Information injection-pump assembly

BOSCH

9 460 610 219

9460610219

ZEXEL

104749-3050

1047493050

MITSUBISHI

MD092628

md092628

Rating:

Components :

| 0. | INJECTION-PUMP ASSEMBLY | 104749-3050 |

| 1. | _ | |

| 2. | FUEL INJECTION PUMP | 104649-3040 |

| 3. | NUMBER PLATE | |

| 4. | _ | 479771-0520 |

| 5. | CAPSULE | |

| 6. | ADJUSTING DEVICE | |

| 7. | NOZZLE AND HOLDER ASSY | 105148-1012 |

| 8. | Nozzle and Holder | MD074540 |

| 9. | Open Pre:MPa(Kqf/cm2) | 11.8{120} |

| 10. | NOZZLE-HOLDER | 105078-0012 |

| 11. | NOZZLE | 105007-1000 |

Scheme ###:

| 1/6. | [1] | 146601-0700 | PACKING RING |

| 1/9. | [1] | 146616-5600 | ADAPTOR |

| 1/10. | [1] | 139512-0500 | GASKET |

| 6. | [1] | 146100-0120 | SUPPLY PUMP |

| 9. | [1] | 146103-0000 | COVER |

| 10. | [2] | 139104-0000 | FLAT-HEAD SCREW |

| 12. | [1] | 146200-0320 | DRIVE SHAFT |

| 12/1. | [1] | 146200-0300 | DRIVE SHAFT |

| 12/2. | [1] | 146201-0000 | WOODRUFF KEY |

| 12/3. | [2] | 146202-0100 | DAMPER |

| 12/4. | [1] | 146203-0000 | TOOTHED GEAR |

| 17. | [1] | 146204-0000 | PLAIN WASHER |

| 20. | [1] | 146210-0220 | ROLLER SET |

| 24. | [1] | 146303-0000 | BEARING PIN |

| 25. | [1] | 146304-0000 | BEARING PIN |

| 26. | [1] | 146305-0000 | CLAMPING BAND |

| 27. | [1] | 146205-0000 | SLOTTED WASHER |

| 29. | [1] | 146220-0020 | CAM PLATE |

| 30. | [1] | 146600-0800 | O-RING |

| 31. | [1] | 146300-0600 | PUMP PLUNGER |

| 32. | [1] | 146301-0000 | SLIDING PIECE |

| 33. | [1] | 146603-0700 | SHIM |

| 34. | [1] | 146302-3400 | COMPRESSION SPRING |

| 34B. | [1] | 146302-3300 | COMPRESSION SPRING |

| 35/1. | [0] | 146603-0700 | SHIM D17.5&7.5T0.60 |

| 35/1. | [0] | 146603-0800 | SHIM D17.5&7.5T0.70 |

| 35/1. | [0] | 146603-0900 | SHIM D17.5&7.5T0.90 |

| 35/1. | [0] | 146603-1000 | SHIM D17.5&7.5T1.00 |

| 35/1. | [0] | 146603-1100 | SHIM D17.5&7.5T1.20 |

| 35/1. | [0] | 146603-3600 | SHIM D17.5&7.5T2.40 |

| 36. | [1] | 146600-0800 | O-RING |

| 37. | [1] | 146310-0000 | COVER |

| 38. | [2] | 146620-5000 | BLEEDER SCREW |

| 39. | [1] | 146310-0100 | COVER |

| 40. | [2] | 146620-5000 | BLEEDER SCREW |

| 43. | [1] | 146230-0000 | SHIM |

| 44. | [1] | 146230-0100 | PLAIN WASHER |

| 45. | [1] | 146231-0001 | SLOTTED WASHER |

| 47. | [2] | 146233-0000 | SLOTTED WASHER |

| 48/1. | [1] | 146603-0000 | SHIM D17.0&5.2T0.50 |

| 48/1. | [1] | 146603-0100 | SHIM D17.0&5.2T0.80 |

| 48/1. | [1] | 146603-0200 | SHIM D17.0&5.2T1.00 |

| 48/1. | [1] | 146603-0300 | SHIM D17.0&5.2T1.20 |

| 48/1. | [1] | 146603-0400 | SHIM D17.0&5.2T1.50 |

| 48/1. | [1] | 146603-0500 | SHIM D17.0&5.2T1.80 |

| 48/1. | [1] | 146603-0600 | SHIM D17.0&5.2T2.00 |

| 48/1. | [1] | 146690-1400 | SHIM D17&5.2T0.9 |

| 48/1. | [1] | 146690-1500 | SHIM D17&5.2T1.1 |

| 48/1. | [1] | 146690-1600 | SHIM D17&5.2T1.3 |

| 48/1. | [1] | 146690-1700 | SHIM D17&5.2T1.4 |

| 48/1. | [1] | 146690-1800 | SHIM D17&5.2T1.6 |

| 48/1. | [1] | 146690-1900 | SHIM D17&5.2T1.7 |

| 48/1. | [1] | 146690-5800 | SHIM D17&5.2T2.1 |

| 48/1. | [1] | 146690-5900 | SHIM D17&5.2T2.2 |

| 48/1. | [1] | 146690-6000 | SHIM D17&5.2T2.3 |

| 48/1. | [1] | 146690-6100 | SHIM D17&5.2T2.4 |

| 48/1. | [1] | 146690-6200 | SHIM D17&5.2T2.5 |

| 48/1. | [1] | 146690-6300 | SHIM D17&5.2T2.6 |

| 48/1. | [1] | 146690-6400 | SHIM D17&5.2T2.7 |

| 48/1. | [1] | 146690-6500 | SHIM D17&5.2T2.8 |

| 48/1. | [1] | 146690-6600 | SHIM D17&5.2T2.9 |

