Information injection-pump assembly

BOSCH

9 460 610 128

9460610128

ZEXEL

104749-2082

1047492082

Rating:

Cross reference number

BOSCH

9 460 610 128

9460610128

ZEXEL

104749-2082

1047492082

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113orSAEJ967d

1404 Test oil ISO4113orSAEJ967d

Test oil temperature

degC

45

45

50

Nozzle

105000-2010

Bosch type code

NP-DN12SD12TT

Nozzle holder

105780-2080

Opening pressure

MPa

14.7

14.7

15.19

Opening pressure

kgf/cm2

150

150

155

Injection pipe

Inside diameter - outside diameter - length (mm) mm 2-6-840

Inside diameter - outside diameter - length (mm) mm 2-6-840

Transfer pump pressure

kPa

20

20

20

Transfer pump pressure

kgf/cm2

0.2

0.2

0.2

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Pump speed

r/min

900

900

900

Average injection quantity

mm3/st.

33

32.5

33.5

Difference in delivery

mm3/st.

2.5

Basic

*

Injection timing adjustment_02

Pump speed

r/min

2500

2500

2500

Average injection quantity

mm3/st.

13.2

9.7

16.7

Injection timing adjustment_03

Pump speed

r/min

2200

2200

2200

Average injection quantity

mm3/st.

33.1

31.1

35.1

Injection timing adjustment_04

Pump speed

r/min

900

900

900

Average injection quantity

mm3/st.

33

32

34

Injection timing adjustment_05

Pump speed

r/min

600

600

600

Average injection quantity

mm3/st.

33.2

31.2

35.2

Injection quantity adjustment

Pump speed

r/min

2500

2500

2500

Average injection quantity

mm3/st.

13.2

10.2

16.2

Basic

*

Injection quantity adjustment_02

Pump speed

r/min

2800

2800

2800

Average injection quantity

mm3/st.

4

Governor adjustment

Pump speed

r/min

325

325

325

Average injection quantity

mm3/st.

8.2

6.7

9.7

Basic

*

Governor adjustment_02

Pump speed

r/min

325

325

325

Average injection quantity

mm3/st.

8.2

6.2

10.2

Difference in delivery

mm3/st.

2.5

Governor adjustment_03

Pump speed

r/min

500

500

500

Average injection quantity

mm3/st.

4

Boost compensator adjustment

Pump speed

r/min

900

900

900

Average injection quantity

mm3/st.

10

5

15

Timer adjustment

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

52

52

Basic

*

Speed control lever angle

Pump speed

r/min

325

325

325

Average injection quantity

mm3/st.

0

0

0

Remarks

Magnet OFF

Magnet OFF

0000000901

Pump speed

r/min

1000

1000

1000

Overflow quantity

cm3/min

348

216

480

Stop lever angle

Pump speed

r/min

900

900

900

Pressure

kPa

313.5

284

343

Pressure

kgf/cm2

3.2

2.9

3.5

Basic

*

Stop lever angle_02

Pump speed

r/min

900

900

900

Pressure

kPa

314

275

353

Pressure

kgf/cm2

3.2

2.8

3.6

Stop lever angle_03

Pump speed

r/min

1800

1800

1800

Pressure

kPa

520

481

559

Pressure

kgf/cm2

5.3

4.9

5.7

Stop lever angle_04

Pump speed

r/min

2200

2200

2200

Pressure

kPa

608

569

647

Pressure

kgf/cm2

6.2

5.8

6.6

0000001101

Pump speed

r/min

900

900

900

Timer stroke

mm

1.4

1.1

1.7

Basic

*

_02

Pump speed

r/min

900

900

900

Timer stroke

mm

1.4

1

1.8

_03

Pump speed

r/min

1800

1800

1800

Timer stroke

mm

5.1

4.5

5.7

_04

Pump speed

r/min

2200

2200

2200

Timer stroke

mm

7.25

6.7

7.8

0000001201

Max. applied voltage

V

8

8

8

Test voltage

V

13

12

14

Timing setting

K dimension

mm

3.3

3.2

3.4

KF dimension

mm

5.8

5.7

5.9

MS dimension

mm

1.2

1.1

1.3

Control lever angle alpha

deg.

