Information injection-pump assembly

BOSCH

9 460 611 191

9460611191

ZEXEL

104749-2671

1047492671

NISSAN

16700G8113

16700g8113

Rating:

Components :

| 0. | INJECTION-PUMP ASSEMBLY | 104749-2671 |

| 1. | _ | |

| 2. | FUEL INJECTION PUMP | 104649-2671 |

| 3. | NUMBER PLATE | 146915-0900 |

| 4. | _ | |

| 5. | CAPSULE | |

| 6. | ADJUSTING DEVICE | |

| 7. | NOZZLE AND HOLDER ASSY | 105141-2422 |

| 8. | Nozzle and Holder | 16600-05E12 |

| 9. | Open Pre:MPa(Kqf/cm2) | 12.7{130} |

| 10. | NOZZLE-HOLDER | 105071-0681 |

| 11. | NOZZLE | 105000-1871 |

Scheme ###:

| 1/6. | [1] | 146601-0700 | PACKING RING |

| 6. | [1] | 146100-0220 | SUPPLY PUMP |

| 9. | [1] | 146103-0100 | COVER |

| 10. | [2] | 139104-0000 | FLAT-HEAD SCREW |

| 12. | [1] | 146200-0420 | DRIVE SHAFT |

| 12/1. | [1] | 146200-0400 | DRIVE SHAFT |

| 12/2. | [1] | 146201-0000 | WOODRUFF KEY |

| 12/3. | [2] | 146202-0100 | DAMPER |

| 12/4. | [1] | 146203-0000 | TOOTHED GEAR |

| 17. | [1] | 146204-0000 | PLAIN WASHER |

| 20. | [1] | 146210-1820 | ROLLER SET |

| 24. | [1] | 146303-0000 | BEARING PIN |

| 25. | [1] | 146304-0000 | BEARING PIN |

| 26. | [1] | 146305-0000 | CLAMPING BAND |

| 27. | [1] | 146205-0000 | SLOTTED WASHER |

| 29. | [1] | 146220-2120 | CAM PLATE |

| 30. | [1] | 146600-0800 | O-RING |

| 31. | [1] | 146311-6520 | PUMP PLUNGER |

| 32. | [1] | 146301-0000 | SLIDING PIECE |

| 34. | [1] | 146312-2500 | COMPRESSION SPRING |

| 34B. | [1] | 146312-2600 | COMPRESSION SPRING |

| 35/1. | [1] | 146690-3200 | SHIM D11.5&9.4T0.1 |

| 35/1. | [1] | 146690-3300 | SHIM D11.5&9.4T0.2 |

| 35/1. | [1] | 146690-3400 | SHIM D11.5&9.4T0.25 |

| 35/1. | [1] | 146690-3500 | SHIM D11.5&9.4T1.0 |

| 35/1. | [1] | 146690-4100 | SHIM D11.5&9.4T2 |

| 35/1. | [1] | 146690-4200 | SHIM D11.5&9.4T0.5 |

| 35/1. | [1] | 146690-4300 | SHIM D11.5&9.4T0.75 |

| 36. | [1] | 146600-0800 | O-RING |

| 37. | [1] | 146310-4020 | COVER |

| 38. | [2] | 146620-5000 | BLEEDER SCREW |

| 39. | [1] | 146310-0100 | COVER |

| 40. | [2] | 146620-5000 | BLEEDER SCREW |

| 41. | [1] | 146312-1900 | COMPRESSION SPRING |

| 43. | [1] | 146230-0000 | SHIM |

| 44. | [1] | 146230-0100 | PLAIN WASHER |

| 45. | [1] | 146231-0001 | SLOTTED WASHER |

| 47. | [2] | 146233-0000 | SLOTTED WASHER |

| 48/1. | [1] | 146603-0000 | SHIM D17.0&5.2T0.50 |

| 48/1. | [1] | 146603-0100 | SHIM D17.0&5.2T0.80 |

| 48/1. | [1] | 146603-0200 | SHIM D17.0&5.2T1.00 |

| 48/1. | [1] | 146603-0300 | SHIM D17.0&5.2T1.20 |

| 48/1. | [1] | 146603-0400 | SHIM D17.0&5.2T1.50 |

| 48/1. | [1] | 146603-0500 | SHIM D17.0&5.2T1.80 |

| 48/1. | [1] | 146603-0600 | SHIM D17.0&5.2T2.00 |

| 48/1. | [1] | 146690-1400 | SHIM D17&5.2T0.9 |

| 48/1. | [1] | 146690-1500 | SHIM D17&5.2T1.1 |

| 48/1. | [1] | 146690-1600 | SHIM D17&5.2T1.3 |

| 48/1. | [1] | 146690-1700 | SHIM D17&5.2T1.4 |

| 48/1. | [1] | 146690-1800 | SHIM D17&5.2T1.6 |

| 48/1. | [1] | 146690-1900 | SHIM D17&5.2T1.7 |

| 48/1. | [1] | 146690-5800 | SHIM |

| 48/1. | [1] | 146690-5900 | SHIM |

| 48/1. | [1] | 146690-6000 | SHIM |

| 48/1. | [1] | 146690-6100 | SHIM |

