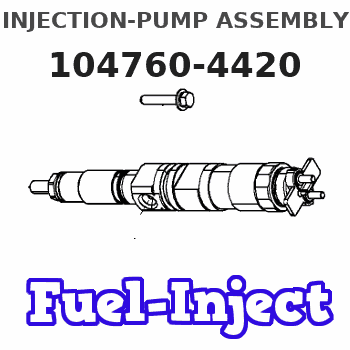

Information injection-pump assembly

ZEXEL

104760-4420

1047604420

NISSAN-DIESEL

1670051N06

1670051n06

Rating:

Cross reference number

ZEXEL

104760-4420

1047604420

NISSAN-DIESEL

1670051N06

1670051n06

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113orSAEJ967d

1404 Test oil ISO4113orSAEJ967d

Test oil temperature

degC

45

45

50

Nozzle

105000-2010

Bosch type code

NP-DN12SD12TT

Nozzle holder

105780-2080

Opening pressure

MPa

14.7

14.7

15.19

Opening pressure

kgf/cm2

150

150

155

Injection pipe

Inside diameter - outside diameter - length (mm) mm 2-6-840

Inside diameter - outside diameter - length (mm) mm 2-6-840

Transfer pump pressure

kPa

20

20

20

Transfer pump pressure

kgf/cm2

0.2

0.2

0.2

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Pump speed

r/min

1000

1000

1000

Average injection quantity

mm3/st.

50.9

50.4

51.4

Difference in delivery

mm3/st.

3.5

Basic

*

Oil temperature

degC

50

48

52

Injection timing adjustment_02

Pump speed

r/min

600

600

600

Average injection quantity

mm3/st.

52.6

50.6

54.6

Oil temperature

degC

50

48

52

Injection timing adjustment_03

Pump speed

r/min

1000

1000

1000

Average injection quantity

mm3/st.

50.9

49.9

51.9

Difference in delivery

mm3/st.

4

Basic

*

Oil temperature

degC

50

48

52

Injection timing adjustment_04

Pump speed

r/min

2000

2000

2000

Average injection quantity

mm3/st.

44.7

42.6

46.8

Oil temperature

degC

52

50

54

Injection quantity adjustment

Pump speed

r/min

2300

2300

2300

Average injection quantity

mm3/st.

16.6

14.6

18.6

Difference in delivery

mm3/st.

5

Basic

*

Oil temperature

degC

52

50

54

Injection quantity adjustment_02

Pump speed

r/min

2500

2500

2500

Average injection quantity

mm3/st.

5

Oil temperature

degC

55

52

58

Injection quantity adjustment_03

Pump speed

r/min

2100

2100

2100

Average injection quantity

mm3/st.

43.8

39.3

48.3

Oil temperature

degC

52

50

54

Injection quantity adjustment_04

Pump speed

r/min

2300

2300

2300

Average injection quantity

mm3/st.

16.6

14.1

19.1

Basic

*

Oil temperature

degC

52

50

54

Governor adjustment

Pump speed

r/min

350

350

350

Average injection quantity

mm3/st.

8.8

6.8

10.8

Difference in delivery

mm3/st.

2

Basic

*

Oil temperature

degC

48

46

50

Governor adjustment_02

Pump speed

r/min

350

350

350

Average injection quantity

mm3/st.

8.8

6.3

11.3

Difference in delivery

mm3/st.

2.5

Basic

*

Oil temperature

degC

48

46

50

Timer adjustment

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

60

50

80

Basic

*

Oil temperature

degC

48

46

50

Remarks

Full

Full

Timer adjustment_02

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

60

50

80

Oil temperature

degC

48

46

50

Speed control lever angle

Pump speed

r/min

350

350

350

Average injection quantity

mm3/st.

0

0

0

Oil temperature

degC

48

46

50

Remarks

Magnet OFF at idling position

Magnet OFF at idling position

Speed control lever angle_02

Pump speed

r/min

250

250

250

Average injection quantity

mm3/st.

