degC

50

48

52

Injection timing adjustment_04

Pump speed

r/min

1300

1300

1300

Average injection quantity

mm3/st.

50

50

50

Oil temperature

degC

50

48

52

Injection timing adjustment_05

Pump speed

r/min

1600

1600

1600

Average injection quantity

mm3/st.

47.1

47.1

47.1

Oil temperature

degC

50

48

52

Injection timing adjustment_06

Pump speed

r/min

2000

2000

2000

Average injection quantity

mm3/st.

42.1

40

44.2

Oil temperature

degC

50

48

52

Injection quantity adjustment

Pump speed

r/min

2300

2300

2300

Average injection quantity

mm3/st.

16.6

14.6

18.6

Difference in delivery

mm3/st.

5

Basic

*

Oil temperature

degC

52

50

54

Injection quantity adjustment_02

Pump speed

r/min

2500

2500

2500

Average injection quantity

mm3/st.

5

Oil temperature

degC

55

52

58

Injection quantity adjustment_03

Pump speed

r/min

2100

2100

2100

Average injection quantity

mm3/st.

40

35.5

44.5

Oil temperature

degC

52

50

54

Injection quantity adjustment_04

Pump speed

r/min

2300

2300

2300

Average injection quantity

mm3/st.

16.6

14.1

19.1

Basic

*

Oil temperature

degC

52

50

54

Governor adjustment

Pump speed

r/min

350

350

350

Average injection quantity

mm3/st.

8.8

6.8

10.8

Difference in delivery

mm3/st.

2

Basic

*

Oil temperature

degC

48

46

50

Governor adjustment_02

Pump speed

r/min

350

350

350

Average injection quantity

mm3/st.

8.8

6.3

11.3

Difference in delivery

mm3/st.

2.5

Basic

*

Oil temperature

degC

48

46

50

Timer adjustment

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

60

50

80

Basic

*

Oil temperature

degC

48

46

50

Remarks

Full

Full

Timer adjustment_02

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

60

50

80

Oil temperature

degC

48

46

50

Remarks

Full

Full

Speed control lever angle

Pump speed

r/min

350

350

350

Average injection quantity

mm3/st.

0

0

0

Oil temperature

degC

48

46

50

Remarks

Magnet OFF at idling position

Magnet OFF at idling position

Speed control lever angle_02

Pump speed

r/min

250

250

250

Average injection quantity

mm3/st.

5

Oil temperature

degC

48

46

50

Remarks

Magnet OFF at full-load position

Magnet OFF at full-load position

0000000901

Pump speed

r/min

1000

1000

1000

Overflow quantity with S/T ON

cm3/min

400

270

530

Oil temperature

degC

50

48

52

_02

Pump speed

r/min

1000

1000

1000

Overflow quantity with S/T ON

cm3/min

450

320

580

Oil temperature

degC

50

48

52

Remarks

Without an O-ring

Without an O-ring

Stop lever angle

Pump speed

r/min

1000

1000

1000

Pressure with S/T ON

kPa

500

461

539

Pressure with S/T ON

kgf/cm2

5.1

4.7

5.5

Pressure with S/T OFF

kPa

324

304

344

Pressure with S/T OFF

kgf/cm2

3.3

3.1

3.5

Basic

*

Oil temperature

degC

50

48

52

Stop lever angle_02

Pump speed

r/min

1000

1000

1000

Pressure

kPa

324

295

353

Pressure

kgf/cm2

3.3

3

3.6

Basic

*

Oil temperature

degC

50

48

52

Stop lever angle_03

Pump speed

r/min

1800

1800

1800

Pressure

kPa

569

530

608

Pressure

kgf/cm2

5.8

5.4

6.2

Oil temperature

degC

50

48

52

0000001101

Pump speed

r/min

1000

1000

1000

Timer stroke with S/T ON

mm

3.8

3.4

4.2

Timer stroke with S/T OFF

mm

1.6

1.4

1.8

Basic

*

Oil temperature

degC

50

48

52

_02

Pump speed

r/min

800

800

800

Timer stroke with S/T OFF

mm

0.5

0

1

Oil temperature

degC

50

48

52

_03

Pump speed

r/min

1000

1000

1000

Timer stroke with S/T ON

mm

3.8

3.3

4.3

Timer stroke with S/T OFF

mm

1.6

1.3

1.9

Basic

*

Oil temperature

degC

50

48

52

_04

Pump speed

r/min

1800

1800

1800

Timer stroke with S/T OFF

mm

5.5

5

6

Oil temperature

degC

50

48

52

_05

Pump speed

r/min

2200

2200

2200

Timer stroke with S/T OFF

mm

7.4

6.9

7.8

Oil temperature

degC

52

50

54

0000001201

Max. applied voltage

V

8

8

8

Test voltage

V

13

12

14

0000001401

Pump speed

r/min

1200

1200

1200

Average injection quantity

mm3/st.

22

21.5

22.5

Timer stroke TA

mm

2.5

2.3

2.7

Timer stroke variation dT

mm

0.1

0.1

0.1

Basic

*

Oil temperature

degC

50

48

52

_02

Pump speed

r/min

1200

1200

1200

Average injection quantity

mm3/st.

22

21

23

Timer stroke TA

mm

2.5

2.2

2.8

Basic

*

Oil temperature

degC

50

48

52

_03

Pump speed

r/min

1200

1200

1200

Average injection quantity

mm3/st.

15

12.5

17.5

Timer stroke TA

mm

2.1

1.4

2.8

Oil temperature

degC

50

48

52

Timing setting

K dimension

mm

3.3

3.2

3.4

KF dimension

mm

6.64

6.54

6.74

MS dimension

mm

1

0.9

1.1

Control lever angle alpha

deg.