| 48/1. | [1] | 146690-6700 | SHIM D17&5.2T3.0 |

| 48/1. | [1] | 146690-6800 | SHIM D17&5.2T3.1 |

| 48/1. | [1] | 146690-6900 | SHIM D17&5.2T3.2 |

| 48/1. | [1] | 146690-7000 | SHIM D17&5.2T3.3 |

| 48/1. | [1] | 146690-7100 | SHIM D17&5.2T3.4 |

| 48/1. | [1] | 146690-7200 | SHIM D17&5.2T0.4 |

| 48/1. | [1] | 146690-7300 | SHIM D17&5.2T0.6 |

| 48/1. | [1] | 146690-7400 | SHIM D17&5.2T0.7 |

| 48/1. | [1] | 146690-7500 | SHIM D17&5.2T1.9 |

| 48/1. | [1] | 146690-7800 | SHIM D17&5.2T0.2 |

| 49. | [2] | 146234-0500 | GUIDE PIN |

| 50. | [1] | 146400-7020 | HYDRAULIC HEAD |

| 50. | [1] | 146400-7020 | HYDRAULIC HEAD |

| 50. | [1] | 146400-7020 | HYDRAULIC HEAD |

| 51. | [1] | 146600-0000 | O-RING |

| 52/1. | [1] | 146420-0000 | SHIM D9.5&3.0T1.90 |

| 52/1. | [1] | 146420-0100 | SHIM D9.5&3.0T1.92 |

| 52/1. | [1] | 146420-0200 | SHIM D9.5&3.0T1.94 |

| 52/1. | [1] | 146420-0300 | SHIM D9.5&3.0T1.96 |

| 52/1. | [1] | 146420-0400 | SHIM D9.5&3.0T1.98 |

| 52/1. | [1] | 146420-0500 | SHIM D9.5&3.0T2.00 |

| 52/1. | [1] | 146420-0600 | SHIM D9.5&3.0T2.02 |

| 52/1. | [1] | 146420-0700 | SHIM D9.5&3.0T2.04 |

| 52/1. | [1] | 146420-0800 | SHIM D9.5&3.0T2.06 |

| 52/1. | [1] | 146420-0900 | SHIM D9.5&3.0T2.08 |

| 52/1. | [1] | 146420-1000 | SHIM D9.5&3.0T2.10 |

| 52/1. | [1] | 146420-1100 | SHIM D9.5&3.0T2.12 |

| 52/1. | [1] | 146420-1200 | SHIM D9.5&3.0T2.14 |

| 52/1. | [1] | 146420-1300 | SHIM D9.5&3.0T2.16 |

| 52/1. | [1] | 146420-1400 | SHIM D9.5&3.0T2.18 |

| 52/1. | [1] | 146420-1500 | SHIM D9.5&3.0T2.20 |

| 52/1. | [1] | 146420-1600 | SHIM D9.5&3.0T2.22 |

| 52/1. | [1] | 146420-1700 | SHIM D9.5&3.0T2.24 |

| 52/1. | [1] | 146420-1800 | SHIM D9.5&3.0T2.26 |

| 52/1. | [1] | 146420-1900 | SHIM D9.5&3.0T2.28 |

| 52/1. | [1] | 146420-2000 | SHIM D9.5&3.0T2.30 |

| 52/1. | [1] | 146420-2100 | SHIM D9.5&3.0T2.32 |

| 52/1. | [1] | 146420-2200 | SHIM D9.5&3.0T2.34 |

| 52/1. | [1] | 146420-2300 | SHIM D9.5&3.0T2.36 |

| 52/1. | [1] | 146420-2400 | SHIM D9.5&3.0T2.38 |

| 52/1. | [1] | 146420-2500 | SHIM D9.5&3.0T2.40 |

| 52/1. | [1] | 146420-2600 | SHIM D9.5&3.0T2.42 |

| 52/1. | [1] | 146420-2700 | SHIM D9.5&3.0T2.44 |

| 52/1. | [1] | 146420-2800 | SHIM D9.5&3.0T2.46 |

| 52/1. | [1] | 146420-2900 | SHIM D9.5&3.0T2.48 |

| 52/1. | [1] | 146420-3000 | SHIM D9.5&3.0T2.50 |

| 52/1. | [1] | 146420-3100 | SHIM D9.5&3.0T2.52 |

| 52/1. | [1] | 146420-3200 | SHIM D9.5&3.0T2.54 |

| 52/1. | [1] | 146420-3300 | SHIM D9.5&3.0T2.56 |

| 52/1. | [1] | 146420-3400 | SHIM D9.5&3.0T2.58 |

| 52/1. | [1] | 146420-3500 | SHIM D9.5&3.0T2.60 |

| 52/1. | [1] | 146420-3600 | SHIM D9.5&3.0T2.62 |

| 52/1. | [1] | 146420-3700 | SHIM D9.5&3.0T2.64 |

| 52/1. | [1] | 146420-3800 | SHIM D9.5&3.0T2.66 |

| 52/1. | [1] | 146420-3900 | SHIM D9.5&3.0T2.68 |

| 52/1. | [1] | 146420-4000 | SHIM D9.5&3.0T2.70 |

| 52/1. | [1] | 146420-4100 | SHIM D9.5&3.0T2.72 |

| 52/1. | [1] | 146420-4200 | SHIM D9.5&3.0T2.74 |

| 52/1. | [1] | 146420-4300 | SHIM D9.5&3.0T2.76 |

| 52/1. | [1] | 146420-4400 | SHIM D9.5&3.0T2.78 |

| 52/1. | [1] | 146420-4500 | SHIM D9.5&3.0T2.80 |

| 52/1. | [1] | 146420-4600 | SHIM D9.5&3.0T2.82 |

| 52/1. | [1] | 146420-4700 | SHIM D9.5&3.0T2.84 |

| 52/1. | [1] | 146420-4800 | SHIM D9.5&3.0T2.86 |

| 52/1. | [1] | 146420-4900 | SHIM D9.5&3.0T2.88 |

| 52/1. | [1] | 146420-5000 | SHIM D9.5&3.0T2.90 |

| 52/1. | [1] | 146420-5100 | SHIM D9.5&3.0T1.74 |

