Information injection-pump assembly

ZEXEL

104749-6170

1047496170

ISUZU

8941782620

8941782620

Rating:

Cross reference number

ZEXEL

104749-6170

1047496170

ISUZU

8941782620

8941782620

Zexel num

Bosch num

Firm num

Name

104749-6170

8941782620 ISUZU

INJECTION-PUMP ASSEMBLY

4FC1J *

4FC1J *

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113orSAEJ967d

1404 Test oil ISO4113orSAEJ967d

Test oil temperature

degC

45

45

50

Nozzle

105000-2010

Bosch type code

NP-DN12SD12TT

Nozzle holder

105780-2080

Opening pressure

MPa

14.7

14.7

15.19

Opening pressure

kgf/cm2

150

150

155

Injection pipe

Inside diameter - outside diameter - length (mm) mm 2-6-840

Inside diameter - outside diameter - length (mm) mm 2-6-840

Transfer pump pressure

kPa

20

20

20

Transfer pump pressure

kgf/cm2

0.2

0.2

0.2

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Pump speed

r/min

1250

1250

1250

Average injection quantity

mm3/st.

38.1

37.6

38.6

Difference in delivery

mm3/st.

3

Basic

*

Oil temperature

degC

50

48

52

Injection timing adjustment_02

Pump speed

r/min

600

600

600

Average injection quantity

mm3/st.

36.6

35.1

38.1

Oil temperature

degC

50

48

52

Injection timing adjustment_03

Pump speed

r/min

1250

1250

1250

Average injection quantity

mm3/st.

38.1

37.1

39.1

Difference in delivery

mm3/st.

3

Basic

*

Oil temperature

degC

50

48

52

Injection timing adjustment_04

Pump speed

r/min

2000

2000

2000

Average injection quantity

mm3/st.

34.1

32.6

35.6

Oil temperature

degC

50

48

52

Injection timing adjustment_05

Pump speed

r/min

2350

2350

2350

Average injection quantity

mm3/st.

34.5

32.9

36.1

Difference in delivery

mm3/st.

4.5

Oil temperature

degC

52

50

54

Injection quantity adjustment

Pump speed

r/min

2650

2650

2650

Average injection quantity

mm3/st.

11

8

14

Difference in delivery

mm3/st.

3.5

Basic

*

Oil temperature

degC

55

52

58

Injection quantity adjustment_02

Pump speed

r/min

2650

2650

2650

Average injection quantity

mm3/st.

11

8

14

Difference in delivery

mm3/st.

3.5

Oil temperature

degC

55

52

58

Injection quantity adjustment_03

Pump speed

r/min

2800

2800

2800

Average injection quantity

mm3/st.

5

Oil temperature

degC

55

52

58

Governor adjustment

Pump speed

r/min

375

375

375

Average injection quantity

mm3/st.

7.5

5.5

9.5

Difference in delivery

mm3/st.

2

Basic

*

Oil temperature

degC

48

46

50

Governor adjustment_02

Pump speed

r/min

375

375

375

Average injection quantity

mm3/st.

7.5

5.5

9.5

Difference in delivery

mm3/st.

2

Oil temperature

degC

48

46

50

Boost compensator adjustment

Pump speed

r/min

1200

1200

1200

Average injection quantity

mm3/st.

7.2

5.2

9.2

Difference in delivery

mm3/st.

2

Basic

*

Oil temperature

degC

50

48

52

Timer adjustment

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

60

60

Basic

*

Oil temperature

degC

48

46

50

Remarks

Full

Full

Timer adjustment_02

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

60

60

Oil temperature

degC

48

46

50

Speed control lever angle

Pump speed

r/min

375

375

375

Average injection quantity

mm3/st.

