Information injection-pump assembly

ZEXEL

104760-2310

1047602310

Rating:

Cross reference number

ZEXEL

104760-2310

1047602310

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113orSAEJ967d

1404 Test oil ISO4113orSAEJ967d

Test oil temperature

degC

45

45

50

Nozzle

105780-0060

Bosch type code

NP-DN0SD1510

Nozzle holder

105780-2150

Opening pressure

MPa

13

13

13.3

Opening pressure

kgf/cm2

133

133

136

Injection pipe

157805-7320

Injection pipe

Inside diameter - outside diameter - length (mm) mm 2-6-450

Inside diameter - outside diameter - length (mm) mm 2-6-450

Joint assembly

157641-4720

Tube assembly

157641-4020

Transfer pump pressure

kPa

20

20

20

Transfer pump pressure

kgf/cm2

0.2

0.2

0.2

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Pump speed

r/min

900

900

900

Average injection quantity

mm3/st.

30.5

30.1

30.9

Difference in delivery

mm3/st.

2

Basic

*

Injection timing adjustment_02

Pump speed

r/min

2600

2600

2600

Average injection quantity

mm3/st.

27

24.5

29.5

Injection timing adjustment_03

Pump speed

r/min

2500

2500

2500

Average injection quantity

mm3/st.

30.7

28.6

32.8

Injection timing adjustment_04

Pump speed

r/min

2300

2300

2300

Average injection quantity

mm3/st.

30.2

28.2

32.2

Injection timing adjustment_05

Pump speed

r/min

1800

1800

1800

Average injection quantity

mm3/st.

30.6

28.6

32.6

Injection timing adjustment_06

Pump speed

r/min

1200

1200

1200

Average injection quantity

mm3/st.

30.9

29.4

32.4

Injection timing adjustment_07

Pump speed

r/min

900

900

900

Average injection quantity

mm3/st.

30.5

29.6

31.4

Injection timing adjustment_08

Pump speed

r/min

600

600

600

Average injection quantity

mm3/st.

31.3

29.5

33.1

Injection quantity adjustment

Pump speed

r/min

2600

2600

2600

Average injection quantity

mm3/st.

27

25

29

Difference in delivery

mm3/st.

4.5

Basic

*

Injection quantity adjustment_02

Pump speed

r/min

2800

2800

2800

Average injection quantity

mm3/st.

6.5

Governor adjustment

Pump speed

r/min

290

290

290

Average injection quantity

mm3/st.

9

8

10

Difference in delivery

mm3/st.

1.1

Basic

*

Governor adjustment_02

Pump speed

r/min

290

290

290

Average injection quantity

mm3/st.

9

8

10

Governor adjustment_03

Pump speed

r/min

500

500

500

Average injection quantity

mm3/st.

3

Boost compensator adjustment

Pump speed

r/min

600

600

600

Average injection quantity

mm3/st.

16.9

10.9

22.9

Remarks

From idle

From idle

Timer adjustment

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

40

40

Difference in delivery

mm3/st.

15

Basic

*

Speed control lever angle

Pump speed

r/min

290

290

290

Average injection quantity

mm3/st.

4

Remarks

Magnet OFF

Magnet OFF

Speed control lever angle_02

Pump speed

r/min

900

900

900

Average injection quantity

mm3/st.

0

0

0

Remarks

Magnet OFF

Magnet OFF

0000000901

Pump speed

r/min

900

900

900

Overflow quantity

cm3/min

390

258

522

Stop lever angle

Pump speed

r/min

900

900

900

Pressure

kPa

372.5

343

402

Pressure

kgf/cm2

3.8

3.5

4.1

Basic

*

Stop lever angle_02

Pump speed

r/min

900

900

900

Pressure

kPa

372.5

343

402

Pressure

kgf/cm2

3.8

3.5

4.1

Stop lever angle_03

Pump speed

r/min

1800

1800

1800

Pressure

kPa

578.5

549

608

Pressure

kgf/cm2

5.9

5.6

6.2

Stop lever angle_04

Pump speed

r/min

2500

2500

2500

Pressure

kPa

745.5

716

775

Pressure

kgf/cm2

7.6

7.3

7.9

0000001101

Pump speed

r/min

900

900

900

Timer stroke

mm

2.9

2.7

3.1

Basic

*

_02

Pump speed

r/min

900

900

900

Timer stroke

mm

2.9

2.6

3.2

_03

Pump speed

r/min

1200

1200

1200

Timer stroke

mm

4.7

4.1

5.3

_04

Pump speed

r/min

1800

1800

1800

Timer stroke

mm

8.1

7.3

8.9

_05

Pump speed

r/min

2300

2300

2300

Timer stroke

mm

9.7

9.2

10.2

0000001201

Max. applied voltage

V

8

8

8

Test voltage

V

13

12

14

Timing setting

K dimension

mm

3.3

3.2

3.4

KF dimension

mm

7.24

7.14

7.34

MS dimension

mm

1.8

1.7

1.9

Control lever angle alpha

deg.