| 48/1. | [1] | 146690-6200 | SHIM |

| 48/1. | [1] | 146690-6300 | SHIM |

| 48/1. | [1] | 146690-6400 | SHIM |

| 48/1. | [1] | 146690-6500 | SHIM |

| 48/1. | [1] | 146690-6600 | SHIM |

| 48/1. | [1] | 146690-6700 | SHIM |

| 48/1. | [1] | 146690-6800 | SHIM |

| 48/1. | [1] | 146690-6900 | SHIM |

| 48/1. | [1] | 146690-7000 | SHIM |

| 48/1. | [1] | 146690-7100 | SHIM |

| 48/1. | [1] | 146690-7200 | SHIM |

| 48/1. | [1] | 146690-7300 | SHIM |

| 48/1. | [1] | 146690-7400 | SHIM |

| 48/1. | [1] | 146690-7500 | SHIM |

| 48/1. | [1] | 146690-7800 | SHIM |

| 49. | [2] | 146234-0020 | GUIDE PIN |

| 50. | [1] | 146400-6820 | HYDRAULIC HEAD |

| 50. | [1] | 146400-6820 | HYDRAULIC HEAD |

| 50. | [1] | 146400-6820 | HYDRAULIC HEAD |

| 51. | [1] | 146600-0000 | O-RING |

| 52/1. | [1] | 146420-0000 | SHIM D9.5&3.0T1.90 |

| 52/1. | [1] | 146420-0100 | SHIM D9.5&3.0T1.92 |

| 52/1. | [1] | 146420-0200 | SHIM D9.5&3.0T1.94 |

| 52/1. | [1] | 146420-0300 | SHIM D9.5&3.0T1.96 |

| 52/1. | [1] | 146420-0400 | SHIM D9.5&3.0T1.98 |

| 52/1. | [1] | 146420-0500 | SHIM D9.5&3.0T2.00 |

| 52/1. | [1] | 146420-0600 | SHIM D9.5&3.0T2.02 |

| 52/1. | [1] | 146420-0700 | SHIM D9.5&3.0T2.04 |

| 52/1. | [1] | 146420-0800 | SHIM D9.5&3.0T2.06 |

| 52/1. | [1] | 146420-0900 | SHIM D9.5&3.0T2.08 |

| 52/1. | [1] | 146420-1000 | SHIM D9.5&3.0T2.10 |

| 52/1. | [1] | 146420-1100 | SHIM D9.5&3.0T2.12 |

| 52/1. | [1] | 146420-1200 | SHIM D9.5&3.0T2.14 |

| 52/1. | [1] | 146420-1300 | SHIM D9.5&3.0T2.16 |

| 52/1. | [1] | 146420-1400 | SHIM D9.5&3.0T2.18 |

| 52/1. | [1] | 146420-1500 | SHIM D9.5&3.0T2.20 |

| 52/1. | [1] | 146420-1600 | SHIM D9.5&3.0T2.22 |

| 52/1. | [1] | 146420-1700 | SHIM D9.5&3.0T2.24 |

| 52/1. | [1] | 146420-1800 | SHIM D9.5&3.0T2.26 |

| 52/1. | [1] | 146420-1900 | SHIM D9.5&3.0T2.28 |

| 52/1. | [1] | 146420-2000 | SHIM D9.5&3.0T2.30 |

| 52/1. | [1] | 146420-2100 | SHIM D9.5&3.0T2.32 |

| 52/1. | [1] | 146420-2200 | SHIM D9.5&3.0T2.34 |

| 52/1. | [1] | 146420-2300 | SHIM D9.5&3.0T2.36 |

| 52/1. | [1] | 146420-2400 | SHIM D9.5&3.0T2.38 |

| 52/1. | [1] | 146420-2500 | SHIM D9.5&3.0T2.40 |

| 52/1. | [1] | 146420-2600 | SHIM D9.5&3.0T2.42 |

| 52/1. | [1] | 146420-2700 | SHIM D9.5&3.0T2.44 |

| 52/1. | [1] | 146420-2800 | SHIM D9.5&3.0T2.46 |

| 52/1. | [1] | 146420-2900 | SHIM D9.5&3.0T2.48 |

| 52/1. | [1] | 146420-3000 | SHIM D9.5&3.0T2.50 |

| 52/1. | [1] | 146420-3100 | SHIM D9.5&3.0T2.52 |

| 52/1. | [1] | 146420-3200 | SHIM D9.5&3.0T2.54 |

| 52/1. | [1] | 146420-3300 | SHIM D9.5&3.0T2.56 |

| 52/1. | [1] | 146420-3400 | SHIM D9.5&3.0T2.58 |

| 52/1. | [1] | 146420-3500 | SHIM D9.5&3.0T2.60 |

| 52/1. | [1] | 146420-3600 | SHIM D9.5&3.0T2.62 |

| 52/1. | [1] | 146420-3700 | SHIM D9.5&3.0T2.64 |

| 52/1. | [1] | 146420-3800 | SHIM D9.5&3.0T2.66 |

| 52/1. | [1] | 146420-3900 | SHIM D9.5&3.0T2.68 |

| 52/1. | [1] | 146420-4000 | SHIM D9.5&3.0T2.70 |

| 52/1. | [1] | 146420-4100 | SHIM D9.5&3.0T2.72 |

| 52/1. | [1] | 146420-4200 | SHIM D9.5&3.0T2.74 |

| 52/1. | [1] | 146420-4300 | SHIM D9.5&3.0T2.76 |

| 52/1. | [1] | 146420-4400 | SHIM D9.5&3.0T2.78 |

