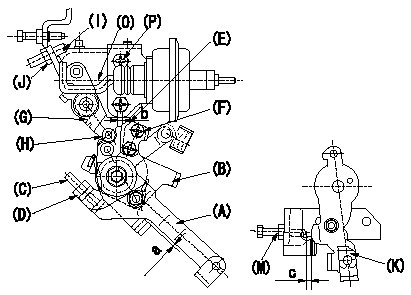

Information injection-pump assembly

BOSCH

9 460 611 243

9460611243

ZEXEL

104749-0443

1047490443

MAZDA

RFC413800C

rfc413800c

Rating:

Components :

| 0. | INJECTION-PUMP ASSEMBLY | 104749-0443 |

| 1. | _ | |

| 2. | FUEL INJECTION PUMP | 104649-0442 |

| 3. | NUMBER PLATE | 146960-4100 |

| 4. | _ | 146672-5021 |

| 5. | CAPSULE | |

| 6. | ADJUSTING DEVICE | 582660-7122 |

| 7. | NOZZLE AND HOLDER ASSY | 105141-2791 |

| 8. | Nozzle and Holder | RFB7 13 H50B |

| 9. | Open Pre:MPa(Kqf/cm2) | 13.2{135} |

| 10. | NOZZLE-HOLDER | 105071-1530 |

| 11. | NOZZLE | 105000-1991 |

Scheme ###:

| 1/6. | [1] | 146601-0700 | PACKING RING |

| 6. | [1] | 146100-0120 | SUPPLY PUMP |

| 9. | [1] | 146103-0000 | COVER |

| 10. | [2] | 139104-0000 | FLAT-HEAD SCREW |

| 12. | [1] | 146200-0720 | DRIVE SHAFT |

| 12/1. | [1] | 146200-0300 | DRIVE SHAFT |

| 12/2. | [1] | 146201-0000 | WOODRUFF KEY |

| 12/3. | [2] | 146202-0100 | DAMPER |

| 12/4. | [1] | 146203-0000 | TOOTHED GEAR |

| 17. | [1] | 146204-0000 | PLAIN WASHER |

| 20. | [1] | 146210-1120 | ROLLER SET |

| 24. | [1] | 146303-0100 | BEARING PIN |

| 25. | [1] | 146304-0000 | BEARING PIN |

| 26. | [1] | 146305-0000 | CLAMPING BAND |

| 27. | [1] | 146205-0000 | SLOTTED WASHER |

| 29. | [1] | 146220-0120 | CAM PLATE |

| 30. | [1] | 146600-0800 | O-RING |

| 31. | [1] | 146300-0600 | PUMP PLUNGER |

| 32. | [1] | 146301-0200 | SLIDING PIECE |

| 33. | [1] | 146603-0700 | SHIM D17.5&7.5T0.60 |

| 34. | [1] | 146302-5400 | COMPRESSION SPRING |

| 35/1. | [0] | 146603-0700 | SHIM D17.5&7.5T0.60 |

| 35/1. | [0] | 146603-0800 | SHIM D17.5&7.5T0.70 |

| 35/1. | [0] | 146603-0900 | SHIM D17.5&7.5T0.90 |

| 35/1. | [0] | 146603-1000 | SHIM D17.5&7.5T1.00 |

| 35/1. | [0] | 146603-1100 | SHIM D17.5&7.5T1.20 |

| 35/1. | [0] | 146603-3600 | SHIM D17.5&7.5T2.40 |

| 36. | [1] | 146600-0800 | O-RING |

| 37. | [1] | 146310-0700 | COVER |

| 38. | [2] | 146620-5000 | BLEEDER SCREW |

| 39. | [1] | 146310-0100 | COVER |

| 40. | [2] | 146620-5000 | BLEEDER SCREW |

| 43. | [1] | 146230-0000 | SHIM |

| 44. | [1] | 146230-0100 | PLAIN WASHER |

| 45. | [1] | 146231-0001 | SLOTTED WASHER |

| 47. | [2] | 146233-0000 | SLOTTED WASHER |

| 48/1. | [1] | 146603-0000 | SHIM D17.0&5.2T0.50 |

| 48/1. | [1] | 146603-0100 | SHIM D17.0&5.2T0.80 |

| 48/1. | [1] | 146603-0200 | SHIM D17.0&5.2T1.00 |

| 48/1. | [1] | 146603-0300 | SHIM D17.0&5.2T1.20 |

| 48/1. | [1] | 146603-0400 | SHIM D17.0&5.2T1.50 |

| 48/1. | [1] | 146603-0500 | SHIM D17.0&5.2T1.80 |

| 48/1. | [1] | 146603-0600 | SHIM D17.0&5.2T2.00 |

| 48/1. | [1] | 146690-1400 | SHIM D17&5.2T0.9 |

| 48/1. | [1] | 146690-1500 | SHIM D17&5.2T1.1 |

| 48/1. | [1] | 146690-1600 | SHIM D17&5.2T1.3 |

| 48/1. | [1] | 146690-1700 | SHIM D17&5.2T1.4 |

| 48/1. | [1] | 146690-1800 | SHIM D17&5.2T1.6 |

| 48/1. | [1] | 146690-1900 | SHIM D17&5.2T1.7 |

| 48/1. | [1] | 146690-5800 | SHIM |

| 48/1. | [1] | 146690-5900 | SHIM |

| 48/1. | [1] | 146690-6000 | SHIM |

| 48/1. | [1] | 146690-6100 | SHIM |

| 48/1. | [1] | 146690-6200 | SHIM |

| 48/1. | [1] | 146690-6300 | SHIM |

| 48/1. | [1] | 146690-6400 | SHIM |

| 48/1. | [1] | 146690-6500 | SHIM |

| 48/1. | [1] | 146690-6600 | SHIM |

| 48/1. | [1] | 146690-6700 | SHIM |

| 48/1. | [1] | 146690-6800 | SHIM |

| 48/1. | [1] | 146690-6900 | SHIM |

| 48/1. | [1] | 146690-7000 | SHIM |

| 48/1. | [1] | 146690-7100 | SHIM |

| 48/1. | [1] | 146690-7200 | SHIM |

| 48/1. | [1] | 146690-7300 | SHIM |

| 48/1. | [1] | 146690-7400 | SHIM |

| 48/1. | [1] | 146690-7500 | SHIM |

| 48/1. | [1] | 146690-7800 | SHIM |

| 49. | [2] | 146234-0020 | GUIDE PIN |

| 50. | [1] | 146403-2620 | HYDRAULIC HEAD |

| 50. | [1] | 146403-2620 | HYDRAULIC HEAD |

| 51. | [1] | 146600-0000 | O-RING |

| 52/1. | [1] | 146420-0000 | SHIM D9.5&3.0T1.90 |

| 52/1. | [1] | 146420-0100 | SHIM D9.5&3.0T1.92 |

| 52/1. | [1] | 146420-0200 | SHIM D9.5&3.0T1.94 |

| 52/1. | [1] | 146420-0300 | SHIM D9.5&3.0T1.96 |

| 52/1. | [1] | 146420-0400 | SHIM D9.5&3.0T1.98 |

| 52/1. | [1] | 146420-0500 | SHIM D9.5&3.0T2.00 |

| 52/1. | [1] | 146420-0600 | SHIM D9.5&3.0T2.02 |

| 52/1. | [1] | 146420-0700 | SHIM D9.5&3.0T2.04 |

| 52/1. | [1] | 146420-0800 | SHIM D9.5&3.0T2.06 |

| 52/1. | [1] | 146420-0900 | SHIM D9.5&3.0T2.08 |

| 52/1. | [1] | 146420-1000 | SHIM D9.5&3.0T2.10 |

| 52/1. | [1] | 146420-1100 | SHIM D9.5&3.0T2.12 |

| 52/1. | [1] | 146420-1200 | SHIM D9.5&3.0T2.14 |

| 52/1. | [1] | 146420-1300 | SHIM D9.5&3.0T2.16 |

| 52/1. | [1] | 146420-1400 | SHIM D9.5&3.0T2.18 |

| 52/1. | [1] | 146420-1500 | SHIM D9.5&3.0T2.20 |

