Information injection-pump assembly

BOSCH

9 460 614 697

9460614697

ZEXEL

104749-1690

1047491690

ISUZU

8941237250

8941237250

Rating:

Components :

| 0. | INJECTION-PUMP ASSEMBLY | 104749-1690 |

| 1. | _ | |

| 2. | FUEL INJECTION PUMP | 104649-1450 |

| 3. | NUMBER PLATE | |

| 4. | _ | |

| 5. | CAPSULE | |

| 6. | ADJUSTING DEVICE | 593175-2221 |

| 7. | NOZZLE AND HOLDER ASSY | 105151-1550 |

| 8. | Nozzle and Holder | |

| 9. | Open Pre:MPa(Kqf/cm2) | 10.3(105) |

| 10. | NOZZLE-HOLDER | 105081-3210 |

| 11. | NOZZLE | 105000-1740 |

Scheme ###:

| 1/6. | [1] | 146601-0700 | PACKING RING |

| 6. | [1] | 146100-0120 | SUPPLY PUMP |

| 9. | [1] | 146103-0000 | COVER |

| 10. | [2] | 139104-0000 | FLAT-HEAD SCREW |

| 12. | [1] | 146200-0320 | DRIVE SHAFT |

| 12/1. | [1] | 146200-0300 | DRIVE SHAFT |

| 12/2. | [1] | 146201-0000 | WOODRUFF KEY |

| 12/3. | [2] | 146202-0100 | DAMPER |

| 12/4. | [1] | 146203-0000 | TOOTHED GEAR |

| 17. | [1] | 146204-0000 | PLAIN WASHER |

| 20. | [1] | 146210-1720 | ROLLER SET |

| 24. | [1] | 146303-0000 | BEARING PIN |

| 25. | [1] | 146304-0000 | BEARING PIN |

| 26. | [1] | 146305-0000 | CLAMPING BAND |

| 27. | [1] | 146205-0000 | SLOTTED WASHER |

| 29. | [1] | 146220-0020 | CAM PLATE |

| 30. | [1] | 146600-0800 | O-RING |

| 31. | [1] | 146300-0900 | PUMP PLUNGER |

| 32. | [1] | 146301-0000 | SLIDING PIECE |

| 33. | [1] | 146603-0700 | SHIM |

| 34. | [1] | 146302-3500 | COMPRESSION SPRING |

| 35/1. | [0] | 146603-0700 | SHIM D17.5&7.5T0.60 |

| 35/1. | [0] | 146603-0800 | SHIM D17.5&7.5T0.70 |

| 35/1. | [0] | 146603-0900 | SHIM D17.5&7.5T0.90 |

| 35/1. | [0] | 146603-1000 | SHIM D17.5&7.5T1.00 |

| 35/1. | [0] | 146603-1100 | SHIM D17.5&7.5T1.20 |

| 35/1. | [0] | 146603-3600 | SHIM D17.5&7.5T2.40 |

| 36. | [1] | 146600-0800 | O-RING |

| 37. | [1] | 146310-0000 | COVER |

| 38. | [2] | 146620-5000 | BLEEDER SCREW |

| 39. | [1] | 146340-0921 | START ADVANCE ASSY |

| 39/1. | [1] | 146342-2200 | DIAPHRAGM HOUSING |

| 39/2. | [1] | 146342-2320 | PUMP PLUNGER |

| 39/3. | [1] | 146342-2421 | COVER |

| 39/4. | [1] | 146342-3700 | COILED SPRING |

| 39/5. | [1] | 146342-3800 | COILED SPRING |

| 39/6. | [1] | 146602-1600 | PLAIN WASHER |

| 39/7/1. | [0] | 146603-4300 | SHIM T0.30 |

| 39/7/1. | [0] | 146603-4400 | SHIM T0.50 |

| 39/7/1. | [0] | 146603-4500 | SHIM T0.70 |

| 39/7/1. | [0] | 146603-4600 | SHIM T1.00 |

| 39/7/1. | [0] | 146603-4700 | SHIM T1.20 |

| 39/9. | [1] | 146342-2800 | CAPSULE |

| 39/10. | [1] | 016500-2220 | O-RING |

| 39/11. | [4] | 020106-1640 | BLEEDER SCREW |

| 39/14. | [1] | 131420-0400 | BLEEDER SCREW |

| 39/15. | [1] | 026506-1040 | GASKET |

| 40. | [2] | 013020-6040 | UNION NUT |

| 43. | [1] | 146230-0000 | SHIM |

| 44. | [1] | 146230-0100 | PLAIN WASHER |

| 45. | [1] | 146231-0001 | SLOTTED WASHER |

| 47. | [2] | 146233-0000 | SLOTTED WASHER |

| 48/1. | [1] | 146603-0000 | SHIM D17.0&5.2T0.50 |

| 48/1. | [1] | 146603-0100 | SHIM D17.0&5.2T0.80 |

| 48/1. | [1] | 146603-0200 | SHIM D17.0&5.2T1.00 |

| 48/1. | [1] | 146603-0300 | SHIM D17.0&5.2T1.20 |

| 48/1. | [1] | 146603-0400 | SHIM D17.0&5.2T1.50 |

| 48/1. | [1] | 146603-0500 | SHIM D17.0&5.2T1.80 |

| 48/1. | [1] | 146603-0600 | SHIM D17.0&5.2T2.00 |

| 48/1. | [1] | 146690-1400 | SHIM D17&5.2T0.9 |

| 48/1. | [1] | 146690-1500 | SHIM D17&5.2T1.1 |