| 52/1. | [1] | 146420-4500 | SHIM D9.5&3.0T2.80 |

| 52/1. | [1] | 146420-4600 | SHIM D9.5&3.0T2.82 |

| 52/1. | [1] | 146420-4700 | SHIM D9.5&3.0T2.84 |

| 52/1. | [1] | 146420-4800 | SHIM D9.5&3.0T2.86 |

| 52/1. | [1] | 146420-4900 | SHIM D9.5&3.0T2.88 |

| 52/1. | [1] | 146420-5000 | SHIM D9.5&3.0T2.90 |

| 52/1. | [1] | 146420-5100 | SHIM D9.5&3.0T1.74 |

| 52/1. | [1] | 146420-5200 | SHIM D9.5&3.0T1.76 |

| 52/1. | [1] | 146420-5300 | SHIM D9.5&3.0T1.78 |

| 52/1. | [1] | 146420-5400 | SHIM D9.5&3.0T1.80 |

| 52/1. | [1] | 146420-5500 | SHIM D9.5&3.0T1.82 |

| 52/1. | [1] | 146420-5600 | SHIM D9.5&3.0T1.84 |

| 52/1. | [1] | 146420-5700 | SHIM D9.5&3.0T1.86 |

| 52/1. | [1] | 146420-5800 | SHIM D9.5&3.0T1.88 |

| 54. | [4] | 146433-0100 | GASKET D12&6.4T1.00 |

| 55. | [4] | 146430-6220 | DELIVERY-VALVE ASSEMBLY |

| 56. | [4] | 146432-0000 | COMPRESSION SPRING |

| 58. | [4] | 146440-2720 | FITTING |

| 60. | [3] | 139106-0100 | FLAT-HEAD SCREW |

| 66. | [1] | 146600-0100 | O-RING |

| 67. | [1] | 146503-8220 | GOVERNOR COVER |

| 67/1. | [1] | 146508-2021 | GOVERNOR COVER |

| 67/13. | [1] | 013020-6040 | UNION NUT M6P1H5 |

| 67/14. | [1] | 146621-1700 | UNION NUT |

| 67/15. | [1] | 146526-2800 | BLEEDER SCREW |

| 67/16. | [1] | 146526-2800 | BLEEDER SCREW |

| 67/78. | [1] | 146600-4400 | SEAL RING |

| 67/200. | [1] | 139308-0300 | PLAIN WASHER |

| 67/201. | [1] | 146545-3400 | THREADED PIN L53.00 |

| 67/201B. | [1] | 146545-3500 | THREADED PIN L55.00 |

| 67/201C. | [1] | 146545-3600 | THREADED PIN L57.00 |

| 67/202. | [1] | 139208-0900 | UNION NUT |

| 67/203. | [1] | 146600-1200 | O-RING |

| 68. | [1] | 146513-0020 | CONTROL SHAFT |

| 69. | [1] | 139310-0200 | PLAIN WASHER |

| 72. | [1] | 146535-1520 | CONTROL LEVER |

| 72B. | [1] | 146535-1620 | CONTROL LEVER |

| 73. | [1] | 014110-6440 | LOCKING WASHER |

| 75. | [1] | 146621-0700 | UNION NUT |

| 95. | [1] | 146851-2120 | FULCRUM LEVER |

| 104. | [2] | 146568-0000 | SLOTTED SPRING PIN |

| 105. | [2] | 026508-1140 | GASKET D11.4&8.2T1 |

| 106. | [2] | 146588-0500 | COILED SPRING |

| 107. | [1] | 146569-0300 | UNION NUT |

| 108. | [1] | 146570-0420 | GOVERNOR SHAFT |

| 109. | [1] | 146600-0400 | O-RING |

| 110/1. | [1] | 146571-0000 | SHIM D20.2&8.3T1.05 |

| 110/1. | [1] | 146571-0100 | SHIM D20.2&8.3T1.25 |

| 110/1. | [1] | 146571-0200 | SHIM D20.2&8.3T1.45 |

| 110/1. | [1] | 146571-0300 | SHIM D20.2&8.3T1.65 |

| 110/1. | [1] | 146571-0400 | SHIM D20.2&8.3T1.85 |

| 110/1. | [1] | 146571-0500 | SHIM D20.2&8.3T1.15 |

| 110/1. | [1] | 146571-0600 | SHIM D20.2&8.3T1.35 |

| 110/1. | [1] | 146571-0700 | SHIM D20.2&8.3T1.55 |

| 110/1. | [1] | 146571-0800 | SHIM D20.2&8.3T1.75 |

| 111. | [1] | 146602-0600 | PLAIN WASHER D20&8.4T1.40 |

| 112. | [1] | 146572-0020 | FLYWEIGHT ASSEMBLY |

| 114. | [1] | 146602-0500 | PLAIN WASHER D17&6.4T1.60 |

| 115. | [1] | 146975-2600 | SLIDING SLEEVE |

| 116. | [1] | 146576-0200 | CAP |

| 117/1. | [1] | 146577-1800 | PLUG L2.10 |

| 117/1. | [1] | 146577-1900 | PLUG L2.30 |

| 117/1. | [1] | 146577-2000 | PLUG L2.50 |

| 117/1. | [1] | 146577-2100 | PLUG L2.70 |