0

0

0

Oil temperature

degC

48

46

50

Remarks

Magnet OFF at idling position

Magnet OFF at idling position

0000000901

Pump speed

r/min

1250

1250

1250

Overflow quantity

cm3/min

420

290

550

Oil temperature

degC

50

48

52

Stop lever angle

Pump speed

r/min

1250

1250

1250

Pressure

kPa

431

411

451

Pressure

kgf/cm2

4.4

4.2

4.6

Basic

*

Oil temperature

degC

50

48

52

Stop lever angle_02

Pump speed

r/min

1250

1250

1250

Pressure

kPa

431

411

451

Pressure

kgf/cm2

4.4

4.2

4.6

Basic

*

Oil temperature

degC

50

48

52

Stop lever angle_03

Pump speed

r/min

2000

2000

2000

Pressure

kPa

647

618

676

Pressure

kgf/cm2

6.6

6.3

6.9

Oil temperature

degC

50

48

52

Stop lever angle_04

Pump speed

r/min

2250

2250

2250

Pressure

kPa

716

687

745

Pressure

kgf/cm2

7.3

7

7.6

Oil temperature

degC

52

50

54

0000001101

Pump speed

r/min

1250

1250

1250

Timer stroke

mm

3

2.8

3.2

Basic

*

Oil temperature

degC

50

48

52

_02

Pump speed

r/min

670

570

770

Timer stroke

mm

0.5

0.5

0.5

Oil temperature

degC

50

48

52

_03

Pump speed

r/min

1250

1250

1250

Timer stroke

mm

3

2.8

3.2

Basic

*

Oil temperature

degC

50

48

52

_04

Pump speed

r/min

2000

2000

2000

Timer stroke

mm

6.3

5.9

6.7

Oil temperature

degC

50

48

52

_05

Pump speed

r/min

2250

2250

2250

Timer stroke

mm

7.4

7.1

7.8

Oil temperature

degC

52

50

54

0000001201

Max. applied voltage

V

8

8

8

Test voltage

V

13

12

14

0000001401

Pump speed

r/min

1250

1250

1250

Average injection quantity

mm3/st.

29

28

30

Timer stroke TA

mm

2.4

2.4

2.4

Timer stroke variation dT

mm

0.6

0.4

0.8

Basic

*

Oil temperature

degC

50

48

52

_02

Pump speed

r/min

1250

1250

1250

Average injection quantity

mm3/st.

29

28

30

Timer stroke variation dT

mm

0.6

0.2

1

Basic

*

Oil temperature

degC

50

48

52

_03

Pump speed

r/min

1250

1250

1250

Average injection quantity

mm3/st.

24

23

25

Timer stroke variation dT

mm

1.3

0.9

1.7

Oil temperature

degC

50

48

52

Timing setting

K dimension

mm

3.3

3.2

3.4

KF dimension

mm

5.8

5.7

5.9

MS dimension

mm

1.6

1.5

1.7

Control lever angle alpha

deg.

20

16

24

Control lever angle beta

deg.

33.5

28.5

38.5

Test data Ex:

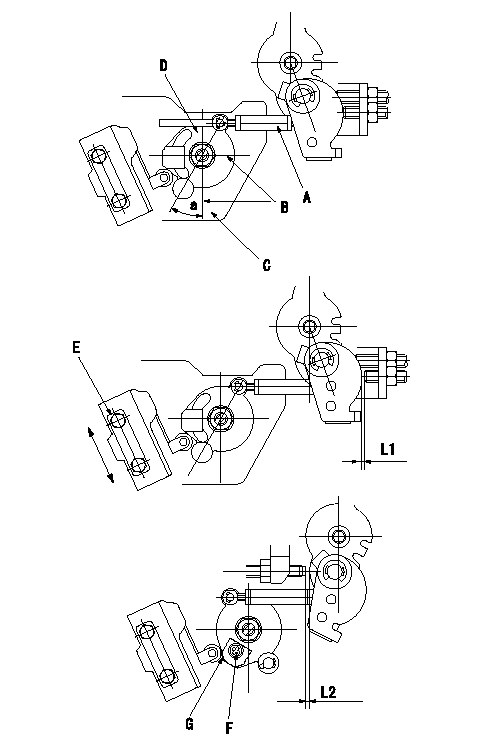

0000001801 MICROSWITCH ADJUSTMENT

Microswitch adjustment

Stepping motor adjustment

1. With the sub-lever and the control lever contacting the idle stopper bolt, adjust the length of the rod so that the stepping motor bracket and the stepping motor lever aligning mark are aligned (Tightening torque T).

A = rod

B = position of angle alignment marking

C = stepping motor bracket

D = stepping motor lever

2. Idle position adjustment

1) Fix so that idle stopper contacts the control lever.

2) Insert shim L1 between the sub-lever and the idle stopper.

3) Move the microswitch in the direction of the arrow to turn it ON.

4) Move the microswitch in the direction of the arrow and fix it where it turns OFF using the microswitch fixing bolt.

E = microswitch fixing bolt (Tightening torque T2)

3. Full position adjustment

1) 1) Fix so that sub lever contacts the control lever.

2) Insert a shim L2 between the control lever and the full stopper.

3) Turn the plate clockwise as shown in the figure above and confirm that the microswitch turns ON.

4) Move the plate counterclockwise and fix it where the microswitch turns OFF.