| 52/1. | [1] | 146420-1600 | SHIM D9.5&3.0T2.22 |

| 52/1. | [1] | 146420-1700 | SHIM D9.5&3.0T2.24 |

| 52/1. | [1] | 146420-1800 | SHIM D9.5&3.0T2.26 |

| 52/1. | [1] | 146420-1900 | SHIM D9.5&3.0T2.28 |

| 52/1. | [1] | 146420-2000 | SHIM D9.5&3.0T2.30 |

| 52/1. | [1] | 146420-2100 | SHIM D9.5&3.0T2.32 |

| 52/1. | [1] | 146420-2200 | SHIM D9.5&3.0T2.34 |

| 52/1. | [1] | 146420-2300 | SHIM D9.5&3.0T2.36 |

| 52/1. | [1] | 146420-2400 | SHIM D9.5&3.0T2.38 |

| 52/1. | [1] | 146420-2500 | SHIM D9.5&3.0T2.40 |

| 52/1. | [1] | 146420-2600 | SHIM D9.5&3.0T2.42 |

| 52/1. | [1] | 146420-2700 | SHIM D9.5&3.0T2.44 |

| 52/1. | [1] | 146420-2800 | SHIM D9.5&3.0T2.46 |

| 52/1. | [1] | 146420-2900 | SHIM D9.5&3.0T2.48 |

| 52/1. | [1] | 146420-3000 | SHIM D9.5&3.0T2.50 |

| 52/1. | [1] | 146420-3100 | SHIM D9.5&3.0T2.52 |

| 52/1. | [1] | 146420-3200 | SHIM D9.5&3.0T2.54 |

| 52/1. | [1] | 146420-3300 | SHIM D9.5&3.0T2.56 |

| 52/1. | [1] | 146420-3400 | SHIM D9.5&3.0T2.58 |

| 52/1. | [1] | 146420-3500 | SHIM D9.5&3.0T2.60 |

| 52/1. | [1] | 146420-3600 | SHIM D9.5&3.0T2.62 |

| 52/1. | [1] | 146420-3700 | SHIM D9.5&3.0T2.64 |

| 52/1. | [1] | 146420-3800 | SHIM D9.5&3.0T2.66 |

| 52/1. | [1] | 146420-3900 | SHIM D9.5&3.0T2.68 |

| 52/1. | [1] | 146420-4000 | SHIM D9.5&3.0T2.70 |

| 52/1. | [1] | 146420-4100 | SHIM D9.5&3.0T2.72 |

| 52/1. | [1] | 146420-4200 | SHIM D9.5&3.0T2.74 |

| 52/1. | [1] | 146420-4300 | SHIM D9.5&3.0T2.76 |

| 52/1. | [1] | 146420-4400 | SHIM D9.5&3.0T2.78 |

| 52/1. | [1] | 146420-4500 | SHIM D9.5&3.0T2.80 |

| 52/1. | [1] | 146420-4600 | SHIM D9.5&3.0T2.82 |

| 52/1. | [1] | 146420-4700 | SHIM D9.5&3.0T2.84 |

| 52/1. | [1] | 146420-4800 | SHIM D9.5&3.0T2.86 |

| 52/1. | [1] | 146420-4900 | SHIM D9.5&3.0T2.88 |

| 52/1. | [1] | 146420-5000 | SHIM D9.5&3.0T2.90 |

| 52/1. | [1] | 146420-5100 | SHIM D9.5&3.0T1.74 |

| 52/1. | [1] | 146420-5200 | SHIM D9.5&3.0T1.76 |

| 52/1. | [1] | 146420-5300 | SHIM D9.5&3.0T1.78 |

| 52/1. | [1] | 146420-5400 | SHIM D9.5&3.0T1.80 |

| 52/1. | [1] | 146420-5500 | SHIM D9.5&3.0T1.82 |

| 52/1. | [1] | 146420-5600 | SHIM D9.5&3.0T1.84 |

| 52/1. | [1] | 146420-5700 | SHIM D9.5&3.0T1.86 |

| 52/1. | [1] | 146420-5800 | SHIM D9.5&3.0T1.88 |

| 54. | [4] | 146433-0100 | GASKET D12&6.4T1.00 |

| 55. | [4] | 146430-3920 | DELIVERY-VALVE ASSEMBLY |

| 56. | [4] | 146432-0000 | COMPRESSION SPRING |

| 58. | [4] | 146440-0220 | FITTING |

| 60. | [3] | 139106-0100 | FLAT-HEAD SCREW |

| 66. | [1] | 146600-0100 | O-RING |

| 67. | [1] | 146752-0920 | MANIFOLD-PRESSURE COMP. |

| 67/1. | [1] | 146805-7520 | GOVERNOR COVER |

| 67/14. | [1] | 146621-1700 | UNION NUT |

| 67/16. | [1] | 146526-3000 | BLEEDER SCREW |

| 67/23. | [1] | 146930-0520 | BRACKET |

| 67/31. | [1] | 146710-0800 | BUSHING |

| 67/32. | [1] | 146711-0000 | PLATE |

| 67/33. | [1] | 139218-0400 | UNION NUT |

| 67/34. | [1] | 146712-0700 | BEARING PIN |

| 67/35. | [1] | 146621-0300 | UNION NUT |

| 67/36. | [1] | 146600-1400 | O-RING |

| 67/37. | [1] | 146710-0100 | BUSHING |

| 67/38. | [1] | 139506-0200 | GASKET D8.9&6.8T1.00 |

| 67/39. | [1] | 146620-0300 | CAPSULE |

| 67/40. | [1] | 026512-1540 | GASKET D15.4&12.2T1.50 |

| 67/41. | [1] | 146713-0400 | ADJUSTING PIN |

| 67/42. | [2] | 146714-0000 | PLATE |

| 67/43. | [1] | 146715-0000 | DIAPHRAGM |

| 67/44. | [1] | 139306-0100 | LOCKING WASHER |

| 67/45. | [1] | 013030-6040 | UNION NUT M6P1H3.6 |

| 67/46. | [1] | 146716-0000 | UNION NUT |

| 67/47. | [1] | 146717-0400 | COILED SPRING |

| 67/48/1. | [1] | 146720-0000 | SPACER BUSHING L3.7 |

| 67/48/1. | [1] | 146720-0100 | SPACER BUSHING L3.9 |

| 67/48/1. | [1] | 146720-0200 | SPACER BUSHING L4.1 |

| 67/48/1. | [1] | 146720-0300 | SPACER BUSHING L4.3 |

| 67/48/1. | [1] | 146720-0400 | SPACER BUSHING L4.5 |

| 67/48/1. | [1] | 146720-0500 | SPACER BUSHING L4.7 |

| 67/48/1. | [1] | 146720-0600 | SPACER BUSHING L4.9 |

| 67/48/1. | [1] | 146720-0700 | SPACER BUSHING L5.1 |

