Information injection-pump assembly

BOSCH

9 460 611 465

9460611465

ZEXEL

104760-2546

1047602546

NISSAN

167006H711

167006h711

Rating:

Components :

| 0. | INJECTION-PUMP ASSEMBLY | 104760-2546 |

| 1. | _ | |

| 2. | FUEL INJECTION PUMP | 104660-2546 |

| 3. | NUMBER PLATE | 146981-0400 |

| 4. | _ | |

| 5. | CAPSULE | |

| 6. | ADJUSTING DEVICE | 146679-0520 |

| 7. | NOZZLE AND HOLDER ASSY | 105141-2991 |

| 8. | Nozzle and Holder | 16600-84T07 |

| 9. | Open Pre:MPa(Kqf/cm2) | 12.7{130} |

| 10. | NOZZLE-HOLDER | 105071-0681 |

| 11. | NOZZLE | 105000-2200 |

Scheme ###:

| 1/6. | [1] | 146601-0700 | PACKING RING |

| 6. | [1] | 146100-0220 | SUPPLY PUMP |

| 9. | [1] | 146103-0100 | COVER |

| 10. | [2] | 139104-0000 | FLAT-HEAD SCREW |

| 12. | [1] | 146200-0420 | DRIVE SHAFT |

| 12/1. | [1] | 146200-0400 | DRIVE SHAFT |

| 12/2. | [1] | 146201-0000 | WOODRUFF KEY |

| 12/3. | [2] | 146202-0100 | DAMPER |

| 12/4. | [1] | 146203-0000 | TOOTHED GEAR |

| 17. | [1] | 146204-0000 | PLAIN WASHER |

| 20. | [1] | 146210-3420 | ROLLER SET |

| 24. | [1] | 146303-0000 | BEARING PIN |

| 25. | [1] | 146304-0000 | BEARING PIN |

| 26. | [1] | 146305-0000 | CLAMPING BAND |

| 27. | [1] | 146205-0000 | SLOTTED WASHER |

| 29. | [1] | 146221-1120 | CAM PLATE |

| 30. | [1] | 146600-0800 | O-RING |

| 31. | [1] | 146311-8620 | PUMP PLUNGER |

| 32. | [1] | 146301-0000 | SLIDING PIECE |

| 34. | [1] | 146312-2600 | COMPRESSION SPRING |

| 34B. | [1] | 146312-3900 | COMPRESSION SPRING |

| 35/1. | [1] | 146690-3200 | SHIM D11.5&9.4T0.1 |

| 35/1. | [1] | 146690-3300 | SHIM D11.5&9.4T0.2 |

| 35/1. | [1] | 146690-3400 | SHIM D11.5&9.4T0.25 |

| 35/1. | [1] | 146690-3500 | SHIM D11.5&9.4T1.0 |

| 35/1. | [1] | 146690-4100 | SHIM D11.5&9.4T2 |

| 35/1. | [1] | 146690-4200 | SHIM D11.5&9.4T0.5 |

| 35/1. | [1] | 146690-4300 | SHIM D11.5&9.4T0.75 |

| 36. | [1] | 146600-0800 | O-RING |

| 37. | [1] | 146310-4020 | COVER |

| 38. | [2] | 146620-5000 | BLEEDER SCREW |

| 39. | [1] | 146310-0100 | COVER |

| 40. | [2] | 146620-5000 | BLEEDER SCREW |

| 41. | [1] | 146312-2000 | COMPRESSION SPRING |

| 43. | [1] | 146230-0000 | SHIM |

| 44. | [1] | 146230-0100 | PLAIN WASHER |

| 45. | [1] | 146231-0001 | SLOTTED WASHER |

| 47. | [2] | 146233-0000 | SLOTTED WASHER |

| 48/1. | [1] | 146603-0000 | SHIM D17.0&5.2T0.50 |

| 48/1. | [1] | 146603-0100 | SHIM D17.0&5.2T0.80 |

| 48/1. | [1] | 146603-0200 | SHIM D17.0&5.2T1.00 |

| 48/1. | [1] | 146603-0300 | SHIM D17.0&5.2T1.20 |

| 48/1. | [1] | 146603-0400 | SHIM D17.0&5.2T1.50 |

| 48/1. | [1] | 146603-0500 | SHIM D17.0&5.2T1.80 |

| 48/1. | [1] | 146603-0600 | SHIM D17.0&5.2T2.00 |

| 48/1. | [1] | 146690-1400 | SHIM D17&5.2T0.9 |

| 48/1. | [1] | 146690-1500 | SHIM D17&5.2T1.1 |

| 48/1. | [1] | 146690-1600 | SHIM D17&5.2T1.3 |

| 48/1. | [1] | 146690-1700 | SHIM D17&5.2T1.4 |

| 48/1. | [1] | 146690-1800 | SHIM D17&5.2T1.6 |

| 48/1. | [1] | 146690-1900 | SHIM D17&5.2T1.7 |

| 48/1. | [1] | 146690-5800 | SHIM |

| 48/1. | [1] | 146690-5900 | SHIM |

| 48/1. | [1] | 146690-6000 | SHIM |

| 48/1. | [1] | 146690-6100 | SHIM |

| 48/1. | [1] | 146690-6200 | SHIM |

| 48/1. | [1] | 146690-6300 | SHIM |

| 48/1. | [1] | 146690-6400 | SHIM |

| 48/1. | [1] | 146690-6500 | SHIM |

| 48/1. | [1] | 146690-6600 | SHIM |

| 48/1. | [1] | 146690-6700 | SHIM |

| 48/1. | [1] | 146690-6800 | SHIM |

| 48/1. | [1] | 146690-6900 | SHIM |

| 48/1. | [1] | 146690-7000 | SHIM |

