Information injection-pump assembly

ZEXEL

104748-2460

1047482460

Rating:

Components :

| 0. | INJECTION-PUMP ASSEMBLY | 104748-2460 |

| 1. | _ | |

| 2. | FUEL INJECTION PUMP | |

| 3. | NUMBER PLATE | 146644-9300 |

| 4. | _ | 146672-1120 |

| 5. | CAPSULE | |

| 6. | ADJUSTING DEVICE | |

| 7. | NOZZLE AND HOLDER ASSY | 105141-2391 |

| 8. | Nozzle and Holder | 16600-16A25 |

| 9. | Open Pre:MPa(Kqf/cm2) | 12.7{130} |

| 10. | NOZZLE-HOLDER | 105071-1361 |

| 11. | NOZZLE | 105000-1760 |

Scheme ###:

| 1/6. | [1] | 146601-0200 | PACKING RING |

| 6. | [1] | 146100-0320 | SUPPLY PUMP D17 SVT |

| 9. | [1] | 146103-0100 | COVER SVT |

| 10. | [2] | 139104-0000 | FLAT-HEAD SCREW |

| 12/1. | [1] | 146200-0000 | DRIVE SHAFT |

| 12/2. | [1] | 146201-0000 | WOODRUFF KEY |

| 12/3. | [2] | 146202-0100 | DAMPER |

| 12/4. | [1] | 146203-0000 | TOOTHED GEAR |

| 17. | [1] | 146204-0000 | PLAIN WASHER |

| 20. | [1] | 146210-2420 | ROLLER SET |

| 24. | [1] | 146303-0000 | BEARING PIN |

| 25. | [1] | 146304-0000 | BEARING PIN |

| 26. | [1] | 146305-0000 | CLAMPING BAND |

| 27. | [1] | 146205-0000 | SLOTTED WASHER |

| 29. | [1] | 146220-0120 | CAM PLATE '01'SK3255 |

| 30. | [1] | 146600-0800 | O-RING |

| 31. | [1] | 146311-4920 | PUMP PLUNGER SVT |

| 32. | [1] | 146301-0000 | SLIDING PIECE |

| 34. | [1] | 146312-0900 | COMPRESSION SPRING K=0.115 |

| 35/1. | [1] | 146603-8100 | SHIM NMC LD28 GY1 |

| 35/1. | [1] | 146603-8200 | SHIM NMC LD28 GY1 |

| 35/1. | [1] | 146603-8300 | SHIM NMC LD28 GY1 |

| 35/1. | [1] | 146603-8400 | SHIM NMC LD28 GY1 |

| 35/1. | [1] | 146603-8500 | SHIM NMC LD28 GY1 |

| 36. | [1] | 146600-0800 | O-RING |

| 37. | [1] | 146310-0600 | COVER NMC LD28 GY1 |

| 38. | [2] | 139106-0000 | FLAT-HEAD SCREW |

| 39. | [1] | 146310-0100 | COVER |

| 40. | [2] | 139106-0000 | FLAT-HEAD SCREW |

| 43. | [1] | 146230-0000 | SHIM |

| 44. | [1] | 146230-0100 | PLAIN WASHER |

| 45. | [1] | 146231-0000 | SLOTTED WASHER |

| 47. | [2] | 146233-0000 | SLOTTED WASHER |

| 48/1. | [1] | 146603-0000 | SHIM |

| 48/1. | [1] | 146603-0100 | SHIM |

| 48/1. | [1] | 146603-0200 | SHIM |

| 48/1. | [1] | 146603-0300 | SHIM |

| 48/1. | [1] | 146603-0400 | SHIM |

| 48/1. | [1] | 146603-0500 | SHIM |

| 48/1. | [1] | 146603-0600 | SHIM |

| 48/1. | [1] | 146690-1400 | SHIM |

| 48/1. | [1] | 146690-1500 | SHIM |

| 48/1. | [1] | 146690-1600 | SHIM |

| 48/1. | [1] | 146690-1700 | SHIM |

| 48/1. | [1] | 146690-1800 | SHIM |

| 48/1. | [1] | 146690-1900 | SHIM |

| 49. | [2] | 146234-0020 | GUIDE PIN |

| 50. | [1] | 146400-4220 | HYDRAULIC HEAD D8 2X1.2 A0.4 |

| 50. | [1] | 146400-4220 | HYDRAULIC HEAD D8 2X1.2 A0.4 |

| 50. | [1] | 146400-4220 | HYDRAULIC HEAD D8 2X1.2 A0.4 |

| 51. | [1] | 146600-0000 | O-RING |