| 52/1. | [1] | 146420-5200 | SHIM D9.5&3.0T1.76 |

| 52/1. | [1] | 146420-5300 | SHIM D9.5&3.0T1.78 |

| 52/1. | [1] | 146420-5400 | SHIM D9.5&3.0T1.80 |

| 52/1. | [1] | 146420-5500 | SHIM D9.5&3.0T1.82 |

| 52/1. | [1] | 146420-5600 | SHIM D9.5&3.0T1.84 |

| 52/1. | [1] | 146420-5700 | SHIM D9.5&3.0T1.86 |

| 52/1. | [1] | 146420-5800 | SHIM D9.5&3.0T1.88 |

| 54. | [4] | 146433-0100 | GASKET |

| 55. | [4] | 146430-0320 | DELIVERY-VALVE ASSEMBLY VE4 |

| 56. | [4] | 146432-0000 | COMPRESSION SPRING |

| 58. | [4] | 146440-0320 | FITTING |

| 60. | [4] | 139106-0100 | FLAT-HEAD SCREW |

| 66. | [1] | 146600-0100 | O-RING |

| 67. | [1] | 146700-2921 | MANIFOLD-PRESSURE COMP. |

| 67/1. | [1] | 146508-2621 | GOVERNOR COVER |

| 67/13. | [1] | 146621-1700 | UNION NUT |

| 67/14. | [1] | 146621-1700 | UNION NUT |

| 67/15. | [1] | 146526-3000 | BLEEDER SCREW |

| 67/16. | [1] | 146526-3000 | BLEEDER SCREW |

| 67/31. | [1] | 146710-0800 | BUSHING |

| 67/32. | [1] | 146711-0000 | PLATE |

| 67/33. | [1] | 139218-0400 | UNION NUT |

| 67/34. | [1] | 146712-0700 | BEARING PIN |

| 67/35. | [1] | 146621-0300 | UNION NUT |

| 67/36. | [1] | 146600-1400 | O-RING |

| 67/37. | [1] | 146710-0100 | BUSHING |

| 67/38. | [1] | 139506-0200 | GASKET |

| 67/39. | [1] | 146620-0300 | CAPSULE |

| 67/40. | [1] | 026512-1540 | GASKET |

| 67/41. | [1] | 146713-4100 | ADJUSTING PIN |

| 67/42. | [2] | 146714-0000 | PLATE |

| 67/43. | [1] | 146715-0000 | DIAPHRAGM |

| 67/44. | [1] | 139306-0100 | LOCKING WASHER |

| 67/45. | [1] | 013030-6040 | UNION NUT |

| 67/46. | [1] | 146716-0000 | UNION NUT |

| 67/47. | [1] | 146717-0400 | COILED SPRING |

| 67/48/1. | [1] | 146720-0000 | SPACER BUSHING L3.7 |

| 67/48/1. | [1] | 146720-0100 | SPACER BUSHING L3.9 |

| 67/48/1. | [1] | 146720-0200 | SPACER BUSHING L4.1 |

| 67/48/1. | [1] | 146720-0300 | SPACER BUSHING L4.3 |

| 67/48/1. | [1] | 146720-0400 | SPACER BUSHING L4.5 |

| 67/48/1. | [1] | 146720-0500 | SPACER BUSHING L4.7 |

| 67/48/1. | [1] | 146720-0600 | SPACER BUSHING L4.9 |

| 67/48/1. | [1] | 146720-0700 | SPACER BUSHING L5.1 |

| 67/48/1. | [1] | 146720-0800 | SPACER BUSHING L5.3 |

| 67/48/1. | [1] | 146720-0900 | SPACER BUSHING L2.7 |

| 67/48/1. | [1] | 146720-1000 | SPACER BUSHING L2.9 |

| 67/48/1. | [1] | 146720-1100 | SPACER BUSHING L3.1 |

| 67/48/1. | [1] | 146720-1200 | SPACER BUSHING L3.3 |

| 67/48/1. | [1] | 146720-1300 | SPACER BUSHING L3.5 |

| 67/48/1. | [1] | 146720-1400 | SPACER BUSHING L2.8 |

| 67/48/1. | [1] | 146720-1500 | SPACER BUSHING L3.0 |

| 67/48/1. | [1] | 146720-1600 | SPACER BUSHING L3.2 |

| 67/48/1. | [1] | 146720-1700 | SPACER BUSHING L3.4 |

| 67/48/1. | [1] | 146720-1800 | SPACER BUSHING L3.6 |

| 67/48/1. | [1] | 146720-1900 | SPACER BUSHING L3.8 |

| 67/48/1. | [1] | 146720-2000 | SPACER BUSHING L4.0 |

| 67/48/1. | [1] | 146720-2100 | SPACER BUSHING L4.2 |

| 67/48/1. | [1] | 146720-2200 | SPACER BUSHING L4.4 |

| 67/48/1. | [1] | 146720-2300 | SPACER BUSHING L4.6 |

| 67/48/1. | [1] | 146720-2400 | SPACER BUSHING L4.8 |

| 67/48/1. | [1] | 146720-2500 | SPACER BUSHING L5.0 |

| 67/48/1. | [1] | 146720-2600 | SPACER BUSHING L5.2 |

| 67/48/1. | [1] | 146720-2700 | SPACER BUSHING L5.4 |

| 67/48/1. | [1] | 146720-2800 | SPACER BUSHING L5.5 |

| 67/48/1. | [1] | 146720-2900 | SPACER BUSHING L5.6 |

| 67/48/1. | [1] | 146720-4500 | SPACER BUSHING L1.8 |

| 67/48/1. | [1] | 146720-4600 | SPACER BUSHING L1.9 |

