Information injection-pump assembly

ZEXEL

104749-6160

1047496160

ISUZU

8941782700

8941782700

Rating:

Cross reference number

ZEXEL

104749-6160

1047496160

ISUZU

8941782700

8941782700

Zexel num

Bosch num

Firm num

Name

104749-6160

8941782700 ISUZU

INJECTION-PUMP ASSEMBLY

4FC1-J *

4FC1-J *

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113orSAEJ967d

1404 Test oil ISO4113orSAEJ967d

Test oil temperature

degC

45

45

50

Nozzle

105000-2010

Bosch type code

NP-DN12SD12TT

Nozzle holder

105780-2080

Opening pressure

MPa

14.7

14.7

15.19

Opening pressure

kgf/cm2

150

150

155

Injection pipe

Inside diameter - outside diameter - length (mm) mm 2-6-840

Inside diameter - outside diameter - length (mm) mm 2-6-840

Transfer pump pressure

kPa

20

20

20

Transfer pump pressure

kgf/cm2

0.2

0.2

0.2

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Pump speed

r/min

1250

1250

1250

Average injection quantity

mm3/st.

36.2

35.7

36.7

Difference in delivery

mm3/st.

3

Basic

*

Oil temperature

degC

50

48

52

Injection timing adjustment_02

Pump speed

r/min

600

600

600

Average injection quantity

mm3/st.

34.7

33.2

36.2

Oil temperature

degC

50

48

52

Injection timing adjustment_03

Pump speed

r/min

1250

1250

1250

Average injection quantity

mm3/st.

36.2

35.2

37.2

Difference in delivery

mm3/st.

3

Basic

*

Oil temperature

degC

50

48

52

Injection timing adjustment_04

Pump speed

r/min

2000

2000

2000

Average injection quantity

mm3/st.

32.2

30.7

33.7

Oil temperature

degC

50

48

52

Injection timing adjustment_05

Pump speed

r/min

2350

2350

2350

Average injection quantity

mm3/st.

32.6

31

34.2

Difference in delivery

mm3/st.

4

Oil temperature

degC

52

50

54

Injection quantity adjustment

Pump speed

r/min

2650

2650

2650

Average injection quantity

mm3/st.

11

8

14

Difference in delivery

mm3/st.

3.5

Basic

*

Oil temperature

degC

55

52

58

Injection quantity adjustment_02

Pump speed

r/min

2650

2650

2650

Average injection quantity

mm3/st.

11

8

14

Difference in delivery

mm3/st.

3.5

Oil temperature

degC

55

52

58

Injection quantity adjustment_03

Pump speed

r/min

2800

2800

2800

Average injection quantity

mm3/st.

5

Oil temperature

degC

55

52

58

Governor adjustment

Pump speed

r/min

400

400

400

Average injection quantity

mm3/st.

7.5

5.5

9.5

Difference in delivery

mm3/st.

2

Basic

*

Oil temperature

degC

48

46

50

Governor adjustment_02

Pump speed

r/min

400

400

400

Average injection quantity

mm3/st.

7.5

5.5

9.5

Difference in delivery

mm3/st.

2

Oil temperature

degC

48

46

50

Timer adjustment

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

60

60

Basic

*

Oil temperature

degC

48

46

50

Remarks

Full

Full

Timer adjustment_02

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

60

60

Oil temperature

degC

48

46

50

Speed control lever angle

Pump speed

r/min

400

400

400

Average injection quantity

mm3/st.

