Information injection-pump assembly

BOSCH

9 460 613 047

9460613047

ZEXEL

104749-2680

1047492680

NISSAN

1670039C10

1670039c10

Rating:

Components :

| 0. | INJECTION-PUMP ASSEMBLY | 104749-2680 |

| 1. | _ | |

| 2. | FUEL INJECTION PUMP | 104649-2680 |

| 3. | NUMBER PLATE | 146915-3500 |

| 4. | _ | |

| 5. | CAPSULE | |

| 6. | ADJUSTING DEVICE | |

| 7. | NOZZLE AND HOLDER ASSY | 105141-2422 |

| 8. | Nozzle and Holder | 16600-05E12 |

| 9. | Open Pre:MPa(Kqf/cm2) | 12.7{130} |

| 10. | NOZZLE-HOLDER | 105071-0681 |

| 11. | NOZZLE | 105000-1871 |

Scheme ###:

| 1/6. | [1] | 146601-0700 | PACKING RING |

| 6. | [1] | 146100-0220 | SUPPLY PUMP |

| 9. | [1] | 146103-0100 | COVER |

| 10. | [2] | 139104-0000 | FLAT-HEAD SCREW |

| 12. | [1] | 146200-0420 | DRIVE SHAFT |

| 12/1. | [1] | 146200-0400 | DRIVE SHAFT |

| 12/2. | [1] | 146201-0000 | WOODRUFF KEY |

| 12/3. | [2] | 146202-0100 | DAMPER |

| 12/4. | [1] | 146203-0000 | TOOTHED GEAR |

| 17. | [1] | 146204-0000 | PLAIN WASHER |

| 20. | [1] | 146210-1820 | ROLLER SET |

| 24. | [1] | 146303-0000 | BEARING PIN |

| 25. | [1] | 146304-0000 | BEARING PIN |

| 26. | [1] | 146305-0000 | CLAMPING BAND |

| 27. | [1] | 146205-0000 | SLOTTED WASHER |

| 29. | [1] | 146220-2120 | CAM PLATE |

| 30. | [1] | 146600-0800 | O-RING |

| 31. | [1] | 146311-6520 | PUMP PLUNGER |

| 32. | [1] | 146301-0000 | SLIDING PIECE |

| 34. | [1] | 146312-2500 | COMPRESSION SPRING |

| 34B. | [1] | 146312-2600 | COMPRESSION SPRING |

| 35/1. | [1] | 146690-3200 | SHIM D11.5&9.4T0.1 |

| 35/1. | [1] | 146690-3300 | SHIM D11.5&9.4T0.2 |

| 35/1. | [1] | 146690-3400 | SHIM D11.5&9.4T0.25 |

| 35/1. | [1] | 146690-3500 | SHIM D11.5&9.4T1.0 |

| 35/1. | [1] | 146690-4100 | SHIM D11.5&9.4T2 |

| 35/1. | [1] | 146690-4200 | SHIM D11.5&9.4T0.5 |

| 35/1. | [1] | 146690-4300 | SHIM D11.5&9.4T0.75 |

| 36. | [1] | 146600-0800 | O-RING |

| 37. | [1] | 146310-4020 | COVER |

| 38. | [2] | 146620-5000 | BLEEDER SCREW |

| 39. | [1] | 146310-0100 | COVER |

| 40. | [2] | 146620-5000 | BLEEDER SCREW |

| 41. | [1] | 146312-1900 | COMPRESSION SPRING |

| 43. | [1] | 146230-0000 | SHIM |

| 44. | [1] | 146230-0100 | PLAIN WASHER |

| 45. | [1] | 146231-0001 | SLOTTED WASHER |

| 47. | [2] | 146233-0000 | SLOTTED WASHER |

| 48/1. | [1] | 146603-0000 | SHIM D17.0&5.2T0.50 |

| 48/1. | [1] | 146603-0100 | SHIM D17.0&5.2T0.80 |

| 48/1. | [1] | 146603-0200 | SHIM D17.0&5.2T1.00 |

| 48/1. | [1] | 146603-0300 | SHIM D17.0&5.2T1.20 |

| 48/1. | [1] | 146603-0400 | SHIM D17.0&5.2T1.50 |

| 48/1. | [1] | 146603-0500 | SHIM D17.0&5.2T1.80 |

| 48/1. | [1] | 146603-0600 | SHIM D17.0&5.2T2.00 |

| 48/1. | [1] | 146690-1400 | SHIM D17&5.2T0.9 |

| 48/1. | [1] | 146690-1500 | SHIM D17&5.2T1.1 |

| 48/1. | [1] | 146690-1600 | SHIM D17&5.2T1.3 |

| 48/1. | [1] | 146690-1700 | SHIM D17&5.2T1.4 |

| 48/1. | [1] | 146690-1800 | SHIM D17&5.2T1.6 |

