Information injection-pump assembly

ZEXEL

104749-0690

1047490690

Rating:

Cross reference number

ZEXEL

104749-0690

1047490690

Zexel num

Bosch num

Firm num

Name

104749-0690

INJECTION-PUMP ASSEMBLY

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113orSAEJ967d

1404 Test oil ISO4113orSAEJ967d

Test oil temperature

degC

45

45

50

Nozzle

105780-0060

Bosch type code

NP-DN0SD1510

Nozzle holder

105780-2150

Opening pressure

MPa

13

13

13.3

Opening pressure

kgf/cm2

133

133

136

Injection pipe

157805-7320

Injection pipe

Inside diameter - outside diameter - length (mm) mm 2-6-450

Inside diameter - outside diameter - length (mm) mm 2-6-450

Joint assembly

157641-4720

Tube assembly

157641-4020

Transfer pump pressure

kPa

20

20

20

Transfer pump pressure

kgf/cm2

0.2

0.2

0.2

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Pump speed

r/min

1250

1250

1250

Boost pressure

kPa

33.3

32

34.6

Boost pressure

mmHg

250

240

260

Average injection quantity

mm3/st.

43.3

42.8

43.8

Difference in delivery

mm3/st.

3.5

Basic

*

Oil temperature

degC

50

48

52

Remarks

CBS

CBS

Injection timing adjustment_02

Pump speed

r/min

1250

1250

1250

Boost pressure

kPa

69.3

68

70.6

Boost pressure

mmHg

520

510

530

Average injection quantity

mm3/st.

48.6

48.1

49.1

Difference in delivery

mm3/st.

4

Basic

*

Oil temperature

degC

50

48

52

Remarks

Full

Full

Injection timing adjustment_03

Pump speed

r/min

750

750

750

Boost pressure

kPa

33.3

32

34.6

Boost pressure

mmHg

250

240

260

Average injection quantity

mm3/st.

42.8

42.8

42.8

Oil temperature

degC

50

48

52

Injection timing adjustment_04

Pump speed

r/min

1250

1250

1250

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

36.7

36.7

36.7

Oil temperature

degC

50

48

52

Injection timing adjustment_05

Pump speed

r/min

1250

1250

1250

Boost pressure

kPa

33.3

32

34.6

Boost pressure

mmHg

250

240

260

Average injection quantity

mm3/st.

43.3

42.3

44.3

Difference in delivery

mm3/st.

4

Oil temperature

degC

50

48

52

Injection timing adjustment_06

Pump speed

r/min

1250

1250

1250

Boost pressure

kPa

69.3

68

70.6

Boost pressure

mmHg

520

510

530

Average injection quantity

mm3/st.

48.6

47.6

49.6

Difference in delivery

mm3/st.

4.5

Oil temperature

degC

50

48

52

Injection timing adjustment_07

Pump speed

r/min

2150

2150

2150

Boost pressure

kPa

69.3

68

70.6

Boost pressure

mmHg

520

510

530

Average injection quantity

mm3/st.

41.4

41.4

41.4

Oil temperature

degC

52

50

54

Injection quantity adjustment

Pump speed

r/min

2500

2500

2500

Boost pressure

kPa

69.3

68

70.6

Boost pressure

mmHg

520

510

530

Average injection quantity

mm3/st.

21.8

19.8

23.8

Basic

*

Oil temperature

degC

55

52

58

Injection quantity adjustment_02

Pump speed

r/min

2800

2800

2800

Boost pressure

kPa

69.3

68

70.6

Boost pressure

mmHg

520

510

530

Average injection quantity

mm3/st.

5

Oil temperature

degC

55

52

58

Injection quantity adjustment_03

Pump speed

r/min

2500

2500

2500

Boost pressure

kPa

69.3

68

70.6

Boost pressure

mmHg

520

510

530

Average injection quantity

mm3/st.

21.8

19.3

24.3

Oil temperature

degC

55

52

58

Governor adjustment

Pump speed

r/min

385

385

385

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

14.2

13.2

15.2

Difference in delivery

mm3/st.

