Information injection-pump assembly

BOSCH

9 460 610 078

9460610078

ZEXEL

104749-3000

1047493000

MITSUBISHI

MD074608

md074608

Rating:

Cross reference number

BOSCH

9 460 610 078

9460610078

ZEXEL

104749-3000

1047493000

MITSUBISHI

MD074608

md074608

Zexel num

Bosch num

Firm num

Name

104749-3000

9 460 610 078

MD074608 MITSUBISHI

INJECTION-PUMP ASSEMBLY

4D6 K

4D6 K

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113orSAEJ967d

1404 Test oil ISO4113orSAEJ967d

Test oil temperature

degC

45

45

50

Nozzle

105000-2010

Bosch type code

NP-DN12SD12TT

Nozzle holder

105780-2080

Opening pressure

MPa

14.7

14.7

15.19

Opening pressure

kgf/cm2

150

150

155

Injection pipe

Inside diameter - outside diameter - length (mm) mm 2-6-840

Inside diameter - outside diameter - length (mm) mm 2-6-840

Transfer pump pressure

kPa

20

20

20

Transfer pump pressure

kgf/cm2

0.2

0.2

0.2

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Pump speed

r/min

1250

1250

1250

Average injection quantity

mm3/st.

34.7

34.2

35.2

Difference in delivery

mm3/st.

3

Basic

*

Injection timing adjustment_02

Pump speed

r/min

600

600

600

Average injection quantity

mm3/st.

30.7

28.7

32.7

Injection timing adjustment_03

Pump speed

r/min

1250

1250

1250

Average injection quantity

mm3/st.

34.7

33.7

35.7

Injection timing adjustment_04

Pump speed

r/min

2250

2250

2250

Average injection quantity

mm3/st.

31.2

29.2

33.2

Injection timing adjustment_05

Pump speed

r/min

2750

2750

2750

Average injection quantity

mm3/st.

6.5

1.5

11.5

Injection quantity adjustment

Pump speed

r/min

2750

2750

2750

Average injection quantity

mm3/st.

6.5

3.5

9.5

Difference in delivery

mm3/st.

2

Basic

*

Injection quantity adjustment_02

Pump speed

r/min

3000

3000

3000

Average injection quantity

mm3/st.

3

Governor adjustment

Pump speed

r/min

375

375

375

Average injection quantity

mm3/st.

6.5

5

8

Difference in delivery

mm3/st.

2

Basic

*

Governor adjustment_02

Pump speed

r/min

375

375

375

Average injection quantity

mm3/st.

8

6

10

Governor adjustment_03

Pump speed

r/min

600

600

600

Average injection quantity

mm3/st.

3

Timer adjustment

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

53

43

63

Basic

*

Speed control lever angle

Pump speed

r/min

375

375

375

Average injection quantity

mm3/st.

0

0

0

Remarks

Magnet OFF

Magnet OFF

0000000901

Pump speed

r/min

1250

1250

1250

Overflow quantity

cm3/min

420

288

552

Stop lever angle

Pump speed

r/min

1250

1250

1250

Pressure

kPa

470.5

441

500

Pressure

kgf/cm2

4.8

4.5

5.1

Basic

*

Stop lever angle_02

Pump speed

r/min

600

600

600

Pressure

kPa

313.5

284

343

Pressure

kgf/cm2

3.2

2.9

3.5

Stop lever angle_03

Pump speed

r/min

1250

1250

1250

Pressure

kPa

470.5

441

500

Pressure

kgf/cm2

4.8

4.5

5.1

Stop lever angle_04

Pump speed

r/min

2250

2250

2250

Pressure

kPa

696.5

667

726

Pressure

kgf/cm2

7.1

6.8

7.4

0000001101

Pump speed

r/min

1250

1250

1250

Timer stroke

mm

4.3

4.1

4.5

Basic

*

_02

Pump speed

r/min

600

600

600

Timer stroke

mm

1.3

0.7

1.9

_03

Pump speed

r/min

1250

1250

1250

Timer stroke

mm

4.3

3.9

4.7

_04

Pump speed

r/min

2250

2250

2250

Timer stroke

mm

8.5

8

9

0000001201

Max. applied voltage

V

8

8

8

Test voltage

V

13

12

14

0000001401

Pump speed

r/min

1250

1250

1250

Average injection quantity

mm3/st.