| 48/1. | [1] | 146690-1900 | SHIM D17&5.2T1.7 |

| 48/1. | [1] | 146690-5800 | SHIM |

| 48/1. | [1] | 146690-5900 | SHIM |

| 48/1. | [1] | 146690-6000 | SHIM |

| 48/1. | [1] | 146690-6100 | SHIM |

| 48/1. | [1] | 146690-6200 | SHIM |

| 48/1. | [1] | 146690-6300 | SHIM |

| 48/1. | [1] | 146690-6400 | SHIM |

| 48/1. | [1] | 146690-6500 | SHIM |

| 48/1. | [1] | 146690-6600 | SHIM |

| 48/1. | [1] | 146690-6700 | SHIM |

| 48/1. | [1] | 146690-6800 | SHIM |

| 48/1. | [1] | 146690-6900 | SHIM |

| 48/1. | [1] | 146690-7000 | SHIM |

| 48/1. | [1] | 146690-7100 | SHIM |

| 48/1. | [1] | 146690-7200 | SHIM |

| 48/1. | [1] | 146690-7300 | SHIM |

| 48/1. | [1] | 146690-7400 | SHIM |

| 48/1. | [1] | 146690-7500 | SHIM |

| 48/1. | [1] | 146690-7800 | SHIM |

| 49. | [2] | 146234-0500 | GUIDE PIN |

| 50. | [1] | 146400-6820 | HYDRAULIC HEAD |

| 50. | [1] | 146400-6820 | HYDRAULIC HEAD |

| 50. | [1] | 146400-6820 | HYDRAULIC HEAD |

| 51. | [1] | 146600-0000 | O-RING |

| 52/1. | [1] | 146420-0000 | SHIM D9.5&3.0T1.90 |

| 52/1. | [1] | 146420-0100 | SHIM D9.5&3.0T1.92 |

| 52/1. | [1] | 146420-0200 | SHIM D9.5&3.0T1.94 |

| 52/1. | [1] | 146420-0300 | SHIM D9.5&3.0T1.96 |

| 52/1. | [1] | 146420-0400 | SHIM D9.5&3.0T1.98 |

| 52/1. | [1] | 146420-0500 | SHIM D9.5&3.0T2.00 |

| 52/1. | [1] | 146420-0600 | SHIM D9.5&3.0T2.02 |

| 52/1. | [1] | 146420-0700 | SHIM D9.5&3.0T2.04 |

| 52/1. | [1] | 146420-0800 | SHIM D9.5&3.0T2.06 |

| 52/1. | [1] | 146420-0900 | SHIM D9.5&3.0T2.08 |

| 52/1. | [1] | 146420-1000 | SHIM D9.5&3.0T2.10 |

| 52/1. | [1] | 146420-1100 | SHIM D9.5&3.0T2.12 |

| 52/1. | [1] | 146420-1200 | SHIM D9.5&3.0T2.14 |

| 52/1. | [1] | 146420-1300 | SHIM D9.5&3.0T2.16 |

| 52/1. | [1] | 146420-1400 | SHIM D9.5&3.0T2.18 |

| 52/1. | [1] | 146420-1500 | SHIM D9.5&3.0T2.20 |

| 52/1. | [1] | 146420-1600 | SHIM D9.5&3.0T2.22 |

| 52/1. | [1] | 146420-1700 | SHIM D9.5&3.0T2.24 |

| 52/1. | [1] | 146420-1800 | SHIM D9.5&3.0T2.26 |

| 52/1. | [1] | 146420-1900 | SHIM D9.5&3.0T2.28 |

| 52/1. | [1] | 146420-2000 | SHIM D9.5&3.0T2.30 |

| 52/1. | [1] | 146420-2100 | SHIM D9.5&3.0T2.32 |

| 52/1. | [1] | 146420-2200 | SHIM D9.5&3.0T2.34 |

| 52/1. | [1] | 146420-2300 | SHIM D9.5&3.0T2.36 |

| 52/1. | [1] | 146420-2400 | SHIM D9.5&3.0T2.38 |

| 52/1. | [1] | 146420-2500 | SHIM D9.5&3.0T2.40 |

| 52/1. | [1] | 146420-2600 | SHIM D9.5&3.0T2.42 |

| 52/1. | [1] | 146420-2700 | SHIM D9.5&3.0T2.44 |

| 52/1. | [1] | 146420-2800 | SHIM D9.5&3.0T2.46 |

| 52/1. | [1] | 146420-2900 | SHIM D9.5&3.0T2.48 |

| 52/1. | [1] | 146420-3000 | SHIM D9.5&3.0T2.50 |

| 52/1. | [1] | 146420-3100 | SHIM D9.5&3.0T2.52 |

| 52/1. | [1] | 146420-3200 | SHIM D9.5&3.0T2.54 |

| 52/1. | [1] | 146420-3300 | SHIM D9.5&3.0T2.56 |

| 52/1. | [1] | 146420-3400 | SHIM D9.5&3.0T2.58 |

| 52/1. | [1] | 146420-3500 | SHIM D9.5&3.0T2.60 |

| 52/1. | [1] | 146420-3600 | SHIM D9.5&3.0T2.62 |