2

Basic

*

Oil temperature

degC

48

46

50

Governor adjustment_02

Pump speed

r/min

385

385

385

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

14.2

12.7

15.7

Difference in delivery

mm3/st.

2.5

Oil temperature

degC

48

46

50

Timer adjustment

Pump speed

r/min

100

100

100

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

58

58

Basic

*

Oil temperature

degC

48

46

50

Remarks

Full

Full

Timer adjustment_02

Pump speed

r/min

100

100

100

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

58

58

Oil temperature

degC

48

46

50

Speed control lever angle

Pump speed

r/min

385

385

385

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

0

0

0

Oil temperature

degC

48

46

50

Remarks

Magnet OFF at idling position

Magnet OFF at idling position

0000000901

Pump speed

r/min

1000

1000

1000

Boost pressure

kPa

69.3

68

70.6

Boost pressure

mmHg

520

510

530

Overflow quantity

cm3/min

600

470

730

Oil temperature

degC

50

48

52

Stop lever angle

Pump speed

r/min

1000

1000

1000

Boost pressure

kPa

69.3

68

70.6

Boost pressure

mmHg

520

510

530

Pressure

kPa

618

589

647

Pressure

kgf/cm2

6.3

6

6.6

Basic

*

Oil temperature

degC

50

48

52

Stop lever angle_02

Pump speed

r/min

1000

1000

1000

Boost pressure

kPa

69.3

68

70.6

Boost pressure

mmHg

520

510

530

Pressure

kPa

618

579

657

Pressure

kgf/cm2

6.3

5.9

6.7

Oil temperature

degC

50

48

52

0000001101

Pump speed

r/min

1000

1000

1000

Boost pressure

kPa

69.3

68

70.6

Boost pressure

mmHg

520

510

530

TCV duty (%) F TCV 60Hz

%

100

100

100

Timer stroke

mm

10.6

10.4

10.8

Basic

*

Oil temperature

degC

50

48

52

_02

Pump speed

r/min

100

100

100

Boost pressure

kPa

69.3

68

70.6

Boost pressure

mmHg

520

510

530

TCV duty (%) F TCV 60Hz

%

100

100

100

Timer stroke

mm

3.5

3.5

3.5

Oil temperature

degC

48

46

50

_03

Pump speed

r/min

1000

1000

1000

Boost pressure

kPa

69.3

68

70.6

Boost pressure

mmHg

520

510

530

TCV duty (%) F TCV 60Hz

%

100

100

100

Timer stroke

mm

10.6

10.6

10.6

Oil temperature

degC

50

48

52

_04

Pump speed

r/min

2150

2150

2150

Boost pressure

kPa

69.3

68

70.6

Boost pressure

mmHg

520

510

530

TCV duty (%) F TCV 60Hz

%

100

100

100

Timer stroke

mm

11.4

11.4

11.4

Oil temperature

degC

52

50

54

0000001301

Max. applied voltage

V

8

8

8

Test voltage

V

13

12

14

0000002701

K dimension

mm

3.3

3.2

3.4

KF dimension

mm

5.8

5.7

5.9

MS dimension

mm

1.7

1.6

1.8

Control lever angle alpha

deg.

0

-4

4

Control lever angle beta

deg.

33.3

30.3

36.3

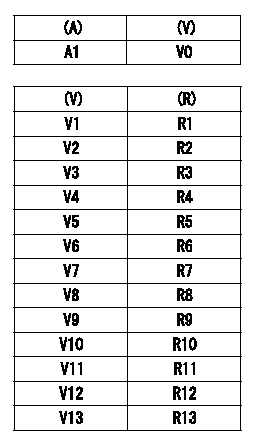

Test data Ex:

0000001901 TIMER PISTON SEVSOR ADJ

TPS (timer piston sensor) adjustment

Use the special circuit (corresponding to H) to measure TPS output voltage.

(1)Measure the TPS output voltage for zero compensation (no resistance).

