Information injection-pump assembly

ZEXEL

104760-2410

1047602410

Rating:

Cross reference number

ZEXEL

104760-2410

1047602410

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113orSAEJ967d

1404 Test oil ISO4113orSAEJ967d

Test oil temperature

degC

45

45

50

Nozzle

105780-0060

Bosch type code

NP-DN0SD1510

Nozzle holder

105780-2150

Opening pressure

MPa

13

13

13.3

Opening pressure

kgf/cm2

133

133

136

Injection pipe

157805-7320

Injection pipe

Inside diameter - outside diameter - length (mm) mm 2-6-450

Inside diameter - outside diameter - length (mm) mm 2-6-450

Joint assembly

157641-4720

Tube assembly

157641-4020

Transfer pump pressure

kPa

20

20

20

Transfer pump pressure

kgf/cm2

0.2

0.2

0.2

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Pump speed

r/min

900

900

900

Average injection quantity

mm3/st.

30.5

30.1

30.9

Difference in delivery

mm3/st.

2

Basic

*

Injection timing adjustment_02

Pump speed

r/min

2600

2600

2600

Average injection quantity

mm3/st.

27

24.5

29.5

Injection timing adjustment_03

Pump speed

r/min

2500

2500

2500

Average injection quantity

mm3/st.

30.7

28.6

32.8

Injection timing adjustment_04

Pump speed

r/min

2300

2300

2300

Average injection quantity

mm3/st.

30.2

28.2

32.2

Injection timing adjustment_05

Pump speed

r/min

1800

1800

1800

Average injection quantity

mm3/st.

30.6

28.6

32.6

Injection timing adjustment_06

Pump speed

r/min

1200

1200

1200

Average injection quantity

mm3/st.

30.9

29.4

32.4

Injection timing adjustment_07

Pump speed

r/min

900

900

900

Average injection quantity

mm3/st.

30.5

29.6

31.4

Injection timing adjustment_08

Pump speed

r/min

600

600

600

Average injection quantity

mm3/st.

31.3

29.5

33.1

Injection quantity adjustment

Pump speed

r/min

2600

2600

2600

Average injection quantity

mm3/st.

27

25

29

Difference in delivery

mm3/st.

4.5

Basic

*

Injection quantity adjustment_02

Pump speed

r/min

2800

2800

2800

Average injection quantity

mm3/st.

6.5

Governor adjustment

Pump speed

r/min

290

290

290

Average injection quantity

mm3/st.

9

8

10

Difference in delivery

mm3/st.

1.1

Basic

*

Governor adjustment_02

Pump speed

r/min

290

290

290

Average injection quantity

mm3/st.

9

8

10

Governor adjustment_03

Pump speed

r/min

500

500

500

Average injection quantity

mm3/st.

3

Boost compensator adjustment

Pump speed

r/min

900

900

900

Average injection quantity

mm3/st.

11.8

5.3

18.3

Remarks

From idle

From idle

Timer adjustment

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

40

40

Difference in delivery

mm3/st.

15

Basic

*

Speed control lever angle

Pump speed

r/min

290

290

290

Average injection quantity

mm3/st.

4

Remarks

Magnet OFF

Magnet OFF

Speed control lever angle_02

Pump speed

r/min

900

900

900

Average injection quantity

mm3/st.

0

0

0

Remarks

Magnet OFF

Magnet OFF

0000000901

Pump speed

r/min

900

900

900

Overflow quantity

cm3/min

390

258

522

Stop lever angle

Pump speed

r/min

900

900

900

Pressure

kPa

372.5

343

402

Pressure

kgf/cm2

3.8

3.5

4.1

Basic

*

Stop lever angle_02

Pump speed

r/min

900

900

900

Pressure

kPa

372.5

343

402

Pressure

kgf/cm2

3.8

3.5

4.1

Stop lever angle_03

Pump speed

r/min

1800

1800

1800

Pressure

kPa

578.5

549

608

Pressure

kgf/cm2

5.9

5.6

6.2

Stop lever angle_04

Pump speed

r/min

2500

2500

2500

Pressure

kPa

745.5

716

775

Pressure

kgf/cm2

7.6

7.3

7.9

0000001101

Pump speed

r/min

900

900

900

Timer stroke

mm

2.9

2.7

3.1

Basic

*

_02

Pump speed

r/min

900

900

900

Timer stroke

mm

2.9

2.6

3.2

_03

Pump speed

r/min

1200

1200

1200

Timer stroke

mm

4.7

4.1

5.3

_04

Pump speed

r/min

1800

1800

1800

Timer stroke

mm

8.1

7.3

8.9

_05

Pump speed

r/min

2300

2300

2300

Timer stroke

mm

9.7

9.2

10.2

0000001201

Max. applied voltage

V

8

8

8

Test voltage

V

13

12

14

Timing setting

K dimension

mm

3.3

3.2

3.4

KF dimension

mm

7.24

7.14

7.34

MS dimension

mm

1.8

1.7

1.9

Control lever angle alpha

deg.