| 52/1. | [1] | 146420-3700 | SHIM D9.5&3.0T2.64 |

| 52/1. | [1] | 146420-3800 | SHIM D9.5&3.0T2.66 |

| 52/1. | [1] | 146420-3900 | SHIM D9.5&3.0T2.68 |

| 52/1. | [1] | 146420-4000 | SHIM D9.5&3.0T2.70 |

| 52/1. | [1] | 146420-4100 | SHIM D9.5&3.0T2.72 |

| 52/1. | [1] | 146420-4200 | SHIM D9.5&3.0T2.74 |

| 52/1. | [1] | 146420-4300 | SHIM D9.5&3.0T2.76 |

| 52/1. | [1] | 146420-4400 | SHIM D9.5&3.0T2.78 |

| 52/1. | [1] | 146420-4500 | SHIM D9.5&3.0T2.80 |

| 52/1. | [1] | 146420-4600 | SHIM D9.5&3.0T2.82 |

| 52/1. | [1] | 146420-4700 | SHIM D9.5&3.0T2.84 |

| 52/1. | [1] | 146420-4800 | SHIM D9.5&3.0T2.86 |

| 52/1. | [1] | 146420-4900 | SHIM D9.5&3.0T2.88 |

| 52/1. | [1] | 146420-5000 | SHIM D9.5&3.0T2.90 |

| 52/1. | [1] | 146420-5100 | SHIM D9.5&3.0T1.74 |

| 52/1. | [1] | 146420-5200 | SHIM D9.5&3.0T1.76 |

| 52/1. | [1] | 146420-5300 | SHIM D9.5&3.0T1.78 |

| 52/1. | [1] | 146420-5400 | SHIM D9.5&3.0T1.80 |

| 52/1. | [1] | 146420-5500 | SHIM D9.5&3.0T1.82 |

| 52/1. | [1] | 146420-5600 | SHIM D9.5&3.0T1.84 |

| 52/1. | [1] | 146420-5700 | SHIM D9.5&3.0T1.86 |

| 52/1. | [1] | 146420-5800 | SHIM D9.5&3.0T1.88 |

| 54. | [4] | 146433-0100 | GASKET D12&6.4T1.00 |

| 55. | [4] | 146430-6220 | DELIVERY-VALVE ASSEMBLY |

| 56. | [4] | 146432-0000 | COMPRESSION SPRING |

| 58. | [4] | 146440-2720 | FITTING |

| 60. | [3] | 139106-0100 | FLAT-HEAD SCREW |

| 66. | [1] | 146600-0100 | O-RING |

| 67. | [1] | 146503-4320 | GOVERNOR COVER |

| 67/1. | [1] | 146508-2021 | GOVERNOR COVER |

| 67/13. | [1] | 013020-6040 | UNION NUT M6P1H5 |

| 67/14. | [1] | 146621-1700 | UNION NUT |

| 67/15. | [1] | 146526-2800 | BLEEDER SCREW |

| 67/16. | [1] | 146526-2800 | BLEEDER SCREW |

| 67/78. | [1] | 146600-4400 | SEAL RING |

| 67/200. | [1] | 139308-0300 | PLAIN WASHER |

| 67/201. | [1] | 146545-3720 | THREADED PIN |

| 67/202. | [1] | 139208-0900 | UNION NUT |

| 67/203. | [1] | 146600-1200 | O-RING |

| 68. | [1] | 146513-0920 | CONTROL SHAFT |

| 69. | [1] | 139310-0200 | PLAIN WASHER |

| 72. | [1] | 146535-1520 | CONTROL LEVER |

| 72B. | [1] | 146535-1620 | CONTROL LEVER |

| 73. | [1] | 014110-6440 | LOCKING WASHER |

| 75. | [1] | 013020-6040 | UNION NUT M6P1H5 |

| 95. | [1] | 146851-2120 | FULCRUM LEVER |

| 104. | [2] | 146568-0000 | SLOTTED SPRING PIN |

| 105. | [2] | 026508-1140 | GASKET D11.4&8.2T1 |

| 106. | [2] | 146588-0500 | COILED SPRING |

| 107. | [1] | 146569-0300 | UNION NUT |

| 108. | [1] | 146570-0100 | GOVERNOR SHAFT |

| 109. | [1] | 146600-0400 | O-RING |

| 110/1. | [1] | 146571-0000 | SHIM D20.2&8.3T1.05 |

| 110/1. | [1] | 146571-0100 | SHIM D20.2&8.3T1.25 |

| 110/1. | [1] | 146571-0200 | SHIM D20.2&8.3T1.45 |

| 110/1. | [1] | 146571-0300 | SHIM D20.2&8.3T1.65 |

| 110/1. | [1] | 146571-0400 | SHIM D20.2&8.3T1.85 |

| 110/1. | [1] | 146571-0500 | SHIM D20.2&8.3T1.15 |

| 110/1. | [1] | 146571-0600 | SHIM D20.2&8.3T1.35 |

| 110/1. | [1] | 146571-0700 | SHIM D20.2&8.3T1.55 |