23

19

27

Control lever angle beta

deg.

42

37

47

Control lever angle gamma

deg.

11

10.5

11.5

Test data Ex:

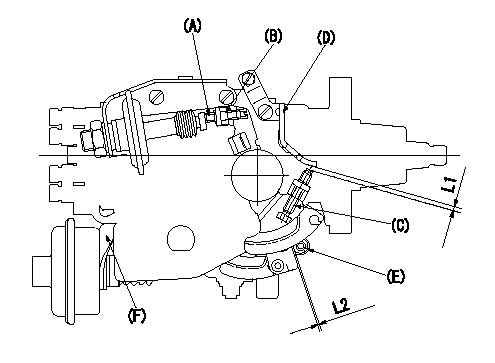

0000001801 DASHPOT ADJUSTMENT

Adjustment of the dash pot

1. Insert a block gauge L1 (thickness gauge) between the idle set screw (C) and the control lever (D).

2. In the above condition, adjust the position of the dash pot so that the dash pot adjustment screw (A) contacts the push rod and then fix the screw using the nut (B).

TT

Note:

(1)Confirm that the dashpot and control lever contact faces are smooth.

(2)Confirm that the control lever returns to the idling position.

ISC actuator installation

1. Maintain the control lever in the idling position.

2. Fix actuator bracket (F) so that the gap between the control lever and the ISC lever's roller (E) is L2.

----------

T=6~7N-m(0.6~0.7kgf-m) L1=2.7+-0.05mm L2=1.0+1.0-0.5mm

----------

L1=2.7+-0.05mm L2=1.0+1.0-0.5mm

----------

T=6~7N-m(0.6~0.7kgf-m) L1=2.7+-0.05mm L2=1.0+1.0-0.5mm

----------

L1=2.7+-0.05mm L2=1.0+1.0-0.5mm

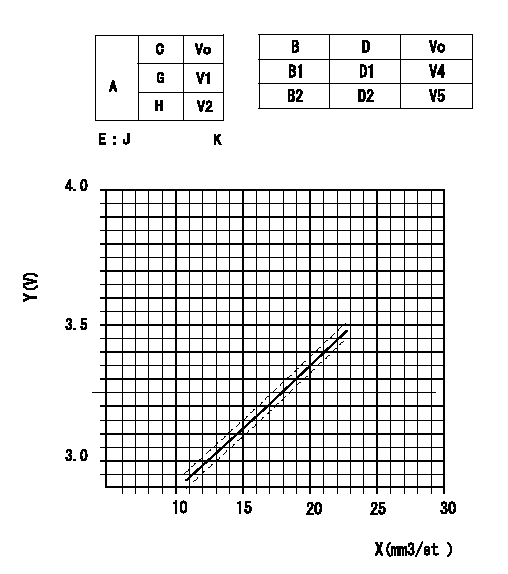

0000001901 POTENTIOMETER ADJUSTMENT

Adjustment of the potentiometer

In the following condition, change the installation position of the potentiometer to adjust the output voltage to within the specified values.

Measure the injection quantity at control lever position a (shim thickness = approximately L mm) at N = N1 r/min, determine the voltage using the formula, and adjust the potentiometer.

A:Performance standards

C:Position of the control lever

N:Pump speed

Vo:Output voltage

E:Conversion formula

G:Idling

H:Full speed

K:Applied voltage

X:Injection quantity (cm3/1,000st)

Y:Voltage (V)

R:At target value Q1cm3/1,000 st, set voltage at V3 (V).

M:The switch voltage specification is the value when the idle lever position is V6.

