Information injection-pump assembly

ZEXEL

104760-4460

1047604460

NISSAN-DIESEL

1670051N04

1670051n04

Rating:

Cross reference number

ZEXEL

104760-4460

1047604460

NISSAN-DIESEL

1670051N04

1670051n04

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113orSAEJ967d

1404 Test oil ISO4113orSAEJ967d

Test oil temperature

degC

45

45

50

Nozzle

105780-0060

Bosch type code

NP-DN0SD1510

Nozzle holder

105780-2150

Opening pressure

MPa

13

13

13.3

Opening pressure

kgf/cm2

133

133

136

Injection pipe

157805-7320

Injection pipe

Inside diameter - outside diameter - length (mm) mm 2-6-450

Inside diameter - outside diameter - length (mm) mm 2-6-450

Joint assembly

157641-4720

Tube assembly

157641-4020

Transfer pump pressure

kPa

20

20

20

Transfer pump pressure

kgf/cm2

0.2

0.2

0.2

Direction of rotation (viewed from drive side)

Right R

Right R

(Solenoid timer adjustment condition)

With S/T O-ring; S/T OFF. OFF

With S/T O-ring; S/T OFF. OFF

Injection timing adjustment

Pump speed

r/min

500

500

500

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

46.3

45.8

46.8

Basic

*

Oil temperature

degC

48

46

50

Remarks

NA

NA

Injection timing adjustment_02

Pump speed

r/min

700

700

700

Boost pressure

kPa

16

14.7

17.3

Boost pressure

mmHg

120

110

130

Average injection quantity

mm3/st.

53.7

53.2

54.2

Basic

*

Oil temperature

degC

50

48

52

Remarks

CBS

CBS

Injection timing adjustment_03

Pump speed

r/min

1000

1000

1000

Boost pressure

kPa

53.3

52

54.6

Boost pressure

mmHg

400

390

410

Average injection quantity

mm3/st.

58.3

57.8

58.8

Difference in delivery

mm3/st.

4

Basic

*

Oil temperature

degC

50

48

52

Injection timing adjustment_04

Pump speed

r/min

500

500

500

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

46.3

45.3

47.3

Basic

*

Oil temperature

degC

48

46

50

Injection timing adjustment_05

Pump speed

r/min

700

700

700

Boost pressure

kPa

16

14.7

17.3

Boost pressure

mmHg

120

110

130

Average injection quantity

mm3/st.

53.7

52.7

54.7

Basic

*

Oil temperature

degC

50

48

52

Remarks

CBS

CBS

Injection timing adjustment_06

Pump speed

r/min

1000

1000

1000

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

51.1

48.6

53.6

Oil temperature

degC

50

48

52

Injection timing adjustment_07

Pump speed

r/min

1000

1000

1000

Boost pressure

kPa

53.3

52

54.6

Boost pressure

mmHg

400

390

410

Average injection quantity

mm3/st.

58.3

57.3

59.3

Difference in delivery

mm3/st.

4.5

Basic

*

Oil temperature

degC

50

48

52

Injection timing adjustment_08

Pump speed

r/min

2000

2000

2000

Boost pressure

kPa

53.3

52

54.6

Boost pressure

mmHg

400

390

410

Average injection quantity

mm3/st.

61.1

58.6

63.6

Oil temperature

degC

50

48

52

Injection quantity adjustment

Pump speed

r/min

2300

2300

2300

Boost pressure

kPa

53.3

52

54.6

Boost pressure

mmHg

400

390

410

Average injection quantity

mm3/st.

18.3

16.3

20.3

Basic

*

Oil temperature

degC

52

50

54

Injection quantity adjustment_02

Pump speed

r/min

2500

2500

2500

Boost pressure

kPa

53.3

52

54.6

Boost pressure

mmHg

400

390

410

Average injection quantity

mm3/st.