| 110/1. | [1] | 146571-0800 | SHIM D20.2&8.3T1.75 |

| 111. | [1] | 146602-0600 | PLAIN WASHER D20&8.4T1.40 |

| 112. | [1] | 146572-0020 | FLYWEIGHT ASSEMBLY |

| 114. | [1] | 146602-0500 | PLAIN WASHER D17&6.4T1.60 |

| 115. | [1] | 146975-4200 | SLIDING SLEEVE |

| 116. | [1] | 146576-0200 | CAP |

| 117/1. | [1] | 146577-1800 | PLUG L2.10 |

| 117/1. | [1] | 146577-1900 | PLUG L2.30 |

| 117/1. | [1] | 146577-2000 | PLUG L2.50 |

| 117/1. | [1] | 146577-2100 | PLUG L2.70 |

| 117/1. | [1] | 146577-2200 | PLUG L2.90 |

| 117/1. | [1] | 146577-2300 | PLUG L3.10 |

| 117/1. | [1] | 146577-2400 | PLUG L3.30 |

| 117/1. | [1] | 146577-2500 | PLUG L3.50 |

| 117/1. | [1] | 146577-2600 | PLUG L3.70 |

| 117/1. | [1] | 146577-2700 | PLUG L3.90 |

| 117/1. | [1] | 146577-2800 | PLUG L4.10 |

| 117/1. | [1] | 146577-2900 | PLUG L4.30 |

| 117/1. | [1] | 146577-3000 | PLUG L4.50 |

| 117/1. | [1] | 146577-3100 | PLUG L4.70 |

| 117/1. | [1] | 146577-3200 | PLUG L4.90 |

| 117/1. | [1] | 146577-3300 | PLUG L5.10 |

| 117/1. | [1] | 146577-6700 | PLUG L2.2 |

| 117/1. | [1] | 146577-6800 | PLUG L2.4 |

| 117/1. | [1] | 146577-6900 | PLUG L2.6 |

| 117/1. | [1] | 146577-7000 | PLUG L2.8 |

| 117/1. | [1] | 146577-7100 | PLUG L3.0 |

| 117/1. | [1] | 146577-7200 | PLUG L3.2 |

| 117/1. | [1] | 146577-7300 | PLUG L3.4 |

| 117/1. | [1] | 146577-7400 | PLUG L3.6 |

| 117/1. | [1] | 146577-7500 | PLUG L3.8 |

| 117/1. | [1] | 146577-7600 | PLUG L4.0 |

| 117/1. | [1] | 146577-7700 | PLUG L4.2 |

| 117/1. | [1] | 146577-7800 | PLUG L4.4 |

| 117/1. | [1] | 146577-7900 | PLUG L4.6 |

| 117/1. | [1] | 146577-8000 | PLUG L4.8 |

| 117/1. | [1] | 146577-8100 | PLUG L5.0 |

| 117/1. | [1] | 146877-0000 | PLUG L5.2 |

| 117/1. | [1] | 146877-0100 | PLUG L5.3 |

| 117/1. | [1] | 146877-0200 | PLUG L5.4 |

| 117/1. | [1] | 146877-0300 | PLUG L5.5 |

| 117/1. | [1] | 146877-4700 | PLUG |

| 117/1. | [1] | 146877-4800 | PLUG |

| 117/1. | [1] | 146877-4900 | PLUG |

| 117/1. | [1] | 146877-5000 | PLUG |

| 123. | [4] | 139106-0200 | FLAT-HEAD SCREW |

| 130. | [1] | 146421-0020 | CAPSULE |

| 130/2. | [1] | 026508-1140 | GASKET D11.4&8.2T1 |

| 130/3. | [1] | 146422-0000 | BLEEDER SCREW |

| 130/4. | [1] | 146600-0500 | O-RING |

| 133. | [1] | 146600-0600 | O-RING |

| 134. | [1] | 146600-0700 | O-RING |

| 135. | [1] | 146110-0220 | CONTROL VALVE |

| 135/5. | [1] | 146114-0000 | SPRING WASHER |

| 136. | [1] | 146120-0220 | OVER FLOW VALVE |

| 137. | [2] | 139512-0200 | GASKET D18.5&12.2T1.00 |

| 138. | [1] | 146605-5520 | INLET UNION |

| 200. | [1] | 146206-0100 | COILED SPRING |

| 217. | [1] | 146541-2900 | SLOTTED WASHER |

| 218. | [1] | 146587-4900 | COILED SPRING |

| 219. | [1] | 146541-3000 | BUSHING |

| 220. | [1] | 146587-5000 | COILED SPRING |

| 221. | [1] | 146627-8320 | BRACKET |

| 222. | [1] | 139006-4600 | BLEEDER SCREW |

| 223. | [1] | 139006-4700 | BLEEDER SCREW |

