Information injection-pump assembly

ZEXEL

104760-2492

1047602492

Rating:

Cross reference number

ZEXEL

104760-2492

1047602492

Zexel num

Bosch num

Firm num

Name

104760-2492

INJECTION-PUMP ASSEMBLY

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113orSAEJ967d

1404 Test oil ISO4113orSAEJ967d

Test oil temperature

degC

45

45

50

Nozzle

105780-0060

Bosch type code

NP-DN0SD1510

Nozzle holder

105780-2150

Opening pressure

MPa

13

13

13.3

Opening pressure

kgf/cm2

133

133

136

Injection pipe

157805-7320

Injection pipe

Inside diameter - outside diameter - length (mm) mm 2-6-450

Inside diameter - outside diameter - length (mm) mm 2-6-450

Joint assembly

157641-4720

Tube assembly

157641-4020

Transfer pump pressure

kPa

20

20

20

Transfer pump pressure

kgf/cm2

0.2

0.2

0.2

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Pump speed

r/min

900

900

900

Average injection quantity

mm3/st.

30.5

30

31

Difference in delivery

mm3/st.

2

Basic

*

Injection timing adjustment_02

Pump speed

r/min

2600

2600

2600

Average injection quantity

mm3/st.

27

24.5

29.5

Injection timing adjustment_03

Pump speed

r/min

2500

2500

2500

Average injection quantity

mm3/st.

30.7

28.6

32.8

Injection timing adjustment_04

Pump speed

r/min

2300

2300

2300

Average injection quantity

mm3/st.

30.2

28.2

32.2

Injection timing adjustment_05

Pump speed

r/min

1800

1800

1800

Average injection quantity

mm3/st.

30.6

28.6

32.6

Injection timing adjustment_06

Pump speed

r/min

1200

1200

1200

Average injection quantity

mm3/st.

30.9

29.4

32.4

Injection timing adjustment_07

Pump speed

r/min

900

900

900

Average injection quantity

mm3/st.

30.5

29.5

31.5

Injection timing adjustment_08

Pump speed

r/min

600

600

600

Average injection quantity

mm3/st.

31.3

29.5

33.1

Injection quantity adjustment

Pump speed

r/min

2600

2600

2600

Average injection quantity

mm3/st.

27

25

29

Difference in delivery

mm3/st.

4.5

Basic

*

Injection quantity adjustment_02

Pump speed

r/min

2800

2800

2800

Average injection quantity

mm3/st.

6.5

Governor adjustment

Pump speed

r/min

290

290

290

Average injection quantity

mm3/st.

9

8

10

Difference in delivery

mm3/st.

1.1

Basic

*

Governor adjustment_02

Pump speed

r/min

500

500

500

Average injection quantity

mm3/st.

3

Governor adjustment_03

Pump speed

r/min

290

290

290

Average injection quantity

mm3/st.

9

7.5

10.5

Boost compensator adjustment

Pump speed

r/min

600

600

600

Average injection quantity

mm3/st.

16.9

10.4

23.4

Timer adjustment

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

40

40

Difference in delivery

mm3/st.

15

Basic

*

Speed control lever angle

Pump speed

r/min

900

900

900

Average injection quantity

mm3/st.

0

0

0

Remarks

Magnet OFF at full-load position

Magnet OFF at full-load position

Speed control lever angle_02

Pump speed

r/min

290

290

290

Average injection quantity

mm3/st.

