Information injection-pump assembly

ZEXEL

104749-2441

1047492441

Rating:

Cross reference number

ZEXEL

104749-2441

1047492441

Zexel num

Bosch num

Firm num

Name

104749-2441

INJECTION-PUMP ASSEMBLY

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113orSAEJ967d

1404 Test oil ISO4113orSAEJ967d

Test oil temperature

degC

45

45

50

Nozzle

105000-2010

Bosch type code

NP-DN12SD12TT

Nozzle holder

105780-2080

Opening pressure

MPa

14.7

14.7

15.19

Opening pressure

kgf/cm2

150

150

155

Injection pipe

Inside diameter - outside diameter - length (mm) mm 2-6-840

Inside diameter - outside diameter - length (mm) mm 2-6-840

Transfer pump pressure

kPa

20

20

20

Transfer pump pressure

kgf/cm2

0.2

0.2

0.2

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Pump speed

r/min

900

900

900

Average injection quantity

mm3/st.

30.4

30

30.8

Difference in delivery

mm3/st.

2

Basic

*

Oil temperature

degC

50

48

52

Injection timing adjustment_02

Pump speed

r/min

600

600

600

Average injection quantity

mm3/st.

30.6

28.6

32.6

Oil temperature

degC

50

48

52

Injection timing adjustment_03

Pump speed

r/min

900

900

900

Average injection quantity

mm3/st.

30.4

29.4

31.4

Oil temperature

degC

50

48

52

Injection timing adjustment_04

Pump speed

r/min

1200

1200

1200

Average injection quantity

mm3/st.

31.8

29.8

33.8

Difference in delivery

mm3/st.

2.5

Basic

*

Oil temperature

degC

50

48

52

Injection timing adjustment_05

Pump speed

r/min

1800

1800

1800

Average injection quantity

mm3/st.

30.8

28.8

32.8

Oil temperature

degC

50

48

52

Injection timing adjustment_06

Pump speed

r/min

2300

2300

2300

Average injection quantity

mm3/st.

30.5

28.5

32.5

Oil temperature

degC

52

50

54

Injection timing adjustment_07

Pump speed

r/min

2500

2500

2500

Average injection quantity

mm3/st.

30.2

28.2

32.2

Oil temperature

degC

55

52

58

Injection quantity adjustment

Pump speed

r/min

2700

2700

2700

Average injection quantity

mm3/st.

14.5

12.5

16.5

Difference in delivery

mm3/st.

4.5

Basic

*

Oil temperature

degC

55

52

58

Injection quantity adjustment_02

Pump speed

r/min

2700

2700

2700

Average injection quantity

mm3/st.

14.5

11

18

Difference in delivery

mm3/st.

5

Basic

*

Oil temperature

degC

55

52

58

Injection quantity adjustment_03

Pump speed

r/min

2800

2800

2800

Average injection quantity

mm3/st.

6

Oil temperature

degC

55

52

58

Governor adjustment

Pump speed

r/min

350

350

350

Average injection quantity

mm3/st.

5.2

4.2

6.2

Difference in delivery

mm3/st.

2

Basic

*

Oil temperature

degC

48

46

50

Governor adjustment_02

Pump speed

r/min

350

350

350

Average injection quantity

mm3/st.

5.2

3.2

7.2

Difference in delivery

mm3/st.

2.5

Basic

*

Oil temperature

degC

48

46

50

Governor adjustment_03

Pump speed

r/min

500

500

500

Average injection quantity

mm3/st.

3

Oil temperature

degC

48

46

50

Boost compensator adjustment

Pump speed

r/min

600

600

600

Average injection quantity

mm3/st.

12.1

7.6

16.6

Oil temperature

degC

50

48

52

Lever angle (shim thickness)

mm

7.2

7.2

7.2

Boost compensator adjustment_02

Pump speed

r/min

900

900

900

Average injection quantity

mm3/st.

7

2

12

Oil temperature

degC

50

48

52

Lever angle (shim thickness)

mm

7.2

7.2

7.2

Timer adjustment

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

50

40

60

Basic

*

Oil temperature

degC

48

46

50

Timer adjustment_02

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

50

40

60

Oil temperature

degC

48

46

50

Speed control lever angle

Pump speed

r/min

350

350

350

Average injection quantity

mm3/st.

0

0

0

Oil temperature

degC

48

46

50

Remarks

Magnet OFF at idling position

Magnet OFF at idling position

Speed control lever angle_02

Pump speed

r/min

900

900

900

Average injection quantity

mm3/st.

