Information injection-pump assembly

ZEXEL

104760-4471

1047604471

NISSAN

1670051N15

1670051n15

Rating:

Cross reference number

ZEXEL

104760-4471

1047604471

NISSAN

1670051N15

1670051n15

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113orSAEJ967d

1404 Test oil ISO4113orSAEJ967d

Test oil temperature

degC

45

45

50

Nozzle

105780-0060

Bosch type code

NP-DN0SD1510

Nozzle holder

105780-2150

Opening pressure

MPa

13

13

13.3

Opening pressure

kgf/cm2

133

133

136

Injection pipe

157805-7320

Injection pipe

Inside diameter - outside diameter - length (mm) mm 2-6-450

Inside diameter - outside diameter - length (mm) mm 2-6-450

Joint assembly

157641-4720

Tube assembly

157641-4020

Transfer pump pressure

kPa

20

20

20

Transfer pump pressure

kgf/cm2

0.2

0.2

0.2

Direction of rotation (viewed from drive side)

Right R

Right R

(Solenoid timer adjustment condition)

With S/T O-ring; S/T OFF. OFF

With S/T O-ring; S/T OFF. OFF

Injection timing adjustment

Pump speed

r/min

500

500

500

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

46.3

45.8

46.8

Basic

*

Oil temperature

degC

48

46

50

Remarks

NA

NA

Injection timing adjustment_02

Pump speed

r/min

700

700

700

Boost pressure

kPa

16

14.7

17.3

Boost pressure

mmHg

120

110

130

Average injection quantity

mm3/st.

53.7

53.2

54.2

Basic

*

Oil temperature

degC

50

48

52

Remarks

CBS

CBS

Injection timing adjustment_03

Pump speed

r/min

1000

1000

1000

Boost pressure

kPa

53.3

52

54.6

Boost pressure

mmHg

400

390

410

Average injection quantity

mm3/st.

58.3

57.8

58.8

Difference in delivery

mm3/st.

4

Basic

*

Oil temperature

degC

50

48

52

Injection timing adjustment_04

Pump speed

r/min

500

500

500

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

46.3

45.3

47.3

Basic

*

Oil temperature

degC

48

46

50

Injection timing adjustment_05

Pump speed

r/min

700

700

700

Boost pressure

kPa

16

14.7

17.3

Boost pressure

mmHg

120

110

130

Average injection quantity

mm3/st.

53.7

52.7

54.7

Basic

*

Oil temperature

degC

50

48

52

Remarks

CBS

CBS

Injection timing adjustment_06

Pump speed

r/min

1000

1000

1000

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

51.1

48.6

53.6

Oil temperature

degC

50

48

52

Injection timing adjustment_07

Pump speed

r/min

1000

1000

1000

Boost pressure

kPa

53.3

52

54.6

Boost pressure

mmHg

400

390

410

Average injection quantity

mm3/st.

58.3

57.3

59.3

Difference in delivery

mm3/st.

4.5

Basic

*

Oil temperature

degC

50

48

52

Injection timing adjustment_08

Pump speed

r/min

2000

2000

2000

Boost pressure

kPa

53.3

52

54.6

Boost pressure

mmHg

400

390

410

Average injection quantity

mm3/st.

61.1

58.6

63.6

Oil temperature

degC

50

48

52

Injection quantity adjustment

Pump speed

r/min

2300

2300

2300

Boost pressure

kPa

53.3

52

54.6

Boost pressure

mmHg

400

390

410

Average injection quantity

mm3/st.

18.3

16.3

20.3

Basic

*

Oil temperature

degC

52

50

54

Injection quantity adjustment_02

Pump speed

r/min

2500

2500

2500

Boost pressure

kPa

53.3

52

54.6

Boost pressure

mmHg

400

390

410

Average injection quantity

mm3/st.

5

Oil temperature

degC

55

52

58

Injection quantity adjustment_03

Pump speed

r/min

2100

2100

2100

Boost pressure

kPa

53.3

52

54.6

Boost pressure

mmHg

400

390

410

Average injection quantity

mm3/st.

55.2

50.7

59.7

Oil temperature

degC

52

50

54

Injection quantity adjustment_04

Pump speed

r/min

2300

2300

2300

Boost pressure

kPa

53.3

52

54.6

Boost pressure

mmHg

400

390

410

Average injection quantity

mm3/st.

