Information injection-pump assembly

BOSCH

9 460 610 217

9460610217

ZEXEL

104749-3030

1047493030

MITSUBISHI

MD077260

md077260

Rating:

Cross reference number

BOSCH

9 460 610 217

9460610217

ZEXEL

104749-3030

1047493030

MITSUBISHI

MD077260

md077260

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113orSAEJ967d

1404 Test oil ISO4113orSAEJ967d

Test oil temperature

degC

45

45

50

Nozzle

105000-2010

Bosch type code

NP-DN12SD12TT

Nozzle holder

105780-2080

Opening pressure

MPa

14.7

14.7

15.19

Opening pressure

kgf/cm2

150

150

155

Injection pipe

Inside diameter - outside diameter - length (mm) mm 2-6-840

Inside diameter - outside diameter - length (mm) mm 2-6-840

Transfer pump pressure

kPa

20

20

20

Transfer pump pressure

kgf/cm2

0.2

0.2

0.2

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Pump speed

r/min

1250

1250

1250

Boost pressure

kPa

78.65

77.3

80

Boost pressure

mmHg

590

580

600

Average injection quantity

mm3/st.

46.8

46.3

47.3

Difference in delivery

mm3/st.

3

Basic

*

Injection timing adjustment_02

Pump speed

r/min

750

750

750

Boost pressure

kPa

33.35

32

34.7

Boost pressure

mmHg

250

240

260

Average injection quantity

mm3/st.

40.7

40.2

41.2

Difference in delivery

mm3/st.

3.5

Basic

*

Injection timing adjustment_03

Pump speed

r/min

2750

2750

2750

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

6.5

1.5

11.5

Injection timing adjustment_04

Pump speed

r/min

2250

2250

2250

Boost pressure

kPa

78.65

77.3

80

Boost pressure

mmHg

590

580

600

Average injection quantity

mm3/st.

40.7

38.2

43.2

Injection timing adjustment_05

Pump speed

r/min

1250

1250

1250

Boost pressure

kPa

78.65

77.3

80

Boost pressure

mmHg

590

580

600

Average injection quantity

mm3/st.

46.8

45.8

47.8

Injection timing adjustment_06

Pump speed

r/min

750

750

750

Boost pressure

kPa

33.35

32

34.7

Boost pressure

mmHg

250

240

260

Average injection quantity

mm3/st.

40.7

39.7

41.7

Injection timing adjustment_07

Pump speed

r/min

600

600

600

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

35.2

32.7

37.7

Injection quantity adjustment

Pump speed

r/min

2750

2750

2750

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

6.5

3.5

9.5

Basic

*

Injection quantity adjustment_02

Pump speed

r/min

3000

3000

3000

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

3

Governor adjustment

Pump speed

r/min

400

400

400

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

6.5

5

8

Difference in delivery

mm3/st.