| 67/48/1. | [1] | 146720-4700 | SPACER BUSHING L2.0 |

| 67/48/1. | [1] | 146720-4800 | SPACER BUSHING L2.1 |

| 67/48/1. | [1] | 146720-4900 | SPACER BUSHING L2.2 |

| 67/48/1. | [1] | 146720-5000 | SPACER BUSHING L2.3 |

| 67/48/1. | [1] | 146720-5100 | SPACER BUSHING L2.4 |

| 67/48/1. | [1] | 146720-5200 | SPACER BUSHING L2.5 |

| 67/48/1. | [1] | 146720-5300 | SPACER BUSHING L2.6 |

| 67/48/1. | [1] | 146725-2500 | SPACER BUSHING L5.7 |

| 67/48/1. | [1] | 146725-2600 | SPACER BUSHING L5.8 |

| 67/48/1. | [1] | 146725-2700 | SPACER BUSHING L5.9 |

| 67/48/1. | [1] | 146725-2800 | SPACER BUSHING L6.0 |

| 67/48/1. | [1] | 146725-2900 | SPACER BUSHING L6.1 |

| 67/48/1. | [1] | 146725-3000 | SPACER BUSHING L6.2 |

| 67/48/1. | [1] | 146725-3100 | SPACER BUSHING L6.3 |

| 67/48/1. | [1] | 146725-3200 | SPACER BUSHING L6.4 |

| 67/48/1. | [1] | 146725-3300 | SPACER BUSHING L6.5 |

| 67/48/1. | [1] | 146725-3400 | SPACER BUSHING L6.6 |

| 67/48/1. | [1] | 146725-3500 | SPACER BUSHING L6.7 |

| 67/48/1. | [1] | 146725-3600 | SPACER BUSHING L6.8 |

| 67/48/1. | [1] | 146725-3700 | SPACER BUSHING L6.9 |

| 67/48/1. | [1] | 146725-3800 | SPACER BUSHING L7.0 |

| 67/48/1. | [1] | 146725-3900 | SPACER BUSHING L7.1 |

| 67/48/1. | [1] | 146725-4000 | SPACER BUSHING L7.2 |

| 67/48/1. | [1] | 146725-4100 | SPACER BUSHING L7.3 |

| 67/48/1. | [1] | 146725-4200 | SPACER BUSHING L7.4 |

| 67/48/1. | [1] | 146725-4300 | SPACER BUSHING L7.5 |

| 67/49. | [1] | 146721-1320 | COVER |

| 67/54. | [3] | 139006-4400 | BLEEDER SCREW |

| 67/55. | [1] | 020006-1440 | BLEEDER SCREW |

| 67/56. | [1] | 146723-0300 | CONTROL LEVER |

| 67/57. | [1] | 146712-0100 | BEARING PIN |

| 67/58. | [2] | 146620-0600 | CAPSULE |

| 67/59. | [2] | 026506-1040 | GASKET |

| 67/60. | [1] | 146724-0300 | ELEMENT |

| 67/61. | [1] | 146724-0600 | CAPSULE |

| 67/64. | [1] | 146626-4120 | BRACKET |

| 67/78. | [1] | 146600-4400 | SEAL RING |

| 67/200. | [1] | 139308-0300 | PLAIN WASHER |

| 67/201. | [1] | 146545-3400 | THREADED PIN L53.00 |

| 67/201B. | [1] | 146545-3500 | THREADED PIN L55.00 |

| 67/201C. | [1] | 146545-3600 | THREADED PIN L57.00 |

| 67/202. | [1] | 139208-0900 | UNION NUT |

| 67/203. | [1] | 146600-1200 | O-RING |

| 68. | [1] | 146510-5120 | CONTROL SHAFT |

| 69. | [1] | 139310-0200 | PLAIN WASHER |

| 72. | [1] | 146533-8720 | CONTROL LEVER |

| 72B. | [1] | 146533-8820 | CONTROL LEVER |

| 73. | [1] | 014110-6440 | LOCKING WASHER D12.2&6.1T1.5 |

| 75. | [1] | 013020-6040 | UNION NUT |

| 95. | [1] | 146551-3620 | FULCRUM LEVER |

| 104. | [2] | 146568-0000 | SLOTTED SPRING PIN |

| 105. | [2] | 026508-1140 | GASKET D11.4&8.2T1.0 |

| 106. | [2] | 146588-0500 | COILED SPRING |

| 107. | [1] | 146569-0300 | UNION NUT |

| 108. | [1] | 146570-0420 | GOVERNOR SHAFT |

| 109. | [1] | 146600-0400 | O-RING |

| 110/1. | [1] | 146571-0000 | SHIM D20.2&8.3T1.05 |

| 110/1. | [1] | 146571-0100 | SHIM D20.2&8.3T1.25 |

| 110/1. | [1] | 146571-0200 | SHIM D20.2&8.3T1.45 |

| 110/1. | [1] | 146571-0300 | SHIM D20.2&8.3T1.65 |

| 110/1. | [1] | 146571-0400 | SHIM D20.2&8.3T1.85 |

| 110/1. | [1] | 146571-0500 | SHIM D20.2&8.3T1.15 |

| 110/1. | [1] | 146571-0600 | SHIM D20.2&8.3T1.35 |

| 110/1. | [1] | 146571-0700 | SHIM D20.2&8.3T1.55 |

| 110/1. | [1] | 146571-0800 | SHIM D20.2&8.3T1.75 |

| 111. | [1] | 146602-0600 | PLAIN WASHER |

| 112. | [1] | 146572-0020 | FLYWEIGHT ASSEMBLY |

