Information injection-pump assembly

BOSCH

9 460 613 717

9460613717

ZEXEL

104749-6111

1047496111

ISUZU

8941769860

8941769860

Rating:

Components :

| 0. | INJECTION-PUMP ASSEMBLY | 104749-6111 |

| 1. | _ | |

| 2. | FUEL INJECTION PUMP | 104649-1621 |

| 3. | NUMBER PLATE | 146639-2000 |

| 4. | _ | 146672-1220 |

| 5. | CAPSULE | |

| 6. | ADJUSTING DEVICE | |

| 7. | NOZZLE AND HOLDER ASSY | 105158-2090 |

| 8. | Nozzle and Holder | 8-94418-161-0 |

| 9. | Open Pre:MPa(Kqf/cm2) | 13.2{135} |

| 10. | NOZZLE-HOLDER | 105088-1042 |

| 11. | NOZZLE | 105007-1061 |

Scheme ###:

| 1/6. | [1] | 146601-0700 | PACKING RING |

| 6. | [1] | 146100-0120 | SUPPLY PUMP |

| 9. | [1] | 146103-0000 | COVER |

| 10. | [2] | 139104-0000 | FLAT-HEAD SCREW |

| 12. | [1] | 146200-1620 | DRIVE SHAFT |

| 12/1. | [1] | 146200-0500 | DRIVE SHAFT |

| 12/2. | [1] | 146201-0000 | WOODRUFF KEY |

| 12/3. | [2] | 146202-0100 | DAMPER |

| 12/4. | [1] | 146203-0000 | TOOTHED GEAR |

| 17. | [1] | 146204-0000 | PLAIN WASHER |

| 20. | [1] | 146210-1720 | ROLLER SET |

| 24. | [1] | 146303-0000 | BEARING PIN |

| 25. | [1] | 146304-0000 | BEARING PIN |

| 26. | [1] | 146305-0000 | CLAMPING BAND |

| 27. | [1] | 146205-0000 | SLOTTED WASHER |

| 29. | [1] | 146220-0020 | CAM PLATE |

| 30. | [1] | 146600-0800 | O-RING |

| 31. | [1] | 146300-0700 | PUMP PLUNGER |

| 32. | [1] | 146301-0000 | SLIDING PIECE |

| 33. | [1] | 146603-0700 | SHIM D17.5&7.5T0.60 |

| 34. | [1] | 146302-3400 | COMPRESSION SPRING |

| 35/1. | [0] | 146603-0700 | SHIM D17.5&7.5T0.60 |

| 35/1. | [0] | 146603-0800 | SHIM D17.5&7.5T0.70 |

| 35/1. | [0] | 146603-0900 | SHIM D17.5&7.5T0.90 |

| 35/1. | [0] | 146603-1000 | SHIM D17.5&7.5T1.00 |

| 35/1. | [0] | 146603-1100 | SHIM D17.5&7.5T1.20 |

| 35/1. | [0] | 146603-3600 | SHIM D17.5&7.5T2.40 |

| 36. | [1] | 146600-0800 | O-RING |

| 37. | [1] | 146310-0000 | COVER |

| 38. | [2] | 146620-5000 | BLEEDER SCREW |

| 39. | [1] | 146310-0100 | COVER |

| 40. | [2] | 146620-5000 | BLEEDER SCREW |

| 43. | [1] | 146230-0000 | SHIM |

| 44. | [1] | 146230-0100 | PLAIN WASHER |

| 45. | [1] | 146231-0001 | SLOTTED WASHER |

| 47. | [2] | 146233-0000 | SLOTTED WASHER |

| 48/1. | [1] | 146603-0000 | SHIM D17.0&5.2T0.50 |

| 48/1. | [1] | 146603-0100 | SHIM D17.0&5.2T0.80 |

| 48/1. | [1] | 146603-0200 | SHIM D17.0&5.2T1.00 |

| 48/1. | [1] | 146603-0300 | SHIM D17.0&5.2T1.20 |

| 48/1. | [1] | 146603-0400 | SHIM D17.0&5.2T1.50 |

| 48/1. | [1] | 146603-0500 | SHIM D17.0&5.2T1.80 |

| 48/1. | [1] | 146603-0600 | SHIM D17.0&5.2T2.00 |

| 48/1. | [1] | 146690-1400 | SHIM D17&5.2T0.9 |

| 48/1. | [1] | 146690-1500 | SHIM D17&5.2T1.1 |

| 48/1. | [1] | 146690-1600 | SHIM D17&5.2T1.3 |

| 48/1. | [1] | 146690-1700 | SHIM D17&5.2T1.4 |

| 48/1. | [1] | 146690-1800 | SHIM D17&5.2T1.6 |