0

0

0

Oil temperature

degC

48

46

50

Remarks

Magnet OFF at idling position

Magnet OFF at idling position

0000000901

Pump speed

r/min

1250

1250

1250

Overflow quantity

cm3/min

420

290

550

Oil temperature

degC

50

48

52

Stop lever angle

Pump speed

r/min

1250

1250

1250

Pressure

kPa

431

411

451

Pressure

kgf/cm2

4.4

4.2

4.6

Basic

*

Oil temperature

degC

50

48

52

Stop lever angle_02

Pump speed

r/min

1250

1250

1250

Pressure

kPa

431

411

451

Pressure

kgf/cm2

4.4

4.2

4.6

Basic

*

Oil temperature

degC

50

48

52

Stop lever angle_03

Pump speed

r/min

2000

2000

2000

Pressure

kPa

647

618

676

Pressure

kgf/cm2

6.6

6.3

6.9

Oil temperature

degC

50

48

52

Stop lever angle_04

Pump speed

r/min

2250

2250

2250

Pressure

kPa

716

687

745

Pressure

kgf/cm2

7.3

7

7.6

Oil temperature

degC

52

50

54

0000001101

Pump speed

r/min

1250

1250

1250

Timer stroke

mm

3

2.8

3.2

Basic

*

Oil temperature

degC

50

48

52

_02

Pump speed

r/min

670

570

770

Timer stroke

mm

0.5

0.5

0.5

Oil temperature

degC

50

48

52

_03

Pump speed

r/min

1250

1250

1250

Timer stroke

mm

3

2.8

3.2

Basic

*

Oil temperature

degC

50

48

52

_04

Pump speed

r/min

2000

2000

2000

Timer stroke

mm

6.3

5.9

6.7

Oil temperature

degC

50

48

52

_05

Pump speed

r/min

2250

2250

2250

Timer stroke

mm

7.4

7.1

7.8

Oil temperature

degC

52

50

54

0000001201

Max. applied voltage

V

8

8

8

Test voltage

V

13

12

14

0000001401

Pump speed

r/min

1250

1250

1250

Average injection quantity

mm3/st.

29

28

30

Timer stroke TA

mm

2.4

2.4

2.4

Timer stroke variation dT

mm

0.6

0.4

0.8

Basic

*

Oil temperature

degC

50

48

52

_02

Pump speed

r/min

1250

1250

1250

Average injection quantity

mm3/st.

29

28

30

Timer stroke variation dT

mm

0.6

0.2

1

Basic

*

Oil temperature

degC

50

48

52

_03

Pump speed

r/min

1250

1250

1250

Average injection quantity

mm3/st.

24

23

25

Timer stroke variation dT

mm

1.3

0.9

1.7

Oil temperature

degC

50

48

52

0000001501

Pump speed

r/min

1250

1250

1250

Height

m

2000

2000

2000

Atmospheric pressure difference

kPa

-21.9

-22.6

-21.2

Atmospheric pressure difference

mmHg

-164

-169

-159

Average injection quantity

mm3/st.

32.6

32.6

32.6

Decrease qty

mm3/st.

3.6

2.6

4.6

Decrease rate

%

10

7

13

Basic

*

Oil temperature

degC

50

48

52

_02

Pump speed

r/min

1250

1250

1250

Height

m

0

0

0

Atmospheric pressure difference

kPa

0

0

0

Atmospheric pressure difference

mmHg

0

0

0

Decrease qty

mm3/st.

0

0

0

Decrease rate

%

0

0

0

Oil temperature

degC

50

48

52

_03

Pump speed

r/min

1250

1250

1250

Height

m

500

500

500

Atmospheric pressure difference

kPa

-5.9

-9.2

-2.6

Atmospheric pressure difference

mmHg

-44

-69

-19

Oil temperature

degC

50

48

52

_04

Pump speed

r/min

1250

1250

1250

Height

m

2000

2000

2000

Atmospheric pressure difference

kPa

-21.9

-22.6

-21.2

Atmospheric pressure difference

mmHg

-164

-169

-159

Decrease qty

mm3/st.

3.6

2.6

4.6

Decrease rate

%

10

7

13

Basic

*

Oil temperature

degC

50

48

52

Timing setting

K dimension

mm

3.3

3.2

3.4

KF dimension

mm

5.8

5.7

5.9

MS dimension

mm

1.6

1.5

1.7

Control lever angle alpha

deg.

24.5

20.5

28.5

Control lever angle beta

deg.

45

40

50

Test data Ex:

0000001801 MICROSWITCH ADJUSTMENT

Microswitch adjustment

With the control lever 'a' from the idle position (idle stopper lever clearance L), adjust the position of the microswitch and fix it in the position where it goes OFF.

After adjustment, the microswitch must not turn OFF at lever position between idle and a.

Also, the microswitch lever must not contact the stopper.

----------

a=26+-1deg L=8.5+-0.2mm

----------

----------

a=26+-1deg L=8.5+-0.2mm

----------

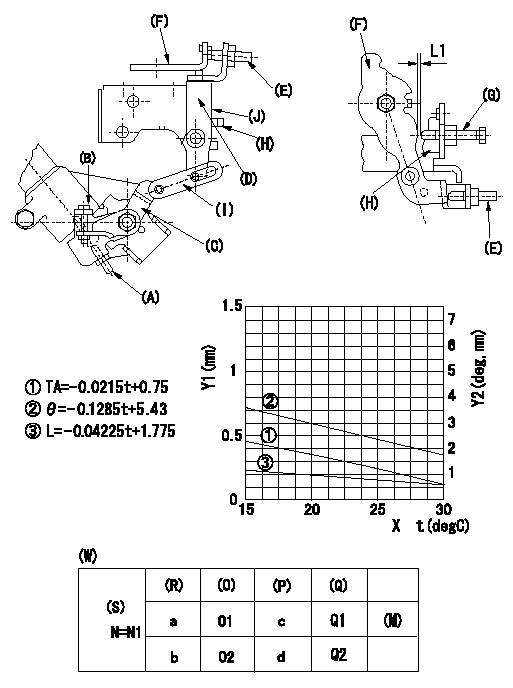

0000001901 W-CSD ADJUSTMENT

Adjustment of the W-CSD

1. Adjustment of the timer stroke

Adjust screw (A) so that the timer stroke is the value determined from the graph.