0

0

0

Oil temperature

degC

50

48

52

Remarks

Magnet OFF at full-load position

Magnet OFF at full-load position

0000000901

Pump speed

r/min

900

900

900

Overflow quantity

cm3/min

330

200

460

Oil temperature

degC

50

48

52

Stop lever angle

Pump speed

r/min

900

900

900

Pressure

kPa

343

314

372

Pressure

kgf/cm2

3.5

3.2

3.8

Basic

*

Oil temperature

degC

50

48

52

Stop lever angle_02

Pump speed

r/min

900

900

900

Pressure

kPa

343

304

382

Pressure

kgf/cm2

3.5

3.1

3.9

Basic

*

Oil temperature

degC

50

48

52

Stop lever angle_03

Pump speed

r/min

1800

1800

1800

Pressure

kPa

539.5

500

579

Pressure

kgf/cm2

5.5

5.1

5.9

Oil temperature

degC

50

48

52

Stop lever angle_04

Pump speed

r/min

2300

2300

2300

Pressure

kPa

706

667

745

Pressure

kgf/cm2

7.2

6.8

7.6

Oil temperature

degC

52

50

54

0000001101

Pump speed

r/min

900

900

900

Timer stroke

mm

1.5

1.3

1.7

Basic

*

Oil temperature

degC

50

48

52

_02

Pump speed

r/min

900

900

900

Timer stroke

mm

1.5

1.2

1.8

Basic

*

Oil temperature

degC

50

48

52

_03

Pump speed

r/min

1200

1200

1200

Timer stroke

mm

3

2.7

3.3

Oil temperature

degC

50

48

52

_04

Pump speed

r/min

2300

2300

2300

Timer stroke

mm

8.4

7.8

9

Oil temperature

degC

52

50

54

0000001201

Max. applied voltage

V

8

8

8

Test voltage

V

13

12

14

Timing setting

K dimension

mm

3.3

3.2

3.4

KF dimension

mm

5.8

5.7

5.9

MS dimension

mm

1.2

1.1

1.3

Control lever angle alpha

deg.

25

21

29

Control lever angle beta

deg.

41

36

46

Test data Ex:

0000001801 POTENTIOMETER ADJUSTMENT

Adjustment of the potentiometer

(1)At pump speed N1 and oil temperature t, and at lever angle a from the idle position (shim thickness L), determine the voltage value from the graph using the injection quantity obtained. Then adjust the potentiometer.

V+-0.05 = 0.155323Q + 2.43145 (applied voltage Vi)

(2)With the control lever turned to the full speed side, confirm that voltage increases.

(3)Confirm V1 at idling.

Q:Injection quantity

----------

N1=600(r/min) t=48~52(deg) a=11(deg) L=7.2+-0.05(mm) Vi=10(V) V1=1.16+-0.9(V)

----------

----------

N1=600(r/min) t=48~52(deg) a=11(deg) L=7.2+-0.05(mm) Vi=10(V) V1=1.16+-0.9(V)

----------

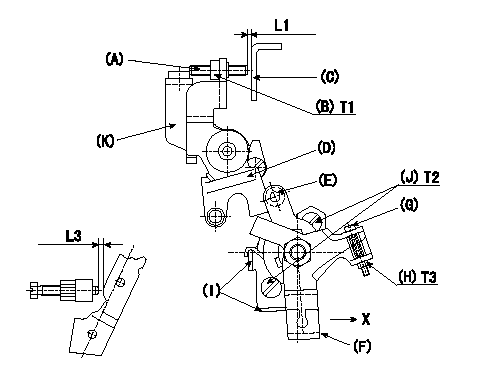

0000001901 M-CSD ADJUSTMENT

M-CSD adjustment

1. Fixing intermediate lever screw (A) [roller (E) must not contact intermediate lever (D)]

(1)Hold the control lever (C) in the idling position.

(2)At this time, adjust screw (A) so that it is horizontal and the clearance between screw (A) and the control lever (C) is L1. Then, fix using nut (B).

2. Fixing the M-CSD stopper (I)

Pull the CSD lever (F) in the direction X until it contacts the stopper (I) and tighten the socket head bolt (J) when the timer advance angle is L2.

3. Screw (G) adjustment

Pull the CSD lever (F) in the direction X until it contacts the stopper (I) and adjust the screw (G) so that the control lever shim thickness is L3. Then, tighten nut (H).

----------

L1=1~2(mm) L2=1.23+-0.2(mm) L3=7.2+-0.5(mm)

----------

T1=6~9(N-m)(0.6~0.9(kgf-m)) T2=5~7(N-m)(0.5~0.7(kgf-m)) T3=2~3(N-m)(0.2~0.3(kgf-m)) L1=1~2(mm) L3=7.2+-0.5(mm)

----------

L1=1~2(mm) L2=1.23+-0.2(mm) L3=7.2+-0.5(mm)

----------

T1=6~9(N-m)(0.6~0.9(kgf-m)) T2=5~7(N-m)(0.5~0.7(kgf-m)) T3=2~3(N-m)(0.2~0.3(kgf-m)) L1=1~2(mm) L3=7.2+-0.5(mm)

Information:

Solution

Caterpillar is aware of this problem and is recommending the following interim corrective action. Please follow the Special Instruction, M0110497, "Removal and Installation Procedure for DEF Heated Lines on Certain Machine Engines" for proper Disassembly and Assembly of the DEF heated lines to avoid failures. If a failure or DEF leak is noted even after following the special instructions, please use Service Magazine, M0103829, "Diesel Exhaust Fluid (DEF) Heated Lines May Be Damage on Certain Cat® Machines" for a temporary line repair. If additional help is needed, please go to the Parts Tech tab and enter a Product Health ticket in PSCRM.The new hose assemblies are listed in Table 1.