| 48/1. | [1] | 146690-1900 | SHIM D17&5.2T1.7 |

| 48/1. | [1] | 146690-5800 | SHIM D17&5.2T2.1 |

| 48/1. | [1] | 146690-5900 | SHIM D17&5.2T2.2 |

| 48/1. | [1] | 146690-6000 | SHIM D17&5.2T2.3 |

| 48/1. | [1] | 146690-6100 | SHIM D17&5.2T2.4 |

| 48/1. | [1] | 146690-6200 | SHIM D17&5.2T2.5 |

| 48/1. | [1] | 146690-6300 | SHIM D17&5.2T2.6 |

| 48/1. | [1] | 146690-6400 | SHIM D17&5.2T2.7 |

| 48/1. | [1] | 146690-6500 | SHIM D17&5.2T2.8 |

| 48/1. | [1] | 146690-6600 | SHIM D17&5.2T2.9 |

| 48/1. | [1] | 146690-6700 | SHIM D17&5.2T3.0 |

| 48/1. | [1] | 146690-6800 | SHIM D17&5.2T3.1 |

| 48/1. | [1] | 146690-6900 | SHIM D17&5.2T3.2 |

| 48/1. | [1] | 146690-7000 | SHIM D17&5.2T3.3 |

| 48/1. | [1] | 146690-7100 | SHIM D17&5.2T3.4 |

| 48/1. | [1] | 146690-7200 | SHIM D17&5.2T0.4 |

| 48/1. | [1] | 146690-7300 | SHIM D17&5.2T0.6 |

| 48/1. | [1] | 146690-7400 | SHIM D17&5.2T0.7 |

| 48/1. | [1] | 146690-7500 | SHIM D17&5.2T1.9 |

| 48/1. | [1] | 146690-7800 | SHIM D17&5.2T0.2 |

| 49. | [2] | 146234-0500 | GUIDE PIN |

| 50. | [1] | 146400-7420 | HYDRAULIC HEAD |

| 50. | [1] | 146400-7420 | HYDRAULIC HEAD |

| 50. | [1] | 146400-7420 | HYDRAULIC HEAD |

| 51. | [1] | 146600-0000 | O-RING |

| 52/1. | [1] | 146420-0000 | SHIM D9.5&3.0T1.90 |

| 52/1. | [1] | 146420-0100 | SHIM D9.5&3.0T1.92 |

| 52/1. | [1] | 146420-0200 | SHIM D9.5&3.0T1.94 |

| 52/1. | [1] | 146420-0300 | SHIM D9.5&3.0T1.96 |

| 52/1. | [1] | 146420-0400 | SHIM D9.5&3.0T1.98 |

| 52/1. | [1] | 146420-0500 | SHIM D9.5&3.0T2.00 |

| 52/1. | [1] | 146420-0600 | SHIM D9.5&3.0T2.02 |

| 52/1. | [1] | 146420-0700 | SHIM D9.5&3.0T2.04 |

| 52/1. | [1] | 146420-0800 | SHIM D9.5&3.0T2.06 |

| 52/1. | [1] | 146420-0900 | SHIM D9.5&3.0T2.08 |

| 52/1. | [1] | 146420-1000 | SHIM D9.5&3.0T2.10 |

| 52/1. | [1] | 146420-1100 | SHIM D9.5&3.0T2.12 |

| 52/1. | [1] | 146420-1200 | SHIM D9.5&3.0T2.14 |

| 52/1. | [1] | 146420-1300 | SHIM D9.5&3.0T2.16 |

| 52/1. | [1] | 146420-1400 | SHIM D9.5&3.0T2.18 |

| 52/1. | [1] | 146420-1500 | SHIM D9.5&3.0T2.20 |

| 52/1. | [1] | 146420-1600 | SHIM D9.5&3.0T2.22 |

| 52/1. | [1] | 146420-1700 | SHIM D9.5&3.0T2.24 |

| 52/1. | [1] | 146420-1800 | SHIM D9.5&3.0T2.26 |

| 52/1. | [1] | 146420-1900 | SHIM D9.5&3.0T2.28 |

| 52/1. | [1] | 146420-2000 | SHIM D9.5&3.0T2.30 |

| 52/1. | [1] | 146420-2100 | SHIM D9.5&3.0T2.32 |

| 52/1. | [1] | 146420-2200 | SHIM D9.5&3.0T2.34 |

| 52/1. | [1] | 146420-2300 | SHIM D9.5&3.0T2.36 |

| 52/1. | [1] | 146420-2400 | SHIM D9.5&3.0T2.38 |

| 52/1. | [1] | 146420-2500 | SHIM D9.5&3.0T2.40 |

| 52/1. | [1] | 146420-2600 | SHIM D9.5&3.0T2.42 |

| 52/1. | [1] | 146420-2700 | SHIM D9.5&3.0T2.44 |

| 52/1. | [1] | 146420-2800 | SHIM D9.5&3.0T2.46 |

| 52/1. | [1] | 146420-2900 | SHIM D9.5&3.0T2.48 |

| 52/1. | [1] | 146420-3000 | SHIM D9.5&3.0T2.50 |

| 52/1. | [1] | 146420-3100 | SHIM D9.5&3.0T2.52 |