18.3

15.8

20.8

Basic

*

Oil temperature

degC

52

50

54

Governor adjustment

Pump speed

r/min

350

350

350

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

12.5

10.5

14.5

Difference in delivery

mm3/st.

2

Basic

*

Oil temperature

degC

48

46

50

Governor adjustment_02

Pump speed

r/min

350

350

350

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

12.5

10

15

Difference in delivery

mm3/st.

2.5

Basic

*

Oil temperature

degC

48

46

50

Timer adjustment

Pump speed

r/min

100

100

100

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

58

48

78

Basic

*

Oil temperature

degC

48

46

50

Remarks

Full

Full

Timer adjustment_02

Pump speed

r/min

100

100

100

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

58

48

78

Oil temperature

degC

48

46

50

Remarks

Full

Full

Speed control lever angle

Pump speed

r/min

350

350

350

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

0

0

0

Oil temperature

degC

48

46

50

Remarks

Magnet OFF at idling position

Magnet OFF at idling position

0000000901

Pump speed

r/min

1000

1000

1000

Boost pressure

kPa

53.3

52

54.6

Boost pressure

mmHg

400

390

410

Overflow quantity with S/T ON

cm3/min

420

290

550

Oil temperature

degC

50

48

52

Remarks

With an O-ring

With an O-ring

_02

Pump speed

r/min

1000

1000

1000

Boost pressure

kPa

53.3

52

54.6

Boost pressure

mmHg

400

390

410

Overflow quantity with S/T ON

cm3/min

564

434

694

Oil temperature

degC

50

48

52

Remarks

Without an O-ring

Without an O-ring

Stop lever angle

Pump speed

r/min

1000

1000

1000

Boost pressure

kPa

53.3

52

54.6

Boost pressure

mmHg

400

390

410

Pressure with S/T ON

kPa

431

392

470

Pressure with S/T ON

kgf/cm2

4.4

4

4.8

Pressure with S/T OFF

kPa

333

304

362

Pressure with S/T OFF

kgf/cm2

3.4

3.1

3.7

Basic

*

Oil temperature

degC

50

48

52

Stop lever angle_02

Pump speed

r/min

1000

1000

1000

Boost pressure

kPa

53.3

52

54.6

Boost pressure

mmHg

400

390

410

Pressure with S/T OFF

kPa

333

294

372

Pressure with S/T OFF

kgf/cm2

3.4

3

3.8

Basic

*

Oil temperature

degC

50

48

52

Stop lever angle_03

Pump speed

r/min

1700

1700

1700

Boost pressure

kPa

53.3

52

54.6

Boost pressure

mmHg

400

390

410

Pressure with S/T OFF

kPa

549

510

588

Pressure with S/T OFF

kgf/cm2

5.6

5.2

6

Oil temperature

degC

50

48

52

0000001101

Pump speed

r/min

1000

1000

1000

Boost pressure

kPa

53.3

52

54.6

Boost pressure

mmHg

400

390

410

Timer stroke with S/T ON

mm

4.8

4.4

5.2

Timer stroke with S/T OFF

mm

2.6

2.4

2.8

Basic

*

Oil temperature

degC

50

48

52

_02

Pump speed

r/min

800

800

800

Boost pressure

kPa

53.3

52

54.6

Boost pressure

mmHg

400

390

410

Timer stroke with S/T OFF

mm

1.1

0.6

1.6

Oil temperature

degC

50

48

52

_03

Pump speed

r/min

1000

1000

1000

Boost pressure

kPa

53.3

52

54.6

Boost pressure

mmHg

400

390

410

Timer stroke with S/T ON

mm

4.8

4.3

5.3

Timer stroke with S/T OFF

mm

2.6

2.3

2.9

Basic

*

Oil temperature

degC

50

48

52

_04

Pump speed

r/min

1700

1700

1700

Boost pressure

kPa

53.3

52

54.6

Boost pressure

mmHg

400

390

410

Timer stroke with S/T OFF

mm

7

6.5

7.4

Oil temperature

degC

50

48

52

_05

Pump speed

r/min

2000

2000

2000

Boost pressure

kPa

53.3

52

54.6

Boost pressure

mmHg

400

390

410

Timer stroke with S/T OFF

mm

7

6.5

7.4

Oil temperature

degC

50

48

52

0000001201

Max. applied voltage

V

8

8

8

Test voltage

V

13

12

14

0000001401

Pump speed

r/min

1000

1000

1000

Boost pressure

kPa

53.3

52

54.6

Boost pressure

mmHg

400

390

410

Average injection quantity

mm3/st.