| 114. | [1] | 146602-0500 | PLAIN WASHER |

| 115. | [1] | 146575-2400 | SLIDING SLEEVE STAMP 24 |

| 116. | [1] | 146576-0000 | SEALING CAP |

| 117/1. | [1] | 146577-1800 | PLUG L2.10 |

| 117/1. | [1] | 146577-1900 | PLUG L2.30 |

| 117/1. | [1] | 146577-2000 | PLUG L2.50 |

| 117/1. | [1] | 146577-2100 | PLUG L2.70 |

| 117/1. | [1] | 146577-2200 | PLUG L2.90 |

| 117/1. | [1] | 146577-2300 | PLUG L3.10 |

| 117/1. | [1] | 146577-2400 | PLUG L3.30 |

| 117/1. | [1] | 146577-2500 | PLUG L3.50 |

| 117/1. | [1] | 146577-2600 | PLUG L3.70 |

| 117/1. | [1] | 146577-2700 | PLUG L3.90 |

| 117/1. | [1] | 146577-2800 | PLUG L4.10 |

| 117/1. | [1] | 146577-2900 | PLUG L4.30 |

| 117/1. | [1] | 146577-3000 | PLUG L4.50 |

| 117/1. | [1] | 146577-3100 | PLUG L4.70 |

| 117/1. | [1] | 146577-3200 | PLUG L4.90 |

| 117/1. | [1] | 146577-3300 | PLUG L5.10 |

| 117/1. | [1] | 146577-6700 | PLUG L2.2 |

| 117/1. | [1] | 146577-6800 | PLUG L2.4 |

| 117/1. | [1] | 146577-6900 | PLUG L2.6 |

| 117/1. | [1] | 146577-7000 | PLUG L2.8 |

| 117/1. | [1] | 146577-7100 | PLUG L3.0 |

| 117/1. | [1] | 146577-7200 | PLUG L3.2 |

| 117/1. | [1] | 146577-7300 | PLUG L3.4 |

| 117/1. | [1] | 146577-7400 | PLUG L3.6 |

| 117/1. | [1] | 146577-7500 | PLUG L3.8 |

| 117/1. | [1] | 146577-7600 | PLUG L4.0 |

| 117/1. | [1] | 146577-7700 | PLUG L4.2 |

| 117/1. | [1] | 146577-7800 | PLUG L4.4 |

| 117/1. | [1] | 146577-7900 | PLUG L4.6 |

| 117/1. | [1] | 146577-8000 | PLUG L4.8 |

| 117/1. | [1] | 146577-8100 | PLUG L5.0 |

| 117/1. | [1] | 146877-0000 | PLUG L5.2 |

| 117/1. | [1] | 146877-0100 | PLUG L5.3 |

| 117/1. | [1] | 146877-0200 | PLUG L5.4 |

| 117/1. | [1] | 146877-0300 | PLUG L5.5 |

| 117/1. | [1] | 146877-4700 | PLUG L5.6 |

| 117/1. | [1] | 146877-4800 | PLUG L5.7 |

| 117/1. | [1] | 146877-4900 | PLUG L5.8 |

| 117/1. | [1] | 146877-5000 | PLUG L5.9 |

| 123. | [4] | 146620-0500 | HEX-SOCKET-HEAD CAP SCREW |

| 130. | [1] | 146421-0020 | CAPSULE |

| 130/2. | [1] | 026508-1140 | GASKET D11.4&8.2T1.0 |

| 130/3. | [1] | 146422-0000 | BLEEDER SCREW |

| 130/4. | [1] | 146600-0500 | O-RING |

| 133. | [1] | 146600-0600 | O-RING |

| 134. | [1] | 146600-0700 | O-RING |

| 135. | [1] | 146110-0220 | CONTROL VALVE STAMP 02 |

| 135/5. | [1] | 146114-0000 | SPRING WASHER |

| 136. | [1] | 146120-0020 | OVER FLOW VALVE |

| 137. | [2] | 139512-0500 | GASKET |

| 138. | [1] | 146609-3221 | INLET UNION |

| 200. | [1] | 146206-0100 | COILED SPRING |

| 220. | [1] | 146587-1500 | COILED SPRING |

| 224. | [1] | 139106-0400 | FLAT-HEAD SCREW |

| 230. | [1] | 146626-2400 | BRACKET |

| 231. | [1] | 139106-0400 | FLAT-HEAD SCREW |

| 232. | [1] | 146659-2320 | CLAMPING BAND |

| 233. | [1] | 146658-9020 | WIRE |

| 234. | [3] | 139106-0500 | FLAT-HEAD SCREW |

| 234. | [3] | 139106-0500 | FLAT-HEAD SCREW |

| 234. | [3] | 139106-0500 | FLAT-HEAD SCREW |

| 235. | [1] | 146659-2400 | CLAMPING BAND |

| 236. | [1] | 146659-1420 | CLAMPING BAND |

| 240. | [1] | 146650-1220 | PULLING ELECTROMAGNET |

| 240/8. | [1] | 146600-1700 | O-RING |

| 243. | [1] | 146621-1000 | UNION NUT |

| 245. | [2] | 139512-0500 | GASKET |

| 246. | [1] | 027412-2440 | EYE BOLT |

| 247. | [1] | 146606-3320 | INLET UNION |

| 275. | [1] | 146626-2500 | BRACKET |

| 276. | [2] | 010010-1640 | BLEEDER SCREW |

| 277. | [2] | 014111-0440 | LOCKING WASHER |

| 280. | [1] | 146360-3220 | START ADVANCE ASSY |