2

Basic

*

Governor adjustment_02

Pump speed

r/min

600

600

600

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

2

Governor adjustment_03

Pump speed

r/min

400

400

400

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

6.5

4.5

8.5

Timer adjustment

Pump speed

r/min

100

100

100

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

53

43

63

Basic

*

Speed control lever angle

Pump speed

r/min

400

400

400

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

0

0

0

Remarks

Magnet OFF

Magnet OFF

0000000901

Pump speed

r/min

1250

1250

1250

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Overflow quantity

cm3/min

420

288

552

Stop lever angle

Pump speed

r/min

1250

1250

1250

Boost pressure

kPa

78.65

77.3

80

Boost pressure

mmHg

590

580

600

Pressure

kPa

470.5

441

500

Pressure

kgf/cm2

4.8

4.5

5.1

Basic

*

Stop lever angle_02

Pump speed

r/min

600

600

600

Boost pressure

kPa

78.65

77.3

80

Boost pressure

mmHg

590

580

600

Pressure

kPa

313.5

284

343

Pressure

kgf/cm2

3.2

2.9

3.5

Stop lever angle_03

Pump speed

r/min

1250

1250

1250

Boost pressure

kPa

78.65

77.3

80

Boost pressure

mmHg

590

580

600

Pressure

kPa

470.5

441

500

Pressure

kgf/cm2

4.8

4.5

5.1

Stop lever angle_04

Pump speed

r/min

2250

2250

2250

Boost pressure

kPa

78.65

77.3

80

Boost pressure

mmHg

590

580

600

Pressure

kPa

696.5

667

726

Pressure

kgf/cm2

7.1

6.8

7.4

0000001101

Pump speed

r/min

1250

1250

1250

Boost pressure

kPa

78.65

77.3

80

Boost pressure

mmHg

590

580

600

Timer stroke

mm

4.1

3.9

4.3

Basic

*

_02

Pump speed

r/min

600

600

600

Boost pressure

kPa

78.65

77.3

80

Boost pressure

mmHg

590

580

600

Timer stroke

mm

1.3

0.7

1.9

_03

Pump speed

r/min

1250

1250

1250

Boost pressure

kPa

78.65

77.3

80

Boost pressure

mmHg

590

580

600

Timer stroke

mm

4.1

3.7

4.5

_04

Pump speed

r/min

2250

2250

2250

Boost pressure

kPa

78.65

77.3

80

Boost pressure

mmHg

590

580

600

Timer stroke

mm

8.2

7.8

8.6

0000001201

Max. applied voltage

V

8

8

8

Test voltage

V

13

12

14

0000001401

Pump speed

r/min

1250

1250

1250

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

33.2

32.2

34.2

Timer stroke variation dT

mm

0.6

0.4

0.8

Basic

*

_02

Pump speed

r/min

1250

1250

1250

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

33.2

32.2

34.2

Timer stroke TA

mm

3.5

3.5

3.5

Timer stroke variation dT

mm

0.6

0.2

1

_03

Pump speed

r/min

1250

1250

1250

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

25.2

24.2

26.2

Timer stroke TA

mm

2.9

2.3

3.5

Timer stroke variation dT

mm

1.2

1.2

1.2

Timing setting

K dimension

mm

3.3

3.2

3.4

KF dimension

mm

5.8

5.7

5.9

MS dimension

mm

1

0.9

1.1

BCS stroke

mm

3.6

3.5

3.7

Control lever angle alpha

deg.

59

55

63

Control lever angle beta

deg.

41

38

44

Test data Ex:

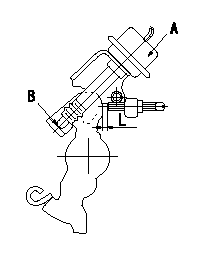

0000001801 DASHPOT ADJUSTMENT

Adjustment of the dash pot

Adjust the lever position so that the lever and the dashpot contact at a deg (L mm) from the idle lever position.

A = dashpot

b = dashpot contact point

----------

a=8+-2deg L=5.2+-1mm

----------

L=4.2~6.2mm

----------

a=8+-2deg L=5.2+-1mm

----------

L=4.2~6.2mm

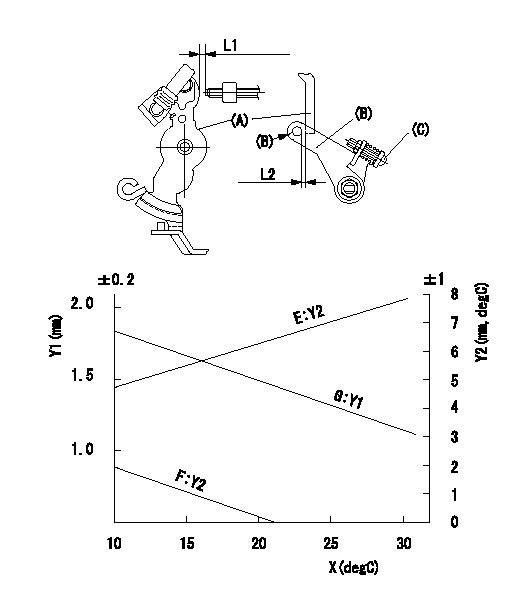

0000001901 W-CSD ADJUSTMENT

Adjustment of the W-CSD

Adjust for the ambient temperature at adjustment in accordance with the graph.

(1)Timer stroke: adjust according to graph.

(2)Fast idle (D): insert a block gauge L1 between the control lever (A) and the idle adjusting screw.

Adjust screw (C) so that clearance between the control lever (A) and the fast idle lever's pin (B) is L2 as determined from the graph.