| 52/1. | [1] | 146420-0000 | SHIM |

| 52/1. | [1] | 146420-0100 | SHIM |

| 52/1. | [1] | 146420-0200 | SHIM |

| 52/1. | [1] | 146420-0300 | SHIM |

| 52/1. | [1] | 146420-0400 | SHIM |

| 52/1. | [1] | 146420-0500 | SHIM |

| 52/1. | [1] | 146420-0600 | SHIM |

| 52/1. | [1] | 146420-0700 | SHIM |

| 52/1. | [1] | 146420-0800 | SHIM |

| 52/1. | [1] | 146420-0900 | SHIM |

| 52/1. | [1] | 146420-1000 | SHIM |

| 52/1. | [1] | 146420-1100 | SHIM |

| 52/1. | [1] | 146420-1200 | SHIM |

| 52/1. | [1] | 146420-1300 | SHIM |

| 52/1. | [1] | 146420-1400 | SHIM |

| 52/1. | [1] | 146420-1500 | SHIM |

| 52/1. | [1] | 146420-1600 | SHIM |

| 52/1. | [1] | 146420-1700 | SHIM |

| 52/1. | [1] | 146420-1800 | SHIM |

| 52/1. | [1] | 146420-1900 | SHIM |

| 52/1. | [1] | 146420-2000 | SHIM |

| 52/1. | [1] | 146420-2100 | SHIM |

| 52/1. | [1] | 146420-2200 | SHIM |

| 52/1. | [1] | 146420-2300 | SHIM |

| 52/1. | [1] | 146420-2400 | SHIM |

| 52/1. | [1] | 146420-2500 | SHIM |

| 52/1. | [1] | 146420-2600 | SHIM |

| 52/1. | [1] | 146420-2700 | SHIM |

| 52/1. | [1] | 146420-2800 | SHIM |

| 52/1. | [1] | 146420-2900 | SHIM |

| 52/1. | [1] | 146420-3000 | SHIM |

| 52/1. | [1] | 146420-3100 | SHIM |

| 52/1. | [1] | 146420-3200 | SHIM |

| 52/1. | [1] | 146420-3300 | SHIM |

| 52/1. | [1] | 146420-3400 | SHIM |

| 52/1. | [1] | 146420-3500 | SHIM |

| 52/1. | [1] | 146420-3600 | SHIM |

| 52/1. | [1] | 146420-3700 | SHIM |

| 52/1. | [1] | 146420-3800 | SHIM |

| 52/1. | [1] | 146420-3900 | SHIM |

| 52/1. | [1] | 146420-4000 | SHIM |

| 52/1. | [1] | 146420-4100 | SHIM |

| 52/1. | [1] | 146420-4200 | SHIM |

| 52/1. | [1] | 146420-4300 | SHIM |

| 52/1. | [1] | 146420-4400 | SHIM |

| 52/1. | [1] | 146420-4500 | SHIM |

| 52/1. | [1] | 146420-4600 | SHIM |

| 52/1. | [1] | 146420-4700 | SHIM |

| 52/1. | [1] | 146420-4800 | SHIM |

| 52/1. | [1] | 146420-4900 | SHIM |

| 52/1. | [1] | 146420-5000 | SHIM |

| 52/1. | [1] | 146420-5100 | SHIM |

| 52/1. | [1] | 146420-5200 | SHIM |

| 52/1. | [1] | 146420-5300 | SHIM |

| 52/1. | [1] | 146420-5400 | SHIM |

| 52/1. | [1] | 146420-5500 | SHIM |

| 52/1. | [1] | 146420-5600 | SHIM |

| 52/1. | [1] | 146420-5700 | SHIM |

| 52/1. | [1] | 146420-5800 | SHIM |

| 54. | [4] | 146433-0100 | GASKET |

| 55. | [4] | 146430-0120 | DELIVERY-VALVE ASSEMBLY 'VE2' VR25 |

| 56. | [4] | 146432-0000 | COMPRESSION SPRING K=0.48 |

| 58. | [4] | 146440-0220 | FITTING D0.45 L=50 |

| 60. | [3] | 139106-0100 | FLAT-HEAD SCREW |

| 66. | [1] | 146600-0100 | O-RING |

| 67. | [1] | 146502-8520 | GOVERNOR COVER CD17 XE |

| 67/1. | [1] | 146508-2820 | GOVERNOR COVER CD17 AUTO |

| 67/4. | [1] | 139310-0200 | PLAIN WASHER |

| 67/6. | [1] | 014110-6440 | LOCKING WASHER D12.2&6.1T1.5 |

