Information injection-pump assembly

BOSCH

9 460 610 079

9460610079

ZEXEL

104749-3010

1047493010

MITSUBISHI

MD077258

md077258

Rating:

Cross reference number

BOSCH

9 460 610 079

9460610079

ZEXEL

104749-3010

1047493010

MITSUBISHI

MD077258

md077258

Zexel num

Bosch num

Firm num

Name

9 460 610 079

MD077258 MITSUBISHI

INJECTION-PUMP ASSEMBLY

4D6 K 11CJ INJECTION PUMP ASSY VE4 VE

4D6 K 11CJ INJECTION PUMP ASSY VE4 VE

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113orSAEJ967d

1404 Test oil ISO4113orSAEJ967d

Test oil temperature

degC

45

45

50

Nozzle

105000-2010

Bosch type code

NP-DN12SD12TT

Nozzle holder

105780-2080

Opening pressure

MPa

14.7

14.7

15.19

Opening pressure

kgf/cm2

150

150

155

Injection pipe

Inside diameter - outside diameter - length (mm) mm 2-6-840

Inside diameter - outside diameter - length (mm) mm 2-6-840

Transfer pump pressure

kPa

20

20

20

Transfer pump pressure

kgf/cm2

0.2

0.2

0.2

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Pump speed

r/min

1250

1250

1250

Boost pressure

kPa

78.65

77.3

80

Boost pressure

mmHg

590

580

600

Average injection quantity

mm3/st.

46.8

46.3

47.3

Difference in delivery

mm3/st.

3

Basic

*

Injection timing adjustment_02

Pump speed

r/min

750

750

750

Boost pressure

kPa

33.35

32

34.7

Boost pressure

mmHg

250

240

260

Average injection quantity

mm3/st.

40.7

40.2

41.2

Difference in delivery

mm3/st.

3

Basic

*

Injection timing adjustment_03

Pump speed

r/min

2750

2750

2750

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

6.5

1.5

11.5

Injection timing adjustment_04

Pump speed

r/min

2250

2250

2250

Boost pressure

kPa

78.65

77.3

80

Boost pressure

mmHg

590

580

600

Average injection quantity

mm3/st.

40.7

38.2

43.2

Injection timing adjustment_05

Pump speed

r/min

1250

1250

1250

Boost pressure

kPa

78.65

77.3

80

Boost pressure

mmHg

590

580

600

Average injection quantity

mm3/st.

46.8

45.8

47.8

Injection timing adjustment_06

Pump speed

r/min

750

750

750

Boost pressure

kPa

33.35

32

34.7

Boost pressure

mmHg

250

240

260

Average injection quantity

mm3/st.

40.7

39.7

41.7

Injection timing adjustment_07

Pump speed

r/min

600

600

600

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

35.2

32.7

37.7

Injection quantity adjustment

Pump speed

r/min

2750

2750

2750

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

6.5

3.5

9.5

Difference in delivery

mm3/st.

2

Basic

*

Injection quantity adjustment_02

Pump speed

r/min

3000

3000

3000

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

3

Governor adjustment

Pump speed

r/min

400

400

400

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

6.5

5

8

Difference in delivery

mm3/st.