| 48/1. | [1] | 146690-7100 | SHIM |

| 48/1. | [1] | 146690-7200 | SHIM |

| 48/1. | [1] | 146690-7300 | SHIM |

| 48/1. | [1] | 146690-7400 | SHIM |

| 48/1. | [1] | 146690-7500 | SHIM |

| 48/1. | [1] | 146690-7800 | SHIM |

| 49. | [2] | 146234-0600 | GUIDE PIN |

| 50. | [1] | 146405-2720 | HYDRAULIC HEAD |

| 50. | [1] | 146405-2720 | HYDRAULIC HEAD |

| 50. | [1] | 146405-2720 | HYDRAULIC HEAD |

| 51. | [1] | 146600-0000 | O-RING |

| 52/1. | [1] | 146420-0000 | SHIM D9.5&3.0T1.90 |

| 52/1. | [1] | 146420-0100 | SHIM D9.5&3.0T1.92 |

| 52/1. | [1] | 146420-0200 | SHIM D9.5&3.0T1.94 |

| 52/1. | [1] | 146420-0300 | SHIM D9.5&3.0T1.96 |

| 52/1. | [1] | 146420-0400 | SHIM D9.5&3.0T1.98 |

| 52/1. | [1] | 146420-0500 | SHIM D9.5&3.0T2.00 |

| 52/1. | [1] | 146420-0600 | SHIM D9.5&3.0T2.02 |

| 52/1. | [1] | 146420-0700 | SHIM D9.5&3.0T2.04 |

| 52/1. | [1] | 146420-0800 | SHIM D9.5&3.0T2.06 |

| 52/1. | [1] | 146420-0900 | SHIM D9.5&3.0T2.08 |

| 52/1. | [1] | 146420-1000 | SHIM D9.5&3.0T2.10 |

| 52/1. | [1] | 146420-1100 | SHIM D9.5&3.0T2.12 |

| 52/1. | [1] | 146420-1200 | SHIM D9.5&3.0T2.14 |

| 52/1. | [1] | 146420-1300 | SHIM D9.5&3.0T2.16 |

| 52/1. | [1] | 146420-1400 | SHIM D9.5&3.0T2.18 |

| 52/1. | [1] | 146420-1500 | SHIM D9.5&3.0T2.20 |

| 52/1. | [1] | 146420-1600 | SHIM D9.5&3.0T2.22 |

| 52/1. | [1] | 146420-1700 | SHIM D9.5&3.0T2.24 |

| 52/1. | [1] | 146420-1800 | SHIM D9.5&3.0T2.26 |

| 52/1. | [1] | 146420-1900 | SHIM D9.5&3.0T2.28 |

| 52/1. | [1] | 146420-2000 | SHIM D9.5&3.0T2.30 |

| 52/1. | [1] | 146420-2100 | SHIM D9.5&3.0T2.32 |

| 52/1. | [1] | 146420-2200 | SHIM D9.5&3.0T2.34 |

| 52/1. | [1] | 146420-2300 | SHIM D9.5&3.0T2.36 |

| 52/1. | [1] | 146420-2400 | SHIM D9.5&3.0T2.38 |

| 52/1. | [1] | 146420-2500 | SHIM D9.5&3.0T2.40 |

| 52/1. | [1] | 146420-2600 | SHIM D9.5&3.0T2.42 |

| 52/1. | [1] | 146420-2700 | SHIM D9.5&3.0T2.44 |

| 52/1. | [1] | 146420-2800 | SHIM D9.5&3.0T2.46 |

| 52/1. | [1] | 146420-2900 | SHIM D9.5&3.0T2.48 |

| 52/1. | [1] | 146420-3000 | SHIM D9.5&3.0T2.50 |

| 52/1. | [1] | 146420-3100 | SHIM D9.5&3.0T2.52 |

| 52/1. | [1] | 146420-3200 | SHIM D9.5&3.0T2.54 |

| 52/1. | [1] | 146420-3300 | SHIM D9.5&3.0T2.56 |

| 52/1. | [1] | 146420-3400 | SHIM D9.5&3.0T2.58 |

| 52/1. | [1] | 146420-3500 | SHIM D9.5&3.0T2.60 |

| 52/1. | [1] | 146420-3600 | SHIM D9.5&3.0T2.62 |

| 52/1. | [1] | 146420-3700 | SHIM D9.5&3.0T2.64 |

| 52/1. | [1] | 146420-3800 | SHIM D9.5&3.0T2.66 |

| 52/1. | [1] | 146420-3900 | SHIM D9.5&3.0T2.68 |

| 52/1. | [1] | 146420-4000 | SHIM D9.5&3.0T2.70 |

| 52/1. | [1] | 146420-4100 | SHIM D9.5&3.0T2.72 |

| 52/1. | [1] | 146420-4200 | SHIM D9.5&3.0T2.74 |

| 52/1. | [1] | 146420-4300 | SHIM D9.5&3.0T2.76 |

| 52/1. | [1] | 146420-4400 | SHIM D9.5&3.0T2.78 |

| 52/1. | [1] | 146420-4500 | SHIM D9.5&3.0T2.80 |

| 52/1. | [1] | 146420-4600 | SHIM D9.5&3.0T2.82 |

| 52/1. | [1] | 146420-4700 | SHIM D9.5&3.0T2.84 |

| 52/1. | [1] | 146420-4800 | SHIM D9.5&3.0T2.86 |

| 52/1. | [1] | 146420-4900 | SHIM D9.5&3.0T2.88 |

| 52/1. | [1] | 146420-5000 | SHIM D9.5&3.0T2.90 |

| 52/1. | [1] | 146420-5100 | SHIM D9.5&3.0T1.74 |

| 52/1. | [1] | 146420-5200 | SHIM D9.5&3.0T1.76 |

| 52/1. | [1] | 146420-5300 | SHIM D9.5&3.0T1.78 |

| 52/1. | [1] | 146420-5400 | SHIM D9.5&3.0T1.80 |

| 52/1. | [1] | 146420-5500 | SHIM D9.5&3.0T1.82 |

| 52/1. | [1] | 146420-5600 | SHIM D9.5&3.0T1.84 |

| 52/1. | [1] | 146420-5700 | SHIM D9.5&3.0T1.86 |