23

19

27

Control lever angle beta

deg.

42

37

47

Test data Ex:

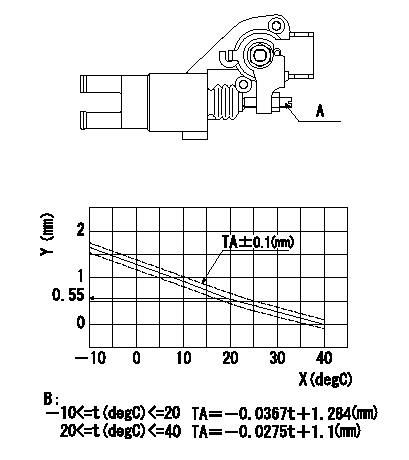

0000001801 W-CSD ADJUSTMENT

Adjustment of the W-CSD

Adjust the timer stroke using the screw so that it is as determined from the graph.

Caution: The temperature of the wax at adjustment must not exceed a.

A:Screw

B:Timer stroke graph

X:Temperature t

Y:Timer stroke TA

----------

a=30degC

----------

----------

a=30degC

----------

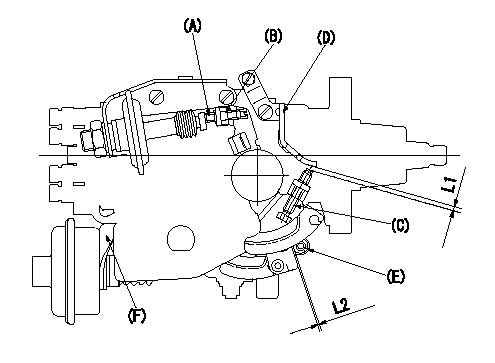

0000001901 DASHPOT ADJUSTMENT

Adjustment of the dash pot

1. Insert a block gauge L1 (thickness gauge) between the idle set screw (C) and the control lever (D).

2. In the above condition, adjust the position of the dash pot so that the dash pot adjustment screw (A) contacts the push rod and then fix the screw using the nut (B).

TT

Note:

(1)Confirm that the dashpot and control lever contact faces are smooth.

(2)Confirm that the control lever returns to the idling position.

ISC actuator installation

1. Maintain the control lever in the idling position.

2. Fix actuator bracket (F) so that the gap between the control lever and the ISC lever's roller (E) is L2.

----------

T=6~7N-m(0.6~0.7kgf-m) L1=2.7+-0.05mm L2=1.0+1.0-0.5mm

----------

L1=2.7+-0.05mm L2=1.0+1.0-0.5mm

----------

T=6~7N-m(0.6~0.7kgf-m) L1=2.7+-0.05mm L2=1.0+1.0-0.5mm

----------

L1=2.7+-0.05mm L2=1.0+1.0-0.5mm

Information:

Lubrication System

OIL LUBRICATION SCHEMATICThe lubrication system is the pressure type. The oil pump draws oil from the sump through a suction pipe and strainer to the pump. The oil pump is driven by the auxiliary drive group which is driven by the timing gears.Pressure oil flows to the oil cooler. The oil cooler is cooled by water from the cooling system. Coolers on T6.3544 Engines have a bypass valve that allows the oil to go around the cooler in case of a restriction or if the oil is too cold and thick. From the cooler, oil passes through the relief valve. On T6.3544 Engines, the relief valve is two stage. At 205 to 225 kPa (30 to 37 psi), oil is fed by a pipe to the piston cooling jet gallery which is a drilled passage the length of the crankcase, above the camshaft chamber. The piston cooling jets are bolted into the gallery and point into the bottom of each cylinder. Oil is sprayed onto the underneath side of each piston which takes heat from the combustion area. The oil then drains back to sump.At 345 to 415 kPa (50 to 60 psi), oil passes through a single oil filter on 6.3544 Engines or two filters on T6.3544 Engines. Oil then flows to the main oil gallery which is a drilled passage the length of the crankcase. Oil also flows from the filters to the turbocharger bearings on T6.3544 Engines. Passages in the crankcase webs feed oil from the main oil gallery to the main bearings. Passages in the crankshaft carry oil to the big end bearings. Through passages in No. 1, 3, 5 and 7 crankcase webs, oil passes from the main bearings to lubricate the camshaft bearings.The No. 2 camshaft bearing supplies a controlled amount of oil to the rocker shaft assembly, which then flows through a small bleed hole in each rocker lever to lubricate the valves and springs.Pistons, cylinder liners, connecting rod small end bushings, cam lobes and valve lifters are splash and oil mist lubricated.Oil flows from the main oil gallery to the two idler gear hubs. The oil passes through the hubs to radial passages in the idler gears to lubricate the teeth of the timing gears.The auxiliary drive group shaft bearings are lubricated by a passage from the main oil gallery to the front auxiliary drive shaft bearing. Oil then passes around a groove in the bearing journal and through another passage along the outer side of the auxiliary drive housing to the rear auxiliary drive shaft bearing. The upper fuel pump bearing is also lubricated from this passage. Also connected to this outer housing passage is a spray tube which directs oil on to the auxiliary drive shaft (worn gear) and gear assembly (worm wheel).Air Inlet And Exhaust System

6.3544 Engines

AIR INLET AND EXHAUST SYSTEM COMPONENTS

1. Exhaust manifold. 2. Inlet manifold. 3. Engine cylinderThe air inlet and exhaust system components on naturally aspirated engines are: the air cleaner, inlet manifold,

OIL LUBRICATION SCHEMATICThe lubrication system is the pressure type. The oil pump draws oil from the sump through a suction pipe and strainer to the pump. The oil pump is driven by the auxiliary drive group which is driven by the timing gears.Pressure oil flows to the oil cooler. The oil cooler is cooled by water from the cooling system. Coolers on T6.3544 Engines have a bypass valve that allows the oil to go around the cooler in case of a restriction or if the oil is too cold and thick. From the cooler, oil passes through the relief valve. On T6.3544 Engines, the relief valve is two stage. At 205 to 225 kPa (30 to 37 psi), oil is fed by a pipe to the piston cooling jet gallery which is a drilled passage the length of the crankcase, above the camshaft chamber. The piston cooling jets are bolted into the gallery and point into the bottom of each cylinder. Oil is sprayed onto the underneath side of each piston which takes heat from the combustion area. The oil then drains back to sump.At 345 to 415 kPa (50 to 60 psi), oil passes through a single oil filter on 6.3544 Engines or two filters on T6.3544 Engines. Oil then flows to the main oil gallery which is a drilled passage the length of the crankcase. Oil also flows from the filters to the turbocharger bearings on T6.3544 Engines. Passages in the crankcase webs feed oil from the main oil gallery to the main bearings. Passages in the crankshaft carry oil to the big end bearings. Through passages in No. 1, 3, 5 and 7 crankcase webs, oil passes from the main bearings to lubricate the camshaft bearings.The No. 2 camshaft bearing supplies a controlled amount of oil to the rocker shaft assembly, which then flows through a small bleed hole in each rocker lever to lubricate the valves and springs.Pistons, cylinder liners, connecting rod small end bushings, cam lobes and valve lifters are splash and oil mist lubricated.Oil flows from the main oil gallery to the two idler gear hubs. The oil passes through the hubs to radial passages in the idler gears to lubricate the teeth of the timing gears.The auxiliary drive group shaft bearings are lubricated by a passage from the main oil gallery to the front auxiliary drive shaft bearing. Oil then passes around a groove in the bearing journal and through another passage along the outer side of the auxiliary drive housing to the rear auxiliary drive shaft bearing. The upper fuel pump bearing is also lubricated from this passage. Also connected to this outer housing passage is a spray tube which directs oil on to the auxiliary drive shaft (worn gear) and gear assembly (worm wheel).Air Inlet And Exhaust System

6.3544 Engines

AIR INLET AND EXHAUST SYSTEM COMPONENTS

1. Exhaust manifold. 2. Inlet manifold. 3. Engine cylinderThe air inlet and exhaust system components on naturally aspirated engines are: the air cleaner, inlet manifold,