Y1 = timer stroke

Y2 = control lever position

X = temperature

Y1 = timer stroke

Y2 = lever position

E = lever position (mm)

F = lever angle (deg)

G = timer stroke (mm)

----------

L1=5.3+-0.05mm

----------

L=5.3mm E=Y2=0.152X+4.29(mm) F=Y2=-(mm) G=Y1=-0.035X+2.2(mm)

----------

L1=5.3+-0.05mm

----------

L=5.3mm E=Y2=0.152X+4.29(mm) F=Y2=-(mm) G=Y1=-0.035X+2.2(mm)

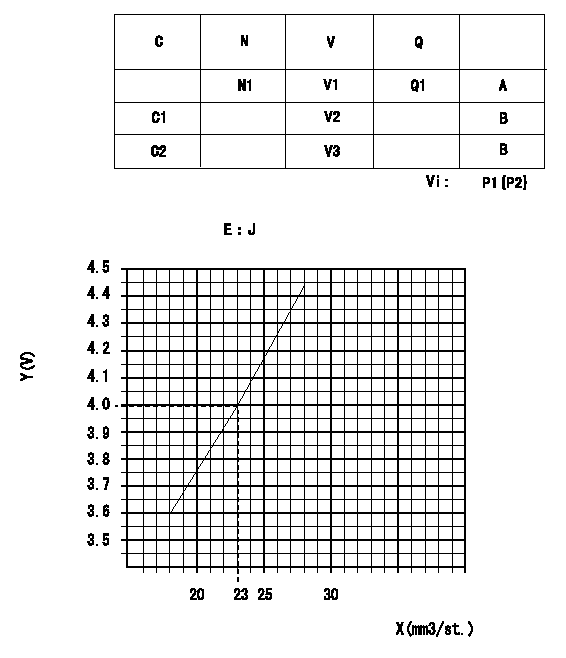

0000002001 POTENTIOMETER ADJUSTMENT

Adjustment of the potentiometer

In the following condition, change the installation position of the potentiometer to adjust the output voltage to within the specified values.

At N (pump speed) = N1 r/min and control lever position a (corresponding to shim thickness L mm), measure the injection quantity, calculate the voltage using the formula and adjust the potentiometer.

Vi:Applied voltage

C:Position of the control lever

N:Pump speed (r/min)

V:Output voltage (V)

Q:Injection quantity (mm3/st)

A:Adjusting point

B:Checking point

C1:Idle

C2:Full speed

P1:Boost pressure

P2:Boost pressure

E:Conversion formula

X:Injection quantity Q (cm3/1,000st)

Y:Voltage (V)

----------

N1=1000r/min a=19deg L=12.1mm

----------

N1=1000r/min V1=4+-0.03V V2=0.8+-0.7V V3=7.7+-1.2V Q1=22.9cm3/1,000st Vi=10V P1=-kPa P2=-mmHg J=V+-0.03=0.0856Q+2.04

----------

N1=1000r/min a=19deg L=12.1mm

----------

N1=1000r/min V1=4+-0.03V V2=0.8+-0.7V V3=7.7+-1.2V Q1=22.9cm3/1,000st Vi=10V P1=-kPa P2=-mmHg J=V+-0.03=0.0856Q+2.04

0000002101 BOOST COMPENSATOR ADJUSTMENT

BCS adjustment procedure

1. At pump speed N1 and boost pressure P1 confirm that the BCS moves through its full stroke and then adjust the injection quantity.

2. At pump speed N2 and boost pressure P2, adjust the full load injection quantity using the BCS spring set screw.

----------

N1=1250r/min N2=750r/min P1=78.6kPa(590mmHg) P2=33.3kPa(250mmHg)

----------

----------

N1=1250r/min N2=750r/min P1=78.6kPa(590mmHg) P2=33.3kPa(250mmHg)

----------

Information:

* Remove any carbon deposits from the injection nozzles before disassembling, assembling, or adjusting the injection nozzle assembly. Before disassembling, check the pressure and shape of the spray and inspect the assembly for fuel leakage. Do not disassemble if no defects are evident.* Do not change the needle valve and nozzle combination on each cylinder.

* Assembly sequenceFollow the disassembly sequence in reverse.Service standards Tightening torque (Unit: N m {kgf m}) Special tools (Unit: mm) Inspection before removal

Inspection: Injection nozzle* Connect the injection nozzle to the nozzle tester and carry out the following inspections.

* Before starting the inspections, operate the lever on the nozzle tester two or three times to bleed out all the air.