| 52/1. | [1] | 146420-3200 | SHIM D9.5&3.0T2.54 |

| 52/1. | [1] | 146420-3300 | SHIM D9.5&3.0T2.56 |

| 52/1. | [1] | 146420-3400 | SHIM D9.5&3.0T2.58 |

| 52/1. | [1] | 146420-3500 | SHIM D9.5&3.0T2.60 |

| 52/1. | [1] | 146420-3600 | SHIM D9.5&3.0T2.62 |

| 52/1. | [1] | 146420-3700 | SHIM D9.5&3.0T2.64 |

| 52/1. | [1] | 146420-3800 | SHIM D9.5&3.0T2.66 |

| 52/1. | [1] | 146420-3900 | SHIM D9.5&3.0T2.68 |

| 52/1. | [1] | 146420-4000 | SHIM D9.5&3.0T2.70 |

| 52/1. | [1] | 146420-4100 | SHIM D9.5&3.0T2.72 |

| 52/1. | [1] | 146420-4200 | SHIM D9.5&3.0T2.74 |

| 52/1. | [1] | 146420-4300 | SHIM D9.5&3.0T2.76 |

| 52/1. | [1] | 146420-4400 | SHIM D9.5&3.0T2.78 |

| 52/1. | [1] | 146420-4500 | SHIM D9.5&3.0T2.80 |

| 52/1. | [1] | 146420-4600 | SHIM D9.5&3.0T2.82 |

| 52/1. | [1] | 146420-4700 | SHIM D9.5&3.0T2.84 |

| 52/1. | [1] | 146420-4800 | SHIM D9.5&3.0T2.86 |

| 52/1. | [1] | 146420-4900 | SHIM D9.5&3.0T2.88 |

| 52/1. | [1] | 146420-5000 | SHIM D9.5&3.0T2.90 |

| 52/1. | [1] | 146420-5100 | SHIM D9.5&3.0T1.74 |

| 52/1. | [1] | 146420-5200 | SHIM D9.5&3.0T1.76 |

| 52/1. | [1] | 146420-5300 | SHIM D9.5&3.0T1.78 |

| 52/1. | [1] | 146420-5400 | SHIM D9.5&3.0T1.80 |

| 52/1. | [1] | 146420-5500 | SHIM D9.5&3.0T1.82 |

| 52/1. | [1] | 146420-5600 | SHIM D9.5&3.0T1.84 |

| 52/1. | [1] | 146420-5700 | SHIM D9.5&3.0T1.86 |

| 52/1. | [1] | 146420-5800 | SHIM D9.5&3.0T1.88 |

| 54. | [4] | 146433-0100 | GASKET D12&6.4T1.00 |

| 55. | [4] | 146430-0120 | DELIVERY-VALVE ASSEMBLY |

| 56. | [4] | 146432-0000 | COMPRESSION SPRING |

| 58. | [4] | 146440-0120 | FITTING |

| 60. | [4] | 139106-0100 | FLAT-HEAD SCREW |

| 66. | [1] | 146600-0100 | O-RING |

| 67. | [1] | 146502-8620 | GOVERNOR COVER |

| 67/1. | [1] | 146505-9520 | GOVERNOR COVER |

| 67/13. | [2] | 013020-6040 | UNION NUT M6P1H5 |

| 67/14. | [1] | 029240-6010 | UNION NUT M6P1.0H5* |

| 67/15. | [2] | 146526-1800 | BLEEDER SCREW |

| 67/16. | [1] | 146526-0200 | BLEEDER SCREW |

| 67/23. | [1] | 146626-2920 | BRACKET |

| 67/64. | [1] | 146627-5720 | BRACKET |

| 67/78. | [1] | 146600-4400 | SEAL RING |

| 67/200. | [1] | 139308-0300 | PLAIN WASHER |

| 67/201. | [1] | 146545-1620 | THREADED PIN |

| 67/202. | [1] | 139208-0100 | UNION NUT |

| 67/203. | [1] | 146600-1200 | O-RING |

| 68. | [1] | 146510-6320 | CONTROL SHAFT |

| 69. | [1] | 139310-0200 | PLAIN WASHER |

| 72. | [1] | 146534-3220 | CONTROL LEVER |

| 72B. | [1] | 146534-3320 | CONTROL LEVER |

| 73. | [1] | 014110-6440 | LOCKING WASHER |

| 75. | [1] | 013020-6040 | UNION NUT M6P1H5 |

| 95. | [1] | 146551-1020 | FULCRUM LEVER |

| 104. | [2] | 146568-0000 | SLOTTED SPRING PIN |

| 105. | [2] | 026508-1140 | GASKET D11.4&8.2T1 |

| 106. | [2] | 146588-0500 | COILED SPRING |

| 107. | [1] | 146569-0100 | UNION NUT |

| 108. | [1] | 146570-0000 | GOVERNOR SHAFT |