| 52/1. | [1] | 146420-5800 | SHIM D9.5&3.0T1.88 |

| 54. | [6] | 146433-0100 | GASKET D12&6.4T1.00 |

| 55. | [6] | 146430-4620 | DELIVERY-VALVE ASSEMBLY |

| 56. | [6] | 146432-0000 | COMPRESSION SPRING |

| 58. | [6] | 146440-2720 | FITTING |

| 60. | [3] | 139106-0100 | FLAT-HEAD SCREW |

| 66. | [1] | 146600-0100 | O-RING |

| 67. | [1] | 146503-8620 | GOVERNOR COVER |

| 67/1. | [1] | 146805-8020 | GOVERNOR COVER |

| 67/14. | [1] | 146621-1700 | UNION NUT |

| 67/16. | [1] | 146526-3400 | BLEEDER SCREW |

| 67/78. | [1] | 146600-4400 | SEAL RING |

| 67/200. | [1] | 139308-0300 | PLAIN WASHER |

| 67/201. | [1] | 146545-3400 | THREADED PIN L53.00 |

| 67/201B. | [1] | 146545-3500 | THREADED PIN L55.00 |

| 67/201C. | [1] | 146545-3600 | THREADED PIN L57.00 |

| 67/202. | [1] | 139208-0900 | UNION NUT |

| 67/203. | [1] | 146600-1200 | O-RING |

| 68. | [1] | 146514-4520 | CONTROL SHAFT |

| 69. | [1] | 139310-0200 | PLAIN WASHER |

| 72. | [1] | 146830-6520 | CONTROL LEVER |

| 72B. | [1] | 146830-6620 | CONTROL LEVER |

| 73. | [1] | 014110-6440 | LOCKING WASHER |

| 75. | [1] | 013020-6040 | UNION NUT M6P1H5 |

| 95. | [1] | 146861-9820 | FULCRUM LEVER |

| 104. | [2] | 146568-0000 | SLOTTED SPRING PIN |

| 105. | [2] | 026508-1140 | GASKET D11.4&8.2T1 |

| 106. | [2] | 146588-0500 | COILED SPRING |

| 107. | [1] | 146569-0300 | UNION NUT |

| 108. | [1] | 146570-0100 | GOVERNOR SHAFT |

| 109. | [1] | 146600-0400 | O-RING |

| 110/1. | [1] | 146571-0000 | SHIM D20.2&8.3T1.05 |

| 110/1. | [1] | 146571-0100 | SHIM D20.2&8.3T1.25 |

| 110/1. | [1] | 146571-0200 | SHIM D20.2&8.3T1.45 |

| 110/1. | [1] | 146571-0300 | SHIM D20.2&8.3T1.65 |

| 110/1. | [1] | 146571-0400 | SHIM D20.2&8.3T1.85 |

| 110/1. | [1] | 146571-0500 | SHIM D20.2&8.3T1.15 |

| 110/1. | [1] | 146571-0600 | SHIM D20.2&8.3T1.35 |

| 110/1. | [1] | 146571-0700 | SHIM D20.2&8.3T1.55 |

| 110/1. | [1] | 146571-0800 | SHIM D20.2&8.3T1.75 |

| 111. | [1] | 146602-0600 | PLAIN WASHER D20&8.4T1.40 |

| 112. | [1] | 146572-0020 | FLYWEIGHT ASSEMBLY |

| 114. | [1] | 146602-0500 | PLAIN WASHER D17&6.4T1.60 |

| 115. | [1] | 146975-4200 | SLIDING SLEEVE |

| 116. | [1] | 146576-0200 | CAP |

| 117/1. | [1] | 146577-1800 | PLUG L2.10 |

| 117/1. | [1] | 146577-1900 | PLUG L2.30 |

| 117/1. | [1] | 146577-2000 | PLUG L2.50 |

| 117/1. | [1] | 146577-2100 | PLUG L2.70 |

| 117/1. | [1] | 146577-2200 | PLUG L2.90 |

| 117/1. | [1] | 146577-2300 | PLUG L3.10 |

| 117/1. | [1] | 146577-2400 | PLUG L3.30 |

| 117/1. | [1] | 146577-2500 | PLUG L3.50 |

| 117/1. | [1] | 146577-2600 | PLUG L3.70 |

| 117/1. | [1] | 146577-2700 | PLUG L3.90 |

| 117/1. | [1] | 146577-2800 | PLUG L4.10 |

| 117/1. | [1] | 146577-2900 | PLUG L4.30 |

| 117/1. | [1] | 146577-3000 | PLUG L4.50 |

| 117/1. | [1] | 146577-3100 | PLUG L4.70 |

| 117/1. | [1] | 146577-3200 | PLUG L4.90 |

| 117/1. | [1] | 146577-3300 | PLUG L5.10 |

| 117/1. | [1] | 146577-6700 | PLUG L2.2 |

| 117/1. | [1] | 146577-6800 | PLUG L2.4 |

| 117/1. | [1] | 146577-6900 | PLUG L2.6 |

| 117/1. | [1] | 146577-7000 | PLUG L2.8 |

| 117/1. | [1] | 146577-7100 | PLUG L3.0 |

| 117/1. | [1] | 146577-7200 | PLUG L3.2 |

| 117/1. | [1] | 146577-7300 | PLUG L3.4 |

| 117/1. | [1] | 146577-7400 | PLUG L3.6 |

| 117/1. | [1] | 146577-7500 | PLUG L3.8 |

| 117/1. | [1] | 146577-7600 | PLUG L4.0 |

| 117/1. | [1] | 146577-7700 | PLUG L4.2 |

| 117/1. | [1] | 146577-7800 | PLUG L4.4 |

| 117/1. | [1] | 146577-7900 | PLUG L4.6 |