| 67/48/1. | [1] | 146720-0800 | SPACER BUSHING L5.3 |

| 67/48/1. | [1] | 146720-0900 | SPACER BUSHING L2.7 |

| 67/48/1. | [1] | 146720-1000 | SPACER BUSHING L2.9 |

| 67/48/1. | [1] | 146720-1100 | SPACER BUSHING L3.1 |

| 67/48/1. | [1] | 146720-1200 | SPACER BUSHING L3.3 |

| 67/48/1. | [1] | 146720-1300 | SPACER BUSHING L3.5 |

| 67/48/1. | [1] | 146720-1400 | SPACER BUSHING L2.8 |

| 67/48/1. | [1] | 146720-1500 | SPACER BUSHING L3.0 |

| 67/48/1. | [1] | 146720-1600 | SPACER BUSHING L3.2 |

| 67/48/1. | [1] | 146720-1700 | SPACER BUSHING L3.4 |

| 67/48/1. | [1] | 146720-1800 | SPACER BUSHING L3.6 |

| 67/48/1. | [1] | 146720-1900 | SPACER BUSHING L3.8 |

| 67/48/1. | [1] | 146720-2000 | SPACER BUSHING L4.0 |

| 67/48/1. | [1] | 146720-2100 | SPACER BUSHING L4.2 |

| 67/48/1. | [1] | 146720-2200 | SPACER BUSHING L4.4 |

| 67/48/1. | [1] | 146720-2300 | SPACER BUSHING L4.6 |

| 67/48/1. | [1] | 146720-2400 | SPACER BUSHING L4.8 |

| 67/48/1. | [1] | 146720-2500 | SPACER BUSHING L5.0 |

| 67/48/1. | [1] | 146720-2600 | SPACER BUSHING L5.2 |

| 67/48/1. | [1] | 146720-2700 | SPACER BUSHING L5.4 |

| 67/48/1. | [1] | 146720-2800 | SPACER BUSHING L5.5 |

| 67/48/1. | [1] | 146720-2900 | SPACER BUSHING L5.6 |

| 67/48/1. | [1] | 146720-4500 | SPACER BUSHING L1.8 |

| 67/48/1. | [1] | 146720-4600 | SPACER BUSHING L1.9 |

| 67/48/1. | [1] | 146720-4700 | SPACER BUSHING L2.0 |

| 67/48/1. | [1] | 146720-4800 | SPACER BUSHING L2.1 |

| 67/48/1. | [1] | 146720-4900 | SPACER BUSHING L2.2 |

| 67/48/1. | [1] | 146720-5000 | SPACER BUSHING L2.3 |

| 67/48/1. | [1] | 146720-5100 | SPACER BUSHING L2.4 |

| 67/48/1. | [1] | 146720-5200 | SPACER BUSHING L2.5 |

| 67/48/1. | [1] | 146720-5300 | SPACER BUSHING L2.6 |

| 67/48/1. | [1] | 146725-2500 | SPACER BUSHING L5.7 |

| 67/48/1. | [1] | 146725-2600 | SPACER BUSHING L5.8 |

| 67/48/1. | [1] | 146725-2700 | SPACER BUSHING L5.9 |

| 67/48/1. | [1] | 146725-2800 | SPACER BUSHING L6.0 |

| 67/48/1. | [1] | 146725-2900 | SPACER BUSHING L6.1 |

| 67/48/1. | [1] | 146725-3000 | SPACER BUSHING L6.2 |

| 67/48/1. | [1] | 146725-3100 | SPACER BUSHING L6.3 |

| 67/48/1. | [1] | 146725-3200 | SPACER BUSHING L6.4 |

| 67/48/1. | [1] | 146725-3300 | SPACER BUSHING L6.5 |

| 67/48/1. | [1] | 146725-3400 | SPACER BUSHING L6.6 |

| 67/48/1. | [1] | 146725-3500 | SPACER BUSHING L6.7 |

| 67/48/1. | [1] | 146725-3600 | SPACER BUSHING L6.8 |

| 67/48/1. | [1] | 146725-3700 | SPACER BUSHING L6.9 |

| 67/48/1. | [1] | 146725-3800 | SPACER BUSHING L7.0 |

| 67/48/1. | [1] | 146725-3900 | SPACER BUSHING L7.1 |

| 67/48/1. | [1] | 146725-4000 | SPACER BUSHING L7.2 |

| 67/48/1. | [1] | 146725-4100 | SPACER BUSHING L7.3 |

| 67/48/1. | [1] | 146725-4200 | SPACER BUSHING L7.4 |

| 67/48/1. | [1] | 146725-4300 | SPACER BUSHING L7.5 |

| 67/49. | [1] | 146721-2120 | COVER |

| 67/52. | [1] | 146620-6100 | BLEEDER SCREW |

| 67/53. | [1] | 139006-4800 | BLEEDER SCREW |

| 67/55. | [1] | 139006-4800 | BLEEDER SCREW |

| 67/56. | [1] | 146723-0300 | CONTROL LEVER |

| 67/57. | [1] | 146712-0100 | BEARING PIN |

| 67/58. | [2] | 146620-0600 | CAPSULE |

| 67/59. | [2] | 026506-1040 | GASKET D9.9&6.2T1 |

| 67/60. | [1] | 146724-0300 | ELEMENT |

| 67/61. | [1] | 146724-0600 | CAPSULE |

| 67/64. | [1] | 146930-1600 | BRACKET |

| 67/78. | [1] | 146600-1000 | SEAL RING |

| 67/98. | [1] | 146648-2800 | SPACER BUSHING |

| 67/102. | [1] | 146927-3400 | BRACKET |

| 67/200. | [1] | 139308-0300 | PLAIN WASHER |

| 67/201. | [1] | 146545-3400 | THREADED PIN L53.00 |

| 67/201B. | [1] | 146545-3500 | THREADED PIN L55.00 |

| 67/201C. | [1] | 146545-3600 | THREADED PIN L57.00 |

| 67/202. | [1] | 139208-0900 | UNION NUT |

| 67/203. | [1] | 146600-1200 | O-RING |

| 68. | [1] | 146513-7920 | CONTROL SHAFT |

| 69. | [1] | 139310-0200 | PLAIN WASHER |

| 72. | [1] | 146539-9520 | CONTROL LEVER |

| 72B. | [1] | 146539-9620 | CONTROL LEVER |

| 73. | [1] | 014110-6440 | LOCKING WASHER |

| 75. | [1] | 146621-0700 | UNION NUT |