| 48/1. | [1] | 146690-1600 | SHIM D17&5.2T1.3 |

| 48/1. | [1] | 146690-1700 | SHIM D17&5.2T1.4 |

| 48/1. | [1] | 146690-1800 | SHIM D17&5.2T1.6 |

| 48/1. | [1] | 146690-1900 | SHIM D17&5.2T1.7 |

| 48/1. | [1] | 146690-5800 | SHIM D17&5.2T2.1 |

| 48/1. | [1] | 146690-5900 | SHIM D17&5.2T2.2 |

| 48/1. | [1] | 146690-6000 | SHIM D17&5.2T2.3 |

| 48/1. | [1] | 146690-6100 | SHIM D17&5.2T2.4 |

| 48/1. | [1] | 146690-6200 | SHIM D17&5.2T2.5 |

| 48/1. | [1] | 146690-6300 | SHIM D17&5.2T2.6 |

| 48/1. | [1] | 146690-6400 | SHIM D17&5.2T2.7 |

| 48/1. | [1] | 146690-6500 | SHIM D17&5.2T2.8 |

| 48/1. | [1] | 146690-6600 | SHIM D17&5.2T2.9 |

| 48/1. | [1] | 146690-6700 | SHIM D17&5.2T3.0 |

| 48/1. | [1] | 146690-6800 | SHIM D17&5.2T3.1 |

| 48/1. | [1] | 146690-6900 | SHIM D17&5.2T3.2 |

| 48/1. | [1] | 146690-7000 | SHIM D17&5.2T3.3 |

| 48/1. | [1] | 146690-7100 | SHIM D17&5.2T3.4 |

| 48/1. | [1] | 146690-7200 | SHIM D17&5.2T0.4 |

| 48/1. | [1] | 146690-7300 | SHIM D17&5.2T0.6 |

| 48/1. | [1] | 146690-7400 | SHIM D17&5.2T0.7 |

| 48/1. | [1] | 146690-7500 | SHIM D17&5.2T1.9 |

| 48/1. | [1] | 146690-7800 | SHIM D17&5.2T0.2 |

| 49. | [2] | 146234-0500 | GUIDE PIN |

| 50. | [1] | 146400-5420 | HYDRAULIC HEAD |

| 50. | [1] | 146400-5420 | HYDRAULIC HEAD |

| 50. | [1] | 146400-5420 | HYDRAULIC HEAD |

| 51. | [1] | 146600-0000 | O-RING |

| 52/1. | [1] | 146420-0000 | SHIM D9.5&3.0T1.90 |

| 52/1. | [1] | 146420-0100 | SHIM D9.5&3.0T1.92 |

| 52/1. | [1] | 146420-0200 | SHIM D9.5&3.0T1.94 |

| 52/1. | [1] | 146420-0300 | SHIM D9.5&3.0T1.96 |

| 52/1. | [1] | 146420-0400 | SHIM D9.5&3.0T1.98 |

| 52/1. | [1] | 146420-0500 | SHIM D9.5&3.0T2.00 |

| 52/1. | [1] | 146420-0600 | SHIM D9.5&3.0T2.02 |

| 52/1. | [1] | 146420-0700 | SHIM D9.5&3.0T2.04 |

| 52/1. | [1] | 146420-0800 | SHIM D9.5&3.0T2.06 |

| 52/1. | [1] | 146420-0900 | SHIM D9.5&3.0T2.08 |

| 52/1. | [1] | 146420-1000 | SHIM D9.5&3.0T2.10 |

| 52/1. | [1] | 146420-1100 | SHIM D9.5&3.0T2.12 |

| 52/1. | [1] | 146420-1200 | SHIM D9.5&3.0T2.14 |

| 52/1. | [1] | 146420-1300 | SHIM D9.5&3.0T2.16 |

| 52/1. | [1] | 146420-1400 | SHIM D9.5&3.0T2.18 |

| 52/1. | [1] | 146420-1500 | SHIM D9.5&3.0T2.20 |

| 52/1. | [1] | 146420-1600 | SHIM D9.5&3.0T2.22 |

| 52/1. | [1] | 146420-1700 | SHIM D9.5&3.0T2.24 |

| 52/1. | [1] | 146420-1800 | SHIM D9.5&3.0T2.26 |

| 52/1. | [1] | 146420-1900 | SHIM D9.5&3.0T2.28 |

| 52/1. | [1] | 146420-2000 | SHIM D9.5&3.0T2.30 |

| 52/1. | [1] | 146420-2100 | SHIM D9.5&3.0T2.32 |

| 52/1. | [1] | 146420-2200 | SHIM D9.5&3.0T2.34 |

| 52/1. | [1] | 146420-2300 | SHIM D9.5&3.0T2.36 |

| 52/1. | [1] | 146420-2400 | SHIM D9.5&3.0T2.38 |

| 52/1. | [1] | 146420-2500 | SHIM D9.5&3.0T2.40 |

| 52/1. | [1] | 146420-2600 | SHIM D9.5&3.0T2.42 |

| 52/1. | [1] | 146420-2700 | SHIM D9.5&3.0T2.44 |

| 52/1. | [1] | 146420-2800 | SHIM D9.5&3.0T2.46 |

| 52/1. | [1] | 146420-2900 | SHIM D9.5&3.0T2.48 |

| 52/1. | [1] | 146420-3000 | SHIM D9.5&3.0T2.50 |

| 52/1. | [1] | 146420-3100 | SHIM D9.5&3.0T2.52 |

| 52/1. | [1] | 146420-3200 | SHIM D9.5&3.0T2.54 |

| 52/1. | [1] | 146420-3300 | SHIM D9.5&3.0T2.56 |

| 52/1. | [1] | 146420-3400 | SHIM D9.5&3.0T2.58 |

| 52/1. | [1] | 146420-3500 | SHIM D9.5&3.0T2.60 |

| 52/1. | [1] | 146420-3600 | SHIM D9.5&3.0T2.62 |

| 52/1. | [1] | 146420-3700 | SHIM D9.5&3.0T2.64 |