| 117/1. | [1] | 146577-2200 | PLUG L2.90 |

| 117/1. | [1] | 146577-2300 | PLUG L3.10 |

| 117/1. | [1] | 146577-2400 | PLUG L3.30 |

| 117/1. | [1] | 146577-2500 | PLUG L3.50 |

| 117/1. | [1] | 146577-2600 | PLUG L3.70 |

| 117/1. | [1] | 146577-2700 | PLUG L3.90 |

| 117/1. | [1] | 146577-2800 | PLUG L4.10 |

| 117/1. | [1] | 146577-2900 | PLUG L4.30 |

| 117/1. | [1] | 146577-3000 | PLUG L4.50 |

| 117/1. | [1] | 146577-3100 | PLUG L4.70 |

| 117/1. | [1] | 146577-3200 | PLUG L4.90 |

| 117/1. | [1] | 146577-3300 | PLUG L5.10 |

| 117/1. | [1] | 146577-6700 | PLUG L2.2 |

| 117/1. | [1] | 146577-6800 | PLUG L2.4 |

| 117/1. | [1] | 146577-6900 | PLUG L2.6 |

| 117/1. | [1] | 146577-7000 | PLUG L2.8 |

| 117/1. | [1] | 146577-7100 | PLUG L3.0 |

| 117/1. | [1] | 146577-7200 | PLUG L3.2 |

| 117/1. | [1] | 146577-7300 | PLUG L3.4 |

| 117/1. | [1] | 146577-7400 | PLUG L3.6 |

| 117/1. | [1] | 146577-7500 | PLUG L3.8 |

| 117/1. | [1] | 146577-7600 | PLUG L4.0 |

| 117/1. | [1] | 146577-7700 | PLUG L4.2 |

| 117/1. | [1] | 146577-7800 | PLUG L4.4 |

| 117/1. | [1] | 146577-7900 | PLUG L4.6 |

| 117/1. | [1] | 146577-8000 | PLUG L4.8 |

| 117/1. | [1] | 146577-8100 | PLUG L5.0 |

| 117/1. | [1] | 146877-0000 | PLUG L5.2 |

| 117/1. | [1] | 146877-0100 | PLUG L5.3 |

| 117/1. | [1] | 146877-0200 | PLUG L5.4 |

| 117/1. | [1] | 146877-0300 | PLUG L5.5 |

| 117/1. | [1] | 146877-4700 | PLUG |

| 117/1. | [1] | 146877-4800 | PLUG |

| 117/1. | [1] | 146877-4900 | PLUG |

| 117/1. | [1] | 146877-5000 | PLUG |

| 123. | [3] | 139106-0200 | FLAT-HEAD SCREW |

| 124. | [1] | 146620-0500 | HEX-SOCKET-HEAD CAP SCREW |

| 130. | [1] | 146421-0020 | CAPSULE |

| 130/2. | [1] | 026508-1140 | GASKET D11.4&8.2T1 |

| 130/3. | [1] | 146422-0000 | BLEEDER SCREW |

| 130/4. | [1] | 146600-0500 | O-RING |

| 133. | [1] | 146600-0600 | O-RING |

| 134. | [1] | 146600-0700 | O-RING |

| 135. | [1] | 146110-0220 | CONTROL VALVE |

| 135/5. | [1] | 146114-0000 | SPRING WASHER |

| 136. | [1] | 146120-0220 | OVER FLOW VALVE |

| 137. | [2] | 139512-0200 | GASKET D18.5&12.2T1.00 |

| 138. | [1] | 146605-8320 | INLET UNION |

| 200. | [1] | 146206-0100 | COILED SPRING |

| 217. | [1] | 146541-2900 | SLOTTED WASHER |

| 218. | [1] | 146587-4900 | COILED SPRING |

| 219. | [1] | 146541-3000 | BUSHING |

| 220. | [1] | 146587-5000 | COILED SPRING |

| 221. | [1] | 146926-1820 | BRACKET |

| 222. | [1] | 139006-4600 | BLEEDER SCREW |

| 223. | [1] | 139006-4700 | BLEEDER SCREW |

| 225. | [1] | 146629-1500 | BRACKET |

| 226. | [2] | 010206-1040 | HEX-SOCKET-HEAD CAP SCREW |

| 227. | [1] | 010206-2040 | HEX-SOCKET-HEAD CAP SCREW |

| 228. | [1] | 146614-6700 | SPACER BUSHING |

| 229. | [1] | 146926-2120 | BRACKET |

| 229/2. | [1] | 146616-9520 | CONTROL LEVER |

| 229/3. | [1] | 146620-1400 | FLAT-HEAD SCREW |

| 229/4. | [1] | 013020-6040 | UNION NUT M6P1H5 |

| 229/5. | [1] | 146587-5100 | COILED SPRING |

| 229/6. | [1] | 146602-2000 | PLAIN WASHER D22&5.5T2 |

| 229/7. | [1] | 014110-5440 | LOCKING WASHER |

| 229/8. | [1] | 013020-5240 | UNION NUT M5P0.8H4 |

| 229/9. | [1] | 139006-4400 | BLEEDER SCREW |