| 83. | [1] | 146549-3600 | BUSHING |

| 84. | [1] | 014010-4140 | PLAIN WASHER D10&4.5T0.8 |

| 85. | [1] | 015316-1040 | SPLIT PIN |

| 95. | [1] | 146851-0120 | FULCRUM LEVER |

| 104. | [2] | 146568-0000 | SLOTTED SPRING PIN |

| 105. | [2] | 026508-1140 | GASKET D11.4&8.2T1 |

| 106. | [2] | 146588-0500 | COILED SPRING |

| 107. | [1] | 146569-0300 | UNION NUT |

| 108. | [1] | 146570-0420 | GOVERNOR SHAFT |

| 109. | [1] | 146600-0400 | O-RING |

| 110/1. | [1] | 146571-0000 | SHIM D20.2&8.3T1.05 |

| 110/1. | [1] | 146571-0100 | SHIM D20.2&8.3T1.25 |

| 110/1. | [1] | 146571-0200 | SHIM D20.2&8.3T1.45 |

| 110/1. | [1] | 146571-0300 | SHIM D20.2&8.3T1.65 |

| 110/1. | [1] | 146571-0400 | SHIM D20.2&8.3T1.85 |

| 110/1. | [1] | 146571-0500 | SHIM D20.2&8.3T1.15 |

| 110/1. | [1] | 146571-0600 | SHIM D20.2&8.3T1.35 |

| 110/1. | [1] | 146571-0700 | SHIM D20.2&8.3T1.55 |

| 110/1. | [1] | 146571-0800 | SHIM D20.2&8.3T1.75 |

| 111. | [1] | 146602-0600 | PLAIN WASHER D20&8.4T1.40 |

| 112. | [1] | 146572-0020 | FLYWEIGHT ASSEMBLY |

| 114. | [1] | 146602-0500 | PLAIN WASHER D17&6.4T1.60 |

| 115. | [1] | 146575-1800 | SLIDING SLEEVE |

| 116. | [1] | 146576-0200 | CAP |

| 117/1. | [1] | 146577-1800 | PLUG L2.10 |

| 117/1. | [1] | 146577-1900 | PLUG L2.30 |

| 117/1. | [1] | 146577-2000 | PLUG L2.50 |

| 117/1. | [1] | 146577-2100 | PLUG L2.70 |

| 117/1. | [1] | 146577-2200 | PLUG L2.90 |

| 117/1. | [1] | 146577-2300 | PLUG L3.10 |

| 117/1. | [1] | 146577-2400 | PLUG L3.30 |

| 117/1. | [1] | 146577-2500 | PLUG L3.50 |

| 117/1. | [1] | 146577-2600 | PLUG L3.70 |

| 117/1. | [1] | 146577-2700 | PLUG L3.90 |

| 117/1. | [1] | 146577-2800 | PLUG L4.10 |

| 117/1. | [1] | 146577-2900 | PLUG L4.30 |

| 117/1. | [1] | 146577-3000 | PLUG L4.50 |

| 117/1. | [1] | 146577-3100 | PLUG L4.70 |

| 117/1. | [1] | 146577-3200 | PLUG L4.90 |

| 117/1. | [1] | 146577-3300 | PLUG L5.10 |

| 117/1. | [1] | 146577-6700 | PLUG L2.2 |

| 117/1. | [1] | 146577-6800 | PLUG L2.4 |

| 117/1. | [1] | 146577-6900 | PLUG L2.6 |

| 117/1. | [1] | 146577-7000 | PLUG L2.8 |

| 117/1. | [1] | 146577-7100 | PLUG L3.0 |

| 117/1. | [1] | 146577-7200 | PLUG L3.2 |

| 117/1. | [1] | 146577-7300 | PLUG L3.4 |

| 117/1. | [1] | 146577-7400 | PLUG L3.6 |

| 117/1. | [1] | 146577-7500 | PLUG L3.8 |

| 117/1. | [1] | 146577-7600 | PLUG L4.0 |

| 117/1. | [1] | 146577-7700 | PLUG L4.2 |

| 117/1. | [1] | 146577-7800 | PLUG L4.4 |

| 117/1. | [1] | 146577-7900 | PLUG L4.6 |

| 117/1. | [1] | 146577-8000 | PLUG L4.8 |

| 117/1. | [1] | 146577-8100 | PLUG L5.0 |

| 117/1. | [1] | 146877-0000 | PLUG L5.2 |

| 117/1. | [1] | 146877-0100 | PLUG L5.3 |

| 117/1. | [1] | 146877-0200 | PLUG L5.4 |

| 117/1. | [1] | 146877-0300 | PLUG L5.5 |

| 117/1. | [1] | 146877-4700 | PLUG |

| 117/1. | [1] | 146877-4800 | PLUG |

| 117/1. | [1] | 146877-4900 | PLUG |

| 117/1. | [1] | 146877-5000 | PLUG |

| 123. | [4] | 146620-0500 | HEX-SOCKET-HEAD CAP SCREW |

| 130. | [1] | 146421-0020 | CAPSULE |

| 130/2. | [1] | 026508-1140 | GASKET D11.4&8.2T1 |

| 130/3. | [1] | 146422-0000 | BLEEDER SCREW |

| 130/4. | [1] | 146600-0500 | O-RING |

| 133. | [1] | 146600-0600 | O-RING |

| 134. | [1] | 146600-0700 | O-RING |

| 135. | [1] | 146110-0920 | CONTROL VALVE |

| 135/5. | [1] | 146114-0000 | SPRING WASHER |

| 136. | [1] | 146120-0920 | OVER FLOW VALVE |

| 137. | [2] | 026512-1540 | GASKET D15.4&12.2T1.50 |

| 138. | [1] | 146608-3720 | INLET UNION |

| 200. | [1] | 146206-0100 | COILED SPRING |

| 205. | [1] | 029470-4030 | WOODRUFF KEY |

| 214. | [1] | 146542-1400 | BUSHING |

| 215. | [1] | 146542-1500 | BUSHING |

| 217. | [1] | 146542-5700 | SLOTTED WASHER |

| 218. | [1] | 146592-4500 | COILED SPRING |

| 219. | [1] | 146541-3000 | BUSHING |

| 220. | [1] | 146592-4900 | COILED SPRING |

| 221. | [1] | 146927-2420 | BRACKET |

| 222. | [1] | 139006-4400 | BLEEDER SCREW |

| 227. | [1] | 013020-6040 | UNION NUT M6P1H5 |

| 228. | [1] | 014110-6440 | LOCKING WASHER |