| 52/1. | [1] | 146420-3800 | SHIM D9.5&3.0T2.66 |

| 52/1. | [1] | 146420-3900 | SHIM D9.5&3.0T2.68 |

| 52/1. | [1] | 146420-4000 | SHIM D9.5&3.0T2.70 |

| 52/1. | [1] | 146420-4100 | SHIM D9.5&3.0T2.72 |

| 52/1. | [1] | 146420-4200 | SHIM D9.5&3.0T2.74 |

| 52/1. | [1] | 146420-4300 | SHIM D9.5&3.0T2.76 |

| 52/1. | [1] | 146420-4400 | SHIM D9.5&3.0T2.78 |

| 52/1. | [1] | 146420-4500 | SHIM D9.5&3.0T2.80 |

| 52/1. | [1] | 146420-4600 | SHIM D9.5&3.0T2.82 |

| 52/1. | [1] | 146420-4700 | SHIM D9.5&3.0T2.84 |

| 52/1. | [1] | 146420-4800 | SHIM D9.5&3.0T2.86 |

| 52/1. | [1] | 146420-4900 | SHIM D9.5&3.0T2.88 |

| 52/1. | [1] | 146420-5000 | SHIM D9.5&3.0T2.90 |

| 52/1. | [1] | 146420-5100 | SHIM D9.5&3.0T1.74 |

| 52/1. | [1] | 146420-5200 | SHIM D9.5&3.0T1.76 |

| 52/1. | [1] | 146420-5300 | SHIM D9.5&3.0T1.78 |

| 52/1. | [1] | 146420-5400 | SHIM D9.5&3.0T1.80 |

| 52/1. | [1] | 146420-5500 | SHIM D9.5&3.0T1.82 |

| 52/1. | [1] | 146420-5600 | SHIM D9.5&3.0T1.84 |

| 52/1. | [1] | 146420-5700 | SHIM D9.5&3.0T1.86 |

| 52/1. | [1] | 146420-5800 | SHIM D9.5&3.0T1.88 |

| 54. | [4] | 146433-0100 | GASKET |

| 55. | [4] | 146430-0120 | DELIVERY-VALVE ASSEMBLY VE2 |

| 56. | [4] | 146432-0000 | COMPRESSION SPRING |

| 58. | [4] | 146440-0120 | FITTING |

| 60. | [4] | 139106-0100 | FLAT-HEAD SCREW |

| 66. | [1] | 146600-0100 | O-RING |

| 67. | [1] | 146705-3622 | ANEROID CAPSULE |

| 67/1. | [1] | 146505-9021 | GOVERNOR COVER |

| 67/13. | [1] | 013020-6040 | UNION NUT |

| 67/14. | [1] | 146621-1700 | UNION NUT |

| 67/15. | [1] | 146526-1800 | BLEEDER SCREW |

| 67/16. | [1] | 146526-3000 | BLEEDER SCREW |

| 67/23. | [1] | 146625-8300 | BRACKET |

| 67/24. | [2] | 010506-1640 | FLAT-HEAD SCREW |

| 67/26. | [1] | 146625-3020 | BRACKET |

| 67/31. | [1] | 146710-0400 | BUSHING |

| 67/32. | [1] | 146602-1800 | PLAIN WASHER |

| 67/33. | [1] | 146716-0200 | UNION NUT |

| 67/34/1. | [1] | 146713-1000 | BEARING PIN L24.6 |

| 67/34/1. | [1] | 146713-1100 | BEARING PIN L24.8 |

| 67/34/1. | [1] | 146713-1200 | BEARING PIN L25.0 |

| 67/34/1. | [1] | 146713-1300 | BEARING PIN L25.2 |

| 67/34/1. | [1] | 146713-1400 | BEARING PIN L25.4 |

| 67/35. | [1] | 146621-0300 | UNION NUT |

| 67/36. | [1] | 146600-1400 | O-RING |

| 67/37. | [1] | 146710-0100 | BUSHING |

| 67/38. | [1] | 139506-0200 | GASKET |

| 67/39. | [1] | 146620-0300 | CAPSULE |

| 67/40. | [1] | 026512-1540 | GASKET |

| 67/41. | [1] | 146713-3500 | ADJUSTING PIN |

| 67/47. | [1] | 146717-0200 | COILED SPRING |

| 67/49. | [1] | 146721-0700 | COVER |

| 67/54. | [4] | 139006-4500 | BLEEDER SCREW |

| 67/56. | [1] | 146723-0200 | CONTROL LEVER |

| 67/57. | [1] | 146712-0100 | BEARING PIN |

| 67/58. | [2] | 146620-0600 | CAPSULE |

| 67/59. | [2] | 026506-1040 | GASKET |

| 67/60. | [1] | 146724-0300 | ELEMENT |

| 67/61. | [1] | 146724-0400 | CAPSULE |

| 67/64. | [1] | 146625-3300 | BRACKET |

| 67/70. | [1] | 016520-6010 | O-RING |

| 67/71. | [1] | 146714-0100 | SLOTTED WASHER |

| 67/72. | [1] | 016010-0920 | LOCKING WASHER |

| 67/73. | [1] | 146715-0120 | BELLOWS |

| 67/74/1. | [0] | 146603-3700 | SHIM T0.20 |

| 67/74/1. | [0] | 146603-3800 | SHIM T0.30 |

| 67/74/1. | [0] | 146603-3900 | SHIM T0.50 |

| 67/74/1. | [0] | 146603-4000 | SHIM T0.70 |

| 67/74/1. | [0] | 146603-4100 | SHIM T1.00 |