| 227. | [1] | 010206-2040 | HEX-SOCKET-HEAD CAP SCREW |

| 228. | [1] | 146614-6700 | SPACER BUSHING |

| 229. | [1] | 146926-2120 | BRACKET |

| 229/1. | [1] | 146628-0510 | BRACKET |

| 229/2. | [1] | 146616-9520 | CONTROL LEVER |

| 229/3. | [1] | 146620-1400 | FLAT-HEAD SCREW |

| 229/4. | [1] | 013020-6040 | UNION NUT M6P1H5 |

| 229/5. | [1] | 146587-5100 | COILED SPRING |

| 229/6. | [1] | 146602-2000 | PLAIN WASHER D22&5.5T2 |

| 229/7. | [1] | 014110-5440 | LOCKING WASHER |

| 229/8. | [1] | 013020-5240 | UNION NUT M5P0.8H4 |

| 229/9. | [1] | 139006-4400 | BLEEDER SCREW |

| 230. | [1] | 146626-8920 | BRACKET |

| 236. | [1] | 139006-4800 | BLEEDER SCREW |

| 237. | [1] | 146620-0200 | HEX-SOCKET-HEAD CAP SCREW |

| 240. | [1] | 146650-0720 | PULLING ELECTROMAGNET |

| 240/8. | [1] | 146600-1700 | O-RING |

| 242. | [1] | 146658-2820 | WIRE |

| 243. | [1] | 146621-1000 | UNION NUT |

| 245. | [3] | 139512-0200 | GASKET D18.5&12.2T1.00 |

| 246. | [1] | 139812-0500 | EYE BOLT |

| 247. | [1] | 146605-8120 | INLET UNION |

| 248. | [1] | 146614-0200 | SPACER BUSHING |

| 275. | [1] | 146612-3920 | BRACKET |

| 276. | [2] | 010010-1640 | BLEEDER SCREW M10P1.5L16 4T |

| 280. | [1] | 146360-5020 | COVER |

| 281. | [1] | 146600-0800 | O-RING |

| 282. | [2] | 010206-1440 | HEX-SOCKET-HEAD CAP SCREW M6P1L14 |

| 800S. | [1] | 146019-5320 | PUMP HOUSING |

| 800S/1/6. | [1] | 146601-0700 | PACKING RING |

| 804S. | [1] | 146232-0220 | COMPRESSION SPRING |

| 805S. | [1] | 146574-0120 | PARTS SET |

| 810S. | [1] | 146600-1120 | REPAIR SET |

| 821S. | [1] | 146210-5720 | ROLLER SET |

| 835S. | [1] | 146598-1000 | CAP |

| 836S/1. | [1] | 146598-0600 | CAP L18 |

| 836S/1. | [1] | 146598-0700 | CAP L21 |

| 836S/1. | [1] | 146598-0800 | CAP L24 |

| 836S/1. | [1] | 146598-0900 | CAP L27 |

| 906. | [1] | 146915-3500 | NAMEPLATE |

Include in #2:

104749-2680

as INJECTION-PUMP ASSEMBLY

Cross reference number

BOSCH

9 460 613 047

9460613047

ZEXEL

104749-2680

1047492680

NISSAN

1670039C10

1670039c10

Zexel num

Bosch num

Firm num

Name

104749-2680

9 460 613 047

1670039C10 NISSAN

INJECTION-PUMP ASSEMBLY

LD20 K

LD20 K

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113orSAEJ967d

1404 Test oil ISO4113orSAEJ967d

Test oil temperature

degC

45

45

50

Nozzle

105780-0060

Bosch type code

NP-DN0SD1510

Nozzle holder

105780-2150

Opening pressure

MPa

13

13

13.3

Opening pressure

kgf/cm2

133

133

136

Injection pipe

157805-7320

Injection pipe

Inside diameter - outside diameter - length (mm) mm 2-6-450

Inside diameter - outside diameter - length (mm) mm 2-6-450

Joint assembly

157641-4720

Tube assembly

157641-4020

Transfer pump pressure

kPa

20

20

20

Transfer pump pressure

kgf/cm2

0.2

0.2

0.2

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Pump speed

r/min

900

900

900

Average injection quantity

mm3/st.