| 229. | [1] | 146930-0820 | BRACKET |

| 236. | [2] | 139006-4800 | BLEEDER SCREW |

| 237. | [1] | 146620-0200 | HEX-SOCKET-HEAD CAP SCREW |

| 240. | [1] | 146650-4320 | PULLING ELECTROMAGNET |

| 240/8. | [1] | 146600-1700 | O-RING |

| 242. | [1] | 146662-0620 | WIRE |

| 243. | [1] | 146621-1000 | UNION NUT |

| 244. | [1] | 139006-4400 | BLEEDER SCREW |

| 245. | [3] | 026512-1540 | GASKET D15.4&12.2T1.50 |

| 246. | [1] | 139812-1900 | EYE BOLT |

| 247. | [1] | 146608-3920 | INLET UNION |

| 248. | [1] | 146614-0200 | SPACER BUSHING |

| 252. | [1] | 139006-4400 | BLEEDER SCREW |

| 275. | [1] | 146612-2700 | BRACKET |

| 276. | [2] | 010010-1640 | BLEEDER SCREW M10P1.5L16 4T |

| 280. | [1] | 146360-8620 | COVER |

| 281. | [1] | 146600-0800 | O-RING |

| 282. | [2] | 010206-1440 | HEX-SOCKET-HEAD CAP SCREW M6P1L14 |

| 309. | [1] | 139006-4400 | BLEEDER SCREW |

| 310. | [1] | 146683-5520 | POTENTCIOMETER |

| 311. | [1] | 146620-7800 | BLEEDER SCREW |

| 312. | [1] | 146930-0920 | BRACKET |

| 313. | [2] | 010006-0870 | BLEEDER SCREW M6P1L8 7T |

| 800S. | [1] | 146019-4620 | PUMP HOUSING |

| 800S/1/6. | [1] | 146601-0700 | PACKING RING |

| 804S. | [1] | 146232-0220 | COMPRESSION SPRING |

| 805S. | [1] | 146574-0120 | PARTS SET |

| 810S. | [1] | 146600-2420 | REPAIR SET |

| 812S. | [1] | 146600-1920 | PARTS SET |

| 835S. | [1] | 146598-1000 | CAP |

| 836S/1. | [1] | 146598-0600 | CAP L18 |

| 836S/1. | [1] | 146598-0700 | CAP L21 |

| 836S/1. | [1] | 146598-0800 | CAP L24 |

| 836S/1. | [1] | 146598-0900 | CAP L27 |

| 903. | [1] | 146672-5021 | PULSE GENERATOR |

| 903/2. | [1] | 146600-1300 | O-RING &13W1.9 |

| 905. | [1] | 582660-7122 | ADJUSTING DEVICE |

| 906. | [1] | 146960-4100 | NAMEPLATE |

Include in #2:

104749-0443

as INJECTION-PUMP ASSEMBLY

Cross reference number

BOSCH

9 460 611 243

9460611243

ZEXEL

104749-0443

1047490443

MAZDA

RFC413800C

rfc413800c

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113orSAEJ967d

1404 Test oil ISO4113orSAEJ967d

Test oil temperature

degC

45

45

50

Nozzle

105000-2010

Bosch type code

NP-DN12SD12TT

Nozzle holder

105780-2080

Opening pressure

MPa

14.7

14.7

15.19

Opening pressure

kgf/cm2

150

150

155

Injection pipe

Inside diameter - outside diameter - length (mm) mm 2-6-840

Inside diameter - outside diameter - length (mm) mm 2-6-840

Transfer pump pressure

kPa

20

20

20

Transfer pump pressure

kgf/cm2

0.2

0.2

0.2

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Pump speed

r/min

1250

1250

1250

Boost pressure

kPa

33.3

32

34.6

Boost pressure

mmHg

250

240

260

Average injection quantity

mm3/st.

43.7

43.2

44.2

Difference in delivery

mm3/st.

3.5

Basic

*

Oil temperature

degC

50

48

52

Remarks

CBS

CBS

Injection timing adjustment_02

Pump speed

r/min

1250

1250

1250

Boost pressure

kPa

69.3

68

70.6

Boost pressure

mmHg

520

510

530

Average injection quantity

mm3/st.

48

47.5

48.5

Difference in delivery

mm3/st.

4

Basic

*

Oil temperature

degC

50

48

52

Remarks

Full

Full

Injection timing adjustment_03

Pump speed

r/min

750

750

750

Boost pressure

kPa

33.3

32

34.6

Boost pressure

mmHg

250

240

260

Average injection quantity

mm3/st.

42

42

42

Oil temperature

degC

50

48

52

Injection timing adjustment_04

Pump speed

r/min

1250

1250

1250

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

38.7

38.7

38.7

Oil temperature

degC

50

48

52

Injection timing adjustment_05

Pump speed

r/min

1250

1250

1250

Boost pressure

kPa

33.3

32

34.6

Boost pressure

mmHg

250

240

260

Average injection quantity

mm3/st.

43.7

42.7

44.7

Difference in delivery

mm3/st.

4

Oil temperature

degC

50

48

52

Injection timing adjustment_06

Pump speed

r/min

1250

1250

1250

Boost pressure

kPa

69.3

68

70.6

Boost pressure

mmHg

520

510

530

Average injection quantity

mm3/st.

48

47

49

Difference in delivery

mm3/st.

