Information injection-pump assembly

ZEXEL

104760-4550

1047604550

NISSAN-DIESEL

167000Y712

167000y712

Rating:

Cross reference number

ZEXEL

104760-4550

1047604550

NISSAN-DIESEL

167000Y712

167000y712

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113orSAEJ967d

1404 Test oil ISO4113orSAEJ967d

Test oil temperature

degC

45

45

50

Nozzle

105000-2010

Bosch type code

NP-DN12SD12TT

Nozzle holder

105780-2080

Opening pressure

MPa

14.7

14.7

15.19

Opening pressure

kgf/cm2

150

150

155

Injection pipe

Inside diameter - outside diameter - length (mm) mm 2-6-840

Inside diameter - outside diameter - length (mm) mm 2-6-840

Transfer pump pressure

kPa

20

20

20

Transfer pump pressure

kgf/cm2

0.2

0.2

0.2

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Pump speed

r/min

1000

1000

1000

Average injection quantity

mm3/st.

48.9

48.4

49.4

Difference in delivery

mm3/st.

3.5

Basic

*

Oil temperature

degC

50

48

52

Injection timing adjustment_02

Pump speed

r/min

600

600

600

Average injection quantity

mm3/st.

49.1

47.1

51.1

Oil temperature

degC

50

48

52

Injection timing adjustment_03

Pump speed

r/min

1000

1000

1000

Average injection quantity

mm3/st.

48.9

47.9

49.9

Difference in delivery

mm3/st.

4

Basic

*

Oil temperature

degC

50

48

52

Injection timing adjustment_04

Pump speed

r/min

1300

1300

1300

Average injection quantity

mm3/st.

50

50

50

Oil temperature

degC

50

48

52

Injection timing adjustment_05

Pump speed

r/min

1600

1600

1600

Average injection quantity

mm3/st.

47.1

47.1

47.1

Oil temperature

degC

50

48

52

Injection timing adjustment_06

Pump speed

r/min

2000

2000

2000

Average injection quantity

mm3/st.

42.1

40

44.2

Oil temperature

degC

50

48

52

Injection quantity adjustment

Pump speed

r/min

2300

2300

2300

Average injection quantity

mm3/st.

16.6

14.6

18.6

Difference in delivery

mm3/st.

5

Basic

*

Oil temperature

degC

52

50

54

Injection quantity adjustment_02

Pump speed

r/min

2500

2500

2500

Average injection quantity

mm3/st.

5

Oil temperature

degC

55

52

58

Injection quantity adjustment_03

Pump speed

r/min

2100

2100

2100

Average injection quantity

mm3/st.

40

35.5

44.5

Oil temperature

degC

52

50

54

Injection quantity adjustment_04

Pump speed

r/min

2300

2300

2300

Average injection quantity

mm3/st.

16.6

14.1

19.1

Basic

*

Oil temperature

degC

52

50

54

Governor adjustment

Pump speed

r/min

350

350

350

Average injection quantity

mm3/st.

8.8

6.8

10.8

Difference in delivery

mm3/st.

2

Basic

*

Oil temperature

degC

48

46

50

Governor adjustment_02

Pump speed

r/min

350

350

350

Average injection quantity

mm3/st.

8.8

6.3

11.3

Difference in delivery

mm3/st.

2.5

Basic

*

Oil temperature

degC

48

46

50

Timer adjustment

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

60

50

80

Basic

*

Oil temperature

degC

48

46

50

Remarks

Full

Full

Timer adjustment_02

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

60

50

80

Oil temperature

degC

48

46

50

Remarks

Full

Full

Speed control lever angle

Pump speed

r/min

350

350

350

Average injection quantity

mm3/st.

0

0

0

Oil temperature

degC

48

46

50

Remarks

Magnet OFF at idling position

Magnet OFF at idling position

Speed control lever angle_02

Pump speed

r/min

250

250

250

Average injection quantity

mm3/st.