2

Basic

*

Governor adjustment_02

Pump speed

r/min

600

600

600

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

2

Governor adjustment_03

Pump speed

r/min

400

400

400

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

6.5

4.5

8.5

Timer adjustment

Pump speed

r/min

100

100

100

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

53

43

63

Basic

*

Speed control lever angle

Pump speed

r/min

400

400

400

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

0

0

0

Remarks

Magnet OFF

Magnet OFF

0000000901

Pump speed

r/min

1250

1250

1250

Boost pressure

kPa

78.65

77.3

80

Boost pressure

mmHg

590

580

600

Overflow quantity

cm3/min

420

288

552

Stop lever angle

Pump speed

r/min

1250

1250

1250

Boost pressure

kPa

78.65

77.3

80

Boost pressure

mmHg

590

580

600

Pressure

kPa

470.5

441

500

Pressure

kgf/cm2

4.8

4.5

5.1

Basic

*

Stop lever angle_02

Pump speed

r/min

600

600

600

Boost pressure

kPa

78.65

77.3

80

Boost pressure

mmHg

590

580

600

Pressure

kPa

313.5

284

343

Pressure

kgf/cm2

3.2

2.9

3.5

Stop lever angle_03

Pump speed

r/min

1250

1250

1250

Boost pressure

kPa

78.65

77.3

80

Boost pressure

mmHg

590

580

600

Pressure

kPa

470.5

441

500

Pressure

kgf/cm2

4.8

4.5

5.1

Stop lever angle_04

Pump speed

r/min

2250

2250

2250

Boost pressure

kPa

78.65

77.3

80

Boost pressure

mmHg

590

580

600

Pressure

kPa

696.5

667

726

Pressure

kgf/cm2

7.1

6.8

7.4

0000001101

Pump speed

r/min

1250

1250

1250

Boost pressure

kPa

78.65

77.3

80

Boost pressure

mmHg

590

580

600

Timer stroke

mm

4.1

3.9

4.3

Basic

*

_02

Pump speed

r/min

600

600

600

Boost pressure

kPa

78.65

77.3

80

Boost pressure

mmHg

590

580

600

Timer stroke

mm

1.3

0.7

1.9

_03

Pump speed

r/min

1250

1250

1250

Boost pressure

kPa

78.65

77.3

80

Boost pressure

mmHg

590

580

600

Timer stroke

mm

4.1

3.7

4.5

_04

Pump speed

r/min

1750

1750

1750

Boost pressure

kPa

78.65

77.3

80

Boost pressure

mmHg

590

580

600

Timer stroke

mm

6.2

5.6

6.8

_05

Pump speed

r/min

2250

2250

2250

Boost pressure

kPa

78.65

77.3

80

Boost pressure

mmHg

590

580

600

Timer stroke

mm

8.2

7.6

8.8

0000001201

Max. applied voltage

V

8

8

8

Test voltage

V

13

12

14

0000001401

Pump speed

r/min

1250

1250

1250

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

33.2

32.2

34.2

Timer stroke variation dT

mm

0.6

0.4

0.8

Basic

*

_02

Pump speed

r/min

1250

1250

1250

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

33.2

31.7

34.7

Timer stroke TA

mm

3.5

3.5

3.5

Timer stroke variation dT

mm

0.6

0.2

1

_03

Pump speed

r/min

1250

1250

1250

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

25.2

23.7

26.7

Timer stroke TA

mm

2.9

2.3

3.5

Timer stroke variation dT

mm

1.2

1.2

1.2

Timing setting

K dimension

mm

3.3

3.2

3.4

KF dimension

mm

5.8

5.7

5.9

MS dimension

mm

1

0.9

1.1

BCS stroke

mm

3.6

3.5

3.7

Control lever angle alpha

deg.

59

55

63

Control lever angle beta

deg.

41

36

46

Test data Ex:

0000001601 BCS ADJUSTMENT

BCS adjustment procedure

1. At pump speed N1 and boost pressure P1 confirm that the BCS moves through its full stroke and then adjust the injection quantity.

2. At pump speed N2 and boost pressure P2, adjust the full load injection quantity using the BCS spring set screw.

----------

N1=1250r/min N2=750r/min P1=78.6kPa(590mmHg) P2=33.3kPa(250mmHg)

----------

----------

N1=1250r/min N2=750r/min P1=78.6kPa(590mmHg) P2=33.3kPa(250mmHg)

----------

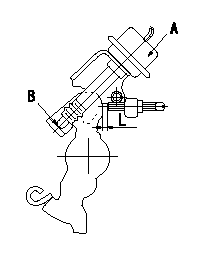

0000001801 DASHPOT ADJUSTMENT

Adjustment of the dash pot

Adjust the lever position so that the lever and the dashpot contact at a deg (L mm) from the idle lever position.

A = dashpot

b = dashpot contact point

----------

a=12+-2deg L=7.6+-1mm

----------

L=7.6+-1mm

----------

a=12+-2deg L=7.6+-1mm

----------

L=7.6+-1mm

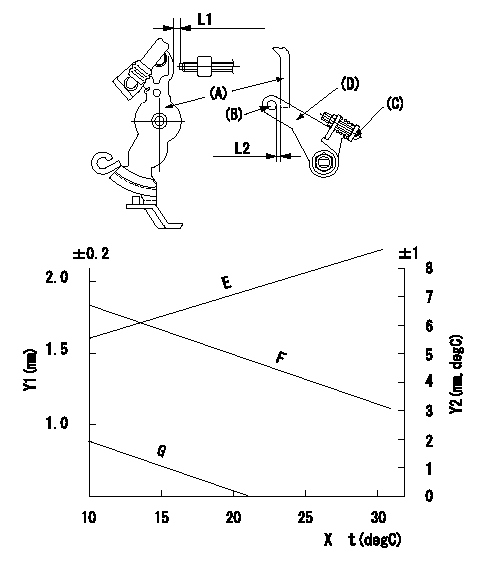

0000001901 W-CSD ADJUSTMENT

Adjustment of the W-CSD

Adjust for the ambient temperature at adjustment in accordance with the graph.

(1)adjust according to graph.

(2)Insert a block gauge L1 between the control lever (A) and the idle adjusting screw.

(3)Adjust screw (C) so that clearance between the control lever and the fast idle lever(D)'s pin (B) is L2 as determined from the graph.

Y1 = timer stroke

Y2 = control lever position

X = temperature t

Y1 = timer stroke (mm)

Y2 = lever position (mm)

Graph E=0.152t+4.29

Graph F=-0.035t+2.2

G=-

----------

L1=5.3+-0.05mm

----------

----------

L1=5.3+-0.05mm

----------

Information:

* Be sure to orient the oil grooves as indicated above, otherwise seizures may occur in the engine.