| 67/8. | [1] | 146515-0020 | LEVER SHAFT |

| 67/9. | [1] | 146587-6700 | COILED SPRING CD17 AUTO |

| 67/10. | [1] | 146600-0200 | O-RING |

| 67/11. | [1] | 146602-0100 | PLAIN WASHER |

| 67/12. | [1] | 146540-3220 | CONTROL LEVER |

| 67/12B. | [1] | 146540-3320 | CONTROL LEVER ' 0' |

| 67/13. | [1] | 146621-1700 | UNION NUT |

| 67/14. | [1] | 146621-1800 | UNION NUT |

| 67/15. | [1] | 146526-3400 | BLEEDER SCREW |

| 67/16. | [1] | 146526-2900 | BLEEDER SCREW |

| 67/25. | [1] | 013020-6040 | UNION NUT |

| 67/78. | [1] | 146600-1000 | SEAL RING |

| 68. | [1] | 146510-8620 | CONTROL SHAFT R=13 W R |

| 68. | [1] | 146510-8620 | CONTROL SHAFT R=13 W R |

| 69. | [1] | 139310-0200 | PLAIN WASHER |

| 72. | [1] | 146537-2620 | CONTROL LEVER |

| 73. | [1] | 014110-6440 | LOCKING WASHER D12.2&6.1T1.5 |

| 75. | [1] | 013020-6040 | UNION NUT |

| 87. | [1] | 139308-0300 | PLAIN WASHER |

| 88. | [1] | 146545-0300 | THREADED PIN |

| 88B. | [1] | 146545-0400 | THREADED PIN |

| 88C. | [1] | 146545-0500 | THREADED PIN |

| 90. | [1] | 139208-0100 | UNION NUT |

| 91. | [1] | 146600-1200 | O-RING |

| 95. | [1] | 146551-4420 | FULCRUM LEVER I=2.2 |

| 104. | [2] | 146568-0000 | SLOTTED SPRING PIN |

| 105. | [2] | 026508-1140 | GASKET |

| 106. | [2] | 146588-0000 | COILED SPRING |

| 107. | [1] | 146569-0000 | UNION NUT |

| 108. | [1] | 146570-0420 | GOVERNOR SHAFT R-L/T |

| 109. | [1] | 146600-0400 | O-RING |

| 110/1. | [1] | 146571-0000 | SHIM |

| 110/1. | [1] | 146571-0100 | SHIM |

| 110/1. | [1] | 146571-0200 | SHIM |

| 110/1. | [1] | 146571-0300 | SHIM |

| 110/1. | [1] | 146571-0400 | SHIM |

| 110/1. | [1] | 146571-0500 | SHIM |

| 110/1. | [1] | 146571-0600 | SHIM |

| 110/1. | [1] | 146571-0700 | SHIM |

| 110/1. | [1] | 146571-0800 | SHIM |

| 111. | [1] | 146602-0600 | PLAIN WASHER |

| 112. | [1] | 146572-0020 | FLYWEIGHT ASSEMBLY |

| 114. | [1] | 146602-0500 | PLAIN WASHER |

| 115. | [1] | 146575-2300 | SLIDING SLEEVE '23' D0.5G2-0.3 |

| 116. | [1] | 146576-0200 | CAP |

| 117/1. | [1] | 146577-1800 | PLUG |

| 117/1. | [1] | 146577-1900 | PLUG |

| 117/1. | [1] | 146577-2000 | PLUG |

| 117/1. | [1] | 146577-2100 | PLUG |

| 117/1. | [1] | 146577-2200 | PLUG |

| 117/1. | [1] | 146577-2300 | PLUG |

| 117/1. | [1] | 146577-2400 | PLUG |

| 117/1. | [1] | 146577-2500 | PLUG |

| 117/1. | [1] | 146577-2600 | PLUG |

| 117/1. | [1] | 146577-2700 | PLUG |

| 117/1. | [1] | 146577-2800 | PLUG |

| 117/1. | [1] | 146577-2900 | PLUG |

| 117/1. | [1] | 146577-3000 | PLUG |

| 117/1. | [1] | 146577-3100 | PLUG |

| 117/1. | [1] | 146577-3200 | PLUG |

| 117/1. | [1] | 146577-3300 | PLUG |

| 117/1. | [1] | 146577-6700 | PLUG |

| 117/1. | [1] | 146577-6800 | PLUG |

| 117/1. | [1] | 146577-6900 | PLUG |