| 109. | [1] | 146600-0400 | O-RING |

| 110/1. | [1] | 146571-0000 | SHIM D20.2&8.3T1.05 |

| 110/1. | [1] | 146571-0100 | SHIM D20.2&8.3T1.25 |

| 110/1. | [1] | 146571-0200 | SHIM D20.2&8.3T1.45 |

| 110/1. | [1] | 146571-0300 | SHIM D20.2&8.3T1.65 |

| 110/1. | [1] | 146571-0400 | SHIM D20.2&8.3T1.85 |

| 110/1. | [1] | 146571-0500 | SHIM D20.2&8.3T1.15 |

| 110/1. | [1] | 146571-0600 | SHIM D20.2&8.3T1.35 |

| 110/1. | [1] | 146571-0700 | SHIM D20.2&8.3T1.55 |

| 110/1. | [1] | 146571-0800 | SHIM D20.2&8.3T1.75 |

| 111. | [1] | 146602-0600 | PLAIN WASHER D20&8.4T1.40 |

| 112. | [1] | 146572-0020 | FLYWEIGHT ASSEMBLY |

| 114. | [1] | 146602-0500 | PLAIN WASHER D17&6.4T1.60 |

| 115. | [1] | 146575-0000 | SLIDING SLEEVE |

| 116. | [1] | 146576-0000 | SEALING CAP |

| 117/1. | [1] | 146577-0000 | PLUG L1.70 |

| 117/1. | [1] | 146577-0100 | PLUG L1.90 |

| 117/1. | [1] | 146577-0200 | PLUG L2.10 |

| 117/1. | [1] | 146577-0300 | PLUG L2.30 |

| 117/1. | [1] | 146577-0400 | PLUG L2.50 |

| 117/1. | [1] | 146577-0500 | PLUG L2.70 |

| 117/1. | [1] | 146577-0600 | PLUG L2.90 |

| 117/1. | [1] | 146577-0700 | PLUG L3.10 |

| 117/1. | [1] | 146577-0800 | PLUG L3.30 |

| 117/1. | [1] | 146577-0900 | PLUG L3.50 |

| 117/1. | [1] | 146577-1000 | PLUG L3.70 |

| 117/1. | [1] | 146577-1100 | PLUG L3.90 |

| 117/1. | [1] | 146577-1200 | PLUG L4.10 |

| 117/1. | [1] | 146577-1300 | PLUG L4.30 |

| 117/1. | [1] | 146577-1400 | PLUG L4.50 |

| 117/1. | [1] | 146577-1500 | PLUG L4.70 |

| 117/1. | [1] | 146577-1600 | PLUG L4.90 |

| 117/1. | [1] | 146577-1700 | PLUG L5.10 |

| 117/1. | [1] | 146577-5000 | PLUG L1.8 |

| 117/1. | [1] | 146577-5100 | PLUG L2.0 |

| 117/1. | [1] | 146577-5200 | PLUG L2.2 |

| 117/1. | [1] | 146577-5300 | PLUG L2.4 |

| 117/1. | [1] | 146577-5400 | PLUG L2.6 |

| 117/1. | [1] | 146577-5500 | PLUG L2.8 |

| 117/1. | [1] | 146577-5600 | PLUG L3.0 |

| 117/1. | [1] | 146577-5700 | PLUG L3.2 |

| 117/1. | [1] | 146577-5800 | PLUG L3.4 |

| 117/1. | [1] | 146577-5900 | PLUG L3.6 |

| 117/1. | [1] | 146577-6000 | PLUG L3.8 |

| 117/1. | [1] | 146577-6100 | PLUG L4.0 |

| 117/1. | [1] | 146577-6200 | PLUG L4.2 |

| 117/1. | [1] | 146577-6300 | PLUG L4.4 |

| 117/1. | [1] | 146577-6400 | PLUG L4.6 |

| 117/1. | [1] | 146577-6500 | PLUG L4.8 |

| 117/1. | [1] | 146577-6600 | PLUG L5.0 |

| 117/1. | [1] | 146877-0400 | PLUG |

| 117/1. | [1] | 146877-0500 | PLUG |

| 117/1. | [1] | 146877-0600 | PLUG |

| 117/1. | [1] | 146877-0700 | PLUG |

| 117/1. | [1] | 146877-4300 | PLUG |

| 117/1. | [1] | 146877-4400 | PLUG |

| 117/1. | [1] | 146877-4500 | PLUG |

| 117/1. | [1] | 146877-4600 | PLUG |

| 123. | [4] | 139106-0200 | FLAT-HEAD SCREW |

| 130. | [1] | 146421-0020 | CAPSULE |

| 130/2. | [1] | 026508-1140 | GASKET D11.4&8.2T1 |

| 130/3. | [1] | 146422-0000 | BLEEDER SCREW |