(A): timer stroke TA

(V): compensation zero TPS output voltage (VTPS)

(2)Compensation resistor installation:

From the table, select and install a compensation resistor so that the compensation output voltage value is zero.

(R): selected compensation resistance

----------

H=479040-5600

----------

A1=0mm V0=0.510+-0.128V V1=0.382~0.401V V2=0.402~0.421V V3=0.422~0.440V V4=0.441~0.460V V5=0.461~0.479V V6=0.480~0.499V V7=0.500~0.519V V8=0.520~0.539V V9=0.540~0.558V V10=0.559~0.578V V11=0.579~0.597V V12=0.598~0.617V V13=0.618~0.637V R1=No.1,0.18kohm R2=No.2,0.30kohm R3=No.3,0.43kohm R4=No.4,0.62kohm R5=No.5,0.82kohm R6=No.6,1.10kohm R7=No.7,1.50kohm R8=No.8,2.00kohm R9=No.9,2.70kohm R10=No.10,3.90kohm R11=No.11,5.60kohm R12=No.12,8.20kohm R13=No.13,15.00kohm

----------

H=479040-5600

----------

A1=0mm V0=0.510+-0.128V V1=0.382~0.401V V2=0.402~0.421V V3=0.422~0.440V V4=0.441~0.460V V5=0.461~0.479V V6=0.480~0.499V V7=0.500~0.519V V8=0.520~0.539V V9=0.540~0.558V V10=0.559~0.578V V11=0.579~0.597V V12=0.598~0.617V V13=0.618~0.637V R1=No.1,0.18kohm R2=No.2,0.30kohm R3=No.3,0.43kohm R4=No.4,0.62kohm R5=No.5,0.82kohm R6=No.6,1.10kohm R7=No.7,1.50kohm R8=No.8,2.00kohm R9=No.9,2.70kohm R10=No.10,3.90kohm R11=No.11,5.60kohm R12=No.12,8.20kohm R13=No.13,15.00kohm

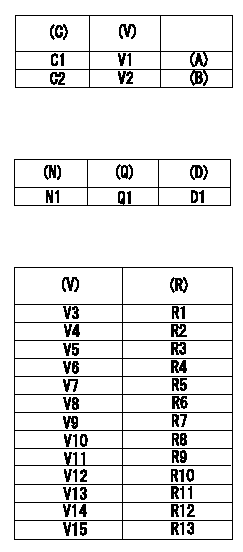

0000002001 POTENTIOMETER ADJUSTMENT

Adjustment of the potentiometer

(1)Potentiometer setting:

(A): Adjusting point

(B): Checking point

(C): Control lever opening

(V): P/N output voltage

(2)Dummy bolt setting:

Fix the control lever with the dummy bolt so that the injection quantity is as shown in the following table at the pump speed = N1.

(N): Speed of the pump

(Q): Injection quantity

(D): Targeted lever angle

C1:Full speed position

C2:Idling position

(3)Read the output voltage (V) of the potentiometer in the state indicated in (2) above. Then, select the compensation resistor from the following table and replace.

(R): Compensation resistance

Note

After replacing the compensation resistor, the output voltage is the potentiometer value when the special compensation circuit (control unit) is used.

Caution: The potentiometer output voltage is the voltage at the applied voltage Vi, and the control unit output voltage is the voltage at the applied voltage ViC.

----------

N1=1000r/min Vi=10V Vic=5V

----------

V1=8.4+-0.03V V2=(2.85+-0.7)V N1=1000r/min Q1=31.9+-1.0cm3/1000st D1=(14.3)deg V3=4.42~4.53V V4=4.54~4.65V V5=4.66~4.77V V6=4.78~4.89V V7=4.90~5.01V V8=5.02~5.13V V9=5.14~5.25V V10=5.26~5.37V V11=5.38~5.49V V12=5.50~5.61V V13=5.62~5.73V V14=5.74~5.85V V15=5.86~5.97V R1=No.1,0.18kohm R2=No.2,0.30kohm R3=No.3,0.43kohm R4=No.4,0.62kohm R5=No.5,0.82kohm R6=No.6,1.10kohm R7=No.7,1.50kohm R8=No.8,2.00kohm R9=No.9,2.70kohm R10=No.10,3.90kohm R11=No.11,5.60kohm R12=No.12,8.20kohm R13=No.13,15.00kohm