| 117/1. | [1] | 146577-7000 | PLUG |

| 117/1. | [1] | 146577-7100 | PLUG |

| 117/1. | [1] | 146577-7200 | PLUG |

| 117/1. | [1] | 146577-7300 | PLUG |

| 117/1. | [1] | 146577-7400 | PLUG |

| 117/1. | [1] | 146577-7500 | PLUG |

| 117/1. | [1] | 146577-7600 | PLUG |

| 117/1. | [1] | 146577-7700 | PLUG |

| 117/1. | [1] | 146577-7800 | PLUG |

| 117/1. | [1] | 146577-7900 | PLUG |

| 117/1. | [1] | 146577-8000 | PLUG |

| 117/1. | [1] | 146577-8100 | PLUG |

| 123. | [4] | 139106-0200 | FLAT-HEAD SCREW |

| 130. | [1] | 146421-0020 | CAPSULE D14 |

| 130/2. | [1] | 026508-1140 | GASKET |

| 130/3. | [1] | 146422-0000 | BLEEDER SCREW |

| 130/4. | [1] | 146600-0500 | O-RING |

| 133. | [1] | 146600-0600 | O-RING |

| 134. | [1] | 146600-0700 | O-RING |

| 135. | [1] | 146110-0220 | CONTROL VALVE '02'4XD1.6K=1.5 |

| 135/5. | [1] | 146114-0000 | SPRING WASHER |

| 136. | [1] | 146120-0220 | OVER FLOW VALVE |

| 137. | [2] | 139512-0200 | GASKET |

| 138. | [1] | 146605-5720 | INLET UNION OUT B1 B1 |

| 200. | [1] | 146206-0100 | COILED SPRING |

| 217. | [1] | 146541-2900 | SLOTTED WASHER |

| 218. | [1] | 146587-6400 | COILED SPRING CD17 AUTO |

| 219. | [1] | 146541-3000 | BUSHING |

| 220. | [1] | 146587-6500 | COILED SPRING CD17 AUTO |

| 221. | [1] | 146628-1720 | BRACKET NMC CD17 XE ISC |

| 230. | [1] | 146628-4420 | BRACKET NMC CD17 |

| 236. | [1] | 139106-0500 | FLAT-HEAD SCREW |

| 237. | [1] | 146620-0200 | HEX-SOCKET-HEAD CAP SCREW |

| 239. | [1] | 023500-5140 | PLAIN WASHER |

| 240. | [1] | 146650-0720 | PULLING ELECTROMAGNET |

| 240/8. | [1] | 146600-1700 | O-RING |

| 242. | [1] | 146658-2820 | WIRE ' 28' 12V |

| 243. | [1] | 013020-5240 | UNION NUT |

| 245. | [3] | 139512-0200 | GASKET |

| 246. | [1] | 139812-0500 | EYE BOLT |

| 247. | [1] | 146606-4120 | INLET UNION IN B3 |

| 248. | [1] | 146614-0200 | SPACER BUSHING |

| 251. | [1] | 146125-0100 | FILTER NMC LD28 GY1 |

| 252. | [1] | 146125-0200 | COILED SPRING NMC LD28 GY1 |

| 275. | [1] | 146612-2120 | BRACKET |

| 276. | [2] | 010010-1640 | BLEEDER SCREW |

| 280. | [1] | 146360-5220 | START ADVANCE ASSY |

| 281. | [1] | 146600-0800 | O-RING |

| 282. | [2] | 010206-1240 | HEX-SOCKET-HEAD CAP SCREW |

| 286. | [1] | 014010-6140 | PLAIN WASHER |

| 287. | [1] | 020106-1440 | BLEEDER SCREW |

| 329. | [1] | 146541-4900 | PLAIN WASHER CD17 AUTO |

| 800S. | [1] | 146019-1620 | PUMP HOUSING CD17 |

| 800S/1/6. | [1] | 146601-0200 | PACKING RING |

| 804S. | [1] | 146232-0320 | COMPRESSION SPRING |

| 805S. | [1] | 146574-0120 | PARTS SET |

| 810S. | [1] | 146600-1120 | REPAIR SET |

| 903. | [1] | 146672-1120 | PULSE GENERATOR |

| 903/2. | [1] | 146600-1300 | O-RING |

| 906. | [1] | 146644-9300 | NUMBER PLATE CD17 |

Include in #2:

104748-2460

as INJECTION-PUMP ASSEMBLY

Cross reference number

ZEXEL

104748-2460

1047482460

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113orSAEJ967d

1404 Test oil ISO4113orSAEJ967d

Test oil temperature

degC

45

45

50

Nozzle

105000-2010

Bosch type code

NP-DN12SD12TT

Nozzle holder

105780-2080

Opening pressure

MPa

14.7

14.7

15.19

Opening pressure

kgf/cm2

150

150

155

Injection pipe

Inside diameter - outside diameter - length (mm) mm 2-6-840

Inside diameter - outside diameter - length (mm) mm 2-6-840

Transfer pump pressure

kPa

20

20

20

Transfer pump pressure

kgf/cm2

0.2

0.2

0.2

Direction of rotation (viewed from drive side)

Left L

Left L

Injection timing adjustment

Pump speed

r/min

1000

1000

1000

Average injection quantity

mm3/st.

27

26.6

27.4

Difference in delivery

mm3/st.

2

Basic

*

Oil temperature

degC

50

48

52

Injection timing adjustment_02

Pump speed

r/min

600

600

600

Average injection quantity

mm3/st.

26.6

24.6

28.6

Oil temperature

degC

50

48

52

Injection timing adjustment_03

Pump speed

r/min

1000

1000

1000

Average injection quantity

mm3/st.

28

27

29

Difference in delivery

mm3/st.

2.5

Basic

*

Oil temperature

degC

50

48

52

Injection timing adjustment_04

Pump speed

r/min

1200

1200

1200

Average injection quantity

mm3/st.

29

27

31

Oil temperature

degC

50

48

52

Injection timing adjustment_05

Pump speed

r/min

1800

1800

1800

Average injection quantity

mm3/st.

28.3

26.3

30.3

Oil temperature

degC

50

48

52

Injection quantity adjustment

Pump speed

r/min

2700

2700

2700

Average injection quantity

mm3/st.

14.8

12.8

16.8

Difference in delivery

mm3/st.

4.5

Basic

*

Oil temperature

degC

55

52

58

Injection quantity adjustment_02

Pump speed

r/min

2900

2900

2900

Average injection quantity

mm3/st.

6

Oil temperature

degC

55

52

58

Injection quantity adjustment_03

Pump speed

r/min

2500

2500

2500

Average injection quantity

mm3/st.

27.4

25.4

29.4

Oil temperature

degC

55

52

58

Governor adjustment

Pump speed

r/min

360

360

360

Average injection quantity

mm3/st.

5.1

4.1

6.1

Difference in delivery

mm3/st.

2

Basic

*

Oil temperature

degC

48

46

50

Governor adjustment_02

Pump speed

r/min

360

360

360

Average injection quantity

mm3/st.

5.1

3.1

7.1

Difference in delivery

mm3/st.

2.5

Basic

*

Oil temperature

degC

48

46

50

Boost compensator adjustment

Pump speed

r/min

700

700

700

Average injection quantity

mm3/st.

15.2

10.7

19.7

Oil temperature

degC

50

48

52

Lever angle (shim thickness)

mm

8.9

8.9

8.9

Boost compensator adjustment_02

Pump speed

r/min

900

900

900

Average injection quantity

mm3/st.

12.4

7.4

17.4

Oil temperature

degC

50

48

52

Lever angle (shim thickness)

mm

8.9

8.9

8.9

Timer adjustment

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

52.5

47.5

57.5

Basic

*

Oil temperature

degC

48

46

50

Timer adjustment_02

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

47.5

42.5

52.5

Oil temperature

degC

48

46

50

Speed control lever angle

Pump speed

r/min

360

360

360

Average injection quantity

mm3/st.