* Use oversize thrust plates when adjusting the crankshaft end play. The upper and lower thrust plates on the same side must be of the same size. The thrust plates on one side may differ in size from those on the other side. Installation: Main bearings

* The upper main bearing has an oil hole while the lower main bearing does not. Do not confuse the two, as incorrect installation can cause seizures in the engine.

* Select and use a main bearing set of a thickness that can accommodate the inside diameter of each main bearing fitting hole between the upper crankcase and lower crankcase and the diameter of the corresponding crankshaft journal. Select the appropriate main bearing set by one of the two following methods.(1) Measurement based selection* Mount the upper crankcase on the lower crankcase without fitting main bearings. * Tighten the main cap bolts to 20 N m {2.0 kgf m}.* Measure the inside diameter of the main bearing fitting hole between the upper crankcase and lower crankcase (vertically from one point), and the diameter of the crankshaft journal (vertically or horizontally from one point).* Select a main bearing set that matches the measurements from the table below. If the color identification mark is indiscernible, measure the thickness of the bearing walls and use the measurements in its place. (Unit: mm) (2) Color identification mark based method* The crankshaft, upper crankcase, and main bearing can be appropriately combined in the following ways according to their color identification marks: No. 1: Position of color identification mark on No. 1 journalNo. 2: Position of color identification mark on No. 2 journalNo. 3: Position of color identification mark on No. 3 journalNo. 4: Position of color identification mark on No. 4 journalNo. 5: Position of color identification mark on No. 5 journal Installation: Lower crankcase

* Before installing the main cap bolt, check the punch marks on each bolt's head. (Bolts with one or two punch marks can be reused.)* The punch marks indicate the number of times each main cap bolt has been tightened using the torque-turn tightening method. Any main cap bolt that already has three punch marks must be replaced.

* Clean the sealant application surfaces of each part. * Apply a bead of sealant to the upper crankcase evenly and without any breaks as shown in the illustration.* Install the lower crankcase within three minutes of applying the sealant to the upper crankcase, being careful not to dislodge the sealant.* Apply engine oil to the threads and seating surface under the head of each of the main cap bolts, and tighten the bolts to a torque of 20 N m {2.0 kgf m} in the order indicated in the illustration (1 to 10). * Then, tighten the main cap bolts further by 90 degrees in the same order.* Tighten them by another 90 degrees in the same order.* After completing

* Use oversize thrust plates when adjusting the crankshaft end play. The upper and lower thrust plates on the same side must be of the same size. The thrust plates on one side may differ in size from those on the other side. Installation: Main bearings

* The upper main bearing has an oil hole while the lower main bearing does not. Do not confuse the two, as incorrect installation can cause seizures in the engine.

* Select and use a main bearing set of a thickness that can accommodate the inside diameter of each main bearing fitting hole between the upper crankcase and lower crankcase and the diameter of the corresponding crankshaft journal. Select the appropriate main bearing set by one of the two following methods.(1) Measurement based selection* Mount the upper crankcase on the lower crankcase without fitting main bearings. * Tighten the main cap bolts to 20 N m {2.0 kgf m}.* Measure the inside diameter of the main bearing fitting hole between the upper crankcase and lower crankcase (vertically from one point), and the diameter of the crankshaft journal (vertically or horizontally from one point).* Select a main bearing set that matches the measurements from the table below. If the color identification mark is indiscernible, measure the thickness of the bearing walls and use the measurements in its place. (Unit: mm) (2) Color identification mark based method* The crankshaft, upper crankcase, and main bearing can be appropriately combined in the following ways according to their color identification marks: No. 1: Position of color identification mark on No. 1 journalNo. 2: Position of color identification mark on No. 2 journalNo. 3: Position of color identification mark on No. 3 journalNo. 4: Position of color identification mark on No. 4 journalNo. 5: Position of color identification mark on No. 5 journal Installation: Lower crankcase

* Before installing the main cap bolt, check the punch marks on each bolt's head. (Bolts with one or two punch marks can be reused.)* The punch marks indicate the number of times each main cap bolt has been tightened using the torque-turn tightening method. Any main cap bolt that already has three punch marks must be replaced.

* Clean the sealant application surfaces of each part. * Apply a bead of sealant to the upper crankcase evenly and without any breaks as shown in the illustration.* Install the lower crankcase within three minutes of applying the sealant to the upper crankcase, being careful not to dislodge the sealant.* Apply engine oil to the threads and seating surface under the head of each of the main cap bolts, and tighten the bolts to a torque of 20 N m {2.0 kgf m} in the order indicated in the illustration (1 to 10). * Then, tighten the main cap bolts further by 90 degrees in the same order.* Tighten them by another 90 degrees in the same order.* After completing