30.4

30

30.8

Difference in delivery

mm3/st.

2

Basic

*

Oil temperature

degC

50

48

52

Injection timing adjustment_02

Pump speed

r/min

600

600

600

Average injection quantity

mm3/st.

29.1

27.1

31.1

Oil temperature

degC

50

48

52

Injection timing adjustment_03

Pump speed

r/min

900

900

900

Average injection quantity

mm3/st.

28.9

27.9

29.9

Difference in delivery

mm3/st.

2.5

Basic

*

Oil temperature

degC

50

48

52

Injection timing adjustment_04

Pump speed

r/min

1200

1200

1200

Average injection quantity

mm3/st.

30.3

28.3

32.3

Oil temperature

degC

50

48

52

Injection timing adjustment_05

Pump speed

r/min

1800

1800

1800

Average injection quantity

mm3/st.

29.3

27.3

31.3

Oil temperature

degC

50

48

52

Injection timing adjustment_06

Pump speed

r/min

2300

2300

2300

Average injection quantity

mm3/st.

28

26

30

Oil temperature

degC

52

50

54

Injection quantity adjustment

Pump speed

r/min

2500

2500

2500

Average injection quantity

mm3/st.

16

14

18

Difference in delivery

mm3/st.

4.5

Basic

*

Oil temperature

degC

55

52

58

Injection quantity adjustment_02

Pump speed

r/min

2500

2500

2500

Average injection quantity

mm3/st.

14.2

10.7

17.7

Difference in delivery

mm3/st.

5

Basic

*

Oil temperature

degC

55

52

58

Injection quantity adjustment_03

Pump speed

r/min

2600

2600

2600

Average injection quantity

mm3/st.

6

Oil temperature

degC

55

52

58

Governor adjustment

Pump speed

r/min

350

350

350

Average injection quantity

mm3/st.

7.6

6.6

8.6

Difference in delivery

mm3/st.

2

Basic

*

Oil temperature

degC

48

46

50

Governor adjustment_02

Pump speed

r/min

350

350

350

Average injection quantity

mm3/st.

5.2

3.2

7.2

Difference in delivery

mm3/st.

2.5

Basic

*

Oil temperature

degC

48

46

50

Governor adjustment_03

Pump speed

r/min

500

500

500

Average injection quantity

mm3/st.

3

Oil temperature

degC

48

46

50

Boost compensator adjustment

Pump speed

r/min

600

600

600

Average injection quantity

mm3/st.

12.1

7.6

16.6

Oil temperature

degC

50

48

52

Lever angle (shim thickness)

mm

7.2

7.15

7.25

Boost compensator adjustment_02

Pump speed

r/min

900

900

900

Average injection quantity

mm3/st.

7

2

12

Oil temperature

degC

50

48

52

Lever angle (shim thickness)

mm

7.2

7.15

7.25

Timer adjustment

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

54

44

64

Basic

*

Oil temperature

degC

48

46

50

Timer adjustment_02

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

50

40

60

Oil temperature

degC

48

46

50

Speed control lever angle

Pump speed

r/min

350

350

350

Average injection quantity

mm3/st.

0

0

0

Oil temperature

degC

48

46

50

Remarks

Magnet OFF at idling position

Magnet OFF at idling position

Speed control lever angle_02

Pump speed

r/min

900

900

900

Average injection quantity

mm3/st.