21.6

20.6

22.6

Timer stroke variation dT

mm

0.5

0.3

0.7

Basic

*

_02

Pump speed

r/min

1250

1250

1250

Average injection quantity

mm3/st.

21.6

20.1

23.1

Timer stroke TA

mm

3.8

3.8

3.8

Timer stroke variation dT

mm

0.5

0.1

0.9

_03

Pump speed

r/min

1250

1250

1250

Average injection quantity

mm3/st.

11.6

10.1

13.1

Timer stroke TA

mm

3.1

2.5

3.7

Timer stroke variation dT

mm

1.2

1.2

1.2

Timing setting

K dimension

mm

3.3

3.2

3.4

KF dimension

mm

5.8

5.7

5.9

MS dimension

mm

1.4

1.3

1.5

Control lever angle alpha

deg.

59

55

63

Control lever angle beta

deg.

41

36

46

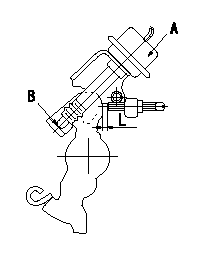

Test data Ex:

0000001801 DASHPOT ADJUSTMENT

Adjustment of the dash pot

Adjust the lever position so that the lever and the dashpot contact at a deg (L mm) from the idle lever position.

A = dashpot

b = dashpot contact point

----------

a=10+-2deg L=6.3+-1mm

----------

L=6.3mm

----------

a=10+-2deg L=6.3+-1mm

----------

L=6.3mm

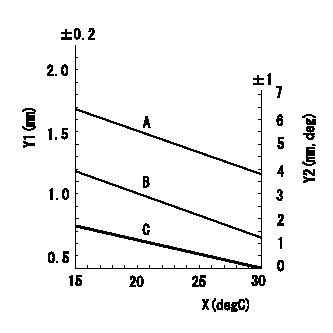

0000001901 W-CSD ADJUSTMENT

Adjustment of the W-CSD

Adjust the timer stroke and the control lever position for the ambient temperature at adjustment in accordance with the figure below.

Y1 = timer stroke

Y2 = control lever position

X = temperature

A = timer stroke

B = lever position

----------

----------

----------

----------

Information:

Precautions for Electrical System

* Before working on the electrical system, disconnect the (-) battery cable to prevent short circuits.

* Make sure the electrical equipment is OFF before disconnecting or connecting battery cable. Semiconductor components may otherwise be damaged.

* Carefully handle sensors relays, and other items that are sensitive to shock and heat. * When applying a voltage to a part for inspection purposes, check that the (+) and (-) cables are connected properly then gradually increase the voltage from zero. Do not exceed the specified voltage. Remember that sensors do not necessarily operate on the battery voltage. * When separating connectors, grasp the connectors themselves rather than the harnesses. * To separate locking connectors, first push them in the direction of the arrows. To reconnect locking connectors, push them together until they click.* Before washing the parts, cover electrical parts to keep them dry. (Use plastic sheets or the like.) Keep water away from harness connectors and sensors and immediately wipe off any water that gets on them. Handling precautions for electric circuits

* Do not pierce wire insulation with test probes or alligator clips when performing electrical inspections. Doing so can, particularly with the chassis harness, hasten corrosion.