| 117/1. | [1] | 146577-8000 | PLUG L4.8 |

| 117/1. | [1] | 146577-8100 | PLUG L5.0 |

| 117/1. | [1] | 146877-0000 | PLUG L5.2 |

| 117/1. | [1] | 146877-0100 | PLUG L5.3 |

| 117/1. | [1] | 146877-0200 | PLUG L5.4 |

| 117/1. | [1] | 146877-0300 | PLUG L5.5 |

| 117/1. | [1] | 146877-4700 | PLUG |

| 117/1. | [1] | 146877-4800 | PLUG |

| 117/1. | [1] | 146877-4900 | PLUG |

| 117/1. | [1] | 146877-5000 | PLUG |

| 123. | [4] | 139106-0200 | FLAT-HEAD SCREW |

| 130. | [1] | 146421-0020 | CAPSULE |

| 130/2. | [1] | 026508-1140 | GASKET D11.4&8.2T1 |

| 130/3. | [1] | 146422-0000 | BLEEDER SCREW |

| 130/4. | [1] | 146600-0500 | O-RING |

| 133. | [1] | 146600-0600 | O-RING |

| 134. | [1] | 146600-0700 | O-RING |

| 135. | [1] | 146110-0220 | CONTROL VALVE |

| 135/5. | [1] | 146114-0000 | SPRING WASHER |

| 136. | [1] | 146650-6020 | PULLING ELECTROMAGNET |

| 136B. | [1] | 146650-5420 | PULLING ELECTROMAGNET |

| 136C. | [1] | 146650-6320 | PULLING ELECTROMAGNET |

| 137. | [2] | 139514-0200 | GASKET |

| 145. | [1] | 146621-1000 | UNION NUT |

| 147. | [1] | 146600-5000 | O-RING |

| 200. | [1] | 146206-0100 | COILED SPRING |

| 214. | [1] | 146542-5000 | BUSHING |

| 216. | [1] | 146542-5100 | BUSHING |

| 217. | [1] | 146541-3100 | SLOTTED WASHER |

| 218. | [1] | 146592-5600 | COILED SPRING |

| 219. | [1] | 146541-3000 | BUSHING |

| 220. | [1] | 146592-5700 | COILED SPRING |

| 221. | [1] | 146927-8020 | BRACKET |

| 222. | [3] | 139006-4600 | BLEEDER SCREW |

| 224. | [1] | 146925-0300 | BRACKET |

| 240. | [1] | 146650-0720 | PULLING ELECTROMAGNET |

| 240/8. | [1] | 146600-1700 | O-RING |

| 243. | [1] | 146621-1000 | UNION NUT |

| 245. | [3] | 139512-0200 | GASKET D18.5&12.2T1.00 |

| 246. | [1] | 139812-0500 | EYE BOLT |

| 247. | [1] | 146666-4321 | PIPE |

| 248. | [1] | 146614-0200 | SPACER BUSHING |

| 275. | [1] | 146612-5020 | BRACKET |

| 276. | [2] | 010010-1640 | BLEEDER SCREW M10P1.5L16 4T |

| 280. | [1] | 146361-1020 | START ADVANCE ASSY |

| 281. | [1] | 146600-0800 | O-RING |

| 282. | [2] | 010206-1240 | HEX-SOCKET-HEAD CAP SCREW M6P1L12 |

| 287. | [1] | 020146-1440 | BLEEDER SCREW M6P1L14 |

| 309. | [4] | 020146-1440 | BLEEDER SCREW M6P1L14 |

| 309. | [4] | 020146-1440 | BLEEDER SCREW M6P1L14 |

| 311. | [2] | 010206-1040 | HEX-SOCKET-HEAD CAP SCREW |

| 318. | [1] | 146931-1620 | BRACKET |

| 330. | [1] | 146927-0600 | PLATE |

| 331. | [2] | 020106-1040 | BLEEDER SCREW M6P1L12 |

| 350. | [1] | 146931-1720 | BRACKET |

| 800S. | [1] | 146019-3520 | PUMP HOUSING |

| 800S/1/6. | [1] | 146601-0700 | PACKING RING |

| 804S. | [1] | 146232-0720 | COMPRESSION SPRING |

| 805S. | [1] | 146574-0120 | PARTS SET |

| 810S. | [1] | 146600-1120 | REPAIR SET |

| 821S. | [1] | 146210-5720 | ROLLER SET |

| 835S. | [1] | 146598-1000 | CAP |

| 836S/1. | [1] | 146598-0600 | CAP L18 |

| 836S/1. | [1] | 146598-0700 | CAP L21 |

| 836S/1. | [1] | 146598-0800 | CAP L24 |

| 836S/1. | [1] | 146598-0900 | CAP L27 |

| 905. | [1] | 146679-0520 | ACTUATOR |

| 906. | [1] | 146981-0400 | NAMEPLATE |

| 916. | [1] | 146662-3020 | WIRE |

| 924. | [1] | 146680-4000 | DAMPER |

| 925. | [5] | 020146-1440 | BLEEDER SCREW M6P1L14 |

| 925. | [5] | 020146-1440 | BLEEDER SCREW M6P1L14 |

| 936. | [1] | 146683-9820 | POTENTCIOMETER |

| 936/2. | [1] | 146931-2520 | BRACKET |

| 936/3. | [2] | 139104-0400 | FLAT-HEAD SCREW |

| 936/4. | [1] | 146649-0400 | JOINT CONNECTION |

| 936/4B. | [1] | 146649-0500 | JOINT CONNECTION |