----------

N1=1000r/min Vi=10V Vic=5V

----------

V1=8.4+-0.03V V2=(2.85+-0.7)V N1=1000r/min Q1=31.9+-1.0cm3/1000st D1=(14.3)deg V3=4.42~4.53V V4=4.54~4.65V V5=4.66~4.77V V6=4.78~4.89V V7=4.90~5.01V V8=5.02~5.13V V9=5.14~5.25V V10=5.26~5.37V V11=5.38~5.49V V12=5.50~5.61V V13=5.62~5.73V V14=5.74~5.85V V15=5.86~5.97V R1=No.1,0.18kohm R2=No.2,0.30kohm R3=No.3,0.43kohm R4=No.4,0.62kohm R5=No.5,0.82kohm R6=No.6,1.10kohm R7=No.7,1.50kohm R8=No.8,2.00kohm R9=No.9,2.70kohm R10=No.10,3.90kohm R11=No.11,5.60kohm R12=No.12,8.20kohm R13=No.13,15.00kohm

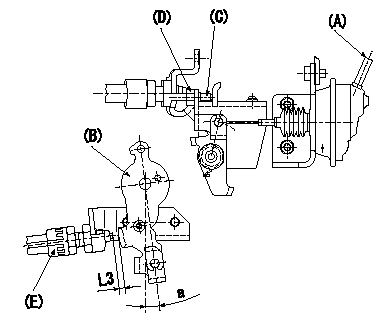

0000002101 WIRE

Wire length confirmation

Accelerator wire: Idle-full stroke: L1

A/T wire: idle~full stroke: L2

Confirmation on the idle SW

Confirm that the switch is ON at the idle lever position.

Adjustment of the double stage actuator:

(1)Apply negative pressure P1 {P2} to the actuator through the negative pressure inlet port.

(2)In status (1) above, adjust the screw C so that the control lever B position is a (ie, the distance between the control lever and the idle switch E is L3). Fix using nut D.

TT

(Reference) actuator stroke:

(1)First step: L4

(2)Second stage: L5

----------

L1=32.5+-3.5mm L2=28.4+-2mm L3=1.9+-0.5mm L4=6+-0.5mm L5=4.5mm a=5deg P1=-66.6kPa P2=-500mmHg T=6~9N-m{0.6~0.9kgf-m}

----------

L3=1.9+-0.5mm a=3.3deg

----------

L1=32.5+-3.5mm L2=28.4+-2mm L3=1.9+-0.5mm L4=6+-0.5mm L5=4.5mm a=5deg P1=-66.6kPa P2=-500mmHg T=6~9N-m{0.6~0.9kgf-m}

----------

L3=1.9+-0.5mm a=3.3deg

Information:

Reference

Refer to the electrical system schematic that is in the Electrical Schematic for the complete electrical system schematic of the engine. Refer to the Electronic Troubleshooting manual for additional information.Grounding Practices

Proper grounding for the vessel's electrical system and the engine electrical system is necessary for proper performance and reliability. Improper grounding will result in unreliable electrical circuit paths and in uncontrolled electrical circuit paths.Uncontrolled engine electrical circuit paths can result in damage to the main bearings, to the crankshaft bearing journal surfaces, and to the aluminum components.Uncontrolled electrical circuit paths can cause electrical noise which may degrade the vessel's performance and the radio performance.In order to ensure proper functioning of the vessel's electrical system and of the engine electrical system, an engine-to-frame ground strap with a direct path to the battery must be used. This is provided by a ground from the electric starting motor to the frame and to the negative battery post.The ground path must be capable of carrying any potential currents. A wire that is AWG 0 or more is recommended for the ground of the electric starting motor.The engine alternator should be grounded to the battery with a wire size that is capable of managing the full charging current of the alternator.