| 67/74/1. | [0] | 146603-4200 | SHIM T1.50 |

| 67/78. | [1] | 146600-4400 | SEAL RING |

| 67/200. | [1] | 139308-0300 | PLAIN WASHER |

| 67/201. | [1] | 146545-3400 | THREADED PIN L53.00 |

| 67/201B. | [1] | 146545-3500 | THREADED PIN L55.00 |

| 67/201C. | [1] | 146545-3600 | THREADED PIN L57.00 |

| 67/202. | [1] | 139208-0900 | UNION NUT |

| 67/203. | [1] | 146600-1200 | O-RING |

| 68. | [1] | 146510-2020 | CONTROL SHAFT |

| 69. | [1] | 139310-0200 | PLAIN WASHER |

| 72. | [1] | 146533-1720 | CONTROL LEVER |

| 72B. | [1] | 146533-1820 | CONTROL LEVER |

| 73. | [1] | 014110-6440 | LOCKING WASHER D12.2&6.1T1.5 |

| 75. | [1] | 013020-6040 | UNION NUT |

| 95. | [1] | 146561-0920 | FULCRUM LEVER |

| 104. | [2] | 146568-0000 | SLOTTED SPRING PIN |

| 105. | [2] | 026508-1140 | GASKET D11.4&8.2T1.0 |

| 106. | [2] | 146588-0500 | COILED SPRING |

| 107. | [1] | 146569-0300 | UNION NUT |

| 108. | [1] | 146570-0100 | GOVERNOR SHAFT |

| 109. | [1] | 146600-0400 | O-RING |

| 110/1. | [1] | 146571-0000 | SHIM D20.2&8.3T1.05 |

| 110/1. | [1] | 146571-0100 | SHIM D20.2&8.3T1.25 |

| 110/1. | [1] | 146571-0200 | SHIM D20.2&8.3T1.45 |

| 110/1. | [1] | 146571-0300 | SHIM D20.2&8.3T1.65 |

| 110/1. | [1] | 146571-0400 | SHIM D20.2&8.3T1.85 |

| 110/1. | [1] | 146571-0500 | SHIM D20.2&8.3T1.15 |

| 110/1. | [1] | 146571-0600 | SHIM D20.2&8.3T1.35 |

| 110/1. | [1] | 146571-0700 | SHIM D20.2&8.3T1.55 |

| 110/1. | [1] | 146571-0800 | SHIM D20.2&8.3T1.75 |

| 111. | [1] | 146602-0600 | PLAIN WASHER |

| 112. | [1] | 146572-0020 | FLYWEIGHT ASSEMBLY |

| 114. | [1] | 146602-0500 | PLAIN WASHER |

| 115. | [1] | 146575-0500 | SLIDING SLEEVE |

| 116. | [1] | 146576-0000 | SEALING CAP |

| 117/1. | [1] | 146577-0000 | PLUG L1.70 |

| 117/1. | [1] | 146577-0100 | PLUG L1.90 |

| 117/1. | [1] | 146577-0200 | PLUG L2.10 |

| 117/1. | [1] | 146577-0300 | PLUG L2.30 |

| 117/1. | [1] | 146577-0400 | PLUG L2.50 |

| 117/1. | [1] | 146577-0500 | PLUG L2.70 |

| 117/1. | [1] | 146577-0600 | PLUG L2.90 |

| 117/1. | [1] | 146577-0700 | PLUG L3.10 |

| 117/1. | [1] | 146577-0800 | PLUG L3.30 |

| 117/1. | [1] | 146577-0900 | PLUG L3.50 |

| 117/1. | [1] | 146577-1000 | PLUG L3.70 |

| 117/1. | [1] | 146577-1100 | PLUG L3.90 |

| 117/1. | [1] | 146577-1200 | PLUG L4.10 |

| 117/1. | [1] | 146577-1300 | PLUG L4.30 |

| 117/1. | [1] | 146577-1400 | PLUG L4.50 |

| 117/1. | [1] | 146577-1500 | PLUG L4.70 |

| 117/1. | [1] | 146577-1600 | PLUG L4.90 |

| 117/1. | [1] | 146577-1700 | PLUG L5.10 |

| 117/1. | [1] | 146577-5000 | PLUG L1.8 |

| 117/1. | [1] | 146577-5100 | PLUG L2.0 |

| 117/1. | [1] | 146577-5200 | PLUG L2.2 |

| 117/1. | [1] | 146577-5300 | PLUG L2.4 |

| 117/1. | [1] | 146577-5400 | PLUG L2.6 |

| 117/1. | [1] | 146577-5500 | PLUG L2.8 |

| 117/1. | [1] | 146577-5600 | PLUG L3.0 |

| 117/1. | [1] | 146577-5700 | PLUG L3.2 |

| 117/1. | [1] | 146577-5800 | PLUG L3.4 |

| 117/1. | [1] | 146577-5900 | PLUG L3.6 |

| 117/1. | [1] | 146577-6000 | PLUG L3.8 |

| 117/1. | [1] | 146577-6100 | PLUG L4.0 |

| 117/1. | [1] | 146577-6200 | PLUG L4.2 |

| 117/1. | [1] | 146577-6300 | PLUG L4.4 |

| 117/1. | [1] | 146577-6400 | PLUG L4.6 |

| 117/1. | [1] | 146577-6500 | PLUG L4.8 |

| 117/1. | [1] | 146577-6600 | PLUG L5.0 |

| 117/1. | [1] | 146877-0400 | PLUG |

| 117/1. | [1] | 146877-0500 | PLUG |