| 936/4C. | [1] | 146649-0600 | JOINT CONNECTION |

| 936/4D. | [1] | 146649-0700 | JOINT CONNECTION |

| 936/4E. | [1] | 146649-0800 | JOINT CONNECTION |

| 936/4F. | [1] | 146649-0900 | JOINT CONNECTION |

| 936/4G. | [1] | 146649-1000 | JOINT CONNECTION |

| 936/4H. | [1] | 146649-1100 | JOINT CONNECTION |

| 936/4I. | [1] | 146649-1200 | JOINT CONNECTION |

| 936/4J. | [1] | 146649-1300 | JOINT CONNECTION |

| 936/4K. | [1] | 146649-1400 | JOINT CONNECTION |

| 936/4L. | [1] | 146649-1500 | JOINT CONNECTION |

| 937. | [1] | 146927-4000 | BRACKET |

| 938. | [3] | 139006-4800 | BLEEDER SCREW |

| 938. | [3] | 139006-4800 | BLEEDER SCREW |

| 939. | [1] | 146620-0200 | HEX-SOCKET-HEAD CAP SCREW |

| 947S. | [1] | 146683-9810 | POTENTCIOMETER |

Include in #2:

104760-2546

as INJECTION-PUMP ASSEMBLY

Cross reference number

BOSCH

9 460 611 465

9460611465

ZEXEL

104760-2546

1047602546

NISSAN

167006H711

167006h711

Zexel num

Bosch num

Firm num

Name

104760-2546

9 460 611 465

167006H711 NISSAN

INJECTION-PUMP ASSEMBLY

RD28 K 11CK INJECTION PUMP ASSY VE6 VE

RD28 K 11CK INJECTION PUMP ASSY VE6 VE

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113orSAEJ967d

1404 Test oil ISO4113orSAEJ967d

Test oil temperature

degC

45

45

50

Nozzle

105780-0060

Bosch type code

NP-DN0SD1510

Nozzle holder

105780-2150

Opening pressure

MPa

13

13

13.3

Opening pressure

kgf/cm2

133

133

136

Injection pipe

157805-7320

Injection pipe

Inside diameter - outside diameter - length (mm) mm 2-6-450

Inside diameter - outside diameter - length (mm) mm 2-6-450

Joint assembly

157641-4720

Tube assembly

157641-4020

Transfer pump pressure

kPa

20

20

20

Transfer pump pressure

kgf/cm2

0.2

0.2

0.2

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Pump speed

r/min

700

700

700

Average injection quantity

mm3/st.

29.3

28.9

29.7

Difference in delivery

mm3/st.

2.5

Basic

*

Oil temperature

degC

50

48

52

Injection timing adjustment_02

Pump speed

r/min

700

700

700

Average injection quantity

mm3/st.

29.3

28.3

30.3

Difference in delivery

mm3/st.

3

Basic

*

Oil temperature

degC

50

48

52

Injection timing adjustment_03

Pump speed

r/min

900

900

900

Average injection quantity

mm3/st.

28.9

25.9

31.9

Oil temperature

degC

50

48

52

Injection timing adjustment_04

Pump speed

r/min

1200

1200

1200

Average injection quantity

mm3/st.

29.9

27.4

32.4

Oil temperature

degC

50

48

52

Injection timing adjustment_05

Pump speed

r/min

1800

1800

1800

Average injection quantity

mm3/st.

31.1

28.1

34.1

Oil temperature

degC

50

48

52

Injection timing adjustment_06

Pump speed

r/min

2300

2300

2300

Average injection quantity

mm3/st.

32.4

28.9

35.9

Oil temperature

degC

52

50

54

Injection timing adjustment_07

Pump speed

r/min

2500

2500

2500

Average injection quantity

mm3/st.

32.3

28.8

35.8

Oil temperature

degC

55

52

58

Injection quantity adjustment

Pump speed

r/min

2600

2600

2600

Average injection quantity

mm3/st.

27

25

29

Difference in delivery

mm3/st.

4.5

Basic

*

Oil temperature

degC

55

52

58

Injection quantity adjustment_02

Pump speed

r/min

2800

2800

2800

Average injection quantity

mm3/st.

6.5

Oil temperature

degC

55

52

58

Injection quantity adjustment_03

Pump speed

r/min

2600

2600

2600

Average injection quantity

mm3/st.

27

23.5

30.5

Difference in delivery

mm3/st.