5

Oil temperature

degC

48

46

50

Remarks

Magnet OFF at full-load position

Magnet OFF at full-load position

0000000901

Pump speed

r/min

1000

1000

1000

Overflow quantity

cm3/min

400

270

530

Oil temperature

degC

50

48

52

Stop lever angle

Pump speed

r/min

1000

1000

1000

Pressure

kPa

324

304

344

Pressure

kgf/cm2

3.3

3.1

3.5

Basic

*

Oil temperature

degC

50

48

52

Stop lever angle_02

Pump speed

r/min

1000

1000

1000

Pressure

kPa

324

295

353

Pressure

kgf/cm2

3.3

3

3.6

Basic

*

Oil temperature

degC

50

48

52

Stop lever angle_03

Pump speed

r/min

1800

1800

1800

Pressure

kPa

608

569

647

Pressure

kgf/cm2

6.2

5.8

6.6

Oil temperature

degC

50

48

52

0000001101

Pump speed

r/min

1000

1000

1000

Timer stroke

mm

1.6

1.4

1.8

Basic

*

Oil temperature

degC

50

48

52

_02

Pump speed

r/min

800

800

800

Timer stroke

mm

0.5

0

1

Oil temperature

degC

50

48

52

_03

Pump speed

r/min

1000

1000

1000

Timer stroke

mm

1.6

1.3

1.9

Basic

*

Oil temperature

degC

50

48

52

_04

Pump speed

r/min

1800

1800

1800

Timer stroke

mm

5.8

5.3

6.3

Oil temperature

degC

50

48

52

_05

Pump speed

r/min

2200

2200

2200

Timer stroke

mm

7.4

6.9

7.8

Oil temperature

degC

52

50

54

0000001201

Max. applied voltage

V

8

8

8

Test voltage

V

13

12

14

0000001401

Pump speed

r/min

1200

1200

1200

Average injection quantity

mm3/st.

22

21.5

22.5

Timer stroke TA

mm

2.5

2.3

2.7

Timer stroke variation dT

mm

0.1

0.1

0.1

Basic

*

Oil temperature

degC

50

48

52

_02

Pump speed

r/min

1200

1200

1200

Average injection quantity

mm3/st.

22

21

23

Timer stroke TA

mm

2.5

2.2

2.8

Basic

*

Oil temperature

degC

50

48

52

_03

Pump speed

r/min

1200

1200

1200

Average injection quantity

mm3/st.

15

12.5

17.5

Timer stroke TA

mm

2.1

1.4

2.8

Oil temperature

degC

50

48

52

Timing setting

K dimension

mm

3.3

3.2

3.4

KF dimension

mm

6.64

6.54

6.74

MS dimension

mm

1

0.9

1.1

Control lever angle alpha

deg.

25

23

27

Control lever angle beta

deg.

40

35

45

Information:

Rework Procedure

Replacement of Diesel Oxidation Catalyst (DOC)

1. Remove three 222-8823 Bolts and three 232-3209 Washers to separate the 360-8875 Bellows Tube Assembly from the 360-8849 Catalytic Converter Group. Refer to Image1.1.1.

Image1.1.1

2. Loosen the clamp. Remove the DOC from the Catalytic Converter Group. Refer to Images1.2.1 and 1.2.2.

Image1.2.1

Image1.2.2

3. Remove the ring from the DOC. Remove the clamp from the catalytic converter. Refer to Images1.3.1 and 1.3.2.

Image1.3.1

Image1.3.2

4. Remove the five screws and five washers from the insulation around the DOC. Remove insulation from the DOC. The insulation will be reused. Refer to Images1.4.1 and 1.4.2.

Image1.4.1

Image1.4.2

5. Install the insulation that was removed from the old DOC on the new DOC. Refer to Image1.5.1.

Image1.5.1

6. Clean the sealing surface of the DOC flange. Clean the sealing surface of the flange on the catalytic converter group. Clean the ring that was removed from the old DOC. Refer to Images1.6.1, 1.6.2, and 1.6.3

Image1.6.1

Image1.6.2

Image1.6.3

7. Apply seal paste to both sides of the ring, to the flange surfaces of the new DOC, and the catalytic converter. Refer to Image1.7.1.

Note: Make sure to cover the complete ring and flange surfaces with seal paste when applying it.

Image1.7.1

8. Place the ring on the flange of the new DOC. Position the new DOC against the catalytic converter. Refer to Images1.8.1 and 1.8.2.

Image1.8.1

Image1.8.2

9. Orient the DOC so that it will line up correctly with the bellows tube. Install and orient the clamp in order to hold the new DOC in place. Apply sealing paste or high temperature grease to the bolt of the clamp. Tighten the clamp. Then reattach the DOC to the bellows tube. Refer to Image1.9.1.

Image1.9.1

10. Tap the clamp around the circumference to properly seat the clamp. Tighten the clamp to a specified torque of 18 N.m (13.3 ft-lb). Apply sealing paste or high temperature grease to the three 222-8823 Bolts to assemble the bellows. Refer to Image1.10.1.

Image1.10.1

11. Please write down the number of active regenerations. This number can be found in the Monitor Service Menu in the Aftertreatment Status section. Please enter this information to the claim story when you submit your claim. Refer to Image1.11.1.

Image1.11.1