| 230. | [1] | 146626-8920 | BRACKET |

| 236. | [1] | 139006-4800 | BLEEDER SCREW |

| 237. | [1] | 146620-0200 | HEX-SOCKET-HEAD CAP SCREW |

| 240. | [1] | 146650-0720 | PULLING ELECTROMAGNET |

| 240/8. | [1] | 146600-1700 | O-RING |

| 242. | [1] | 146658-2820 | WIRE |

| 243. | [1] | 146621-1000 | UNION NUT |

| 245. | [3] | 139512-0200 | GASKET D18.5&12.2T1.00 |

| 246. | [1] | 139812-0500 | EYE BOLT |

| 247. | [1] | 146605-8120 | INLET UNION |

| 248. | [1] | 146614-0200 | SPACER BUSHING |

| 251. | [1] | 146125-0101 | FILTER |

| 252. | [1] | 146125-0200 | COILED SPRING |

| 275. | [1] | 146612-3920 | BRACKET |

| 276. | [2] | 010010-1640 | BLEEDER SCREW M10P1.5L16 4T |

| 280. | [1] | 146360-5020 | COVER |

| 281. | [1] | 146600-0800 | O-RING |

| 282. | [2] | 010206-1440 | HEX-SOCKET-HEAD CAP SCREW M6P1L14 |

| 309. | [1] | 139006-4400 | BLEEDER SCREW |

| 310. | [1] | 146673-6622 | POTENTCIOMETER |

| 311. | [2] | 010206-1040 | HEX-SOCKET-HEAD CAP SCREW |

| 800S. | [1] | 146019-3420 | PUMP HOUSING |

| 800S/1/6. | [1] | 146601-0700 | PACKING RING |

| 804S. | [1] | 146232-0220 | COMPRESSION SPRING |

| 805S. | [1] | 146574-0120 | PARTS SET |

| 810S. | [1] | 146600-1120 | REPAIR SET |

| 821S. | [1] | 146210-5720 | ROLLER SET |

| 835S. | [1] | 146598-1000 | CAP |

| 836S/1. | [1] | 146598-0600 | CAP L18 |

| 836S/1. | [1] | 146598-0700 | CAP L21 |

| 836S/1. | [1] | 146598-0800 | CAP L24 |

| 836S/1. | [1] | 146598-0900 | CAP L27 |

| 847S. | [1] | 146684-2010 | POTENTCIOMETER |

| 906. | [1] | 146915-0900 | NAMEPLATE |

Include in #2:

104749-2671

as INJECTION-PUMP ASSEMBLY

Cross reference number

BOSCH

9 460 611 191

9460611191

ZEXEL

104749-2671

1047492671

NISSAN

16700G8113

16700g8113

Zexel num

Bosch num

Firm num

Name

104749-2671

9 460 611 191

16700G8113 NISSAN

INJECTION-PUMP ASSEMBLY

LD20 * K 11CJ VE4 VE

LD20 * K 11CJ VE4 VE

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113orSAEJ967d

1404 Test oil ISO4113orSAEJ967d

Test oil temperature

degC

45

45

50

Nozzle

105000-2010

Bosch type code

NP-DN12SD12TT

Nozzle holder

105780-2080

Opening pressure

MPa

14.7

14.7

15.19

Opening pressure

kgf/cm2

150

150

155

Injection pipe

Inside diameter - outside diameter - length (mm) mm 2-6-840

Inside diameter - outside diameter - length (mm) mm 2-6-840

Transfer pump pressure

kPa

20

20

20

Transfer pump pressure

kgf/cm2

0.2

0.2

0.2

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Pump speed

r/min

900

900

900

Average injection quantity

mm3/st.

28.9

28.5

29.3

Difference in delivery

mm3/st.

2

Basic

*

Oil temperature

degC

50

48

52

Injection timing adjustment_02

Pump speed

r/min

600

600

600

Average injection quantity

mm3/st.

29.1

27.1

31.1

Oil temperature

degC

50

48

52

Injection timing adjustment_03

Pump speed

r/min

900

900

900

Average injection quantity

mm3/st.

28.9

27.9

29.9

Difference in delivery

mm3/st.

2.5

Basic

*

Oil temperature

degC

50

48

52

Injection timing adjustment_04

Pump speed

r/min

1200

1200

1200

Average injection quantity

mm3/st.