When jump starting an engine, the instructions in the Operation and Maintenance Manual, "Starting with Jump Start Cables" should be followed in order to properly start the engine.This engine may be equipped with a 12 volt starting system or with a 24 volt starting system. Only equal voltage for boost starting should be used. The use of a welder or of a higher voltage will damage the electrical system.

The engine has several input components which are electronic. These components require an operating voltage.This engine is tolerant of common external sources of electrical noise. Electromechanical buzzers can cause disruptions in the power supply. If electromechanical buzzers are used on the vessel, the engine electronics should be powered directly from the battery system through a dedicated relay. The engine electronics should not be powered through a common power bus with other devices that are activated by the keyswitch.Engine Electrical System

The electrical system can have three separate circuits. The three circuits are the charging circuit, the starting circuit, and the low amperage circuit. Some of the electrical system components are used in more than one circuit.The charging circuit is in operation when the engine is running. The charging circuit uses an alternator in order to create electricity. A voltage regulator in the circuit controls the electrical output in order to maintain the battery at full charge.The starting circuit is in operation when the start switch is activated.The low amperage circuit and the charging circuit are connected through the ammeter. The starting circuit is not connected through the ammeter.Starting System Components

Solenoid

Illustration 1 g00292316

Typical cross section of a solenoidA solenoid is an electromagnetic switch that performs two basic functions:

The solenoid closes the high current circuit for the electric starting motor with a low current start switch circuit.

The solenoid engages

Refer to the electrical system schematic that is in the Electrical Schematic for the complete electrical system schematic of the engine. Refer to the Electronic Troubleshooting manual for additional information.Grounding Practices

Proper grounding for the vessel's electrical system and the engine electrical system is necessary for proper performance and reliability. Improper grounding will result in unreliable electrical circuit paths and in uncontrolled electrical circuit paths.Uncontrolled engine electrical circuit paths can result in damage to the main bearings, to the crankshaft bearing journal surfaces, and to the aluminum components.Uncontrolled electrical circuit paths can cause electrical noise which may degrade the vessel's performance and the radio performance.In order to ensure proper functioning of the vessel's electrical system and of the engine electrical system, an engine-to-frame ground strap with a direct path to the battery must be used. This is provided by a ground from the electric starting motor to the frame and to the negative battery post.The ground path must be capable of carrying any potential currents. A wire that is AWG 0 or more is recommended for the ground of the electric starting motor.The engine alternator should be grounded to the battery with a wire size that is capable of managing the full charging current of the alternator.

When jump starting an engine, the instructions in the Operation and Maintenance Manual, "Starting with Jump Start Cables" should be followed in order to properly start the engine.This engine may be equipped with a 12 volt starting system or with a 24 volt starting system. Only equal voltage for boost starting should be used. The use of a welder or of a higher voltage will damage the electrical system.

The engine has several input components which are electronic. These components require an operating voltage.This engine is tolerant of common external sources of electrical noise. Electromechanical buzzers can cause disruptions in the power supply. If electromechanical buzzers are used on the vessel, the engine electronics should be powered directly from the battery system through a dedicated relay. The engine electronics should not be powered through a common power bus with other devices that are activated by the keyswitch.Engine Electrical System

The electrical system can have three separate circuits. The three circuits are the charging circuit, the starting circuit, and the low amperage circuit. Some of the electrical system components are used in more than one circuit.The charging circuit is in operation when the engine is running. The charging circuit uses an alternator in order to create electricity. A voltage regulator in the circuit controls the electrical output in order to maintain the battery at full charge.The starting circuit is in operation when the start switch is activated.The low amperage circuit and the charging circuit are connected through the ammeter. The starting circuit is not connected through the ammeter.Starting System Components

Solenoid

Illustration 1 g00292316

Typical cross section of a solenoidA solenoid is an electromagnetic switch that performs two basic functions:

The solenoid closes the high current circuit for the electric starting motor with a low current start switch circuit.

The solenoid engages

Have questions with 104749-0690?

Group cross 104749-0690 ZEXEL

104749-0690

INJECTION-PUMP ASSEMBLY