0

0

0

Oil temperature

degC

50

48

52

Remarks

Magnet OFF at full-load position

Magnet OFF at full-load position

0000000901

Pump speed

r/min

900

900

900

Overflow quantity

cm3/min

330

200

460

Oil temperature

degC

50

48

52

Stop lever angle

Pump speed

r/min

900

900

900

Pressure

kPa

343

314

372

Pressure

kgf/cm2

3.5

3.2

3.8

Basic

*

Oil temperature

degC

50

48

52

Stop lever angle_02

Pump speed

r/min

900

900

900

Pressure

kPa

343

304

382

Pressure

kgf/cm2

3.5

3.1

3.9

Basic

*

Oil temperature

degC

50

48

52

Stop lever angle_03

Pump speed

r/min

1800

1800

1800

Pressure

kPa

539

500

578

Pressure

kgf/cm2

5.5

5.1

5.9

Oil temperature

degC

50

48

52

Stop lever angle_04

Pump speed

r/min

2500

2500

2500

Pressure

kPa

647

608

686

Pressure

kgf/cm2

6.6

6.2

7

Oil temperature

degC

52

50

54

0000001101

Pump speed

r/min

900

900

900

Timer stroke

mm

1.5

1.3

1.7

Basic

*

Oil temperature

degC

50

48

52

_02

Pump speed

r/min

900

900

900

Timer stroke

mm

1.5

1.2

1.8

Basic

*

Oil temperature

degC

50

48

52

_03

Pump speed

r/min

1200

1200

1200

Timer stroke

mm

3

2.6

3.4

Oil temperature

degC

50

48

52

_04

Pump speed

r/min

2300

2300

2300

Timer stroke

mm

8.6

7.8

9

Oil temperature

degC

52

50

54

0000001201

Max. applied voltage

V

8

8

8

Test voltage

V

13

12

14

Timing setting

K dimension

mm

3.3

3.2

3.4

KF dimension

mm

5.8

5.7

5.9

MS dimension

mm

1.2

1.1

1.3

Control lever angle alpha

deg.

25

21

29

Control lever angle beta

deg.

41

36

46

Test data Ex:

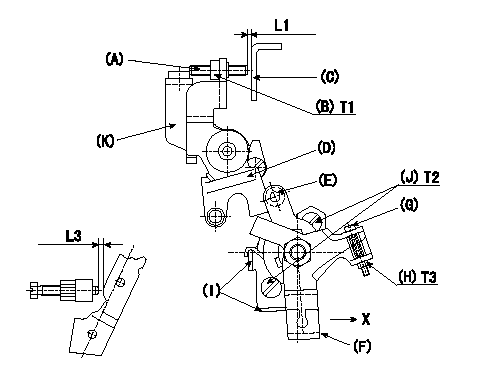

0000001801 M-CSD ADJUSTMENT

M-CSD adjustment

1. Fixing intermediate lever screw (A) [roller (E) must not contact intermediate lever (D)]

(1)Hold the control lever (C) in the idling position.

(2)At this time, adjust screw (A) so that it is horizontal and the clearance between screw (A) and the control lever (C) is L1. Then, fix using nut (B).

2. Fixing the M-CSD stopper (I)

Pull the CSD lever (F) in the direction X until it contacts the stopper (I) and tighten the socket head bolt (J) when the timer advance angle is L2.

3. Screw (G) adjustment

Pull the CSD lever (F) in the direction X until it contacts the stopper (I) and adjust the screw (G) so that the control lever shim thickness is L3. Then, tighten nut (H).

----------

L1=1~2mm L2=1.23+-0.2mm L3=7.2+-0.5mm

----------

T1=6~9N-m(0.6~0.9kgf-m) T2=5~7N-m(0.5~0.7kgf-m) T3=2~3N-m(0.2~0.3kgf-m) L1=1~2mm L3=7.2+-0.2mm

----------

L1=1~2mm L2=1.23+-0.2mm L3=7.2+-0.5mm

----------

T1=6~9N-m(0.6~0.9kgf-m) T2=5~7N-m(0.5~0.7kgf-m) T3=2~3N-m(0.2~0.3kgf-m) L1=1~2mm L3=7.2+-0.2mm

Information:

(b) 4.248 Engines (4 Ring)

**Spring Loaded Conformable Scraper - above gudgeon pin.Internally Stepped Compression - third groove.*Internally Stepped Compression - second groove.Chrome Insert Barrel Faced Compression - top groove.When fitting sealed power rings, ensure that the ends of the spring loaded segment butt together and do not overlap.**Some earlier A4.248 engines had a sealed power scraper ring fitted in the 4th groove. *On some earlier A4.248 engines rated up to 2,000 rev/min, the second compression ring is plain cast iron.Some later engines, rated up to 2,000 rev/min, have internally stepped chrome faced rings in both 2nd and 3rd grooves.When fitting internally stepped compression rings, ensure that the step is towards the piston crown.When fitting the spring loaded conformable scraper ring, ensure that the latch pin enters both ends of the spring. With the ring gap diametrically opposite to the latch pin, position the oil control ring over spring correctly located in annular groove of ring, i.e., between the oil control ring and the bottom of the ring groove in the piston.(c) 4.248 Engines (3 Ring)