5

Basic

*

Oil temperature

degC

55

52

58

Governor adjustment

Pump speed

r/min

290

290

290

Average injection quantity

mm3/st.

11

10

12

Difference in delivery

mm3/st.

1

Basic

*

Oil temperature

degC

48

46

50

Governor adjustment_02

Pump speed

r/min

290

290

290

Average injection quantity

mm3/st.

11

9

13

Difference in delivery

mm3/st.

1.7

Basic

*

Oil temperature

degC

48

46

50

Governor adjustment_03

Pump speed

r/min

500

500

500

Average injection quantity

mm3/st.

7

Oil temperature

degC

48

46

50

Boost compensator adjustment

Pump speed

r/min

600

600

600

Average injection quantity

mm3/st.

17

10.5

23.5

Oil temperature

degC

50

48

52

Lever angle (shim thickness)

mm

4.6

4.55

4.65

Boost compensator adjustment_02

Pump speed

r/min

900

900

900

Average injection quantity

mm3/st.

10.4

3.4

17.4

Oil temperature

degC

50

48

52

Lever angle (shim thickness)

mm

4.6

4.55

4.65

Timer adjustment

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

35

35

Oil temperature

degC

48

46

50

Remarks

Full

Full

Timer adjustment_02

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

35

35

Oil temperature

degC

48

46

50

Remarks

Full

Full

Speed control lever angle

Pump speed

r/min

290

290

290

Average injection quantity

mm3/st.

6

Oil temperature

degC

48

46

50

Remarks

Magnet OFF at idling position

Magnet OFF at idling position

Speed control lever angle_02

Pump speed

r/min

900

900

900

Average injection quantity

mm3/st.

0

0

0

Oil temperature

degC

50

48

52

Remarks

Magnet OFF at full-load position

Magnet OFF at full-load position

0000000901

Pump speed

r/min

900

900

900

Overflow quantity with S/T ON

cm3/min

465

335

595

Oil temperature

degC

50

48

52

Stop lever angle

Pump speed

r/min

900

900

900

Pressure with S/T ON

kPa

422

393

451

Pressure with S/T ON

kgf/cm2

4.3

4

4.6

Pressure with S/T OFF

kPa

343

294

392

Pressure with S/T OFF

kgf/cm2

3.5

3

4

Basic

*

Oil temperature

degC

50

48

52

Remarks

ON

ON

Stop lever angle_02

Pump speed

r/min

900

900

900

Pressure with S/T ON

kPa

422

383

461

Pressure with S/T ON

kgf/cm2

4.3

3.9

4.7

Pressure with S/T OFF

kPa

343

284

402

Pressure with S/T OFF

kgf/cm2

3.5

2.9

4.1

Basic

*

Oil temperature

degC

50

48

52

Remarks

ON

ON

Stop lever angle_03

Pump speed

r/min

1800

1800

1800

Pressure with S/T ON

kPa

628

589

667

Pressure with S/T ON

kgf/cm2

6.4

6

6.8

Oil temperature

degC

50

48

52

Stop lever angle_04

Pump speed

r/min

2500

2500

2500

Pressure with S/T ON

kPa

775

736

814

Pressure with S/T ON

kgf/cm2

7.9

7.5

8.3

Oil temperature

degC

55

52

58

0000001101

Pump speed

r/min

900

900

900

Timer stroke with S/T ON

mm

4.6

4.4

4.8

Timer stroke with S/T OFF

mm

2.9

2.5

3.3

Basic

*

Oil temperature

degC

50

48

52

Remarks

ON

ON

_02

Pump speed

r/min

900

900

900

Timer stroke with S/T ON

mm

4.6

4.3

4.9

Timer stroke with S/T OFF

mm

2.9

2.4

3.4

Basic

*

Oil temperature

degC

50

48

52

Remarks

ON

ON

_03

Pump speed

r/min

1200

1200

1200

Timer stroke with S/T ON

mm

6.1

5.6

6.6

Oil temperature

degC

50

48

52

_04

Pump speed

r/min

1800

1800

1800

Timer stroke with S/T ON

mm

9.1

8.4

9.8

Oil temperature

degC

50

48

52

_05

Pump speed

r/min

2300

2300

2300

Timer stroke with S/T ON

mm

11.1

10.6

11.5

Oil temperature

degC

52

50

54

0000001201

Max. applied voltage

V

8

8

8

Test voltage

V

13

12

14

Timing setting

K dimension

mm

3.3

3.2

3.4

KF dimension

mm

7.22

7.12

7.32

MS dimension

mm

1.8

1.7

1.9

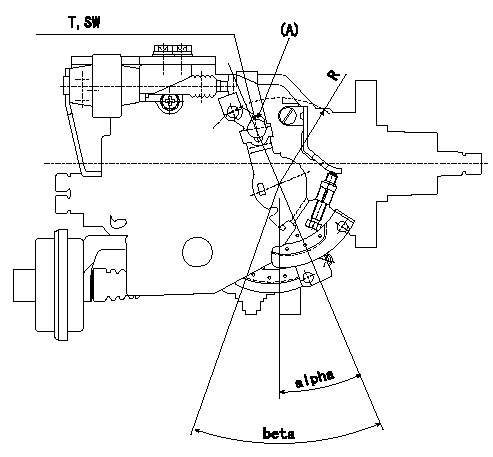

Control lever angle alpha

deg.

23

19

27

Control lever angle beta

deg.