4

Remarks

Magnet OFF at idling position

Magnet OFF at idling position

0000000901

Pump speed

r/min

900

900

900

Overflow quantity

cm3/min

390

258

522

Stop lever angle

Pump speed

r/min

900

900

900

Pressure

kPa

372.5

343

402

Pressure

kgf/cm2

3.8

3.5

4.1

Basic

*

Stop lever angle_02

Pump speed

r/min

900

900

900

Pressure

kPa

372.5

343

402

Pressure

kgf/cm2

3.8

3.5

4.1

Stop lever angle_03

Pump speed

r/min

1800

1800

1800

Pressure

kPa

578.5

549

608

Pressure

kgf/cm2

5.9

5.6

6.2

Stop lever angle_04

Pump speed

r/min

2500

2500

2500

Pressure

kPa

745.5

716

775

Pressure

kgf/cm2

7.6

7.3

7.9

0000001101

Pump speed

r/min

900

900

900

Timer stroke

mm

2.3

2.1

2.5

Basic

*

_02

Pump speed

r/min

900

900

900

Timer stroke

mm

2.3

2

2.6

_03

Pump speed

r/min

1200

1200

1200

Timer stroke

mm

3.8

3.2

4.4

_04

Pump speed

r/min

1800

1800

1800

Timer stroke

mm

7

6.2

7.8

_05

Pump speed

r/min

2300

2300

2300

Timer stroke

mm

8.9

8.4

9.4

0000001201

Max. applied voltage

V

8

8

8

Test voltage

V

13

12

14

Timing setting

K dimension

mm

3.3

3.2

3.4

KF dimension

mm

7.24

7.14

7.34

MS dimension

mm

1.8

1.7

1.9

Control lever angle alpha

deg.

23

19

27

Control lever angle beta

deg.

42

37

47

Control lever angle gamma

deg.

14.4

13.9

14.9

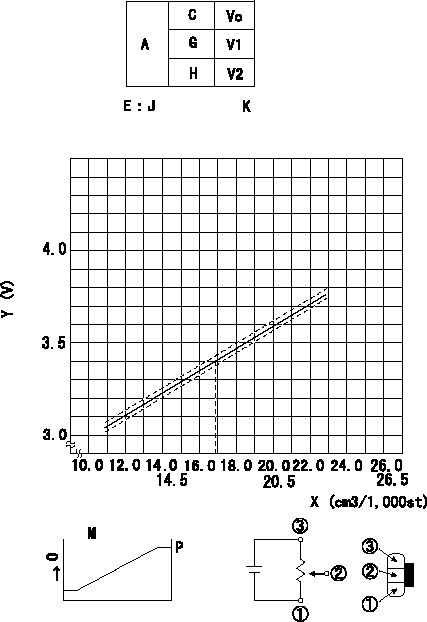

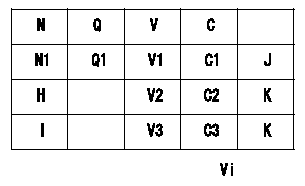

Test data Ex:

0000001801 POTENTIOMETER ADJUSTMENT

Adjustment of the potentiometer

In the following condition, change the installation position of the potentiometer to adjust the output voltage to within the specified values.

At N = N1 and control lever position a (corresponding to shim thickness L), measure the injection quantity, calculate the voltage from the graph, and then adjust the potentiometer.

A:Performance standards

C:Position of the control lever

N:Pump speed

Vo:Output voltage

E:Conversion formula (J)

G:Idle

H:Full speed

K:Applied voltage

X:Injection quantity (mm3/st)

Y:Voltage (V)

M:Connecting diagram for the potentiometer

O:Output

P:Output when (2) and (3) connected.

----------

N1=600r/min a=14.4deg L=7.7mm

----------

V1=1.00+-0.6V V2=7.80+-1.4V J=V+-0.03=0.0592X+-2.394 K=10V

----------

N1=600r/min a=14.4deg L=7.7mm

----------

V1=1.00+-0.6V V2=7.80+-1.4V J=V+-0.03=0.0592X+-2.394 K=10V

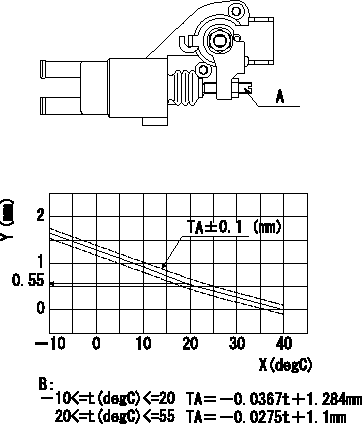

0000001901 W-CSD ADJUSTMENT

Adjustment of the W-CSD

Adjust the timer stroke using the screw so that it is as determined from the graph.