| 130/4. | [1] | 146600-0500 | O-RING |

| 133. | [1] | 146600-0600 | O-RING |

| 134. | [1] | 146600-0700 | O-RING |

| 135. | [1] | 146110-0220 | CONTROL VALVE |

| 135/5. | [1] | 146114-0000 | SPRING WASHER |

| 136. | [1] | 146120-0020 | OVER FLOW VALVE |

| 137. | [2] | 139512-0500 | GASKET |

| 138. | [1] | 146606-5120 | INLET UNION |

| 200. | [1] | 146206-0100 | COILED SPRING |

| 205. | [1] | 146201-0100 | WOODRUFF KEY |

| 218. | [1] | 146587-7320 | COILED SPRING |

| 220. | [1] | 146587-7600 | COILED SPRING |

| 232. | [1] | 146659-2820 | CLAMPING BAND |

| 240. | [1] | 146650-1220 | PULLING ELECTROMAGNET |

| 240/8. | [1] | 146600-1700 | O-RING |

| 242. | [1] | 146658-7320 | WIRE |

| 243. | [1] | 146621-1000 | UNION NUT |

| 244. | [1] | 146613-5620 | PLATE |

| 245. | [3] | 139512-0500 | GASKET |

| 245. | [3] | 139512-0500 | GASKET |

| 246. | [1] | 146125-0020 | EYE BOLT |

| 247. | [1] | 146606-1020 | INLET UNION |

| 248. | [1] | 146614-0200 | SPACER BUSHING |

| 275. | [1] | 146619-6220 | BRACKET |

| 276. | [2] | 010010-1888 | BLEEDER SCREW |

| 450. | [1] | 146676-1620 | ADJUSTING DEVICE |

| 455. | [1] | 146549-1800 | BUSHING |

| 460. | [1] | 016010-0440 | LOCKING WASHER |

| 465. | [1] | 146616-4200 | SPACER BUSHING |

| 470. | [1] | 139106-0500 | FLAT-HEAD SCREW M6P1.0H25 |

| 471. | [1] | 139106-0400 | FLAT-HEAD SCREW M6P1.0H12 |

| 472. | [2] | 010206-1040 | HEX-SOCKET-HEAD CAP SCREW |

| 800S. | [1] | 146009-4720 | PUMP HOUSING |

| 800S/1/6. | [1] | 146601-0700 | PACKING RING |

| 800S/1/6. | [1] | 146601-0700 | PACKING RING |

| 804S. | [1] | 146232-0220 | COMPRESSION SPRING |

| 805S. | [1] | 146574-0120 | PARTS SET |

| 810S. | [1] | 146600-1120 | REPAIR SET |

| 821S. | [1] | 146210-5720 | ROLLER SET |

| 903. | [1] | 146672-1220 | PULSE GENERATOR |

| 903/2. | [1] | 146600-1300 | O-RING &13W1.9 |

| 906. | [1] | 146639-2000 | NAMEPLATE |

Include in #2:

104749-6111

as INJECTION-PUMP ASSEMBLY

Cross reference number

BOSCH

9 460 613 717

9460613717

ZEXEL

104749-6111

1047496111

ISUZU

8941769860

8941769860

Zexel num

Bosch num

Firm num

Name

104749-6111

9 460 613 717

8941769860 ISUZU

INJECTION-PUMP ASSEMBLY

4FC1J K

4FC1J K

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113orSAEJ967d

1404 Test oil ISO4113orSAEJ967d

Test oil temperature

degC

45

45

50

Nozzle

105000-2010

Bosch type code

NP-DN12SD12TT

Nozzle holder

105780-2080

Opening pressure

MPa

14.7

14.7

15.19

Opening pressure

kgf/cm2

150

150

155

Injection pipe

Inside diameter - outside diameter - length (mm) mm 2-6-840

Inside diameter - outside diameter - length (mm) mm 2-6-840

Transfer pump pressure

kPa

20

20

20

Transfer pump pressure

kgf/cm2

0.2

0.2

0.2

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Pump speed

r/min

1250

1250

1250

Average injection quantity

mm3/st.