41

36

46

Test data Ex:

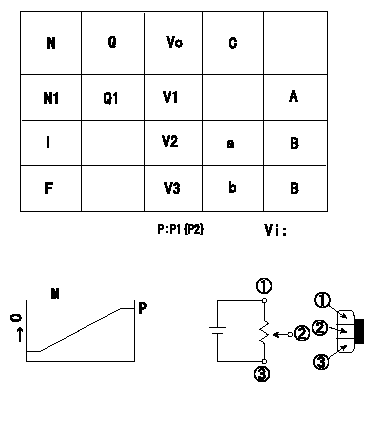

0000001801 POTENTIOMETER ADJUSTMENT

Adjustment of the potentiometer

Adjusting method (dummy bolt method)

1. Position the control lever at the adjusting points in the table, hold the dummy bolt against the lever and fix.

2. In the fixed position, install the potentiometer so that the output voltage is V1 (supply voltage Vi).

3. After completing potentiometer installation, remove the dummy bolt.

A:Adjusting point

B:Checking point

C:Control lever angle

N:Pump speed

Q:Injection quantity

Vo:Output voltage

M:Connecting diagram for the potentiometer

O:Output

P:Output when (2) and (3) connected.

I:Idle position

F:Full speed position

P:Boost pressure

----------

Vi=10V V1=3.20+-0.03V

----------

N1=600r/min V1=3.20+-0.03V V2=1.73+-0.67V V3=9.6--V Q1=16.9+-1.0cm3/1,000st a=0deg b=(41)deg Vi=10V

----------

Vi=10V V1=3.20+-0.03V

----------

N1=600r/min V1=3.20+-0.03V V2=1.73+-0.67V V3=9.6--V Q1=16.9+-1.0cm3/1,000st a=0deg b=(41)deg Vi=10V

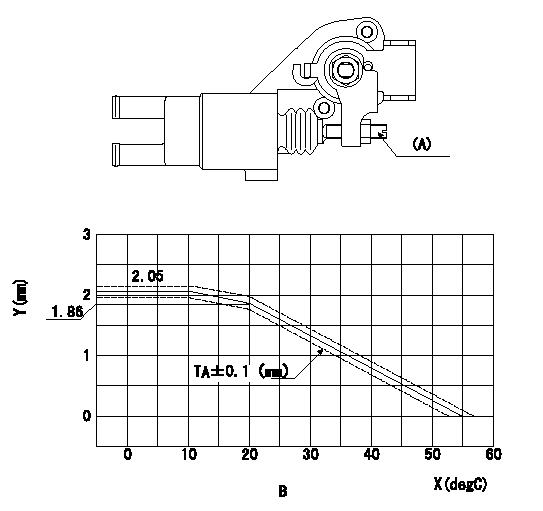

0000001901 W-CSD ADJUSTMENT

Adjustment of the W-CSD

Adjust the timer stroke determined from the graph below using screw (A).

X:Temperature t (deg C)

Y:Timer stroke TA

B:Timer stroke TA:

(O): diagram 1.

(P): diagram 2

----------

----------

B:t(degC)<=10:TA=2.05mm 10<=t(degC)<=20:TA=-0.019t+2.24 20<=t(degC)<=55:TA=-0.0531t+2.922

----------

----------

B:t(degC)<=10:TA=2.05mm 10<=t(degC)<=20:TA=-0.019t+2.24 20<=t(degC)<=55:TA=-0.0531t+2.922

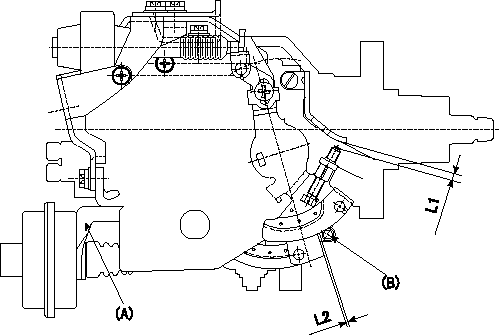

0000002001 DASHPOT ADJUSTMENT

Adjustment of the dash pot

1. Insert a block gauge L1 (thickness gauge) between the idle set screw and the bracket.

2. In the above condition, adjust the elongated hole so that the pushrod contacts the control lever. Then, fix using the bolt.

TT

Note:

(1)The dashpot and control lever contact faces must be smooth.

(2)Confirm that the control lever returns to the idling position.

ISC actuator installation

1. Maintain the control lever in the idling position.

2. Fix the actuator bracket (A) so that the clearance between the control lever and the ISC lever's roller (B) is L2.

----------

L1=3.9+-0.05mm L2=1.0+1.0-0.5mm T=6~9Nm{0.6~0.9kgfm}

----------

L1=3.9+-0.05mm L2=1.0+1.0-0.5mm

----------

L1=3.9+-0.05mm L2=1.0+1.0-0.5mm T=6~9Nm{0.6~0.9kgfm}

----------

L1=3.9+-0.05mm L2=1.0+1.0-0.5mm

0000002101 A/T PLATE ADJUSTMENT

A/T wire installation plate adjustment

Confirm angle beta and adjust the A/T wire installation plate using angle beta in (1), (2) and (3) below.

(1)When a <= beta <= b, adjust the plate so that R = R1.

(2)When c <= beta <= d, adjust the plate so that R = R2.

(3)When e <= beta <= f, adjust the plate so that R = R3.