Caution: The temperature of the wax at adjustment must not exceed a.

A:Screw

B:Timer stroke graph

X:Temperature t

Y:Timer stroke TA

----------

a=30degC

----------

----------

a=30degC

----------

0000002001 DASHPOT ADJUSTMENT

Adjustment of the dash pot

1. Insert a block gauge L1 (thickness gauge) between the idle set screw (C) and the control lever (D).

2. In the above condition, adjust the position of the dash pot so that the dash pot adjustment screw (A) contacts the push rod and then fix the screw using the nut (B).

TT

Note:

(1)The adjusting screw and pushrod contact faces must be smooth.

(2)Confirm that the control lever returns to the idling position.

ISC actuator installation

1. Maintain the control lever in the idling position.

2. Fix actuator bracket (F) so that the gap between the control lever and the ISC lever's roller (E) is L2.

----------

L1=1.8+-0.05mm L2=1.0-0.5+1.0mm T=6~9Nm{0.6~0.9kgfm}

----------

L1=1.8+-0.05mm L2=1.0-0.5+1.0mm

----------

L1=1.8+-0.05mm L2=1.0-0.5+1.0mm T=6~9Nm{0.6~0.9kgfm}

----------

L1=1.8+-0.05mm L2=1.0-0.5+1.0mm

Information:

Termination Date

October 31, 1993Problem

Certain 2S7264 and 3S1467 Fuel Injection Pump Assemblies need to be removed from parts stock.

Action Required

Remove all 2S7264 and 3S1467 Fuel Injection Pump Assemblies from parts stock with date codes of December 1992 through March 1993. The date code appears at the bottom of the part number label on the pump box. The first two numbers indicate the month and the next two numbers indicate the year as shown in the example below:

Service Claim Allowances

Submit one claim for all 2S7264 and 3S1467 Fuel Injection Pump Assemblies removed from parts stock.

US and Canadian Dealers Only - When submitting a parts stock claim use 99Z00007 in the Product Identification Number Field.

Parts Disposition

U.S. And Canadian Dealers

Return all 2S7264 and 3S1467 Fuel Injection Pump Assemblies that are removed from parts stock and a copy of the claim to:

Caterpillar Inc.

Memory Lane

B Receiving

York, PA 17402

Attention: Quality Dept./PI7318

All Other Dealers

Handle the parts in accordance with your Warranty Bulletin on warranty parts handling.

October 31, 1993Problem

Certain 2S7264 and 3S1467 Fuel Injection Pump Assemblies need to be removed from parts stock.

Action Required

Remove all 2S7264 and 3S1467 Fuel Injection Pump Assemblies from parts stock with date codes of December 1992 through March 1993. The date code appears at the bottom of the part number label on the pump box. The first two numbers indicate the month and the next two numbers indicate the year as shown in the example below:

Service Claim Allowances

Submit one claim for all 2S7264 and 3S1467 Fuel Injection Pump Assemblies removed from parts stock.

US and Canadian Dealers Only - When submitting a parts stock claim use 99Z00007 in the Product Identification Number Field.

Parts Disposition

U.S. And Canadian Dealers

Return all 2S7264 and 3S1467 Fuel Injection Pump Assemblies that are removed from parts stock and a copy of the claim to:

Caterpillar Inc.

Memory Lane

B Receiving

York, PA 17402

Attention: Quality Dept./PI7318

All Other Dealers

Handle the parts in accordance with your Warranty Bulletin on warranty parts handling.

Have questions with 104760-2492?

Group cross 104760-2492 ZEXEL

Nissan

104760-2492

INJECTION-PUMP ASSEMBLY