58

56

60

Control lever angle beta

deg.

41

36

46

Control lever angle gamma

deg.

11

10.5

11.5

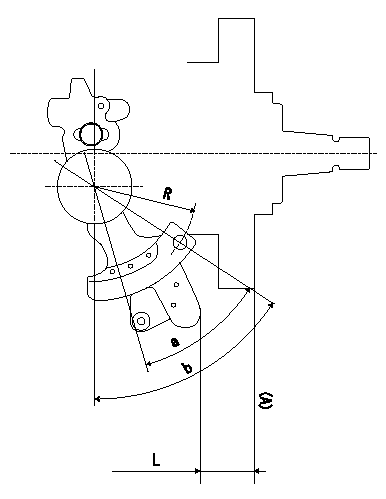

Test data Ex:

0000001801 CONTROL LEVER ANGLE

Control lever angle measurement

1. Measure the dimension L from the lever tip to the flange face (A).

2. Measure the lever angle from the pin hole R (plate).

Alpha = a

beta = b

----------

R=50mm L=8.9~13.2mm

----------

R=50mm a=41+-5deg b=58+-2deg L=8.9~13.2mm

----------

R=50mm L=8.9~13.2mm

----------

R=50mm a=41+-5deg b=58+-2deg L=8.9~13.2mm

Information:

Tooling, Test, and Bulk Ground Fill Support Equipment

Diesel Exhaust Fluid (DEF)

Two container sizes of DEF are available through the Cat® dealers in North America. DEF must meet ISO 22241-1 specifications.

Table 1

Tool Part Number Description

350-8733 Diesel Exhaust Fluid 9.5 L (2.5 US gal) bottle

350-8734 Diesel Exhaust Fluid 1378 L (364 US gal) tote

443-0955 Removal Tool DEF filter removal tool Dispensing Equipment

Three different dispensing kits are offered to protect DEF quality. Optional flow meter and coupler are also available.

Table 2

Tool Part Number Description

422-1185 Pump Adapter (DEF DISPENSER) 12 V dispenser unit

423-7843 Pump Adapter (DEF DISPENSER) 110 V dispenser unit

423-7844 Pump Adapter (DEF DISPENSER) 230 V dispenser unit with"smart start"tote base

423-7795 Flow Meter In line DEF flow meter

423-7799 Coupler MicroMatic coupler Dispenser Unit Repair Parts

Table 3

Tool Part Number Description

436-6643 Repair Kit 12 V dispenser unit

436-6646 Diesel Exhaust Fluid Pump 12 V repair group

436-6642 Hose 20'/4'

436-6644 Swivel

436-6645 Repair Kit 1/2 hp pump

436-6647 Nozzle (DIESEL EXHAUST FLUID) Dispensing nozzle Storage and Transportation

Preventing DEF contamination does not stop at the pump. Protect your DEF supply with climate-specific enclosures and transportation tanks.

Table 4

Part Number Description

435-8671 Dispenser Warm-weather enclosure

435-8672 Dispenser Cold-weather enclosure

460-4077 Tank 121 L (32 US gal)

460-4078 Tank 269 L (71 US gal) Fast Fill Vehicle Interface

Illustration 1 g06516654

584-9979 Nozzle As

Table 5

584-9979 Nozzle As

Repair parts for 584-9979 Nozzle As

- 587-3371 Rear Cap

- 587-3372 Handle

- 587-3373 Hose (3/4")

- 587-3374 O-Ring Seal

- 587-3375 Handle (optional)

459-9296 Receiver As (Permanently mounted on vehicle)

For heated DEF hose repair connectors, kits, and instructions , refer to Service Magazine, M0103829, "Repair Kits for Quick Connect Diesel Exhaust Fluid (DEF) Line Fittings Are Now Available for Certain Cat® Machine Engines". Testing Equipment

Test your DEF supply and DEF injector with DEF-specific testing equipment. Complete kits or individual testing components are available for your needs.