5

Oil temperature

degC

55

52

58

Injection quantity adjustment_03

Pump speed

r/min

2100

2100

2100

Boost pressure

kPa

53.3

52

54.6

Boost pressure

mmHg

400

390

410

Average injection quantity

mm3/st.

55.2

50.7

59.7

Oil temperature

degC

52

50

54

Injection quantity adjustment_04

Pump speed

r/min

2300

2300

2300

Boost pressure

kPa

53.3

52

54.6

Boost pressure

mmHg

400

390

410

Average injection quantity

mm3/st.

18.3

15.8

20.8

Basic

*

Oil temperature

degC

52

50

54

Governor adjustment

Pump speed

r/min

350

350

350

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

12.5

10.5

14.5

Difference in delivery

mm3/st.

2

Basic

*

Oil temperature

degC

48

46

50

Governor adjustment_02

Pump speed

r/min

350

350

350

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

12.5

10

15

Difference in delivery

mm3/st.

2.5

Basic

*

Oil temperature

degC

48

46

50

Timer adjustment

Pump speed

r/min

100

100

100

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

58

48

78

Basic

*

Oil temperature

degC

48

46

50

Remarks

Full

Full

Timer adjustment_02

Pump speed

r/min

100

100

100

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

58

48

78

Oil temperature

degC

48

46

50

Remarks

Full

Full

Speed control lever angle

Pump speed

r/min

350

350

350

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

0

0

0

Oil temperature

degC

48

46

50

Remarks

Magnet OFF at idling position

Magnet OFF at idling position

0000000901

Pump speed

r/min

1000

1000

1000

Boost pressure

kPa

53.3

52

54.6

Boost pressure

mmHg

400

390

410

Overflow quantity with S/T ON

cm3/min

420

290

550

Oil temperature

degC

50

48

52

Remarks

With an O-ring

With an O-ring

_02

Pump speed

r/min

1000

1000

1000

Boost pressure

kPa

53.3

52

54.6

Boost pressure

mmHg

400

390

410

Overflow quantity with S/T ON

cm3/min

470

340

600

Oil temperature

degC

50

48

52

Remarks

Without an O-ring

Without an O-ring

Stop lever angle

Pump speed

r/min

1000

1000

1000

Boost pressure

kPa

53.3

52

54.6

Boost pressure

mmHg

400

390

410

Pressure with S/T ON

kPa

431

392

470

Pressure with S/T ON

kgf/cm2

4.4

4

4.8

Pressure with S/T OFF

kPa

333

304

362

Pressure with S/T OFF

kgf/cm2

3.4

3.1

3.7

Basic

*

Oil temperature

degC

50

48

52

Stop lever angle_02

Pump speed

r/min

1000

1000

1000

Boost pressure

kPa

53.3

52

54.6

Boost pressure

mmHg

400

390

410

Pressure with S/T OFF

kPa

333

294

372

Pressure with S/T OFF

kgf/cm2

3.4

3

3.8

Basic

*

Oil temperature

degC

50

48

52

Stop lever angle_03

Pump speed

r/min

1700

1700

1700

Boost pressure

kPa

53.3

52

54.6

Boost pressure

mmHg

400

390

410

Pressure with S/T OFF

kPa

549

510

588

Pressure with S/T OFF

kgf/cm2

5.6

5.2

6

Oil temperature

degC

50

48

52

0000001101

Pump speed

r/min

1000

1000

1000

Boost pressure

kPa

53.3

52

54.6

Boost pressure