| 281. | [1] | 146600-0800 | O-RING |

| 800S. | [1] | 146009-6220 | PUMP HOUSING |

| 800S/1/6. | [1] | 146601-0700 | PACKING RING |

| 800S/1/8. | [0] | 146616-6100 | |

| 800S/1/9. | [1] | 146616-5600 | ADAPTOR |

| 800S/1/10. | [1] | 139512-0500 | GASKET |

| 804S. | [1] | 146232-0320 | COMPRESSION SPRING |

| 805S. | [1] | 146574-0120 | PARTS SET |

| 810S. | [1] | 146600-1120 | REPAIR SET |

| 812S. | [1] | 146600-1920 | PARTS SET |

| 821S. | [1] | 146210-5720 | ROLLER SET |

| 835S. | [1] | 146598-1000 | CAP |

| 903. | [1] | 479771-0520 | PULSE GENERATOR |

| 906. | [1] | 146641-9300 | NAMEPLATE |

| 907. | [1] | 029470-4030 | WOODRUFF KEY |

| 908. | [1] | 013121-4140 | UNION NUT |

| 909. | [1] | 029321-4050 | LOCKING WASHER |

| 924. | [1] | 146680-0520 | DAMPER |

Include in #2:

104749-3050

as INJECTION-PUMP ASSEMBLY

Cross reference number

BOSCH

9 460 610 219

9460610219

ZEXEL

104749-3050

1047493050

MITSUBISHI

MD092628

md092628

Zexel num

Bosch num

Firm num

Name

104749-3050

9 460 610 219

MD092628 MITSUBISHI

INJECTION-PUMP ASSEMBLY

4D65 K

4D65 K

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113orSAEJ967d

1404 Test oil ISO4113orSAEJ967d

Test oil temperature

degC

45

45

50

Nozzle

105000-2010

Bosch type code

NP-DN12SD12TT

Nozzle holder

105780-2080

Opening pressure

MPa

14.7

14.7

15.19

Opening pressure

kgf/cm2

150

150

155

Injection pipe

Inside diameter - outside diameter - length (mm) mm 2-6-840

Inside diameter - outside diameter - length (mm) mm 2-6-840

Transfer pump pressure

kPa

20

20

20

Transfer pump pressure

kgf/cm2

0.2

0.2

0.2

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Pump speed

r/min

1250

1250

1250

Boost pressure

kPa

78.65

77.3

80

Boost pressure

mmHg

590

580

600

Average injection quantity

mm3/st.

43.8

43.3

44.3

Difference in delivery

mm3/st.

3.5

Basic

*

Injection timing adjustment_02

Pump speed

r/min

750

750

750

Boost pressure

kPa

33.35

32

34.7

Boost pressure

mmHg

250

240

260

Average injection quantity

mm3/st.

40.7

40.2

41.2

Difference in delivery

mm3/st.

3

Basic

*

Injection timing adjustment_03

Pump speed

r/min

2750

2750

2750

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

6.5

1.5

11.5

Injection timing adjustment_04

Pump speed

r/min

2250

2250

2250

Boost pressure

kPa

78.65

77.3

80

Boost pressure

mmHg

590

580

600

Average injection quantity

mm3/st.

37.7

35.2

40.2

Injection timing adjustment_05

Pump speed

r/min

1250

1250

1250

Boost pressure

kPa

78.65

77.3

80

Boost pressure

mmHg

590

580

600

Average injection quantity

mm3/st.

43.8

42.8

44.8

Injection timing adjustment_06

Pump speed

r/min

750

750

750

Boost pressure

kPa

33.35

32

34.7

Boost pressure

mmHg

250

240

260

Average injection quantity

mm3/st.

40.7

39.7

41.7

Injection timing adjustment_07

Pump speed

r/min

600

600

600

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

34.2

31.7

36.7

Injection quantity adjustment

Pump speed

r/min

2750

2750

2750

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

6.5

3.5

9.5

Basic

*

Injection quantity adjustment_02

Pump speed

r/min

3000

3000

3000

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

3

Governor adjustment

Pump speed

r/min

400

400

400

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

6.5

5

8

Difference in delivery

mm3/st.