34.2

33.7

34.7

Difference in delivery

mm3/st.

2.5

Basic

*

Injection timing adjustment_02

Pump speed

r/min

2600

2600

2600

Average injection quantity

mm3/st.

15.6

14.1

17.1

Injection timing adjustment_03

Pump speed

r/min

2250

2250

2250

Average injection quantity

mm3/st.

32.7

30.6

34.8

Injection timing adjustment_04

Pump speed

r/min

1800

1800

1800

Average injection quantity

mm3/st.

33.7

31.7

35.7

Injection timing adjustment_05

Pump speed

r/min

1250

1250

1250

Average injection quantity

mm3/st.

34.2

33.2

35.2

Injection timing adjustment_06

Pump speed

r/min

600

600

600

Average injection quantity

mm3/st.

28.2

26.2

30.2

Injection quantity adjustment

Pump speed

r/min

2600

2600

2600

Average injection quantity

mm3/st.

15.6

14.6

16.6

Difference in delivery

mm3/st.

4.5

Basic

*

Injection quantity adjustment_02

Pump speed

r/min

2900

2900

2900

Average injection quantity

mm3/st.

4.5

Governor adjustment

Pump speed

r/min

390

390

390

Average injection quantity

mm3/st.

7.5

5.5

9.5

Difference in delivery

mm3/st.

2

Basic

*

Governor adjustment_02

Pump speed

r/min

390

390

390

Average injection quantity

mm3/st.

7.5

5.5

9.5

Governor adjustment_03

Pump speed

r/min

520

520

520

Average injection quantity

mm3/st.

0

0

0

Boost compensator adjustment

Pump speed

r/min

1200

1200

1200

Average injection quantity

mm3/st.

7.2

6.2

8.2

Timer adjustment

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

60

50

70

Basic

*

Speed control lever angle

Pump speed

r/min

390

390

390

Average injection quantity

mm3/st.

0

0

0

Remarks

Magnet OFF

Magnet OFF

0000000901

Pump speed

r/min

1250

1250

1250

Overflow quantity

cm3/min

459

330

588

Stop lever angle

Pump speed

r/min

1250

1250

1250

Pressure

kPa

470.5

451

490

Pressure

kgf/cm2

4.8

4.6

5

Basic

*

Stop lever angle_02

Pump speed

r/min

1250

1250

1250

Pressure

kPa

470.5

451

490

Pressure

kgf/cm2

4.8

4.6

5

Stop lever angle_03

Pump speed

r/min

2000

2000

2000

Pressure

kPa

637.5

608

667

Pressure

kgf/cm2

6.5

6.2

6.8

Stop lever angle_04

Pump speed

r/min

2250

2250

2250

Pressure

kPa

715.5

686

745

Pressure

kgf/cm2

7.3

7

7.6

0000001101

Pump speed

r/min

1250

1250

1250

Timer stroke

mm

3.9

3.7

4.1

Basic

*

_02

Pump speed

r/min

1250

1250

1250

Timer stroke

mm

3.75

3.6

3.9

_03

Pump speed

r/min

1800

1800

1800

Timer stroke

mm

6.7

6.1

7.3

_04

Pump speed

r/min

2250

2250

2250

Timer stroke

mm

9

8.6

9.4

0000001201

Max. applied voltage

V

8

8

8

Test voltage

V

13

12

14

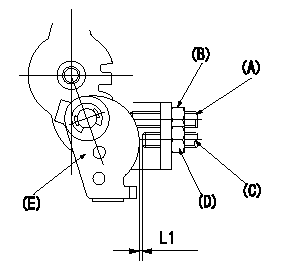

Timing setting

K dimension

mm

3.3

3.2

3.4

KF dimension

mm

5.8

5.7

5.9

MS dimension

mm

1.6

1.5

1.7

Pre-stroke

mm

0.25

0.23

0.27

Control lever angle alpha

deg.

18.5

14.5

22.5

Control lever angle beta

deg.

32

27

37

Test data Ex:

0000001801 PARTIAL SETTING

Partial injection quantity adjustment

(A) Stopper bolt

(B) Fixed nut

(C) Sub lever stopper bolt

(D) Fixed nut

(E) Sub lever

1. At pump speed N1, adjust the stopper bolt (A) so that the idle injection quantity is Q1. Then fix using the nut (B).

2. Confirm that the idle injection quantity is Q2 when the pump speed is N2.

3. Insert a shim L1 between the sub lever (E) and the sub lever stopper bolt (C). Adjust the sub lever stopper bolt so that the injection quantity is Q3 at pump speed N3 and fix using the nut.