| 117/1. | [1] | 146877-0600 | PLUG |

| 117/1. | [1] | 146877-0700 | PLUG |

| 117/1. | [1] | 146877-4300 | PLUG |

| 117/1. | [1] | 146877-4400 | PLUG |

| 117/1. | [1] | 146877-4500 | PLUG |

| 117/1. | [1] | 146877-4600 | PLUG |

| 123. | [4] | 146620-0500 | HEX-SOCKET-HEAD CAP SCREW |

| 130. | [1] | 146421-0020 | CAPSULE |

| 130/2. | [1] | 026508-1140 | GASKET D11.4&8.2T1.0 |

| 130/3. | [1] | 146422-0000 | BLEEDER SCREW |

| 130/4. | [1] | 146600-0500 | O-RING |

| 133. | [1] | 146600-0600 | O-RING |

| 134. | [1] | 146600-0700 | O-RING |

| 135. | [1] | 146110-0220 | CONTROL VALVE STAMP 02 |

| 135/5. | [1] | 146114-0000 | SPRING WASHER |

| 135B. | [1] | 146110-1020 | CONTROL VALVE STAMP 10 |

| 135B/5. | [1] | 146114-0000 | SPRING WASHER |

| 136. | [1] | 146120-0020 | OVER FLOW VALVE |

| 137. | [2] | 139512-0500 | GASKET |

| 138. | [1] | 146606-1320 | PIPE |

| 150. | [2] | 014020-6140 | PLAIN WASHER D11.5&6.5 |

| 151. | [2] | 139010-0300 | STUD |

| 153. | [1] | 139808-0301 | EYE BOLT |

| 154. | [2] | 026508-1140 | GASKET D11.4&8.2T1.0 |

| 200. | [1] | 146206-0100 | COILED SPRING |

| 205. | [1] | 025804-1610 | WOODRUFF KEY |

| 206. | [1] | 013121-4140 | UNION NUT |

| 207. | [1] | 029321-4050 | LOCKING WASHER |

| 214. | [1] | 146541-1900 | BUSHING |

| 216. | [1] | 146541-2000 | BUSHING |

| 220. | [1] | 146587-2600 | COILED SPRING |

| 240. | [1] | 146650-1220 | PULLING ELECTROMAGNET |

| 240/8. | [1] | 146600-1700 | O-RING |

| 242. | [1] | 146658-7320 | WIRE |

| 243. | [1] | 146621-1000 | UNION NUT |

| 244. | [1] | 146613-5620 | PLATE |

| 245. | [3] | 139512-0500 | GASKET |

| 246. | [1] | 146125-0020 | EYE BOLT |

| 247. | [1] | 146610-8620 | INLET UNION |

| 248. | [1] | 146614-0200 | SPACER BUSHING |

| 260. | [1] | 146611-0021 | BRACKET |

| 261. | [2] | 146621-4700 | UNION NUT |

| 270. | [1] | 146615-0000 | TIMER CORE |

| 800S. | [1] | 146009-6020 | PUMP HOUSING |

| 800S/1/6. | [1] | 146601-0700 | PACKING RING |

| 804S. | [1] | 146232-0220 | COMPRESSION SPRING |

| 805S. | [1] | 146574-0120 | PARTS SET |

| 810S. | [1] | 146600-1120 | REPAIR SET |

| 811S. | [1] | 146600-2120 | PARTS SET |

| 812S. | [1] | 146600-2220 | PARTS SET |

| 821S. | [1] | 146210-5720 | ROLLER SET |

| 903. | [1] | 146620-0120 | CAPSULE |

| 903/2. | [1] | 146600-1300 | O-RING |

| 905. | [1] | 593175-2221 | ADJUSTING DEVICE |

| 905/1. | [1] | 593174-2301 | BRACKET |

| 906. | [1] | 146635-6300 | NAMEPLATE |

| 912. | [2] | 020146-1270 | BLEEDER SCREW |

Include in #2:

104749-1690

as INJECTION-PUMP ASSEMBLY

Cross reference number

BOSCH

9 460 614 697

9460614697

ZEXEL

104749-1690

1047491690

ISUZU

8941237250

8941237250

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113orSAEJ967d

1404 Test oil ISO4113orSAEJ967d

Test oil temperature

degC

45

45

50

Nozzle

105000-2010

Bosch type code

NP-DN12SD12TT

Nozzle holder

105780-2080

Opening pressure

MPa

14.7

14.7

15.19

Opening pressure

kgf/cm2

150

150

155

Injection pipe

Inside diameter - outside diameter - length (mm) mm 2-6-840

Inside diameter - outside diameter - length (mm) mm 2-6-840

Transfer pump pressure

kPa

20

20

20

Transfer pump pressure

kgf/cm2

0.2

0.2

0.2

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Pump speed

r/min

1250

1250

1250

Average injection quantity

mm3/st.