mmHg

400

390

410

Timer stroke with S/T ON

mm

4.8

4.4

5.2

Timer stroke with S/T OFF

mm

2.6

2.4

2.8

Basic

*

Oil temperature

degC

50

48

52

_02

Pump speed

r/min

800

800

800

Boost pressure

kPa

53.3

52

54.6

Boost pressure

mmHg

400

390

410

Timer stroke with S/T OFF

mm

1.1

0.6

1.6

Oil temperature

degC

50

48

52

_03

Pump speed

r/min

1000

1000

1000

Boost pressure

kPa

53.3

52

54.6

Boost pressure

mmHg

400

390

410

Timer stroke with S/T ON

mm

4.8

4.3

5.3

Timer stroke with S/T OFF

mm

2.6

2.3

2.9

Basic

*

Oil temperature

degC

50

48

52

_04

Pump speed

r/min

1700

1700

1700

Boost pressure

kPa

53.3

52

54.6

Boost pressure

mmHg

400

390

410

Timer stroke with S/T OFF

mm

7

6.5

7.4

Oil temperature

degC

50

48

52

_05

Pump speed

r/min

2000

2000

2000

Boost pressure

kPa

53.3

52

54.6

Boost pressure

mmHg

400

390

410

Timer stroke with S/T OFF

mm

7

6.5

7.4

Oil temperature

degC

50

48

52

0000001201

Max. applied voltage

V

8

8

8

Test voltage

V

13

12

14

0000001401

Pump speed

r/min

1000

1000

1000

Boost pressure

kPa

53.3

52

54.6

Boost pressure

mmHg

400

390

410

Average injection quantity

mm3/st.

38

37.5

38.5

Timer stroke TA

mm

2.3

2.3

2.3

Timer stroke variation dT

mm

0.3

0.1

0.5

Basic

*

Oil temperature

degC

50

48

52

_02

Pump speed

r/min

1000

1000

1000

Boost pressure

kPa

53.3

52

54.6

Boost pressure

mmHg

400

390

410

Average injection quantity

mm3/st.

38

37

39

Timer stroke variation dT

mm

0.3

0

0.6

Basic

*

Oil temperature

degC

50

48

52

_03

Pump speed

r/min

1000

1000

1000

Boost pressure

kPa

53.3

52

54.6

Boost pressure

mmHg

400

390

410

Average injection quantity

mm3/st.

26

23.5

28.5

Timer stroke variation dT

mm

0.8

0.4

1.2

Oil temperature

degC

50

48

52

Timing setting

K dimension

mm

3.3

3.2

3.4

KF dimension

mm

6.64

6.54

6.74

MS dimension

mm

1

0.9

1.1

BCS stroke

mm

1.8

1.6

2

Control lever angle alpha

deg.

10

6

14

Control lever angle beta

deg.

40

35

45

Test data Ex:

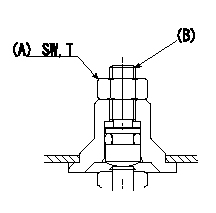

0000001601 BOOST COMPENSATOR ADJUSTMENT

BCS adjustment procedure

1. At full boost pressure, set so that the full injection quantity is within the specifications (adjusting point).

2. Perform boost compensator intermediate operation point adjustment (pump speed N1, boost pressure P1).

3. When injection quantity at boost pressure P2 and pump speed N2 is not as specified, loosen nut (A) and adjust position of screw (B) so that injection quantity is as specified. The screw position should be within +-1 turn of initial position.

4. The nut tightening torque is T.

----------

N1=700r/min N2=500r/min P1=16.0kPa(120mmHg) P2=0kPa(0mmHg) T=6~9N-m(0.6~0.9kgf-m)

----------

SW=10mm T=6~9N-m(0.6~0.9kgf-m)

----------

N1=700r/min N2=500r/min P1=16.0kPa(120mmHg) P2=0kPa(0mmHg) T=6~9N-m(0.6~0.9kgf-m)

----------

SW=10mm T=6~9N-m(0.6~0.9kgf-m)