4.5

Oil temperature

degC

50

48

52

Injection timing adjustment_07

Pump speed

r/min

2150

2150

2150

Boost pressure

kPa

69.3

68

70.6

Boost pressure

mmHg

520

510

530

Average injection quantity

mm3/st.

38.2

38.2

38.2

Oil temperature

degC

52

50

54

Injection quantity adjustment

Pump speed

r/min

2500

2500

2500

Boost pressure

kPa

69.3

68

70.6

Boost pressure

mmHg

520

510

530

Average injection quantity

mm3/st.

19.4

17.4

21.4

Basic

*

Oil temperature

degC

55

52

58

Injection quantity adjustment_02

Pump speed

r/min

2850

2850

2850

Boost pressure

kPa

69.3

68

70.6

Boost pressure

mmHg

520

510

530

Average injection quantity

mm3/st.

5

Oil temperature

degC

55

52

58

Injection quantity adjustment_03

Pump speed

r/min

2500

2500

2500

Boost pressure

kPa

69.3

68

70.6

Boost pressure

mmHg

520

510

530

Average injection quantity

mm3/st.

19.4

16.9

21.9

Oil temperature

degC

55

52

58

Governor adjustment

Pump speed

r/min

360

360

360

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

12.5

11.5

13.5

Difference in delivery

mm3/st.

2

Basic

*

Oil temperature

degC

48

46

50

Governor adjustment_02

Pump speed

r/min

360

360

360

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

12.5

11

14

Difference in delivery

mm3/st.

2.5

Oil temperature

degC

48

46

50

Timer adjustment

Pump speed

r/min

100

100

100

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

55

55

Basic

*

Oil temperature

degC

48

46

50

Remarks

Full

Full

Timer adjustment_02

Pump speed

r/min

100

100

100

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

55

55

Oil temperature

degC

48

46

50

Speed control lever angle

Pump speed

r/min

360

360

360

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

0

0

0

Oil temperature

degC

48

46

50

Remarks

Magnet OFF at idling position

Magnet OFF at idling position

0000000901

Pump speed

r/min

1000

1000

1000

Boost pressure

kPa

69.3

68

70.6

Boost pressure

mmHg

520

510

530

Overflow quantity

cm3/min

380

250

510

Oil temperature

degC

50

48

52

Stop lever angle

Pump speed

r/min

1250

1250

1250

Boost pressure

kPa

69.3

68

70.6

Boost pressure

mmHg

520

510

530

Pressure

kPa

471

451

491

Pressure

kgf/cm2

4.8

4.6

5

Basic

*

Oil temperature

degC

50

48

52

Stop lever angle_02

Pump speed

r/min

1250

1250

1250

Boost pressure

kPa

69.3

68

70.6

Boost pressure

mmHg

520

510

530

Pressure

kPa

471

442

500

Pressure

kgf/cm2

4.8

4.5

5.1

Oil temperature

degC

50

48

52

0000001101

Pump speed

r/min

1250

1250

1250

Boost pressure

kPa

69.3

68

70.6

Boost pressure

mmHg

520

510

530

Timer stroke

mm

2.9

2.7

3.1

Basic

*

Oil temperature

degC

50

48

52

_02

Pump speed

r/min

1000

1000

1000

Boost pressure

kPa

69.3

68

70.6

Boost pressure

mmHg

520

510

530

Oil temperature

degC

50

48

52

Remarks

MEASURE

MEASURE

_03

Pump speed

r/min

1250

1250

1250

Boost pressure

kPa

69.3

68

70.6

Boost pressure

mmHg

520

510

530

Timer stroke

mm

2.9

2.5

3.3

Oil temperature

degC

50

48

52

_04

Pump speed

r/min

2150

2150

2150

Boost pressure

kPa

69.3

68

70.6

Boost pressure

mmHg

520

510

530

Timer stroke

mm

8.2

7.7

8.6

Oil temperature

degC

52

50

54

0000001201

Max. applied voltage

V

8

8

8

Test voltage

V

13

12

14

0000001401

Pump speed

r/min

1250

1250

1250

Boost pressure

kPa

69.3

68

70.6

Boost pressure

mmHg

520

510

530

Average injection quantity

mm3/st.

35.5

35

36

Timer stroke TA

mm

2.2

2

2.4

Timer stroke variation dT

mm

0.7

0.7

0.7

Basic

*

Oil temperature

degC

50

48

52

_02

Pump speed

r/min

1250

1250

1250

Boost pressure

kPa

69.3

68

70.6

Boost pressure

mmHg

520

510

530

Average injection quantity

mm3/st.

35.5

34.5

36.5

Timer stroke TA

mm

2.2

1.8

2.6

Oil temperature

degC

50

48

52

_03

Pump speed

r/min

1250

1250

1250

Boost pressure

kPa

69.3

68

70.6

Boost pressure

mmHg

520

510

530

Average injection quantity

mm3/st.

28.5

27

30

Timer stroke TA

mm

1.2

0.4

2

Oil temperature

degC

50

48

52

Timing setting

K dimension

mm

3.3

3.2

3.4

KF dimension

mm

5.8

5.7

5.9

MS dimension

mm

1.7

1.6

1.8

BCS stroke

mm

3.6

3.5

3.7

Control lever angle alpha

deg.

0

-4

4

Control lever angle beta

deg.