5

Oil temperature

degC

48

46

50

Remarks

Magnet OFF at full-load position

Magnet OFF at full-load position

0000000901

Pump speed

r/min

1000

1000

1000

Overflow quantity

cm3/min

400

270

530

Oil temperature

degC

50

48

52

Stop lever angle

Pump speed

r/min

1000

1000

1000

Pressure

kPa

324

304

344

Pressure

kgf/cm2

3.3

3.1

3.5

Basic

*

Oil temperature

degC

50

48

52

Stop lever angle_02

Pump speed

r/min

1000

1000

1000

Pressure

kPa

324

295

353

Pressure

kgf/cm2

3.3

3

3.6

Basic

*

Oil temperature

degC

50

48

52

Stop lever angle_03

Pump speed

r/min

1800

1800

1800

Pressure

kPa

608

569

647

Pressure

kgf/cm2

6.2

5.8

6.6

Oil temperature

degC

50

48

52

0000001101

Pump speed

r/min

1000

1000

1000

Timer stroke

mm

1.6

1.4

1.8

Basic

*

Oil temperature

degC

50

48

52

_02

Pump speed

r/min

800

800

800

Timer stroke

mm

0.5

0

1

Oil temperature

degC

50

48

52

_03

Pump speed

r/min

1000

1000

1000

Timer stroke

mm

1.6

1.3

1.9

Basic

*

Oil temperature

degC

50

48

52

_04

Pump speed

r/min

1800

1800

1800

Timer stroke

mm

5.8

5.3

6.3

Oil temperature

degC

50

48

52

_05

Pump speed

r/min

2200

2200

2200

Timer stroke

mm

7.4

6.9

7.8

Oil temperature

degC

52

50

54

0000001201

Max. applied voltage

V

8

8

8

Test voltage

V

13

12

14

0000001401

Pump speed

r/min

1200

1200

1200

Average injection quantity

mm3/st.

22

21.5

22.5

Timer stroke TA

mm

2.5

2.3

2.7

Timer stroke variation dT

mm

0.1

0.1

0.1

Basic

*

Oil temperature

degC

50

48

52

_02

Pump speed

r/min

1200

1200

1200

Average injection quantity

mm3/st.

22

21

23

Timer stroke TA

mm

2.5

2.2

2.8

Basic

*

Oil temperature

degC

50

48

52

_03

Pump speed

r/min

1200

1200

1200

Average injection quantity

mm3/st.

15

12.5

17.5

Timer stroke TA

mm

2.1

1.4

2.8

Oil temperature

degC

50

48

52

Timing setting

K dimension

mm

3.3

3.2

3.4

KF dimension

mm

6.64

6.54

6.74

MS dimension

mm

1

0.9

1.1

Control lever angle alpha

deg.

25

23

27

Control lever angle beta

deg.

40

35

45

Test data Ex:

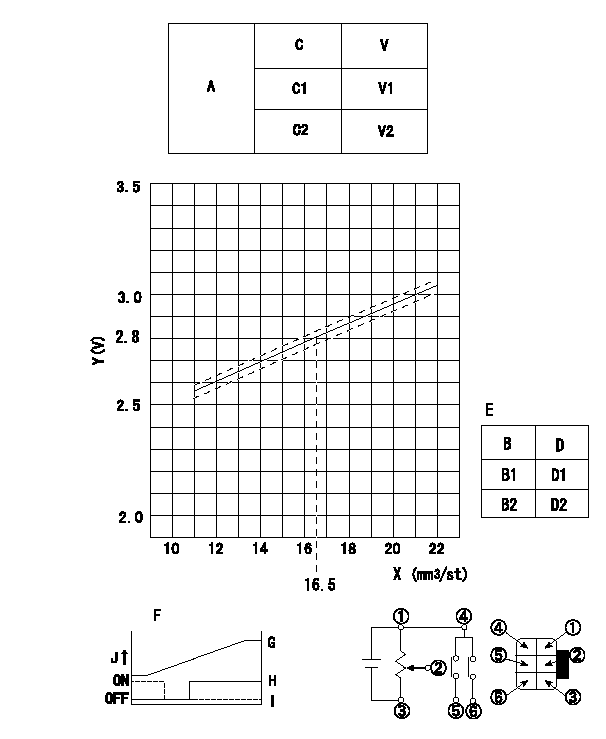

0000001801 POTENTIOMETER ADJUSTMENT

Adjustment of the potentiometer

At pump speed N1 and a control lever position a from idle (gap L1), measure the injection quantity and convert it to a voltage value. Then adjust the potentiometer.