38

37.5

38.5

Timer stroke TA

mm

2.3

2.3

2.3

Timer stroke variation dT

mm

0.3

0.1

0.5

Basic

*

Oil temperature

degC

50

48

52

_02

Pump speed

r/min

1000

1000

1000

Boost pressure

kPa

53.3

52

54.6

Boost pressure

mmHg

400

390

410

Average injection quantity

mm3/st.

38

37

39

Timer stroke variation dT

mm

0.3

0

0.6

Basic

*

Oil temperature

degC

50

48

52

_03

Pump speed

r/min

1000

1000

1000

Boost pressure

kPa

53.3

52

54.6

Boost pressure

mmHg

400

390

410

Average injection quantity

mm3/st.

26

23.5

28.5

Timer stroke variation dT

mm

0.8

0.4

1.2

Oil temperature

degC

50

48

52

Timing setting

K dimension

mm

3.3

3.2

3.4

KF dimension

mm

6.64

6.54

6.74

MS dimension

mm

1

0.9

1.1

BCS stroke

mm

1.8

1.6

2

Control lever angle alpha

deg.

10

6

14

Control lever angle beta

deg.

40

35

45

Test data Ex:

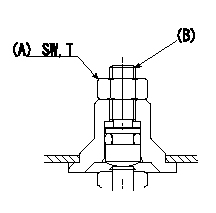

0000001601 BOOST COMPENSATOR ADJUSTMENT

BCS adjustment procedure

1. At full boost pressure, set so that the full injection quantity is within the specifications (adjusting point).

2. Perform boost compensator intermediate operation point adjustment (pump speed N1, boost pressure P1).

3. When injection quantity at boost pressure P2 and pump speed N2 is not as specified, loosen nut (A) and adjust position of screw (B) so that injection quantity is as specified. The screw position should be within +-1 turn of initial position.

4. The nut tightening torque is T.

----------

N1=700r/min N2=500r/min P1=16.0kPa(120mmHg) P2=0kPa(0mmHg) T=6~9N-m(0.6~0.9kgf-m)

----------

SW=10mm T=6~9N-m(0.6~0.9kgf-m)

----------

N1=700r/min N2=500r/min P1=16.0kPa(120mmHg) P2=0kPa(0mmHg) T=6~9N-m(0.6~0.9kgf-m)

----------

SW=10mm T=6~9N-m(0.6~0.9kgf-m)

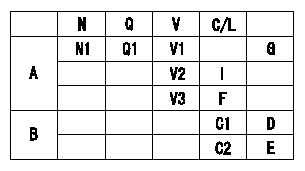

0000001801 POTENTIOMETER ADJUSTMENT

Potentiometer adjustment

1. Applied voltage: Vi

2. Boost pressure = P1

3. Set the control lever at the adjusting point. Position the dummy bolt against the lever and fix.

4. Assemble the potentiometer to obtain output voltage V1 at the fixed position.

5. After mounting the potentiometer, remove the dummy bolt.

A:Performance standards

B:ON, OFF switch standard

N:Pump speed

Q:Injection quantity

V:Output voltage

C/L: control lever position

I:Idle

F:Full speed

D:OFF-->ON

E:OFF-->ON

G:Adjusting point

----------

Vi=10.0V P1=0kPa(0mmHg) V1=3.3+-0.03V

----------

N1=700r/min Q1=24.7+-1.0mm3/st V1=3.3+-0.03V V2=1.48+-0.34V V3=(8.14+-0.74V) C1=(5.6+-2.6deg) C2=(20.1+-3deg)

----------

Vi=10.0V P1=0kPa(0mmHg) V1=3.3+-0.03V

----------

N1=700r/min Q1=24.7+-1.0mm3/st V1=3.3+-0.03V V2=1.48+-0.34V V3=(8.14+-0.74V) C1=(5.6+-2.6deg) C2=(20.1+-3deg)

Information:

Introduction

The 7C8966, 7C8972, 8N5651, 8N5887, 9N0495, and 9N5864 Fuel Injection Pump Groups (new), or the 0R0766, 0R0902, 0R0903, 0R2374, and 0R2385 Fuel Injection Pump Group [remanufactured - (reconditioning has been done to a used fuel injection pump and governor group to give the same quality as a new pump group)] are service replacements for the fuel injection pump and governor groups used on 3208 engines, according to the adaptability shown in the chart. These service groups have only those gaskets and seals that are needed to install the fuel injection pump and governor on the engine.Reference: Parts Manual, Service Manual, Engine Information Plate, Fuel Setting Information Microfiche, Fuel System and Related Information MicroficheDo not perform any procedure, outlined in this publication, or order any parts until you read and understand the information contained within.Service Group Chart