35

32

38

Test data Ex:

0000001801 POTENTIOMETER ADJUSTMENT

Adjustment of the idle SW

Potentiometer confirmation (input voltage: V3)

Control lever: (1) idle position : V1 (adjusting point)

(2)Full position: V2 (check point)

Wire length confirmation

(1)Accelerator wire : idle~full stroke: L1

(2)A/T wire: idle~full stroke: L2

----------

V1=1.6+-0.03V V2=7.44+-0.7V V3=10.00V L1=33.5+-3.5mm L2=30.0+-2mm

----------

----------

V1=1.6+-0.03V V2=7.44+-0.7V V3=10.00V L1=33.5+-3.5mm L2=30.0+-2mm

----------

0000001901 M-CSD ADJUSTMENT

M-CSD adjustment

1. Fixing the M-CSD

(1)At roller holder advance angle d, adjust the lever shaft ball pin so that it contacts the roller holder.

(2)At this time, adjust the position of the M-CSD lever (A) using adjusting screw (C) so that the clearance a between the M-CSD lever (A) and the stopper (B) becomes L1. Then fix using nut (D). Tightening torque T1.

2. Fixing CSD lever plate (E)

(1)Make the clearance between the CSD lever (A) and the stopper (B) L2.

(2)Fix the CSD lever plate (E) using the bolt (F) so that the clearance b between the intermediate lever (G)'s roller (H) and the CSD lever plate is L3. Tightening torque T2.

3. Fixing the FICD screw (I)

(1)Move the CSD lever (A) through its full stroke.

(2)Adjust the intermediate lever G's FICD lever screw I so that the control lever K's position is e (the gap c between the control lever and the screw M is L4). Then fix using the nut J. Tightening torque T1.

4. V-FICD adjustment

(1)Move the actuator O through its full stroke.

(2)Adjust the position of the actuator (O) so that the control lever (K)'s position is f [the clearance between the control lever (K) and the screw (M) is c = L5]. Then, fix using the bolt (P). Tightening torque T1.

----------

L1=0.5+2mm L2=0mm L3=4mm L4=4.2+-0.5mm L5=2.0+-0.5mm d=0deg e=7deg f=3.5deg T1=6~9N-m(0.6~0.9kg-fm) T2=3.4~4.9N-m(0.35~0.5kgf-m)

----------

a=L1=0.5+2mm a=L2=0mm b=L3=4mm c=L4=4.2+-0.5mm c=L5=2.0+-0.5mm

----------

L1=0.5+2mm L2=0mm L3=4mm L4=4.2+-0.5mm L5=2.0+-0.5mm d=0deg e=7deg f=3.5deg T1=6~9N-m(0.6~0.9kg-fm) T2=3.4~4.9N-m(0.35~0.5kgf-m)

----------

a=L1=0.5+2mm a=L2=0mm b=L3=4mm c=L4=4.2+-0.5mm c=L5=2.0+-0.5mm

Information:

Failure to follow these oil recommendations can cause shortened engine service life due to deposits and/or excessive wear.

Total Base Number (TBN) and Fuel Sulfur Levels for Direct Injection (DI) Diesel Engines

The Total Base Number (TBN) for an oil depends on the fuel sulfur level. For direct injection engines that use distillate fuel, the minimum TBN must be 10 times the fuel sulfur level. The TBN is determined by the "ASTM D2896" procedure. The minimum TBN of the oil is 5 regardless of a low fuel sulfur level. Illustration 1 demonstrates the TBN.

Illustration 1 g00104890

(Y) TBN by "ASTM D2896"

(X) Percentage of fuel sulfur by weight

(1) TBN of new oil

(2) Change the used oil when the TBN reaches this level. Use the following guidelines for fuel sulfur levels that exceed 1.5 percent:

Choose an oil with the highest TBN that meets one of these classifications:

API CG-4

API CH-4

API CI-4Note: API CH-4 oils and API CI-4 oils are acceptable if the requirements of Caterpillar's ECF-1 (Engine Crankcase Fluid specification-1) are met. CH-4 oils and CI-4 oils that have not met the requirements of Caterpillar's ECF-1 Specification may cause reduced engine life.

Reduce the oil change interval. Base the oil change interval on the oil analysis. Ensure that the oil analysis includes the condition of the oil and a wear metal analysis. Excessive piston deposits can be produced by an oil with a high TBN. These deposits can lead to a loss of control of the oil consumption and to the polishing of the cylinder bore.

Operating Direct Injection (DI) diesel engines with fuel sulfur levels over 1.0 percent may require shortened oil change intervals in order to help maintain adequate wear protection.

Lubricant Viscosity Recommendations for Direct Injection (DI) Diesel Engines

The proper SAE viscosity grade of oil is determined by the minimum ambient temperature during cold engine start-up, and the maximum ambient temperature during engine operation. Refer to Table 1 (minimum temperature) in order to determine the required oil viscosity for starting a cold engine.Refer to Table 1 (maximum temperature) in order to select the oil viscosity for engine operation at the highest ambient temperature that is anticipated.Note: Generally, use the highest oil viscosity that is available to meet the requirement for the temperature at start-up.If ambient temperature conditions at engine start-up require the use of multigrade SAE 0W oil, SAE 0W-40 viscosity grade is generally preferred over SAE 0W-20 or SAE 0W-30.Note: SAE 10W-30 is the preferred viscosity grade for the following diesel engines when the ambient temperature is above −18 °C (0 °F), and below 40 °C (104 °F).

C7

C-9

C9

3116

3126When an engine is started and an engine is operated in ambient temperatures below −20 °C (−4 °F), use multigrade oils that are capable of flowing in low temperatures.These oils have lubricant viscosity grades of SAE 0W or SAE 5W.When an engine is started and operated in ambient temperatures below −30 °C (−22 °F), use a synthetic base stock multigrade oil with a 0W viscosity grade or with a 5W viscosity grade. Use an oil with a