2

Basic

*

Governor adjustment_02

Pump speed

r/min

600

600

600

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

2

Governor adjustment_03

Pump speed

r/min

400

400

400

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

6.5

4.5

8.5

Timer adjustment

Pump speed

r/min

100

100

100

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

53

43

63

Basic

*

Speed control lever angle

Pump speed

r/min

400

400

400

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

0

0

0

Remarks

Magnet OFF

Magnet OFF

0000000901

Pump speed

r/min

1250

1250

1250

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Overflow quantity

cm3/min

420

288

552

Stop lever angle

Pump speed

r/min

1250

1250

1250

Boost pressure

kPa

78.65

77.3

80

Boost pressure

mmHg

590

580

600

Pressure

kPa

470.5

441

500

Pressure

kgf/cm2

4.8

4.5

5.1

Basic

*

Stop lever angle_02

Pump speed

r/min

600

600

600

Boost pressure

kPa

78.65

77.3

80

Boost pressure

mmHg

590

580

600

Pressure

kPa

313.5

284

343

Pressure

kgf/cm2

3.2

2.9

3.5

Stop lever angle_03

Pump speed

r/min

1250

1250

1250

Boost pressure

kPa

78.65

77.3

80

Boost pressure

mmHg

590

580

600

Pressure

kPa

470.5

441

500

Pressure

kgf/cm2

4.8

4.5

5.1

Stop lever angle_04

Pump speed

r/min

2250

2250

2250

Boost pressure

kPa

78.65

77.3

80

Boost pressure

mmHg

590

580

600

Pressure

kPa

696.5

667

726

Pressure

kgf/cm2

7.1

6.8

7.4

0000001101

Pump speed

r/min

1250

1250

1250

Boost pressure

kPa

78.65

77.3

80

Boost pressure

mmHg

590

580

600

Timer stroke

mm

4.1

3.9

4.3

Basic

*

_02

Pump speed

r/min

600

600

600

Boost pressure

kPa

78.65

77.3

80

Boost pressure

mmHg

590

580

600

Timer stroke

mm

1.3

0.7

1.9

_03

Pump speed

r/min

1250

1250

1250

Boost pressure

kPa

78.65

77.3

80

Boost pressure

mmHg

590

580

600

Timer stroke

mm

4.1

3.7

4.5

_04

Pump speed

r/min

2250

2250

2250

Boost pressure

kPa

78.65

77.3

80

Boost pressure

mmHg

590

580

600

Timer stroke

mm

8.2

7.8

8.6

0000001201

Max. applied voltage

V

8

8

8

Test voltage

V

13

12

14

0000001401

Pump speed

r/min

1250

1250

1250

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

33.2

32.2

34.2

Timer stroke variation dT

mm

0.6

0.4

0.8

Basic

*

_02

Pump speed

r/min

1250

1250

1250

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

33.2

32.2

34.2

Timer stroke TA

mm

3.5

3.5

3.5

Timer stroke variation dT

mm

0.6

0.2

1

_03

Pump speed

r/min

1250

1250

1250

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

25.2

24.2

26.2

Timer stroke TA

mm

2.9

2.3

3.5

Timer stroke variation dT

mm

1.2

1.2

1.2

Timing setting

K dimension

mm

3.3

3.2

3.4

KF dimension

mm

5.8

5.7

5.9

MS dimension

mm

1

0.9

1.1

BCS stroke

mm

2.9

2.8

3

Control lever angle alpha

deg.

59

55

63

Control lever angle beta

deg.

41

36

46

Test data Ex:

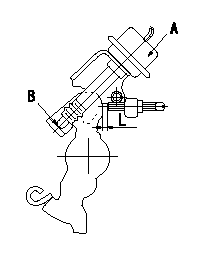

0000001801 DASHPOT ADJUSTMENT

Adjustment of the dash pot

Adjust the lever position so that the lever and the dashpot contact at a deg (L mm) from the idle lever position.

A = dashpot

b = dashpot contact point

----------

a=8+-2deg L=5.2+-1mm

----------

L=4.2~6.2mm

----------

a=8+-2deg L=5.2+-1mm

----------

L=4.2~6.2mm

0000001901 BOOST COMPENSATOR ADJUSTMENT

BCS adjustment procedure

1. At pump speed N1 and boost pressure P1 confirm that the BCS moves through its full stroke and then adjust the injection quantity.

2. At pump speed N2 and boost pressure P2, adjust the full load injection quantity using the BCS spring set screw.

----------

N1=1250r/min N2=750r/min P1=78.6kPa(590mmHg) P2=33.3kPa(250mmHg)

----------

----------

N1=1250r/min N2=750r/min P1=78.6kPa(590mmHg) P2=33.3kPa(250mmHg)

----------

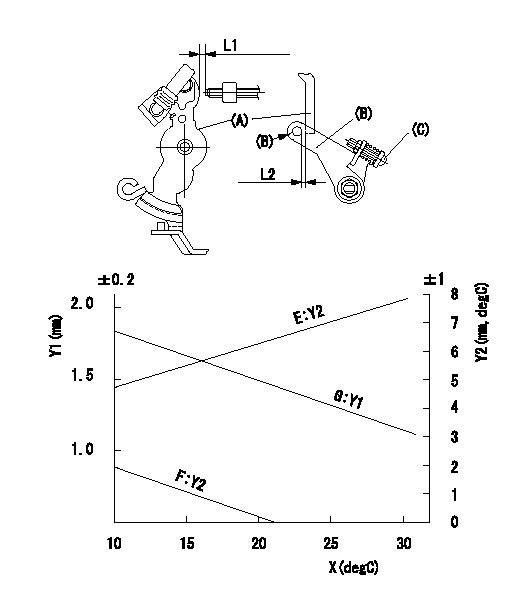

0000002001 W-CSD ADJUSTMENT

Adjustment of the W-CSD

Adjust for the ambient temperature at adjustment in accordance with the graph.

(1)Timer stroke: adjust according to graph.

(2)Fast idle (D): insert a block gauge L1 between the control lever (A) and the idle adjusting screw.

Adjust screw (C) so that clearance between the control lever (A) and the fast idle lever's pin (B) is L2 as determined from the graph.

Y1 = timer stroke

Y2 = control lever position

X = temperature

Y1 = timer stroke

Y2 = lever position

E = lever position (mm)

F = lever angle (deg)

G = timer stroke (mm)

----------

L1=5.3+-0.05mm

----------

L=5.3mm E=Y2=0.152X+4.29(mm) F=Y2=-(mm) G=Y1=-0.035X+2.2(mm)

----------

L1=5.3+-0.05mm

----------

L=5.3mm E=Y2=0.152X+4.29(mm) F=Y2=-(mm) G=Y1=-0.035X+2.2(mm)

Information:

* For the frequency and timing of cleaning, refer to the relevant instruction manual. More frequent cleaning than necessary could damage the element or cause dust and foreign matter to be sucked into the engine.* Do not strike the element or hit it against another object to remove dust.* Do not blow compressed air against outside surfaces of the element.