Table 1

Item Qty New Part Number Part Name

1 1 457-9011 Return Hose Assembly

2 1 457-9013 Return Hose Assembly

3 1 457-9026 Return Hose Assembly

4 1 457-9027 Return Hose Assembly

5 1 462-4206 Hose As

6 1 462-4210 Hose As

7 1 462-4211 Hose As

8 1 462-4219 Hose As

9 1 462-4220 Hose As

10 1 462-4221 Hose As

11 1 462-4223 Hose As

12 1 462-4224 Hose As

13 1 475-3231 Hose As

14 1 475-3232 Hose As

15 1 475-3233 Hose As

16 1 475-3234 Hose As

17 1 475-9989 Hose As

18 1 478-9071 Hose As

19 1 478-9072 Hose As

20 1 478-9074 Hose As

21 1 478-9075 Hose As

22 1 478-9077 Hose As

23 1 478-9078 Hose As

24 1 478-9079 Hose As

25 1 478-9081 Hose As

26 1 478-9082 Hose As

27 1 478-9083 Hose As

28 1 478-9085 Hose As

29 1 478-9086 Hose As

30 1 497-9305 Hose As

31 1 497-9306 Hose As

32 1 497-9307 Hose As

33 1 497-9308 Hose As

34 1 500-6215 Return Hose Assembly

35 1 500-6216 Return Hose Assembly

36 1 500-6217 Hose As

37 1 500-6218 Hose As

38 1 500-6219 Hose As

39 1 500-6220 Hose As

40 1 500-6221 Hose As

41 1 500-6222 Hose As

42 1 500-6223 Hose As

43 1 500-6224 Hose As

44 1 510-5191 Return Hose Assembly

45 1 510-5192 Hose As

46 1 510-5193 Hose As

47 1 510-5194 Hose As

48 1 552-3292 Hose As

49 1 552-3293 Hose As

50 1 552-3294 Hose As

51 1 552-3295 Hose As

52 1 579-9200 Hose As

53 1 579-9201 Hose As

54 1 579-9202 Hose As

55 1 579-9203 Hose As

Caterpillar is aware of this problem and is recommending the following interim corrective action. Please follow the Special Instruction, M0110497, "Removal and Installation Procedure for DEF Heated Lines on Certain Machine Engines" for proper Disassembly and Assembly of the DEF heated lines to avoid failures. If a failure or DEF leak is noted even after following the special instructions, please use Service Magazine, M0103829, "Diesel Exhaust Fluid (DEF) Heated Lines May Be Damage on Certain Cat® Machines" for a temporary line repair. If additional help is needed, please go to the Parts Tech tab and enter a Product Health ticket in PSCRM.The new hose assemblies are listed in Table 1.

Table 1

Item Qty New Part Number Part Name

1 1 457-9011 Return Hose Assembly

2 1 457-9013 Return Hose Assembly

3 1 457-9026 Return Hose Assembly

4 1 457-9027 Return Hose Assembly

5 1 462-4206 Hose As

6 1 462-4210 Hose As

7 1 462-4211 Hose As

8 1 462-4219 Hose As

9 1 462-4220 Hose As

10 1 462-4221 Hose As

11 1 462-4223 Hose As

12 1 462-4224 Hose As

13 1 475-3231 Hose As

14 1 475-3232 Hose As

15 1 475-3233 Hose As

16 1 475-3234 Hose As

17 1 475-9989 Hose As

18 1 478-9071 Hose As

19 1 478-9072 Hose As

20 1 478-9074 Hose As

21 1 478-9075 Hose As

22 1 478-9077 Hose As

23 1 478-9078 Hose As

24 1 478-9079 Hose As

25 1 478-9081 Hose As

26 1 478-9082 Hose As

27 1 478-9083 Hose As

28 1 478-9085 Hose As

29 1 478-9086 Hose As

30 1 497-9305 Hose As

31 1 497-9306 Hose As

32 1 497-9307 Hose As

33 1 497-9308 Hose As

34 1 500-6215 Return Hose Assembly

35 1 500-6216 Return Hose Assembly

36 1 500-6217 Hose As

37 1 500-6218 Hose As

38 1 500-6219 Hose As

39 1 500-6220 Hose As

40 1 500-6221 Hose As

41 1 500-6222 Hose As

42 1 500-6223 Hose As

43 1 500-6224 Hose As

44 1 510-5191 Return Hose Assembly

45 1 510-5192 Hose As

46 1 510-5193 Hose As

47 1 510-5194 Hose As

48 1 552-3292 Hose As

49 1 552-3293 Hose As

50 1 552-3294 Hose As

51 1 552-3295 Hose As

52 1 579-9200 Hose As

53 1 579-9201 Hose As

54 1 579-9202 Hose As

55 1 579-9203 Hose As

Have questions with 104749-2441?

Group cross 104749-2441 ZEXEL

Nissan

Nitco(Misa)

Nissan

Nitco(Misa)

104749-2441

INJECTION-PUMP ASSEMBLY