2. Adjustment of the position of the intermediate lever.

(1)Insert a shim L1 between the control lever (F) and the idle set screw (G).

(2)Set intermediate lever (D) adjusting screw (E) so that adjusting screw (E) contacts control lever, and so that when intermediate lever is at right angles to pump center, intermediate lever and idle stopper bracket (H) overlap at position (J).

3. W-CSD adjustment

Insert a shim L1+-0.05 between the control lever (F) and the idle set screw (G).

Use adjusting screw (B) to fix the CSD lever (C) in the position where it operates the intermediate lever (D) via the rod (I).

X:Temperature t (deg C)

Y1:Timer stroke TA (mm)

Y2:Control lever position at theta L (deg, mm)

(W) Cold advancer

(R) Cooling water temperature (deg C)

(S) Cooling water temperature: increase direction

(O) Timer piston stroke (mm)

(P) Lever position (deg)

(Q) lever position (mm)

(M) standard point

N:Pump speed

----------

L1=0.93+-0.05mm

----------

N1=500r/min a=20degC b=-20degC c=2.9+-1deg d=8+-3deg O1=0.3+-0.4mm O2=1.2+-0.6mm Q1=0.93+-0.3mm Q2=2.62+-1mm

----------

L1=0.93+-0.05mm

----------

N1=500r/min a=20degC b=-20degC c=2.9+-1deg d=8+-3deg O1=0.3+-0.4mm O2=1.2+-0.6mm Q1=0.93+-0.3mm Q2=2.62+-1mm

Information:

An additional 5 hours is allowed if the harness must replaced.

Product smu/age whichever comes first Caterpillar Dealer Suggested Customer Suggested

Parts % Labor Hrs% Parts % Labor Hrs% Parts % Labor Hrs%

*******Group 2*******

0-4000 hrs,

0-12 mo 100.0% 100.0% 0.0% 0.0% 0.0% 0.0%

This is a 3.0-hour job for Group 2

An additional 10 hours is allowed if the harness must replaced.

PARTS DISPOSITION

Handle the parts in accordance with your Warranty Bulletin on warranty parts handling.

Rework Procedure

Group Number 1

Injector Harness Inspection

-Raise the engine enclosure hood.

-Remove the air intake pipe connecting the air filter to the turbo inlet.

-Remove the valve covers.

-Inspect the injector harness wiring for contact between the harness and valve springs.

Image1.1.1

Repair

-If the harness is close to the valve spring, adjust the harness by disconnecting the injector connector rotating the connector 360 degrees and reconnecting it. This should slightly twist the wires and pull them away from the springs.

Image1.2.1

Injector Harness Replacement (If Necessary)

-If the injector harness has contacted the spring and cut the wire or exposed the wire, then replace the injector harness that is under the valve cover.

-When installing the new harness to the valve cover base make sure the tabs do not turn while torquing down the bolts(see the picture below). Keep the tabs straight, and this will help keep the wiring away from the valve springs.

Image1.3.1

Group Number 2

Injector Harness Inspection

-Remove the rear engine enclosure.

-Remove the clamp for flex boot on the air filter housing.

-Remove the rubber elbow on the inlet of the compressor side of the turbocharger.

-Remove the clamps called out in the photo for the turbocharger outlet pipe that connects to the aftercooler.

Image2.1.1

-Remove all three engine valve covers.

-Inspect the injector harness wiring for contact between the harness and valve springs.

Image2.2.1

Repair

-If the harness is close to the valve spring, adjust the harness by disconnecting the injector connector rotating the connector 360 degrees and reconnecting it. This should slightly twist the wires and pull them away from the springs.

Image2.3.1

Injector Harness Replacement (If Necessary)

-If the injector harness has contacted the spring and cut the wire or exposed the wire, then replace the injector harness that is under the valve cover.

-Remove the doors, hood, Clean Emissions Module (CEM) and mounting plate, and valve cover base.

-When installing the new harness to the valve cover base make sure the tabs do not turn while torquing down the bolts(see the picture below). Keep the tabs straight, and this will help keep the wiring away from the valve springs.

Image2.4.1

-Reinstall the previously removed hardware, and use the new 344-8311 exhaust clamp.

Image2.5.1

Have questions with 104749-6160?

Group cross 104749-6160 ZEXEL

Isuzu

104749-6160

8941782700

INJECTION-PUMP ASSEMBLY

4FC1-J

4FC1-J