25

23

27

Control lever angle beta

deg.

40

35

45

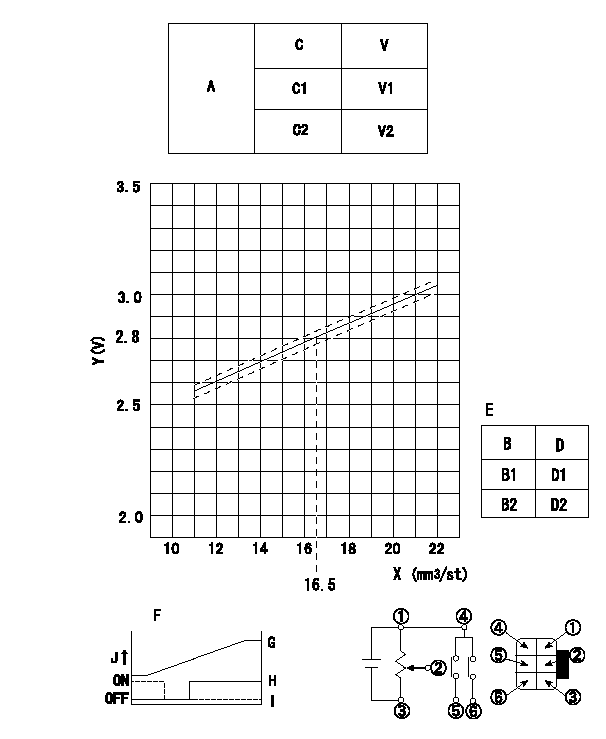

Test data Ex:

0000001801 POTENTIOMETER ADJUSTMENT

Adjustment of the potentiometer

At pump speed N1 and a control lever position a from idle (gap L1), measure the injection quantity and convert it to a voltage value. Then adjust the potentiometer.

Voltage conversion formula: V+-0.03 = 0.044Q+2.07

A:Potentiometer performance standards

C:Position of the control lever

C1:Idle

C2:Full speed

V:Potentiometer voltage

E:Standards for the potentiometer's ON - OFF switch

B:Conversion point

B1:OFF-->ON

B2:OFF-->ON

D:Lever opening (from idle)

Vi:Applied voltage

F:Connecting diagram for the potentiometer

G:Output when (2) and (3) connected.

H:When (4) or (6) connected: switch OFF to ON.

I:When (4) or (5) connected: switch ON to OFF.

J:Output

----------

N1=700r/min a=7.5deg L1=4.9mm Vi=10V

----------

V1=1.6+-0.4V V2=8.0+-0.55V D1=6.0+-3.5deg D2=19.5+-3.5deg Vi=10V

----------

N1=700r/min a=7.5deg L1=4.9mm Vi=10V

----------

V1=1.6+-0.4V V2=8.0+-0.55V D1=6.0+-3.5deg D2=19.5+-3.5deg Vi=10V

Information:

Start By:a. remove radiatorb. remove hydraulic pumpc. remove crankshaft pulleyd. remove alternatore. remove intake manifoldf. remove starting motorg. remove oil filterh. remove transmission

All wires, hoses, lines and linkage that is disconnected must be tied or wired out of the way to prevent damage when removing engine.

1. Identify and disconnect all electrical connections to the engine. Disconnect hydraulic lines and cab heater hoses. Disconnect all fuel lines and throttle controls. Tie or wire all wires, hoses, lines and linkage out of the way for engine removal.2. Remove front and rear engine mount bolts (1). 3. With the forks of a lift truck positioned together, position forks centered over the engine as illustrated. Install tooling (A) and then run a chain through the existing engine lifting eyes and tooling (A) as illustrated. Raise engine up slightly and start to remove engine. 4. With the engine part of the way out, remove four bolts (2) and remove rear mount bracket (3). Repeat step for the other rear mount bracket. With both rear mount brackets removed, finish removing engine. Weight of the engine is 340 Kg (750 lbs.). At the time of installation, tighten front mount bolts to a torque of 370 50 N m (270 37 lb.ft.) and rear mount bolts to a torque of 100 15 N m (75 11 lb.ft.). Install in the reverse order.End By:a. install transmissionb. install oil filterc. install starting motord. install intake manifolde. install alternatorf. install crankshaft pulleyg. install hydraulic pumph. install radiator

All wires, hoses, lines and linkage that is disconnected must be tied or wired out of the way to prevent damage when removing engine.

1. Identify and disconnect all electrical connections to the engine. Disconnect hydraulic lines and cab heater hoses. Disconnect all fuel lines and throttle controls. Tie or wire all wires, hoses, lines and linkage out of the way for engine removal.2. Remove front and rear engine mount bolts (1). 3. With the forks of a lift truck positioned together, position forks centered over the engine as illustrated. Install tooling (A) and then run a chain through the existing engine lifting eyes and tooling (A) as illustrated. Raise engine up slightly and start to remove engine. 4. With the engine part of the way out, remove four bolts (2) and remove rear mount bracket (3). Repeat step for the other rear mount bracket. With both rear mount brackets removed, finish removing engine. Weight of the engine is 340 Kg (750 lbs.). At the time of installation, tighten front mount bolts to a torque of 370 50 N m (270 37 lb.ft.) and rear mount bolts to a torque of 100 15 N m (75 11 lb.ft.). Install in the reverse order.End By:a. install transmissionb. install oil filterc. install starting motord. install intake manifolde. install alternatorf. install crankshaft pulleyg. install hydraulic pumph. install radiator