Chrome Faced Spring Loaded ConformableScraper - above gudgeon pin.Internally Stepped Taper Faced Compression - second groove.Molybdenum Faced Internally Stepped Barrel Faced Compression - top groove.When fitting the spring loaded conformable scraper ring, ensure that the latch pin enters both ends of the spring. With the ring gap diametrically opposite to the latch pin, position the oil control ring over the spring correctly located in the annular groove of ring, i.e., between the oil control ring and the bottom of the ring groove in the piston.When fitting the internally stepped compression rings in the second and top grooves, ensure that the "step" is towards the piston crown.(d) T4.236 Engines (see Fig. F.6)

F6Chrome Faced Spring Loaded Conformable Scraper - above gudgeon pin.Cast Iron Taper Faced Compression - second groove.Molybdenum Faced Wedge Compression - top groove.When fitting the spring loaded conformable scraper ring, ensure that the latch pin enters both ends of the spring. With the ring gap diametrically opposite to the latch pin, position the oil control ring over spring correctly located in annular groove, i.e., between the oil control ring and the bottom of the ring groove in the piston.When fitting the compression rings, ensure that the manufacturers mark is towards the piston crown.(e) 4.236 Engines fitted with cast iron liners

Slotted Scraper - below gudgeon pin.Slotted Scraper - above gudgeon pin.Internally Stepped Compression - third groove.Internally Stepped Compression - second groove.*Chrome Faced Compression - top groove*With later combine engines, a plain cast iron ring is fitted in the top groove. This plain ring is completely interchangeable with the earlier chrome faced ring. When overhauling combine engines, the later plain ring should always be fitted (in engine sets). From Engine No. 236U68569 fitted to combine applications, some piston ring packs have been altered from five to four rings. The two slotted scraper rings fitted in the forth and fifth grooves have been replaced by one conformable chrome faced ring in the fourth groove only, leaving the

**Spring Loaded Conformable Scraper - above gudgeon pin.Internally Stepped Compression - third groove.*Internally Stepped Compression - second groove.Chrome Insert Barrel Faced Compression - top groove.When fitting sealed power rings, ensure that the ends of the spring loaded segment butt together and do not overlap.**Some earlier A4.248 engines had a sealed power scraper ring fitted in the 4th groove. *On some earlier A4.248 engines rated up to 2,000 rev/min, the second compression ring is plain cast iron.Some later engines, rated up to 2,000 rev/min, have internally stepped chrome faced rings in both 2nd and 3rd grooves.When fitting internally stepped compression rings, ensure that the step is towards the piston crown.When fitting the spring loaded conformable scraper ring, ensure that the latch pin enters both ends of the spring. With the ring gap diametrically opposite to the latch pin, position the oil control ring over spring correctly located in annular groove of ring, i.e., between the oil control ring and the bottom of the ring groove in the piston.(c) 4.248 Engines (3 Ring)

Chrome Faced Spring Loaded ConformableScraper - above gudgeon pin.Internally Stepped Taper Faced Compression - second groove.Molybdenum Faced Internally Stepped Barrel Faced Compression - top groove.When fitting the spring loaded conformable scraper ring, ensure that the latch pin enters both ends of the spring. With the ring gap diametrically opposite to the latch pin, position the oil control ring over the spring correctly located in the annular groove of ring, i.e., between the oil control ring and the bottom of the ring groove in the piston.When fitting the internally stepped compression rings in the second and top grooves, ensure that the "step" is towards the piston crown.(d) T4.236 Engines (see Fig. F.6)

F6Chrome Faced Spring Loaded Conformable Scraper - above gudgeon pin.Cast Iron Taper Faced Compression - second groove.Molybdenum Faced Wedge Compression - top groove.When fitting the spring loaded conformable scraper ring, ensure that the latch pin enters both ends of the spring. With the ring gap diametrically opposite to the latch pin, position the oil control ring over spring correctly located in annular groove, i.e., between the oil control ring and the bottom of the ring groove in the piston.When fitting the compression rings, ensure that the manufacturers mark is towards the piston crown.(e) 4.236 Engines fitted with cast iron liners

Slotted Scraper - below gudgeon pin.Slotted Scraper - above gudgeon pin.Internally Stepped Compression - third groove.Internally Stepped Compression - second groove.*Chrome Faced Compression - top groove*With later combine engines, a plain cast iron ring is fitted in the top groove. This plain ring is completely interchangeable with the earlier chrome faced ring. When overhauling combine engines, the later plain ring should always be fitted (in engine sets). From Engine No. 236U68569 fitted to combine applications, some piston ring packs have been altered from five to four rings. The two slotted scraper rings fitted in the forth and fifth grooves have been replaced by one conformable chrome faced ring in the fourth groove only, leaving the

Have questions with 104749-2680?

Group cross 104749-2680 ZEXEL

Nissan

104749-2680

9 460 613 047

1670039C10

INJECTION-PUMP ASSEMBLY

LD20

LD20