(1) Checking the valve opening pressure* Push down the lever on the nozzle tester at a rate of one to two seconds per stroke. This will cause the pressure gauge reading to rise gradually, and the needle will suddenly deflect. Note the pressure at which the needle starts to deflect. * If the measurement is out of the standard value range, disassemble the nozzle, clean it, and then adjust it using an adjusting shim.* Available adjusting shims (thickness): 1.2 mm to 1.7 mm (11 different thicknesses in increments of 0.05 mm)* If the valve opening pressure is still incorrect after the adjustment, replace the injection nozzle assembly.

* Do not touch the spray that comes out of the nozzle.

(2) Inspecting the spray condition * Pump the lever on the nozzle at a rate of about one to two seconds per stroke and keep it spraying continuously.A Spray in the form of straight line (Good: spray angle at 10° or less)B Spray angle too large (Bad)C Spray deviates from centerline (Bad)D Irregular spray (Bad)

* Do not touch the spray that comes out of the nozzle.

* Check that no fuel drips from the nozzle after the spray is complete.* If defects are evident, disassemble and clean the injection nozzle, and then inspect its spray condition once again.* If defects persist after reinspection, replace the injection nozzle assembly.(3) Checking for leakage * Decrease the nozzle pressure to a pressure 1960 kPa {20 kgf/cm2} lower than the first valve opening pressure. Maintain this pressure for 10 seconds and check that no fuel drips from the end of the nozzle.* If fuel drips are evident, disassemble and clean the injection nozzle, and then perform a leakage test once again.* If leakage is detected during the reinspection, replace the injection nozzle assembly.Removal procedure

Removal: Injection nozzle

* Do not touch the sliding surfaces of the needle valve. If you accidentally touch it, clean it with a cleaning fluid (such as gas oil).* Do not change the needle valve and nozzle combination on each cylinder.

Cleaning procedure

Cleaning: Injection nozzle* Wash the needle valve and nozzle in a cleaning fluid (such as gas oil), then use

to remove any carbon deposits according to the following procedure. * Remove carbon deposits from the tip of the needle valve using the clean bar of

.

* Do not use a wire brush

* Assembly sequenceFollow the disassembly sequence in reverse.Service standards Tightening torque (Unit: N m {kgf m}) Special tools (Unit: mm) Inspection before removal

Inspection: Injection nozzle* Connect the injection nozzle to the nozzle tester and carry out the following inspections.

* Before starting the inspections, operate the lever on the nozzle tester two or three times to bleed out all the air.

(1) Checking the valve opening pressure* Push down the lever on the nozzle tester at a rate of one to two seconds per stroke. This will cause the pressure gauge reading to rise gradually, and the needle will suddenly deflect. Note the pressure at which the needle starts to deflect. * If the measurement is out of the standard value range, disassemble the nozzle, clean it, and then adjust it using an adjusting shim.* Available adjusting shims (thickness): 1.2 mm to 1.7 mm (11 different thicknesses in increments of 0.05 mm)* If the valve opening pressure is still incorrect after the adjustment, replace the injection nozzle assembly.

* Do not touch the spray that comes out of the nozzle.

(2) Inspecting the spray condition * Pump the lever on the nozzle at a rate of about one to two seconds per stroke and keep it spraying continuously.A Spray in the form of straight line (Good: spray angle at 10° or less)B Spray angle too large (Bad)C Spray deviates from centerline (Bad)D Irregular spray (Bad)

* Do not touch the spray that comes out of the nozzle.

* Check that no fuel drips from the nozzle after the spray is complete.* If defects are evident, disassemble and clean the injection nozzle, and then inspect its spray condition once again.* If defects persist after reinspection, replace the injection nozzle assembly.(3) Checking for leakage * Decrease the nozzle pressure to a pressure 1960 kPa {20 kgf/cm2} lower than the first valve opening pressure. Maintain this pressure for 10 seconds and check that no fuel drips from the end of the nozzle.* If fuel drips are evident, disassemble and clean the injection nozzle, and then perform a leakage test once again.* If leakage is detected during the reinspection, replace the injection nozzle assembly.Removal procedure

Removal: Injection nozzle

* Do not touch the sliding surfaces of the needle valve. If you accidentally touch it, clean it with a cleaning fluid (such as gas oil).* Do not change the needle valve and nozzle combination on each cylinder.

Cleaning procedure

Cleaning: Injection nozzle* Wash the needle valve and nozzle in a cleaning fluid (such as gas oil), then use

to remove any carbon deposits according to the following procedure. * Remove carbon deposits from the tip of the needle valve using the clean bar of

.

* Do not use a wire brush