B:Conversion point

B1:ON-->OFF

B2:OFF-->ON

D:Lever opening (from idle)

----------

N1=600r/min a=10.3deg L=5.6mm Q1=-cm3/1,000st V3=-V V6=-V

----------

V1=Above 0.5V V2=Below 9.6V V4=-V V5=-V K=10V D1=5.0+-2.5deg D2=Above 23.5deg J:V+-0.03=0.0459X+2.4219

----------

N1=600r/min a=10.3deg L=5.6mm Q1=-cm3/1,000st V3=-V V6=-V

----------

V1=Above 0.5V V2=Below 9.6V V4=-V V5=-V K=10V D1=5.0+-2.5deg D2=Above 23.5deg J:V+-0.03=0.0459X+2.4219

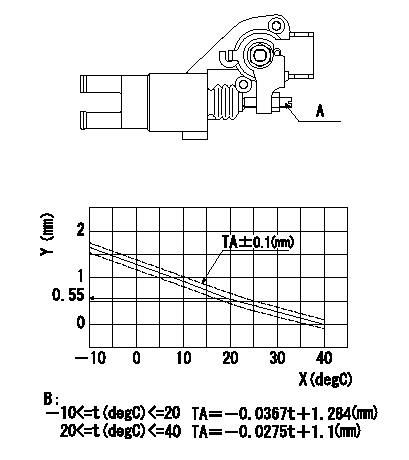

0000002001 W-CSD ADJUSTMENT

Adjustment of the W-CSD

Adjust the timer stroke using the screw so that it is as determined from the graph.

Caution: The temperature of the wax at adjustment must not exceed a.

A:Screw

B:Timer stroke graph

X:Temperature t

Y:Timer stroke TA

----------

a=30degC

----------

----------

a=30degC

----------

Information:

ACTION REQUIRED

Refer to the attached Rework Procedure.

OWNER NOTIFICATION

U.S. and Canadian owners will receive the attached Owner Notification.

SERVICE CLAIM ALLOWANCES

Caterpillar Dealer Suggested Customer Suggested

Parts % Labor Hrs% Parts % Labor Hrs% Parts % Labor Hrs%

100% 100% 0% 0% 0% 0%

This is a 4.0-hour job

PARTS DISPOSITION

Handle the parts in accordance with your Warranty Bulletin on warranty parts handling.

MAKE EVERY EFFORT TO COMPLETE THIS PROGRAM AS SOON AS POSSIBLE.

COPY OF OWNER NOTIFICATION FOR U.S. AND CANADIAN OWNERS

XYZ Corporation

3240 Arrow Drive

Anywhere, YZ 99999

PRIORITY - PRODUCT IMPROVEMENT PROGRAM FOR REPLACING THE DIESEL PARTICULATE FILTER ON CERTAIN SKID STEER LOADERS AND COMPACT TRACK LOADERS

MODELS INVOLVED - 272D Skid Steer Loaders and 299D Compact Track Loaders

Dear Cat Product Owner:

The diesel particulate filter needs to be replaced on certain 272D Skid Steer Loaders and 299D Compact Track Loaders. The existing diesel particulate filter has been installed incorrectly which can result in decreased performance of the filter. You will not be charged for the service performed.

Contact your local Cat dealer immediately to schedule this service. The dealer will advise you of the time required to complete this service.

Please refer the dealer to their Service Letter dated 06Aug2012 when scheduling this service.

We regret the inconvenience this may cause you, but urge you to have this service performed as soon as possible to prevent unscheduled downtime.

Caterpillar Inc.

Identification #(s)

Attached to 06Aug2012 Service Letter

Rework Procedure

1. Remove the cooling package. Refer UENR2328, Disassembly and Assembly, "Radiator and Hydraulic Oil Cooler - Removal Procedure".

2. Record the diesel particulate filter serial number prior to installing. The serial number is etched into the diesel particulate filter housing in the location shown in Image1.1.1. It is the lower set of digits. Send the new diesel particulate filter serial number and machine serial number to Rob McHardy (MCHARDY_ROBERT_W).

Image1.1.1

Image1.1.2

3. Replace the 389-5370 Diesel Particulate Filter section. Refer to UENR0129, Disassembly and Assembly, "Diesel Particulate Filter - Remove and Install" and "Diesel Particulate Filter - Disassemble".

4. When performing this work, replace the three 389-5373 Gaskets (metal) for the diesel particulate filter section and the 345-3579 Gasket between the turbo flange and the DOC inlet.

5. Ensure the diesel particulate filter is installed with the exhaust flowing in the direction of the arrow that is on the diesel particulate filter. Refer to Image1.2.1.

6. Cover both ends of the diesel particulate filter to ensure the ash and soot remain within the diesel particulate filter. Package the diesel particulate filter according to REHS3827, "Procedure to Handle and Ship Diesel Particulate Filters (DPF) and Catalytic Converter Mufflers (CCM)".

7. Connect Caterpillar Electronic Technician (ET). Version 2012A is acceptable but version 2012B is recommended. Go to Service Tab and select "DPF Soot Load Reset". At the next two screens select the "Reset" button in the bottom left corner.

Image1.2.1