Removal and Installation

1. Remove the pump and governor from the engine. Refer to the Service Manual.

When a replacement fuel injection pump and governor is installed on an engine (or when replacement parts are put in a fuel injection pump and governor), use the information on the engine information plate and always check engine low idle speed, set point and the fuel setting dimension. These settings and dimensions must be checked and adjustments made by a mechanic that has the necessary training in fuel system maintenance. Before the fuel system checks and adjustment are made, remove the original factory fuel system seal. After all fuel system work has been completed, install your Dealer seal as a replacement seal. Refer to Fuel System and Related Information or Fuel Setting Information for additional specifications.

2. Put the new service pump group in a 2P8315 Bracket Assembly (1) so it will be easier to work on. Remove the shut-off solenoid and the solenoid ground wire from the old fuel system. Remove the fuel line fittings from the old fuel system. Install these parts in the same location on the new fuel system.3. Locate the engine serial number and write it down. Make reference to the Fuel Setting Information or Fuel System and Related Information to find the part number of the governor high idle spring that is needed for the engine. The same part number governor high idle spring given in the Fuel Setting Information, or the Fuel System and Related Information must be installed in the new service pump group. The 9L6508 High Idle Spring is already installed in the service pump and governor groups. The governor high idle spring needs to be changed only if the needed part number is different than 9L6508. If it is necessary to change the high idle spring, refer to the Service Manual. The part number of the low idle spring is 4N5663 and is the same for all fuel systems.4. A 4N0527 Overfueling Spring is installed in the service pump and governor groups. Refer to the Parts Manual to determine which overfueling spring is required. If the overfueling spring must be changed, refer to the Service Manual for the

The 7C8966, 7C8972, 8N5651, 8N5887, 9N0495, and 9N5864 Fuel Injection Pump Groups (new), or the 0R0766, 0R0902, 0R0903, 0R2374, and 0R2385 Fuel Injection Pump Group [remanufactured - (reconditioning has been done to a used fuel injection pump and governor group to give the same quality as a new pump group)] are service replacements for the fuel injection pump and governor groups used on 3208 engines, according to the adaptability shown in the chart. These service groups have only those gaskets and seals that are needed to install the fuel injection pump and governor on the engine.Reference: Parts Manual, Service Manual, Engine Information Plate, Fuel Setting Information Microfiche, Fuel System and Related Information MicroficheDo not perform any procedure, outlined in this publication, or order any parts until you read and understand the information contained within.Service Group Chart

Removal and Installation

1. Remove the pump and governor from the engine. Refer to the Service Manual.

When a replacement fuel injection pump and governor is installed on an engine (or when replacement parts are put in a fuel injection pump and governor), use the information on the engine information plate and always check engine low idle speed, set point and the fuel setting dimension. These settings and dimensions must be checked and adjustments made by a mechanic that has the necessary training in fuel system maintenance. Before the fuel system checks and adjustment are made, remove the original factory fuel system seal. After all fuel system work has been completed, install your Dealer seal as a replacement seal. Refer to Fuel System and Related Information or Fuel Setting Information for additional specifications.

2. Put the new service pump group in a 2P8315 Bracket Assembly (1) so it will be easier to work on. Remove the shut-off solenoid and the solenoid ground wire from the old fuel system. Remove the fuel line fittings from the old fuel system. Install these parts in the same location on the new fuel system.3. Locate the engine serial number and write it down. Make reference to the Fuel Setting Information or Fuel System and Related Information to find the part number of the governor high idle spring that is needed for the engine. The same part number governor high idle spring given in the Fuel Setting Information, or the Fuel System and Related Information must be installed in the new service pump group. The 9L6508 High Idle Spring is already installed in the service pump and governor groups. The governor high idle spring needs to be changed only if the needed part number is different than 9L6508. If it is necessary to change the high idle spring, refer to the Service Manual. The part number of the low idle spring is 4N5663 and is the same for all fuel systems.4. A 4N0527 Overfueling Spring is installed in the service pump and governor groups. Refer to the Parts Manual to determine which overfueling spring is required. If the overfueling spring must be changed, refer to the Service Manual for the