(1) Inspection of harnesses (1.1) Inspections with connectors fitted together* Waterproof connectors* Connect an inspection harness and connector. A between the connectors B of the circuit to be inspected. Perform the inspection by applying a test probe C to the connectors of the inspection harness. Do not insert the test probe C into the wire-entry sides of the waterproof connectors since this would damage their waterproof seals and lead to rust. * Non-waterproof connectors* Perform the inspection by inserting a test probe C into the wire-entry sides of the connectors. An extra-narrow probe is required for control unit connectors, which are smaller than other types of connector. Do not force a regular-size probe into control unit connectors since this would cause damage. (1.2) Inspections with connectors separated* Inspections on female terminals* Perform the inspection by carefully inserting a test probe into the terminals. Do not force the test probe into the terminals since this could deform them and cause poor connections. * Inspections on male terminals* Perform the inspection by applying test probes directly to the pins.

* Be careful not to short-circuit pins together with the test probes. With control unit connectors, short-circuiting of pins can cause damage to the control unit's internal circuitry.

* When using a multimeter to check continuity, do not allow the test probes to touch the wrong terminals. (2) Inspection of connectors (2.1) Visual inspection* Check that the connectors are fitted together securely. * Check whether wires have been separated from their terminals due to pulling of the harness. * Check that male and female terminals fit together tightly. * Check for defective connections caused by loose terminals, by rust on terminals, or by contamination of terminals by foreign substances. (2.2) Checking for loose terminals* If connector terminal retainers become damaged, male and female terminals may not

* Before working on the electrical system, disconnect the (-) battery cable to prevent short circuits.

* Make sure the electrical equipment is OFF before disconnecting or connecting battery cable. Semiconductor components may otherwise be damaged.

* Carefully handle sensors relays, and other items that are sensitive to shock and heat. * When applying a voltage to a part for inspection purposes, check that the (+) and (-) cables are connected properly then gradually increase the voltage from zero. Do not exceed the specified voltage. Remember that sensors do not necessarily operate on the battery voltage. * When separating connectors, grasp the connectors themselves rather than the harnesses. * To separate locking connectors, first push them in the direction of the arrows. To reconnect locking connectors, push them together until they click.* Before washing the parts, cover electrical parts to keep them dry. (Use plastic sheets or the like.) Keep water away from harness connectors and sensors and immediately wipe off any water that gets on them. Handling precautions for electric circuits

* Do not pierce wire insulation with test probes or alligator clips when performing electrical inspections. Doing so can, particularly with the chassis harness, hasten corrosion.

(1) Inspection of harnesses (1.1) Inspections with connectors fitted together* Waterproof connectors* Connect an inspection harness and connector. A between the connectors B of the circuit to be inspected. Perform the inspection by applying a test probe C to the connectors of the inspection harness. Do not insert the test probe C into the wire-entry sides of the waterproof connectors since this would damage their waterproof seals and lead to rust. * Non-waterproof connectors* Perform the inspection by inserting a test probe C into the wire-entry sides of the connectors. An extra-narrow probe is required for control unit connectors, which are smaller than other types of connector. Do not force a regular-size probe into control unit connectors since this would cause damage. (1.2) Inspections with connectors separated* Inspections on female terminals* Perform the inspection by carefully inserting a test probe into the terminals. Do not force the test probe into the terminals since this could deform them and cause poor connections. * Inspections on male terminals* Perform the inspection by applying test probes directly to the pins.

* Be careful not to short-circuit pins together with the test probes. With control unit connectors, short-circuiting of pins can cause damage to the control unit's internal circuitry.

* When using a multimeter to check continuity, do not allow the test probes to touch the wrong terminals. (2) Inspection of connectors (2.1) Visual inspection* Check that the connectors are fitted together securely. * Check whether wires have been separated from their terminals due to pulling of the harness. * Check that male and female terminals fit together tightly. * Check for defective connections caused by loose terminals, by rust on terminals, or by contamination of terminals by foreign substances. (2.2) Checking for loose terminals* If connector terminal retainers become damaged, male and female terminals may not

Have questions with 104749-3000?

Group cross 104749-3000 ZEXEL

Mitsubishi

104749-3000

9 460 610 078

MD074608

INJECTION-PUMP ASSEMBLY

4D6

4D6