30.3

28.3

32.3

Oil temperature

degC

50

48

52

Injection timing adjustment_05

Pump speed

r/min

1800

1800

1800

Average injection quantity

mm3/st.

29.3

27.3

31.3

Oil temperature

degC

50

48

52

Injection timing adjustment_06

Pump speed

r/min

2300

2300

2300

Average injection quantity

mm3/st.

29

27

31

Oil temperature

degC

52

50

54

Injection timing adjustment_07

Pump speed

r/min

2500

2500

2500

Average injection quantity

mm3/st.

28.7

26.7

30.7

Oil temperature

degC

55

52

58

Injection quantity adjustment

Pump speed

r/min

2700

2700

2700

Average injection quantity

mm3/st.

14.5

12.5

16.5

Difference in delivery

mm3/st.

4.5

Basic

*

Oil temperature

degC

55

52

58

Injection quantity adjustment_02

Pump speed

r/min

2700

2700

2700

Average injection quantity

mm3/st.

14.5

11

18

Difference in delivery

mm3/st.

5

Basic

*

Oil temperature

degC

55

52

58

Injection quantity adjustment_03

Pump speed

r/min

2800

2800

2800

Average injection quantity

mm3/st.

6

Oil temperature

degC

55

52

58

Governor adjustment

Pump speed

r/min

375

375

375

Average injection quantity

mm3/st.

5.7

4.7

6.7

Difference in delivery

mm3/st.

2

Basic

*

Oil temperature

degC

48

46

50

Governor adjustment_02

Pump speed

r/min

375

375

375

Average injection quantity

mm3/st.

5.7

3.7

7.7

Difference in delivery

mm3/st.

2.5

Oil temperature

degC

48

46

50

Governor adjustment_03

Pump speed

r/min

500

500

500

Average injection quantity

mm3/st.

3

Oil temperature

degC

48

46

50

Boost compensator adjustment

Pump speed

r/min

600

600

600

Average injection quantity

mm3/st.

12.1

7.6

16.6

Oil temperature

degC

50

48

52

Lever angle (shim thickness)

mm

5.95

5.9

6

Boost compensator adjustment_02

Pump speed

r/min

900

900

900

Average injection quantity

mm3/st.

7

2

12

Oil temperature

degC

50

48

52

Lever angle (shim thickness)

mm

5.95

5.9

6

Timer adjustment

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

50

40

60

Basic

*

Oil temperature

degC

48

46

50

Timer adjustment_02

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

50

40

60

Oil temperature

degC

48

46

50

Speed control lever angle

Pump speed

r/min

375

375

375

Average injection quantity

mm3/st.

0

0

0

Oil temperature

degC

48

46

50

Remarks

Magnet OFF at idling position

Magnet OFF at idling position

Speed control lever angle_02

Pump speed

r/min

900

900

900

Average injection quantity

mm3/st.

0

0

0

Oil temperature

degC

50

48

52

Remarks

Magnet OFF at full-load position

Magnet OFF at full-load position

0000000901

Pump speed

r/min

900

900

900

Overflow quantity

cm3/min

330

200

460

Oil temperature

degC

50

48

52

Stop lever angle

Pump speed

r/min

900

900

900

Pressure

kPa

343

314

372

Pressure

kgf/cm2

3.5

3.2

3.8

Basic

*

Oil temperature

degC

50

48

52

Stop lever angle_02

Pump speed

r/min

900

900

900

Pressure

kPa

343

304

382

Pressure

kgf/cm2

3.5

3.1

3.9

Basic

*

Oil temperature

degC

50

48

52

Stop lever angle_03

Pump speed

r/min

1800

1800

1800

Pressure

kPa

539

500

578

Pressure

kgf/cm2

5.5

5.1

5.9

Oil temperature

degC

50

48

52

Stop lever angle_04

Pump speed

r/min

2500

2500

2500

Pressure

kPa

706

667

745

Pressure

kgf/cm2

7.2

6.8

7.6

Oil temperature

degC

55

52

58

0000001101

Pump speed

r/min

900

900

900

Timer stroke

mm

1.5

1.3

1.7

Basic

*

Oil temperature

degC

50

48

52

_02

Pump speed

r/min

900

900

900

Timer stroke

mm

1.5

1.2

1.8

Basic

*

Oil temperature

degC

50

48

52

_03

Pump speed

r/min

1200

1200

1200

Timer stroke

mm

3

2.6

3.4

Oil temperature

degC

50

48

52

_04

Pump speed

r/min

2300

2300

2300

Timer stroke

mm

8.6

8.1

9

Oil temperature

degC

52

50

54

0000001201

Max. applied voltage

V

8

8

8

Test voltage

V

13

12

14

0000001401

Pump speed

r/min

900

900

900

Average injection quantity

mm3/st.

17

16

18

Timer stroke TA

mm

0.85

0.55

1.15

Timer stroke variation dT

mm

0.65

0.65

0.65

Basic

*

Oil temperature

degC

50

48

52

_02

Pump speed

r/min

900

900

900

Average injection quantity

mm3/st.