Voltage conversion formula: V+-0.03 = 0.044Q+2.07

A:Potentiometer performance standards

C:Position of the control lever

C1:Idle

C2:Full speed

V:Potentiometer voltage

E:Standards for the potentiometer's ON - OFF switch

B:Conversion point

B1:OFF-->ON

B2:OFF-->ON

D:Lever opening (from idle)

Vi:Applied voltage

F:Connecting diagram for the potentiometer

G:Output when (2) and (3) connected.

H:When (4) or (6) connected: switch OFF to ON.

I:When (4) or (5) connected: switch ON to OFF.

J:Output

----------

N1=700r/min a=7.5deg L1=4.9mm Vi=10V

----------

V1=1.6+-0.4V V2=8.0+-0.55V D1=6.0+-3.5deg D2=19.5+-3.5deg Vi=10V

----------

N1=700r/min a=7.5deg L1=4.9mm Vi=10V

----------

V1=1.6+-0.4V V2=8.0+-0.55V D1=6.0+-3.5deg D2=19.5+-3.5deg Vi=10V

Information:

1. Remove the bolts that hold timing gear case cover (1) to the timing gear case. Remove the timing gear case cover.

Later type crankshaft front seals (with protruding dust lip) do not use a slinger. Seal damage can occur if a slinger is used.

2. On earlier models, remove slinger (2). 3. Remove seal (3) from timing gear case cover (1).Install Timing Gear Case Cover

*New, improved crankshaft front oil seals have a dust lip protrusion molded on to the front of the seal. The centering tool (PD162) must be reworked as shown in this illustration to prevent damage to this dust lip when the new type seal is installed. 1. Put timing gear case cover (1) in position with a new gasket. Install the bolts and lockwashers that hold it, but do not tighten them at this time. Use tool (A) to properly locate the timing gear case cover with respect to the crankshaft.2. Install tool (A) over the crankshaft and into the timing gear case cover seal bore. Hold tool (A) firmly in the timing gear case cover. Tighten the bolts that hold the timing gear case cover.

Washer (2) replaces the slinger, which is not used on later type seals with protruding dust lip.

3. Install washer (2). 4. Put seal (3) in position in the timing gear case cover. Install the seal with the lip toward the crankshaft gear. The seal surface must be clean and dry. Do not handle the lip of the seal.5. Use tool (A) and a soft hammer to install seal (3). Install the seal until it is 3.17 mm (.125 in) below the surface of the timing gear case cover.End By:a. install crankshaft pulleyb. install fan assembly

Later type crankshaft front seals (with protruding dust lip) do not use a slinger. Seal damage can occur if a slinger is used.

2. On earlier models, remove slinger (2). 3. Remove seal (3) from timing gear case cover (1).Install Timing Gear Case Cover

*New, improved crankshaft front oil seals have a dust lip protrusion molded on to the front of the seal. The centering tool (PD162) must be reworked as shown in this illustration to prevent damage to this dust lip when the new type seal is installed. 1. Put timing gear case cover (1) in position with a new gasket. Install the bolts and lockwashers that hold it, but do not tighten them at this time. Use tool (A) to properly locate the timing gear case cover with respect to the crankshaft.2. Install tool (A) over the crankshaft and into the timing gear case cover seal bore. Hold tool (A) firmly in the timing gear case cover. Tighten the bolts that hold the timing gear case cover.

Washer (2) replaces the slinger, which is not used on later type seals with protruding dust lip.

3. Install washer (2). 4. Put seal (3) in position in the timing gear case cover. Install the seal with the lip toward the crankshaft gear. The seal surface must be clean and dry. Do not handle the lip of the seal.5. Use tool (A) and a soft hammer to install seal (3). Install the seal until it is 3.17 mm (.125 in) below the surface of the timing gear case cover.End By:a. install crankshaft pulleyb. install fan assembly