Inspection Procedure Inspection: Outer Element* Shine some electric light inside the element.* Replace the element if thin spots or broken parts are evident in the filter paper, or if the packing at the top of the element is damaged. Also replace the element if the dust on the element is damp with oily smoke or soot, regardless of the replacement schedule. Inspection: Operation of dust indicator under specific negative pressure * Perform the following inspection and, if faulty, replace the dust indicator.* With no vacuum applied to the dust indicator, take measurement between the terminals 1 and 2. There should be no continuity.* Gradually apply vacuum to the dust indicator. Measure the vacuum when the continuity is made between the terminals 1 and 2.Turbocharger

Removal Sequence1 Turbocharger coupler2 Gasket3 Turbocharger insulator B4 Turbocharger insulator A5 Oil return pipe6 Gasket7 Eyebolt8 Oil pipe9 Turbocharger (See later sections.)10 Gasket*a: Exhaust manifoldX: Non-reusable parts Installation SequenceFollow the removal sequence in reverse.Tightening torque (Unit: N m {kgf m} Lubricant and/or sealant Installation Procedure Installation: Turbocharger* When installing the turbocharger, pour an appropriate amount of engine oil from the oil port so that each part operates smoothly.Turbocharger Disassembly Sequence1 Hose2 Actuator3 Coupling4 Turbine housing5 Snap ring6 Compressor cover7 O-ring8 Cartridge assemblyX: Non-resusable parts Assembly SequenceFollow the disassembly sequence in reverse.Service standards (Unit: mm) Tightening torque (Unit: N m {kgf m} Lubricant and/or sealant Work Before Removal Mating Marks* Draw a line across the coupling, turbine housing, compressor cover, and cartridge assembly. This line will serve as mating marks in the installation procedure. Removal Procedure Removal: Turbine housing

* Tap all around the end of the turbine housing with a rubber hammer or a similar tool, being careful not to damage the turbine housing.* Do not let the blades of the cartridge assembly hit the turbine housing, as they are easily bent.

Removal: Compressor Cover

* Tap all around the end of the turbine housing with a rubber hammer or a similar tool, being careful not damage the turbine housing.* Do not let the blades of the cartridge assembly hit the turbine housing, as they are easily bent.

Work after Disassembly Cleaning* Before cleaning the parts, carry out a visual inspection for any marks of burns or wear that may become difficult to find after the cleaning. If any defects are evident, replace the part(s).* Immerse the disassembled parts in an inflammable solvent (a 5 to 10 aqueous solution of Oil Clean from New Hope Co., Ltd.). Take out the parts from the solvent and dry them with compressed air. If there is any solid matter remaining on the parts, remove them with a plastic scraper or a bristle brush.

*

Inspection Procedure Inspection: Outer Element* Shine some electric light inside the element.* Replace the element if thin spots or broken parts are evident in the filter paper, or if the packing at the top of the element is damaged. Also replace the element if the dust on the element is damp with oily smoke or soot, regardless of the replacement schedule. Inspection: Operation of dust indicator under specific negative pressure * Perform the following inspection and, if faulty, replace the dust indicator.* With no vacuum applied to the dust indicator, take measurement between the terminals 1 and 2. There should be no continuity.* Gradually apply vacuum to the dust indicator. Measure the vacuum when the continuity is made between the terminals 1 and 2.Turbocharger

Removal Sequence1 Turbocharger coupler2 Gasket3 Turbocharger insulator B4 Turbocharger insulator A5 Oil return pipe6 Gasket7 Eyebolt8 Oil pipe9 Turbocharger (See later sections.)10 Gasket*a: Exhaust manifoldX: Non-reusable parts Installation SequenceFollow the removal sequence in reverse.Tightening torque (Unit: N m {kgf m} Lubricant and/or sealant Installation Procedure Installation: Turbocharger* When installing the turbocharger, pour an appropriate amount of engine oil from the oil port so that each part operates smoothly.Turbocharger Disassembly Sequence1 Hose2 Actuator3 Coupling4 Turbine housing5 Snap ring6 Compressor cover7 O-ring8 Cartridge assemblyX: Non-resusable parts Assembly SequenceFollow the disassembly sequence in reverse.Service standards (Unit: mm) Tightening torque (Unit: N m {kgf m} Lubricant and/or sealant Work Before Removal Mating Marks* Draw a line across the coupling, turbine housing, compressor cover, and cartridge assembly. This line will serve as mating marks in the installation procedure. Removal Procedure Removal: Turbine housing

* Tap all around the end of the turbine housing with a rubber hammer or a similar tool, being careful not to damage the turbine housing.* Do not let the blades of the cartridge assembly hit the turbine housing, as they are easily bent.

Removal: Compressor Cover

* Tap all around the end of the turbine housing with a rubber hammer or a similar tool, being careful not damage the turbine housing.* Do not let the blades of the cartridge assembly hit the turbine housing, as they are easily bent.

Work after Disassembly Cleaning* Before cleaning the parts, carry out a visual inspection for any marks of burns or wear that may become difficult to find after the cleaning. If any defects are evident, replace the part(s).* Immerse the disassembled parts in an inflammable solvent (a 5 to 10 aqueous solution of Oil Clean from New Hope Co., Ltd.). Take out the parts from the solvent and dry them with compressed air. If there is any solid matter remaining on the parts, remove them with a plastic scraper or a bristle brush.

*

Have questions with 104749-3050?

Group cross 104749-3050 ZEXEL

Mitsubishi

104749-3050

9 460 610 219

MD092628

INJECTION-PUMP ASSEMBLY

4D65

4D65