17

15.5

18.5

Timer stroke TA

mm

0.85

0.45

1.25

Oil temperature

degC

50

48

52

Timing setting

K dimension

mm

3.3

3.2

3.4

KF dimension

mm

5.8

5.7

5.9

MS dimension

mm

1.2

1.1

1.3

Control lever angle alpha

deg.

25

21

29

Control lever angle beta

deg.

39

34

44

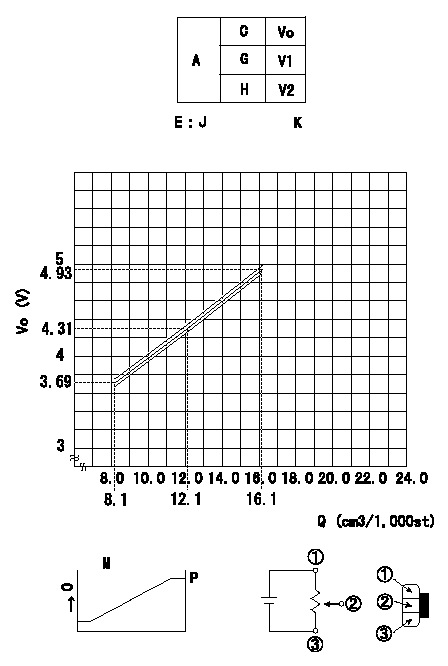

Test data Ex:

0000001801 POTENTIOMETER ADJUSTMENT

Adjustment of the potentiometer

In the following condition, change the installation position of the potentiometer to adjust the output voltage to within the specified values.

Measure the injection quantity at control lever position a (shim thickness = approximately L mm) at N = N1 r/min, determine the voltage using the formula, and adjust the potentiometer.

A:Adjustment conditions

B:Adjustment value

C:Position of the control lever

N:Pump speed

Q:Injection quantity

Vo:Output voltage

D:Measured injection quantity

E:Conversion formula

F:Adjusting point

G:Idle

H:Full speed

I:Checking point

K:Applied voltage

X:Injection quantity (cm3/1,000st)

Y:Voltage (V)

M:Connecting diagram for the potentiometer

O:Output

P:Output when (2) and (3) connected.

R:At target value Q1cm3/1,000 st, set voltage at V3 (V).

----------

N1=600r/min a=9.0+-0.5deg L=5.95+-0.05mm

----------

J=V+-0.05=0.155323Q+2.43145 V1=1.73+-0.9V V2=-V K=10V

----------

N1=600r/min a=9.0+-0.5deg L=5.95+-0.05mm

----------

J=V+-0.05=0.155323Q+2.43145 V1=1.73+-0.9V V2=-V K=10V

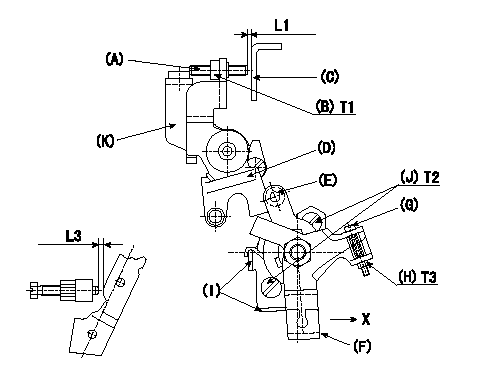

0000001901 M-CSD ADJUSTMENT

M-CSD adjustment

1. Fixing intermediate lever screw (A) [roller (E) must not contact intermediate lever (D)]

(1)Hold the control lever (C) in the idling position.

(2)At this time, adjust screw (A) so that it is horizontal and the clearance between screw (A) and the control lever (C) is L1. Then, fix using nut (B).

2. Fixing the M-CSD stopper (I)

Pull the CSD lever (F) in the direction X until it contacts the stopper (I) and tighten the socket head bolt (J) when the timer advance angle is L2.

3. Screw (G) adjustment

Pull the CSD lever (F) in the direction X until it contacts the stopper (I) and adjust the screw (G) so that the control lever shim thickness is L3. Then, tighten nut (H).

----------

L1=1~2mm L2=1.23+-0.2mm L3=7.2+-0.5mm

----------

T1=6~9N-m(0.6~0.9kgf-m) T2=5~7N-m(0.5~0.7kgf-m) T3=2~3N-m(0.2~0.3kgf-m) L1=1~2mm L3=7.2+-0.5mm

----------

L1=1~2mm L2=1.23+-0.2mm L3=7.2+-0.5mm

----------

T1=6~9N-m(0.6~0.9kgf-m) T2=5~7N-m(0.5~0.7kgf-m) T3=2~3N-m(0.2~0.3kgf-m) L1=1~2mm L3=7.2+-0.5mm

Information:

To Reassemble

1. Fit oil feed connection to rocker shaft and secure with the locating screw, ensuring that the screw enters the locating hole in the shaft.2. Refit the support brackets, springs, and rocker levers in the correct order (Fig. E.4). The support brackets are interchangeable and when fitting them ensure that the securing stud/setscrew holes are to the right viewing the shaft from the front end, with each pair of rockers inclined away from each other at the valve end.3. Fit securing washer and circlip to each end of the shaft.Push Rods

Check the push rods for straightness. If any are bent, fit replacements.Valve Stem Oil Seals

Where oversize valves are fitted, always ensure that correct size valve seals or 'O' rings are used.