36.1

35.6

36.6

Difference in delivery

mm3/st.

3

Basic

*

Injection timing adjustment_02

Pump speed

r/min

2550

2550

2550

Average injection quantity

mm3/st.

11.1

7.5

14.7

Injection timing adjustment_03

Pump speed

r/min

2175

2175

2175

Average injection quantity

mm3/st.

35.05

32.5

37.6

Injection timing adjustment_04

Pump speed

r/min

1250

1250

1250

Average injection quantity

mm3/st.

36.1

35.1

37.1

Injection timing adjustment_05

Pump speed

r/min

600

600

600

Average injection quantity

mm3/st.

33.55

31

36.1

Injection timing adjustment_06

Pump speed

r/min

1250

1250

1250

Average injection quantity

mm3/st.

35.2

34.7

35.7

Difference in delivery

mm3/st.

3

Basic

*

Remarks

For Japan

For Japan

Injection timing adjustment_07

Pump speed

r/min

2550

2550

2550

Average injection quantity

mm3/st.

10.8

7.3

14.3

Remarks

For Japan

For Japan

Injection timing adjustment_08

Pump speed

r/min

2175

2175

2175

Average injection quantity

mm3/st.

34.2

31.7

36.7

Remarks

For Japan

For Japan

Injection timing adjustment_09

Pump speed

r/min

1250

1250

1250

Average injection quantity

mm3/st.

35.2

34.2

36.2

Remarks

For Japan

For Japan

Injection timing adjustment_10

Pump speed

r/min

600

600

600

Average injection quantity

mm3/st.

32.7

30.2

35.2

Remarks

For Japan

For Japan

Injection quantity adjustment

Pump speed

r/min

2550

2550

2550

Average injection quantity

mm3/st.

11.05

8

14.1

Difference in delivery

mm3/st.

3.5

Basic

*

Injection quantity adjustment_02

Pump speed

r/min

2700

2700

2700

Average injection quantity

mm3/st.

4.1

Injection quantity adjustment_03

Pump speed

r/min

2550

2550

2550

Average injection quantity

mm3/st.

10.8

7.8

13.8

Difference in delivery

mm3/st.

3.5

Basic

*

Remarks

For Japan

For Japan

Injection quantity adjustment_04

Pump speed

r/min

2700

2700

2700

Average injection quantity

mm3/st.

4

Remarks

For Japan

For Japan

Governor adjustment

Pump speed

r/min

375

375

375

Average injection quantity

mm3/st.

7.75

5.7

9.8

Difference in delivery

mm3/st.

2

Basic

*

Governor adjustment_02

Pump speed

r/min

375

375

375

Average injection quantity

mm3/st.

7.75

5.7

9.8

Governor adjustment_03

Pump speed

r/min

500

500

500

Average injection quantity

mm3/st.

3.1

Governor adjustment_04

Pump speed

r/min

375

375

375

Average injection quantity

mm3/st.

7.6

5.6

9.6

Difference in delivery

mm3/st.

2

Basic

*

Remarks

For Japan

For Japan

Governor adjustment_05

Pump speed

r/min

375

375

375

Average injection quantity

mm3/st.

7.6

5.6

9.6

Remarks

For Japan

For Japan

Governor adjustment_06

Pump speed

r/min

500

500

500

Average injection quantity

mm3/st.

3

Remarks

For Japan

For Japan

Timer adjustment

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

64.6

64.6

Basic

*

Timer adjustment_02

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

63

63

Basic

*

Remarks

For Japan

For Japan

Speed control lever angle

Pump speed

r/min

375

375

375

Average injection quantity

mm3/st.

0

0

0

Remarks

Magnet OFF

Magnet OFF

Speed control lever angle_02

Pump speed

r/min

375

375

375

Average injection quantity

mm3/st.