(A) = A/T wire installation plate

----------

a=37deg b=40.0deg c=40.0deg d=43.5deg e=43.5deg f=47deg R1=62.5mm R2=57.5+-0.4mm R3=53.5mm

----------

T=6~9N-m{0.6~0.9kgf-m} SW=SW10

----------

a=37deg b=40.0deg c=40.0deg d=43.5deg e=43.5deg f=47deg R1=62.5mm R2=57.5+-0.4mm R3=53.5mm

----------

T=6~9N-m{0.6~0.9kgf-m} SW=SW10

Information:

2. Loosen clamp (1).3. Remove two bolts (2).4. Remove two bolts (3) and washers.5. Remove water pump (4) and the gasket. When installing replace the gasket. Make sure all gasket surfaces are clean and free of dirt. For installation of the water pump, reverse the removal steps.6. Fill the radiator with coolant to the proper level. See the Operation & Maintenance Manual.Disassemble & Assemble Water Pump

The following tools are needed for disassembly. Start By:a. remove water pump 1. Remove bolt (15) and the washer. Remove bearing (12) and gear (10) as a unit.2. Use Tool (A), (C) and a press, and remove bearing (12) from gear (10).3. Remove snap ring (8) with Tool (B).4. Remove two bolts (1), the washers, cover (14) and gasket (2) from water pump housing (18).5. Loosen bolt (13) approximately 6.4 mm (.25 in). Hit the bolt with a soft hammer to loosen impeller (16) from shaft (9).6. Remove bolt (13), washer (11), impeller (16), spring (3) and seal assembly (4) from shaft (9).7. Remove bearing (7) and shaft (9) as a unit.8. Use Tool (A), (C) and a press to remove bearing (7) from shaft (9).9. Remove ceramic seal (5) and seal (17) from water pump housing (18).10. Use Tool (C) to remove lip-type seal (6) from the water pump housing. The following steps are for assembly of the water pump. The following tools are needed for assembly. 11. Install lip-type seal (6) in water pump housing (18) with Tool (C). The lip of the seal must be toward the bearings. Put clean engine oil on the lip of the seal.12. Install shaft (9) in bearing (7) with a press.13. Install shaft (9) and bearing (7) as a unit in water pump housing (18).14. Install snap ring (8) with Tool (B).

Clean water only is permitted for use as a lubricant for assembly. Do not damage or put hands on the wear surface of the carbon ring or the ceramic ring. Install the ceramic ring with the smoothest face of the ring toward the carbon seal assembly.

15. Put ceramic ring (5) in position in seal (17). Use hand pressure and Tool (D) to install the ceramic ring.16. Remove spring (3) from seal assembly (4). Use hand pressure and Tool (D) to install the seal assembly. Push seal assembly (4) on shaft (9) until it makes light contact with ceramic ring (5).17. Install spring (3) on seal assembly (4). Put impeller (16) in position on shaft (9), and install washer (11) and bolt (13) that hold it. Tighten bolt (13) to a torque of 38.0 1.5 N m (28 1 lb ft).18. Put gasket (2) and cover (14) in position on water pump housing (18). Install the two washers and bolts (1) that hold them.19. Install bearing (12) on gear (10) with a press.20. Position gear (10) and bearing (12) as a unit on shaft (9). Install the washer and bolt (15) that hold them together. Tighten bolt (15) to a torque of

The following tools are needed for disassembly. Start By:a. remove water pump 1. Remove bolt (15) and the washer. Remove bearing (12) and gear (10) as a unit.2. Use Tool (A), (C) and a press, and remove bearing (12) from gear (10).3. Remove snap ring (8) with Tool (B).4. Remove two bolts (1), the washers, cover (14) and gasket (2) from water pump housing (18).5. Loosen bolt (13) approximately 6.4 mm (.25 in). Hit the bolt with a soft hammer to loosen impeller (16) from shaft (9).6. Remove bolt (13), washer (11), impeller (16), spring (3) and seal assembly (4) from shaft (9).7. Remove bearing (7) and shaft (9) as a unit.8. Use Tool (A), (C) and a press to remove bearing (7) from shaft (9).9. Remove ceramic seal (5) and seal (17) from water pump housing (18).10. Use Tool (C) to remove lip-type seal (6) from the water pump housing. The following steps are for assembly of the water pump. The following tools are needed for assembly. 11. Install lip-type seal (6) in water pump housing (18) with Tool (C). The lip of the seal must be toward the bearings. Put clean engine oil on the lip of the seal.12. Install shaft (9) in bearing (7) with a press.13. Install shaft (9) and bearing (7) as a unit in water pump housing (18).14. Install snap ring (8) with Tool (B).

Clean water only is permitted for use as a lubricant for assembly. Do not damage or put hands on the wear surface of the carbon ring or the ceramic ring. Install the ceramic ring with the smoothest face of the ring toward the carbon seal assembly.

15. Put ceramic ring (5) in position in seal (17). Use hand pressure and Tool (D) to install the ceramic ring.16. Remove spring (3) from seal assembly (4). Use hand pressure and Tool (D) to install the seal assembly. Push seal assembly (4) on shaft (9) until it makes light contact with ceramic ring (5).17. Install spring (3) on seal assembly (4). Put impeller (16) in position on shaft (9), and install washer (11) and bolt (13) that hold it. Tighten bolt (13) to a torque of 38.0 1.5 N m (28 1 lb ft).18. Put gasket (2) and cover (14) in position on water pump housing (18). Install the two washers and bolts (1) that hold them.19. Install bearing (12) on gear (10) with a press.20. Position gear (10) and bearing (12) as a unit on shaft (9). Install the washer and bolt (15) that hold them together. Tighten bolt (15) to a torque of

Have questions with 104760-2546?

Group cross 104760-2546 ZEXEL

Nissan

104760-2546

9 460 611 465

167006H711

INJECTION-PUMP ASSEMBLY

RD28

RD28