E3 1. Collets2. Valve Spring Cap3. Oil Deflector4. Inner Valve Spring5. Outer Valve Spring6. Valve Spring Seat7. Exhaust Valve8. Inlet ValveAll hydraulically governed engines and certain mechanically governed engines have rubber oil deflectors fitted to inlet valve stems only (see Fig. E.3). When fitting these oil deflectors, the open end should be towards the cylinder head.With the majority of mechanically governed engines, oil seals are fitted to both inlet and exhaust valves. Earlier engines had a shallow rubber oil deflector fitted to the valve stems and positioned above the conical valve spring seating collar, the open end of the deflector being fitted towards the cylinder head. Later engines have a thin valve spring seating washer and a rubber oil seal which fits over the integral valve guide protrusion. In some cases, this latter seal has a nylon insert. The later sealing arrangement, due to a change in the diameter of the valve guide protrusion, is not interchangeable with the earlier sealing arrangement.On some engines, the seals are manufactured from Viton or silicon rubber material and they have a garter spring fitted around their outer circumference.In manufacturing, some engines have a red coloured material for inlet valve seals and black for exhaust valve seals. The red seal may only be fitted over the inlet valve. It is unsuitable for exhaust valves but the black seal may be fitted to either exhaust or inlet.The 4.2482 engine has a valve stem oil seal on both inlet and exhaust valves. The seals have garter springs round the seal neck for improved oil control.To Re-Assemble the Cylinder Head

1. Lightly oil valve stems.2. Fit valve to its correct guide or bore.3. Fit valve stem oil seals.4. Locate spring seat washers, valve springs and spring caps in position.5. Compress each valve spring and fit the valve collets.

E11, Valve Cap Sealing Arrangement As from Engine No. LD-----U778518H, 'O' ring seals have been fitted in the valve spring caps under the collets. The valve spring caps have been changed which have a deeper body so that the seal can be fitted as shown in Fig. E.11. The new caps are fitted to both valves, but the seals are fitted to exhaust valves only. T4.236 engines have two 'O' rings fitted in each valve spring cap.Cylinder Head

1. Fit oil feed connection to rocker shaft and secure with the locating screw, ensuring that the screw enters the locating hole in the shaft.2. Refit the support brackets, springs, and rocker levers in the correct order (Fig. E.4). The support brackets are interchangeable and when fitting them ensure that the securing stud/setscrew holes are to the right viewing the shaft from the front end, with each pair of rockers inclined away from each other at the valve end.3. Fit securing washer and circlip to each end of the shaft.Push Rods

Check the push rods for straightness. If any are bent, fit replacements.Valve Stem Oil Seals

Where oversize valves are fitted, always ensure that correct size valve seals or 'O' rings are used.

E3 1. Collets2. Valve Spring Cap3. Oil Deflector4. Inner Valve Spring5. Outer Valve Spring6. Valve Spring Seat7. Exhaust Valve8. Inlet ValveAll hydraulically governed engines and certain mechanically governed engines have rubber oil deflectors fitted to inlet valve stems only (see Fig. E.3). When fitting these oil deflectors, the open end should be towards the cylinder head.With the majority of mechanically governed engines, oil seals are fitted to both inlet and exhaust valves. Earlier engines had a shallow rubber oil deflector fitted to the valve stems and positioned above the conical valve spring seating collar, the open end of the deflector being fitted towards the cylinder head. Later engines have a thin valve spring seating washer and a rubber oil seal which fits over the integral valve guide protrusion. In some cases, this latter seal has a nylon insert. The later sealing arrangement, due to a change in the diameter of the valve guide protrusion, is not interchangeable with the earlier sealing arrangement.On some engines, the seals are manufactured from Viton or silicon rubber material and they have a garter spring fitted around their outer circumference.In manufacturing, some engines have a red coloured material for inlet valve seals and black for exhaust valve seals. The red seal may only be fitted over the inlet valve. It is unsuitable for exhaust valves but the black seal may be fitted to either exhaust or inlet.The 4.2482 engine has a valve stem oil seal on both inlet and exhaust valves. The seals have garter springs round the seal neck for improved oil control.To Re-Assemble the Cylinder Head

1. Lightly oil valve stems.2. Fit valve to its correct guide or bore.3. Fit valve stem oil seals.4. Locate spring seat washers, valve springs and spring caps in position.5. Compress each valve spring and fit the valve collets.

E11, Valve Cap Sealing Arrangement As from Engine No. LD-----U778518H, 'O' ring seals have been fitted in the valve spring caps under the collets. The valve spring caps have been changed which have a deeper body so that the seal can be fitted as shown in Fig. E.11. The new caps are fitted to both valves, but the seals are fitted to exhaust valves only. T4.236 engines have two 'O' rings fitted in each valve spring cap.Cylinder Head

Have questions with 104749-2671?

Group cross 104749-2671 ZEXEL

Nissan

104749-2671

9 460 611 191

16700G8113

INJECTION-PUMP ASSEMBLY

LD20

LD20