0

0

0

Remarks

For Japan: Magnet OFF

For Japan: Magnet OFF

0000000901

Pump speed

r/min

1000

1000

1000

Overflow quantity

cm3/min

402

276

528

_02

Pump speed

r/min

1000

1000

1000

Overflow quantity

cm3/min

420

288

552

Remarks

For Japan

For Japan

Stop lever angle

Pump speed

r/min

1500

1500

1500

Pressure

kPa

539.5

520

559

Pressure

kgf/cm2

5.5

5.3

5.7

Basic

*

Stop lever angle_02

Pump speed

r/min

1000

1000

1000

Pressure

kPa

411.5

382

441

Pressure

kgf/cm2

4.2

3.9

4.5

Stop lever angle_03

Pump speed

r/min

1500

1500

1500

Pressure

kPa

539.5

520

559

Pressure

kgf/cm2

5.5

5.3

5.7

Stop lever angle_04

Pump speed

r/min

2175

2175

2175

Pressure

kPa

686.5

657

716

Pressure

kgf/cm2

7

6.7

7.3

Stop lever angle_05

Pump speed

r/min

1500

1500

1500

Pressure

kPa

529.5

510

549

Pressure

kgf/cm2

5.4

5.2

5.6

Basic

*

Remarks

For Japan

For Japan

Stop lever angle_06

Pump speed

r/min

1000

1000

1000

Pressure

kPa

402

373

431

Pressure

kgf/cm2

4.1

3.8

4.4

Remarks

For Japan

For Japan

Stop lever angle_07

Pump speed

r/min

1500

1500

1500

Pressure

kPa

529.5

510

549

Pressure

kgf/cm2

5.4

5.2

5.6

Remarks

For Japan

For Japan

Stop lever angle_08

Pump speed

r/min

2175

2175

2175

Pressure

kPa

676.5

647

706

Pressure

kgf/cm2

6.9

6.6

7.2

Remarks

For Japan

For Japan

0000001101

Pump speed

r/min

1500

1500

1500

Timer stroke

mm

4.5

4.3

4.7

Basic

*

_02

Pump speed

r/min

1000

1000

1000

Timer stroke

mm

2.25

1.6

2.9

_03

Pump speed

r/min

1500

1500

1500

Timer stroke

mm

4.5

4.2

4.8

_04

Pump speed

r/min

2175

2175

2175

Timer stroke

mm

7.55

7.2

7.9

_05

Pump speed

r/min

410

310

510

Basic

*

Remarks

C.D.. cancel speed.

C.D.. cancel speed.

_06

Pump speed

r/min

0

0

0

Timer stroke

mm

2.9

2.7

3.1

_07

Pump speed

r/min

385

260

510

Remarks

C.D.. cancel speed.

C.D.. cancel speed.

_08

Pump speed

r/min

1500

1500

1500

Timer stroke

mm

4.4

4.2

4.6

Basic

*

Remarks

For Japan

For Japan

_09

Pump speed

r/min

1000

1000

1000

Timer stroke

mm

2.2

1.6

2.8

Remarks

For Japan

For Japan

_10

Pump speed

r/min

1500

1500

1500

Timer stroke

mm

4.4

4.1

4.7

Remarks

For Japan

For Japan

_11

Pump speed

r/min

2175

2175

2175

Timer stroke

mm

7.45

7

7.9

Remarks

For Japan

For Japan

_12

Pump speed

r/min

450

350

550

Basic

*

Remarks

For Japan: CSD cancel speed

For Japan: CSD cancel speed

_13

Pump speed

r/min

0

0

0

Timer stroke

mm

2.9

2.7

3.1

Remarks

For Japan

For Japan

_14

Pump speed

r/min

425

300

550

Remarks

For Japan: CSD cancel speed

For Japan: CSD cancel speed

0000001201

Max. applied voltage

V

8

8

8

Test voltage

V

13

12

14

0000001501

Pump speed

r/min

1250

1250

1250

Atmospheric pressure difference

kPa

-21.9

-22.6

-21.2

Atmospheric pressure difference

mmHg

-164

-169

-159

Decrease qty

mm3/st.

5.4

4.3

6.5

Basic

*

_02

Pump speed

r/min

1250

1250

1250

Atmospheric pressure difference

kPa

-21.9

-22.6

-21.2

Atmospheric pressure difference

mmHg

-164

-169

-159

Decrease qty

mm3/st.

5.4

3.6

7.2

_03

Pump speed

r/min

1250

1250

1250

Atmospheric pressure difference

kPa

-21.9

-22.6

-21.2

Atmospheric pressure difference

mmHg

-164

-169

-159

Decrease qty

mm3/st.

5.25

4.2

6.3

Basic

*

Remarks

For Japan

For Japan

_04

Pump speed

r/min

1250

1250

1250

Atmospheric pressure difference

kPa

-21.9

-22.6

-21.2

Atmospheric pressure difference

mmHg

-164

-169

-159

Decrease qty

mm3/st.

4.95

2.9

7

Remarks

For Japan

For Japan

Timing setting

K dimension

mm

3.3

3.2

3.4

KF dimension

mm

5.8

5.7

5.9

MS dimension

mm

1.6

1.5

1.7

Control lever angle alpha

deg.

15

11

19

Control lever angle beta

deg.

35

30

40

Test data Ex:

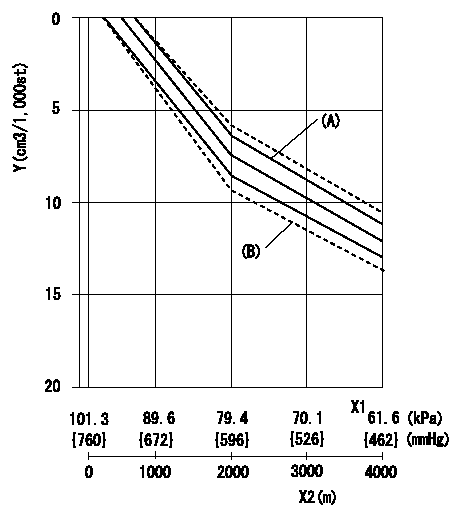

0000001501 ANEROID COMPENSATOR

ACS adjustment

Full load injection quantity at high altitudes and ACS adjusting method

1. Full load injection quantity adjustment

(1)Remove the ACS cover and remove the bellows and adjusting shim.

(2)Perform all adjustments as per the adjustment standard except for ACS adjustment.

2. ACS adjustment

(1)Assemble the ACS cover, bellows and adjusting shim.

(2)At pump speed N1, adjust using a shim to obtain the decrease for the altitude shown in the table.