0

0

0

Oil temperature

degC

48

46

50

Remarks

Magnet OFF at idling position

Magnet OFF at idling position

0000000901

Pump speed

r/min

1200

1200

1200

Overflow quantity

cm3/min

350

220

480

Oil temperature

degC

50

48

52

Stop lever angle

Pump speed

r/min

1200

1200

1200

Pressure

kPa

373

344

402

Pressure

kgf/cm2

3.8

3.5

4.1

Basic

*

Oil temperature

degC

50

48

52

Stop lever angle_02

Pump speed

r/min

1200

1200

1200

Pressure

kPa

372.5

333

412

Pressure

kgf/cm2

3.8

3.4

4.2

Basic

*

Oil temperature

degC

50

48

52

Stop lever angle_03

Pump speed

r/min

1800

1800

1800

Pressure

kPa

510

471

549

Pressure

kgf/cm2

5.2

4.8

5.6

Oil temperature

degC

50

48

52

Stop lever angle_04

Pump speed

r/min

2500

2500

2500

Pressure

kPa

667

628

706

Pressure

kgf/cm2

6.8

6.4

7.2

Oil temperature

degC

55

52

58

0000001101

Pump speed

r/min

1200

1200

1200

Timer stroke

mm

2.9

2.7

3.1

Basic

*

Oil temperature

degC

50

48

52

_02

Pump speed

r/min

900

900

900

Timer stroke

mm

1.6

1.2

2

Oil temperature

degC

50

48

52

_03

Pump speed

r/min

1200

1200

1200

Timer stroke

mm

2.9

2.6

3.2

Basic

*

Oil temperature

degC

50

48

52

_04

Pump speed

r/min

2500

2500

2500

Timer stroke

mm

8.15

7.7

8.6

Oil temperature

degC

55

52

58

0000001201

Max. applied voltage

V

8

8

8

Test voltage

V

13

12

14

0000001401

Pump speed

r/min

1200

1200

1200

Average injection quantity

mm3/st.

16.5

15.5

17.5

Timer stroke TA

mm

2.3

2.1

2.5

Timer stroke variation dT

mm

0.6

0.6

0.6

Basic

*

Oil temperature

degC

50

48

52

_02

Pump speed

r/min

1200

1200

1200

Average injection quantity

mm3/st.

14

12

16

Timer stroke TA

mm

1.7

1.3

2.1

Oil temperature

degC

50

48

52

Timing setting

K dimension

mm

3.3

3.2

3.4

KF dimension

mm

5.8

5.7

5.9

MS dimension

mm

1.6

1.5

1.7

Control lever angle alpha

deg.

25

23

27

Control lever angle beta

deg.

44

39

49

Test data Ex:

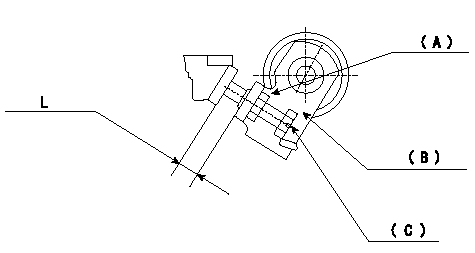

0000001801 STARTING I/Q ADJUSTMENT

Starting injection quantity adjustment

Adjust adjusting bolt so that the starting injection quantity is within the standard.

Fix using nut.

(A): Lock nut.

(B): Stopping lever

(C): Adjustment bolt

----------

----------

L=5.9~8.2mm

----------

----------

L=5.9~8.2mm

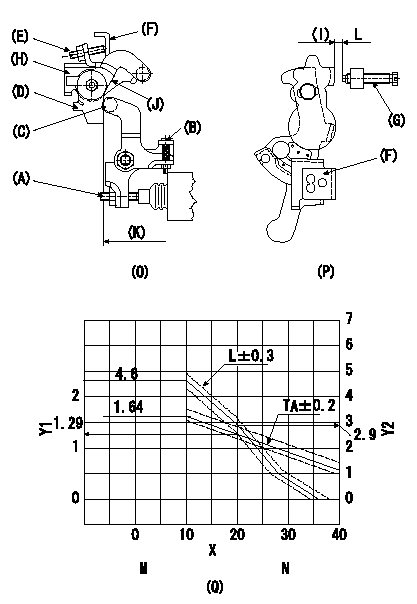

0000001901 W-CSD ADJUSTMENT

Adjustment of the W-CSD

1. Timer advance adjustment (refer to Fig 1 [O], 3 [Q]).

(1)Determine the timer advance angle from the graph in Fig. 3 (Q).

(2)(1) Adjust with the screw (A) so that the timer advance angle determined in the item (1) is obtained.

2. Setting the intermediate lever position (refer to fig 1 and fig 2)

(1)Insert a block gauge L1 between the idling set screw (G) and the control lever (F).