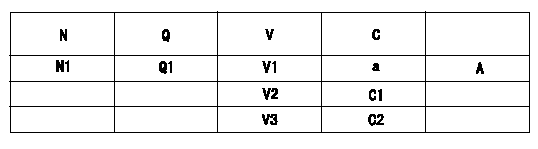

0000001801 POTENTIOMETER ADJUSTMENT

Potentiometer adjustment

1. Applied voltage: Vi

2. Boost pressure = P1

3. Set the control lever at the adjusting point. Position the dummy bolt against the lever and fix.

4. Assemble the potentiometer to obtain output voltage V1 at the fixed position.

5. After mounting the potentiometer, remove the dummy bolt.

N:Pump speed

Q:Injection quantity

V:Output voltage

C:Position of the control lever

A:Adjusting point

C1:Idle

C2:Full-speed

----------

V1=5.52+-0.03V P1=0kPa(0mmHg) Vi=10V

----------

N1=850r/min Q1=13.8+-1.0mm3/st V1=5.52+-0.03V V2=2.42+-0.78V V3=(10V) a=-

----------

V1=5.52+-0.03V P1=0kPa(0mmHg) Vi=10V

----------

N1=850r/min Q1=13.8+-1.0mm3/st V1=5.52+-0.03V V2=2.42+-0.78V V3=(10V) a=-

Information:

04Feb2016

U-58

A-46

D-55

O-52

Parts stock action only

PRODUCT IMPROVEMENT PROGRAM FOR REMOVING 398-1498 AND 463-1678 FUEL INJECTION PUMPS FROM DEALER PARTS STOCK

7750 PI70604

Caterpillar’s obligations under this Service Letter are subject to, and shall not apply in contravention of, the laws, rules, regulations, directives, ordinances, orders, or statutes of the United States, or of any other applicable jurisdiction, without recourse or liability with respect to Caterpillar.

When submitting claim for Parts Stock Action, Use the appropriate 99Z as the s/n, the appropriate Service Letter Program Number as the Part number in the Part Causing Failure field, "7751" as the Group Number, "56" as the Description Code.

The information supplied in this service letter may not be valid after the termination date of this program.Do not perform the work outlined in this Service Letter after the termination date without first contacting your Caterpillar product analyst.

TERMINATION DATE

31May2016

PROBLEM

The existing 398-1498 and 463-1678 Fuel Injection Pumps can fail. Fuel Injection Pumps up to and inclusive of component serial number 06369GJG, are suspect.

ACTION REQUIRED

Inspect all 398-1498 and 463-1678 Fuel Injection Pumps in dealer parts stock. Review the component serial number on each 398-1498 and 463-1678 Fuel Injection Pump. The Fuel Injection Pump component serial number can be located on the Fuel Injection Pump data plate, affixed to the side of the Fuel Injection Pump body.

The Fuel Injection Pump component serial number is alphanumeric, Refer to Image 1 for explanation on component serial number translation. In the given example the date code would translate to the following - 6369th pump built in July 2015.

NOTE - The build facility is not applicable in determining if the Fuel Injection Pump is suspect or not.

Refer to Image 2 for the build month and build year translation table.

Please action according to the following build month and build year color code -

Red = Remove from dealer part stock

Orange = Check Fuel Injection Pump Serial Number (06369 and below = Remove from dealer part stock / 06370 and Up = Return to dealer part stock).

Green = OK, Return to dealer part stock.

- If the Fuel Injection Pump is removed from dealer parts stock. Refer to the Service Claim Allowances and Parts Disposition.

- If the Fuel Injection Pump is returned to dealer parts stock, mark the box as inspected.

Image1

Image2

SERVICE CLAIM ALLOWANCES

Submit one claim for all Fuel Injection Pumps removed from dealer parts stock. Include the date code (e.g. 06369GJG) in the claim story for each Fuel Injection Pump removed from dealer parts stock.

PARTS DISPOSITION

NACD:

Hold all 398-1498 and 463-1678 Fuel Injection Pumps removed from dealer parts stock for a Parts Return Request (PRR). A Parts Return Request (PRR) will be issued to you through the Send-It-Back process after the claim is submitted. Make sure to list the service letter program number on the packing