----------

N1=390r/min N2=520r/min N3=1200r/min Q1=5.5~9.5mm3/st Q2=0mm3/st Q3=6.2~8.2mm3/st L1=9.5+-0.1mm

----------

L1=9.5+-0.1mm

----------

N1=390r/min N2=520r/min N3=1200r/min Q1=5.5~9.5mm3/st Q2=0mm3/st Q3=6.2~8.2mm3/st L1=9.5+-0.1mm

----------

L1=9.5+-0.1mm

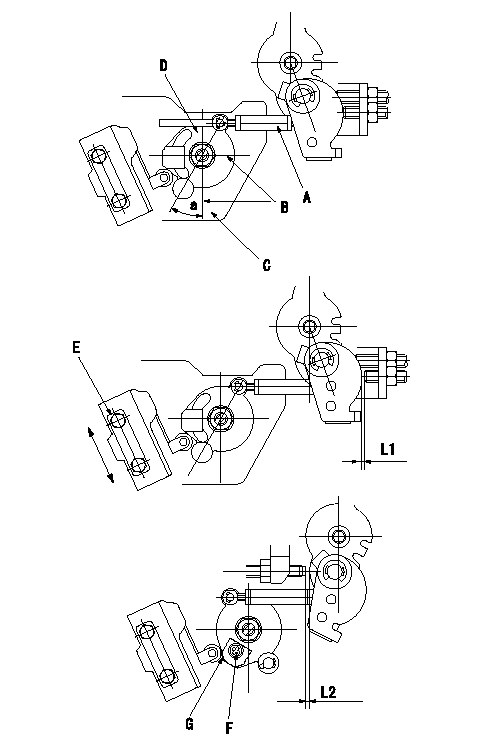

0000001901 MICROSWITCH ADJUSTMENT

Microswitch adjustment

Stepping motor adjustment

1. With the sub-lever and the control lever contacting the idle stopper bolt, adjust the length of the rod so that the stepping motor bracket and the stepping motor lever aligning mark are aligned (Tightening torque T).

A = rod

B = position of angle alignment marking

C = stepping motor bracket

D = stepping motor lever

2. Idle position adjustment

1) Fix so that idle stopper contacts the control lever.

2) Insert shim L1 between the sub-lever and the idle stopper.

3) Move the microswitch in the direction of the arrow to turn it ON.

4) Move the microswitch in the direction of the arrow and fix it where it turns OFF using the microswitch fixing bolt.

E = microswitch fixing bolt (Tightening torque T2)

3. Full position adjustment

1) 1) Fix so that sub lever contacts the control lever.

2) Insert a shim L2 between the control lever and the full stopper.

3) Turn the plate clockwise as shown in the figure above and confirm that the microswitch turns ON.

4) Move the plate counterclockwise and fix it where the microswitch turns OFF.

F = bolt (Tightening torque T2)

G = plate

----------

L1=1.2mm L2=0.7mm T1=3.4~4.9N-m(0.35~0.5kgf-m) T2=2.0~2.9N-m(0.2~0.3kgf-m)

----------

a=30+-1deg L1=1.2mm L2=0.7mm

----------

L1=1.2mm L2=0.7mm T1=3.4~4.9N-m(0.35~0.5kgf-m) T2=2.0~2.9N-m(0.2~0.3kgf-m)

----------

a=30+-1deg L1=1.2mm L2=0.7mm

Information:

5.3 Assembly

Assembly sequence: piston and connecting rod assemblies and crankshaftThe assembly sequence is indicated by the numbers in the drawing above. KEY POINTS FOR ASSEMBLY(1) Installing Main Bearings(a) Press the main bearings (upper and lower) into the cylinder block and main bearing caps, respectively, such that the bearings' lugs fit into the grooves.

Installing main bearings(b) Fit the flanged main bearing in the No. 3 journal position.(c) Smear a little engine oil on the inner surface of each bearing.

Installing flanged main bearing(2) Installing Crankshaft(a) Wash the crankshaft thoroughly in cleaning solvent, then dry it with compressed air.(b) Keeping the crankshaft horizontal, gently lower it into the cylinder block.(c) Smear a little engine oil on each crankshaft journal.

Installing crankshaft(3) Installing Main Bearing Caps(a) Before installing the main bearing caps, apply sealant to the mating surfaces of the frontmost and rearmost caps and to the corresponding surfaces in the cylinder block.

Installing main bearing caps(b) Referring to the cap numbers, fit the main bearing caps sequentially starting at the front of the engine. The arrow on each cap must point toward the front of the engine.

Make sure the frontmost and rearmost caps fit flush against the cylinder block.

Front marks and cap numbers(4) Tightening Bearing Cap BoltsTighten the bearing cap bolts alternately a little at a time, then torque each bolt to specification.

Tightening bearing cap bolts(5) Checking Crankshaft RotationConfirm that the crankshaft turns smoothly.