(2)Align the intermediate lever (D) with the aligning line (J) and position it perpendicularly.

3. W-CSD lever adjustment [refer to fig 1 (O) and fig 2 (P)]

(1)After completing (2) above, remove the block gauge L2.

(2)Insert a block gauge (I) L3 determined from the graph (L-theta) in figure 3 (Q) between the idling set screw (G) and the control lever (F).

(3)Fix screw (B) so that the W-CSD lever (C)'s roller contacts the intermediate lever (D). Fix using the nut.

Note:

The temperature of the wax at adjustment must not exceed a.

X:Temperature theta (deg C)

Y1:Timer stroke TA (mm)

Y2:Control lever L dimension (mm; control lever position)

K:Vertical position

M:TA-theta line

10 <= theta (deg C) <= 20: TA = -0.0355 theta + 1.995

20 <= theta (deg C) <= 60: TA = -0.03515 theta + 1.988

N:L-theta graph

theta (deg C) <= 10: L = 4.6

10 <= theta (deg C) <= 20: L = -0.17 theta + 6.3

20 <= theta (deg C) <= 28.5: L = -0.235 theta + 7.6

28.5 <= theta (deg C) <= 36: L = -0.12theta + 4.32

----------

L1=L=2.9+-0.05mm L2=2.9mm L3=L+-0.05mm a=30degC

----------

----------

L1=L=2.9+-0.05mm L2=2.9mm L3=L+-0.05mm a=30degC

----------

Information:

Illustration 74 g02026337 Appendix D

Cleaned Filter Specification

Note: Scope: The following steps determine a properly cleaned Caterpillar filter.Note: This specification applies to filters that were cleaned of ash only. This specification is only valid subsequent to the "Recommended Cleaning Procedure". This specification should not be used to determine if soot filled filters are properly cleaned. All filters must be baked appropriately using the "Recommended Cleaning Procedure" prior to application of this specification.HEALTH AND SAFETY

Wear goggles, gloves, protective clothing, and a National Institute for Occupational Safety and Health (NIOSH) approved P95 or N95 half-face respirator when handling a used Diesel Particulate Filter or Catalytic Converter Muffler. Failure to do so could result in personal injury.

Adhere to all local Health and Safety rules and regulations. Use all the personal protective equipment listed below:

Respirator

Safety shoes

Safety glasses

Latex gloves

Lab coatRESOURCESNecessary equipment:

38 cm (15 inch) long by 0.9 mm (0.04 inch) thick stainless steel probe for "200 cpsi" (Cells/Square inch) filters

Tape measureMETHODEvaluation of a cleaned filter:Note: A filter MUST meet all criteria in this section below to be considered clean.

Inspect both inlet and outlet surfaces for oil/fuel contamination, gouges and/or cracks. No cracks may be visible. Gouges may not be exceed 4.0 mm (0.15 inch) deep.

There must be no filter movement within the filters banding. This movement is defined as the substrate moving past the bent-over flange. The filter must be even or below the bent-over flange.

There must not be any signs of the steel fiber ring coming loose or any mat material (cottony gauze) slipping past the filter. See Illustration 75 below.

The flanges are not damaged beyond repair.

There are no dents deeper than 6.4 mm (0.25 inch) in the outer can of the filter and the outer can is not cracked, torn or otherwise breached.

No more than 20 cells are allowed to be damaged (showing soot) on the outlet face of the filter. Refer to Illustrations 76 and 77.

Inspect the ash depth in the cells using the "Check Cell Depth" instructions below.

Illustration 75 g02026392

Proper placement of the filter within the banding

(1) Outside Can

(2) Bent-over flange

(3) Steel fiber ring

(4) Mat material

(5) FilterNote: Filter must be below the bent over-flange (2).

Illustration 76 g02026398

Acceptable filter with less than 20 damaged cells

Illustration 77 g02026399

Unacceptable filter with too many damaged cells

Check Cell Depth

Check cell depth by dropping the stainless steel probe into a cell location noted by a dot in Illustration 78 below.

Lightly tap the probe with a finger until the probe does not travel into the cell any further. Mark the probe to record the depth.

Illustration 78 g02026405

Measure the distance from the tip of the probe which entered the cell to the mark made on the probe. This distance is the cell depth. Repeat this step 17 times per Illustration 78.

If the probe travels a minimum of 28.6 cm (11.25 inch) in all cells, the filter is considered clean.

If the probe encounters heavy resistance in