Table 6

441-0451 Tool Gp (includes hard case, foam insert, and hardware)

- 441-0454 Container

- 443-7055 Test Kit

- 398-4985 Probe

- 398-4987 Probe

- 398-5080 Lead

- 398-5081 Lead

- 398-5083 Plug

450-1515 Tool Gp (DIESEL EXHAUST FLUID) (includes hard case, foam insert, and hardware)

- 441-0454 Container

- 398-4985 Probe

- 398-4987 Probe

- 398-5080 Lead

- 398-5081 Lead

- 398-5083 Plug

441-0454 Container

443-7055 Test Kit

431-7087 Tool Gp (REFRACTOMETER (DEF))

360-0774 Refractometer

372-5260 Test Lead Tool Group

576-6134 Test Strip

Diesel Exhaust Fluid (DEF)

Two container sizes of DEF are available through the Cat® dealers in North America. DEF must meet ISO 22241-1 specifications.

Table 1

Tool Part Number Description

350-8733 Diesel Exhaust Fluid 9.5 L (2.5 US gal) bottle

350-8734 Diesel Exhaust Fluid 1378 L (364 US gal) tote

443-0955 Removal Tool DEF filter removal tool Dispensing Equipment

Three different dispensing kits are offered to protect DEF quality. Optional flow meter and coupler are also available.

Table 2

Tool Part Number Description

422-1185 Pump Adapter (DEF DISPENSER) 12 V dispenser unit

423-7843 Pump Adapter (DEF DISPENSER) 110 V dispenser unit

423-7844 Pump Adapter (DEF DISPENSER) 230 V dispenser unit with"smart start"tote base

423-7795 Flow Meter In line DEF flow meter

423-7799 Coupler MicroMatic coupler Dispenser Unit Repair Parts

Table 3

Tool Part Number Description

436-6643 Repair Kit 12 V dispenser unit

436-6646 Diesel Exhaust Fluid Pump 12 V repair group

436-6642 Hose 20'/4'

436-6644 Swivel

436-6645 Repair Kit 1/2 hp pump

436-6647 Nozzle (DIESEL EXHAUST FLUID) Dispensing nozzle Storage and Transportation

Preventing DEF contamination does not stop at the pump. Protect your DEF supply with climate-specific enclosures and transportation tanks.

Table 4

Part Number Description

435-8671 Dispenser Warm-weather enclosure

435-8672 Dispenser Cold-weather enclosure

460-4077 Tank 121 L (32 US gal)

460-4078 Tank 269 L (71 US gal) Fast Fill Vehicle Interface

Illustration 1 g06516654

584-9979 Nozzle As

Table 5

584-9979 Nozzle As

Repair parts for 584-9979 Nozzle As

- 587-3371 Rear Cap

- 587-3372 Handle

- 587-3373 Hose (3/4")

- 587-3374 O-Ring Seal

- 587-3375 Handle (optional)

459-9296 Receiver As (Permanently mounted on vehicle)

For heated DEF hose repair connectors, kits, and instructions , refer to Service Magazine, M0103829, "Repair Kits for Quick Connect Diesel Exhaust Fluid (DEF) Line Fittings Are Now Available for Certain Cat® Machine Engines". Testing Equipment

Test your DEF supply and DEF injector with DEF-specific testing equipment. Complete kits or individual testing components are available for your needs.

Table 6

441-0451 Tool Gp (includes hard case, foam insert, and hardware)

- 441-0454 Container

- 443-7055 Test Kit

- 398-4985 Probe

- 398-4987 Probe

- 398-5080 Lead

- 398-5081 Lead

- 398-5083 Plug

450-1515 Tool Gp (DIESEL EXHAUST FLUID) (includes hard case, foam insert, and hardware)

- 441-0454 Container

- 398-4985 Probe

- 398-4987 Probe

- 398-5080 Lead

- 398-5081 Lead

- 398-5083 Plug

441-0454 Container

443-7055 Test Kit

431-7087 Tool Gp (REFRACTOMETER (DEF))

360-0774 Refractometer

372-5260 Test Lead Tool Group

576-6134 Test Strip