Checking crankshaft rotation(6) Measuring End Play of CrankshaftApply a dial gauge to the end of the crankshaft and measure the end play. If the measurement exceeds the specified limit, replace the No. 3 flanged bearing.

Unit: mm (in.)

Measuring end play of crankshaft(7) Inserting Side Seals(a) Apply sealant to the mating surfaces of each side seal. (b) With the radius of each side seal facing the outside, push the side seals part-way into the frontmost and rearmost caps by hand.

Alignment of side seals for installation(c) Press each side seal completely into position using a flat implement. Be careful not to bend the side seals.

Inserting side seals(8) Preparation for Installation of Piston and Connecting Rod Assemblies(a) Clean each cylinder's inner surface with a rag, then smear each with engine oil.(b) Press the connecting rod bearings (upper and lower) into the connecting rods and caps such that the bearings' lugs fit into the grooves.(c) Smear the connecting rod bearings with engine oil.(d) Turn the cylinder block onto its side.

Preparation for installation of piston and connecting rod assemblies(9) Preparation for Installation of Piston and Connecting Rod Assemblies(a) Smear the pistons' sliding surfaces and piston rings with engine oil.(b) Position the piston ring gaps as shown in the drawing. Do not align any ring gap with the piston pin or at 90° to the piston pin.

Piston ring positions(c) Turn the crankshaft until the crank pin onto which the connecting rod is to be fitted reaches its TDC position.(d) Align the piston such that its front mark (this is stamped on the piston crown) points toward the timing gear case mounting surface (the front of the engine).(e)

Assembly sequence: piston and connecting rod assemblies and crankshaftThe assembly sequence is indicated by the numbers in the drawing above. KEY POINTS FOR ASSEMBLY(1) Installing Main Bearings(a) Press the main bearings (upper and lower) into the cylinder block and main bearing caps, respectively, such that the bearings' lugs fit into the grooves.

Installing main bearings(b) Fit the flanged main bearing in the No. 3 journal position.(c) Smear a little engine oil on the inner surface of each bearing.

Installing flanged main bearing(2) Installing Crankshaft(a) Wash the crankshaft thoroughly in cleaning solvent, then dry it with compressed air.(b) Keeping the crankshaft horizontal, gently lower it into the cylinder block.(c) Smear a little engine oil on each crankshaft journal.

Installing crankshaft(3) Installing Main Bearing Caps(a) Before installing the main bearing caps, apply sealant to the mating surfaces of the frontmost and rearmost caps and to the corresponding surfaces in the cylinder block.

Installing main bearing caps(b) Referring to the cap numbers, fit the main bearing caps sequentially starting at the front of the engine. The arrow on each cap must point toward the front of the engine.

Make sure the frontmost and rearmost caps fit flush against the cylinder block.

Front marks and cap numbers(4) Tightening Bearing Cap BoltsTighten the bearing cap bolts alternately a little at a time, then torque each bolt to specification.

Tightening bearing cap bolts(5) Checking Crankshaft RotationConfirm that the crankshaft turns smoothly.

Checking crankshaft rotation(6) Measuring End Play of CrankshaftApply a dial gauge to the end of the crankshaft and measure the end play. If the measurement exceeds the specified limit, replace the No. 3 flanged bearing.

Unit: mm (in.)

Measuring end play of crankshaft(7) Inserting Side Seals(a) Apply sealant to the mating surfaces of each side seal. (b) With the radius of each side seal facing the outside, push the side seals part-way into the frontmost and rearmost caps by hand.

Alignment of side seals for installation(c) Press each side seal completely into position using a flat implement. Be careful not to bend the side seals.

Inserting side seals(8) Preparation for Installation of Piston and Connecting Rod Assemblies(a) Clean each cylinder's inner surface with a rag, then smear each with engine oil.(b) Press the connecting rod bearings (upper and lower) into the connecting rods and caps such that the bearings' lugs fit into the grooves.(c) Smear the connecting rod bearings with engine oil.(d) Turn the cylinder block onto its side.

Preparation for installation of piston and connecting rod assemblies(9) Preparation for Installation of Piston and Connecting Rod Assemblies(a) Smear the pistons' sliding surfaces and piston rings with engine oil.(b) Position the piston ring gaps as shown in the drawing. Do not align any ring gap with the piston pin or at 90° to the piston pin.

Piston ring positions(c) Turn the crankshaft until the crank pin onto which the connecting rod is to be fitted reaches its TDC position.(d) Align the piston such that its front mark (this is stamped on the piston crown) points toward the timing gear case mounting surface (the front of the engine).(e)

Have questions with 104749-6111?

Group cross 104749-6111 ZEXEL

Isuzu

104749-6111

9 460 613 717

8941769860

INJECTION-PUMP ASSEMBLY

4FC1J

4FC1J