F = bolt (Tightening torque T2)

G = plate

----------

L1=1.2mm L2=0.7mm T1=3.4~4.9N-m(0.35~0.5kgf-m) T2=2.0~2.9N-m(0.2~0.3kgf-m)

----------

a=30+-1deg L1=1.2mm L2=0.7mm

----------

L1=1.2mm L2=0.7mm T1=3.4~4.9N-m(0.35~0.5kgf-m) T2=2.0~2.9N-m(0.2~0.3kgf-m)

----------

a=30+-1deg L1=1.2mm L2=0.7mm

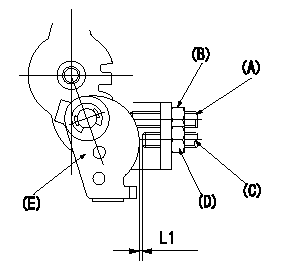

0000001901 PARTIAL SETTING

Partial injection quantity adjustment

(A) Stopper bolt

(B) Fixed nut

(C) Sub lever stopper bolt

(D) Fixed nut

(E) Sub lever

1. At pump speed N1, adjust the stopper bolt (A) so that the idle injection quantity is Q1. Then fix using the nut (B).

2. Confirm that the idle injection quantity is Q2 when the pump speed is N2.

3. Insert a shim L1 between the sub lever (E) and the sub lever stopper bolt (C). Adjust the sub lever stopper bolt so that the injection quantity is Q3 at pump speed N3 and fix using the nut.

----------

N1=375r/min N2=450r/min N3=1200r/min Q1=7.5+-2.0mm3/st Q2=3--mm3/st Q3=(7.2+-1mm3/st) L1=9.5+-0.1mm

----------

L1=9.5+-0.1mm

----------

N1=375r/min N2=450r/min N3=1200r/min Q1=7.5+-2.0mm3/st Q2=3--mm3/st Q3=(7.2+-1mm3/st) L1=9.5+-0.1mm

----------

L1=9.5+-0.1mm

Information:

In this manual, specifications, service standards, adjustment procedures, disassembly procedures, inspection procedures, and reassembly procedures for the engine are shown in groups. The contents of each group are listed in the index and at the beginning of that group. For instructions on operation and periodic inspection, refer to the operation manual. For instructions on ordering replacement parts, refer to the parts catalog. For information on the engine's structure and function, refer to relevant training material.Items Shown in this Manual

(1) Parts mentioned in the text and shown exploded views are numbered in their disassembly sequences.(2) Inspections to be preformed during disassembly are shown in

in the exploded views.(3) Service standards for inspection and repair operations are indicated at relevant places in the text and in a table in Group 2.(4) The sequences in which parts should be reassembled during reassembly operations are shown under reassembly drawings in this manner:

(5) The symbols and headings shown below are used in this manual to highlight particularly important and safety-critical instruction.

Indicates a potentially hazardous situation which, if not avoided, can result in death or serious injury.

Indicates a potentially hazardous situation which, if not avoided, can result in minor or moderate injury.

Indicates a potentially hazardous situation which, if not avoided, can result in property damage.

Indicates important information or information which is useful for engine operation or maintenance.(6) With regard to tightening torques, points to which engine oil must be applied are labeled "Wet". Where there is no such indication, parts should be tightened in a dry condition.Terms Used in This Manual

Terms used in this manual are defined as follows:(1) Front and RearThe term "front" refers to the fan side of the engine, and the term "rear" applies to the flywheel side.(2) Left and RightThe term "left" and "right" apply to the sides of the engine as seen from the flywheel.(3) Service Standards* Standard ValueThis term indicates a designed nominal dimension, the designed dimension of a single part, the standard clearance between two parts after assembly, or a standard performance value for an assembly.* LimitThis term indicates a value beyond which a part is no longer usable in terms of performance and strength and must be repaired or replaced.

(1) Parts mentioned in the text and shown exploded views are numbered in their disassembly sequences.(2) Inspections to be preformed during disassembly are shown in

in the exploded views.(3) Service standards for inspection and repair operations are indicated at relevant places in the text and in a table in Group 2.(4) The sequences in which parts should be reassembled during reassembly operations are shown under reassembly drawings in this manner:

(5) The symbols and headings shown below are used in this manual to highlight particularly important and safety-critical instruction.

Indicates a potentially hazardous situation which, if not avoided, can result in death or serious injury.

Indicates a potentially hazardous situation which, if not avoided, can result in minor or moderate injury.

Indicates a potentially hazardous situation which, if not avoided, can result in property damage.

Indicates important information or information which is useful for engine operation or maintenance.(6) With regard to tightening torques, points to which engine oil must be applied are labeled "Wet". Where there is no such indication, parts should be tightened in a dry condition.Terms Used in This Manual

Terms used in this manual are defined as follows:(1) Front and RearThe term "front" refers to the fan side of the engine, and the term "rear" applies to the flywheel side.(2) Left and RightThe term "left" and "right" apply to the sides of the engine as seen from the flywheel.(3) Service Standards* Standard ValueThis term indicates a designed nominal dimension, the designed dimension of a single part, the standard clearance between two parts after assembly, or a standard performance value for an assembly.* LimitThis term indicates a value beyond which a part is no longer usable in terms of performance and strength and must be repaired or replaced.

Have questions with 104749-6170?

Group cross 104749-6170 ZEXEL

Isuzu

104749-6170

8941782620

INJECTION-PUMP ASSEMBLY

4FC1J

4FC1J