X1 = atmospheric pressure

X2 = altitude

Y = decrease quantity

(A) = adjustment value

(B) = test value

----------

N1=1250r/min

----------

----------

N1=1250r/min

----------

Information:

Introduction

There have been instances of issues with DEF pumps. After analysis, the cause of the issues has been found as contamination with hydrocarbons.Note: Diesel fuel is an example of a hydrocarbon.The DEF filter is equipped with a compensator located in the center of the filter assembly. If the compensator comes into contact with hydrocarbons, the compensator will swell and is designed to block the filter assembly and protect the DEF pump.Solution

The following procedure is designed to diagnose if the DEF pump has been contaminated with hydrocarbons.

Do not operate or work on this product unless you have read and understood the instruction and warnings in the relevant Operation and Maintenance Manuals and relevant service literature. Failure to follow the instructions or heed the warnings could result in injury or death. Proper care is your responsibility.

Ensure that the engine is stopped before any servicing or repair is performed. The Diesel Exhaust Fluid (DEF) system must have completed a proper shutdown. Service on the DEF pump prior to completion of a proper shutdown can result in DEF spray and spillage.

Do not turn off the battery disconnect switch until the indicator lamp has turned off. If the switch is turned off when the indicator lamp is illuminated, the Diesel Exhaust Fluid (DEF) system may not shut down properly. If the DEF system does not shut down properly, DEF could freeze and damage the pump and lines.

Care must be taken to ensure that fluids are contained during performance of inspection, maintenance, testing, adjusting, and repair of the product. Be prepared to collect the fluid with suitable containers before opening any compartment or disassembling any component containing fluids.Refer to Special Publication, NENG2500, "Cat Dealer Service Tool Catalog" or refer to Special Publication, PECJ0003, "Cat Shop Supplies and Tools Catalog" for tools and supplies suitable to collect and contain fluids on Cat products.Dispose of all fluids according to local regulations and mandates.

Note: Clean water should be used to wash spilled DEF off machine components and surfaces.Note: Wear gloves when handling the DEF filter.

Illustration 1 g06278274

(1) Protective cover

Remove protective cover (1).

Illustration 2 g06278289

(2) DEF filter cap

Use a suitable tool to remove DEF filter cap (2).

Illustration 3 g06278325

(3) Compensator

With the filter installed in the DEF pump, carefully remove compensator (3).

Illustration 4 g06614423

(A) 85 mm (3.3 inch)

(B) 17 mm (0.7 inch)

Check the measurements of compensator (3). Check if the measurements are greater than specified in Illustration 4. This condition indicates that the DEF pump is contaminated with hydrocarbons.

If the measurements indicate contamination, replace the DEF pump filter. Refer to Operation and Maintenance Manual, Diesel Exhaust Fluid Filter - Replace.Flush the DEF tank. Refer to Systems Operation, Testing and Adjusting, Diesel Exhaust Fluid Tank - Flush.

If the measurements are within the specification, continue to follow the appropriate troubleshooting procedure to determine if the DEF pump has a fault.

There have been instances of issues with DEF pumps. After analysis, the cause of the issues has been found as contamination with hydrocarbons.Note: Diesel fuel is an example of a hydrocarbon.The DEF filter is equipped with a compensator located in the center of the filter assembly. If the compensator comes into contact with hydrocarbons, the compensator will swell and is designed to block the filter assembly and protect the DEF pump.Solution

The following procedure is designed to diagnose if the DEF pump has been contaminated with hydrocarbons.

Do not operate or work on this product unless you have read and understood the instruction and warnings in the relevant Operation and Maintenance Manuals and relevant service literature. Failure to follow the instructions or heed the warnings could result in injury or death. Proper care is your responsibility.

Ensure that the engine is stopped before any servicing or repair is performed. The Diesel Exhaust Fluid (DEF) system must have completed a proper shutdown. Service on the DEF pump prior to completion of a proper shutdown can result in DEF spray and spillage.

Do not turn off the battery disconnect switch until the indicator lamp has turned off. If the switch is turned off when the indicator lamp is illuminated, the Diesel Exhaust Fluid (DEF) system may not shut down properly. If the DEF system does not shut down properly, DEF could freeze and damage the pump and lines.

Care must be taken to ensure that fluids are contained during performance of inspection, maintenance, testing, adjusting, and repair of the product. Be prepared to collect the fluid with suitable containers before opening any compartment or disassembling any component containing fluids.Refer to Special Publication, NENG2500, "Cat Dealer Service Tool Catalog" or refer to Special Publication, PECJ0003, "Cat Shop Supplies and Tools Catalog" for tools and supplies suitable to collect and contain fluids on Cat products.Dispose of all fluids according to local regulations and mandates.

Note: Clean water should be used to wash spilled DEF off machine components and surfaces.Note: Wear gloves when handling the DEF filter.

Illustration 1 g06278274

(1) Protective cover

Remove protective cover (1).

Illustration 2 g06278289

(2) DEF filter cap

Use a suitable tool to remove DEF filter cap (2).

Illustration 3 g06278325

(3) Compensator

With the filter installed in the DEF pump, carefully remove compensator (3).

Illustration 4 g06614423

(A) 85 mm (3.3 inch)

(B) 17 mm (0.7 inch)

Check the measurements of compensator (3). Check if the measurements are greater than specified in Illustration 4. This condition indicates that the DEF pump is contaminated with hydrocarbons.

If the measurements indicate contamination, replace the DEF pump filter. Refer to Operation and Maintenance Manual, Diesel Exhaust Fluid Filter - Replace.Flush the DEF tank. Refer to Systems Operation, Testing and Adjusting, Diesel Exhaust Fluid Tank - Flush.

If the measurements are within the specification, continue to follow the appropriate troubleshooting procedure to determine if the DEF pump has a fault.