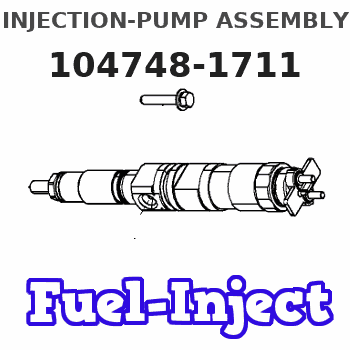

Information injection-pump assembly

ZEXEL

104748-1711

1047481711

ISUZU

8944638841

8944638841

Rating:

Cross reference number

ZEXEL

104748-1711

1047481711

ISUZU

8944638841

8944638841

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113orSAEJ967d

1404 Test oil ISO4113orSAEJ967d

Test oil temperature

degC

45

45

50

Nozzle

105000-2010

Bosch type code

NP-DN12SD12TT

Nozzle holder

105780-2080

Opening pressure

MPa

14.7

14.7

15.19

Opening pressure

kgf/cm2

150

150

155

Injection pipe

Inside diameter - outside diameter - length (mm) mm 2-6-840

Inside diameter - outside diameter - length (mm) mm 2-6-840

Transfer pump pressure

kPa

20

20

20

Transfer pump pressure

kgf/cm2

0.2

0.2

0.2

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Pump speed

r/min

1000

1000

1000

Average injection quantity

mm3/st.

23.3

22.8

23.8

Difference in delivery

mm3/st.

2

Basic

*

Oil temperature

degC

50

48

52

Injection timing adjustment_02

Pump speed

r/min

600

600

600

Average injection quantity

mm3/st.

22.2

20.7

23.7

Oil temperature

degC

50

48

52

Injection timing adjustment_03

Pump speed

r/min

1000

1000

1000

Average injection quantity

mm3/st.

23.3

22.3

24.3

Difference in delivery

mm3/st.

2

Basic

*

Oil temperature

degC

50

48

52

Injection timing adjustment_04

Pump speed

r/min

1200

1200

1200

Average injection quantity

mm3/st.

24.9

23.3

26.5

Oil temperature

degC

50

48

52

Injection quantity adjustment

Pump speed

r/min

1325

1325

1325

Average injection quantity

mm3/st.

4.7

1.7

7.7

Difference in delivery

mm3/st.

2

Basic

*

Oil temperature

degC

50

48

52

Injection quantity adjustment_02

Pump speed

r/min

1400

1400

1400

Average injection quantity

mm3/st.

0

0

0

Oil temperature

degC

50

48

52

Injection quantity adjustment_03

Pump speed

r/min

1325

1325

1325

Average injection quantity

mm3/st.

4.7

1.7

7.7

Difference in delivery

mm3/st.

2

Oil temperature

degC

50

48

52

Governor adjustment

Pump speed

r/min

350

350

350

Average injection quantity

mm3/st.

5.3

3.3

7.3

Difference in delivery

mm3/st.

2

Basic

*

Oil temperature

degC

48

46

50

Governor adjustment_02

Pump speed

r/min

350

350

350

Average injection quantity

mm3/st.

5.3

3.3

7.3

Difference in delivery

mm3/st.

2

Oil temperature

degC

48

46

50

Timer adjustment

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

47

47

54

Basic

*

Oil temperature

degC

48

46

50

Remarks

Full

Full

Timer adjustment_02

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

47

47

54

Oil temperature

degC

48

46

50

Speed control lever angle

Pump speed

r/min

350

350

350

Average injection quantity

mm3/st.

0

0

0

Oil temperature

degC

48

46

50

Remarks

Magnet OFF at idling position

Magnet OFF at idling position

0000000901

Pump speed

r/min

1000

1000

1000

Overflow quantity

cm3/min

360

230

490

Oil temperature

degC

50

48

52

Stop lever angle

Pump speed

r/min

1000

1000

1000

Pressure

kPa

392

372

412

Pressure

kgf/cm2

4

3.8

4.2

Basic

*

Oil temperature

degC

50

48

52

Stop lever angle_02

Pump speed

r/min

1000

1000

1000

Pressure

kPa

392

372

412

Pressure

kgf/cm2

4

3.8

4.2

Basic

*

Oil temperature

degC

50

48

52

Stop lever angle_03

Pump speed

r/min

1200

1200

1200

Pressure

kPa

441

412

470

Pressure

kgf/cm2

4.5

4.2

4.8

Oil temperature

degC

50

48

52

0000001101

Pump speed

r/min

1000

1000

1000

Timer stroke

mm

1.1

0.9

1.3

Basic

*

Oil temperature

degC

50

48

52

_02

Pump speed

r/min

850

750

950

Timer stroke

mm

0.5

0.5

0.5

Oil temperature

degC

50

48

52

_03

Pump speed

r/min

1000

1000

1000

Timer stroke

mm

1.1

0.9

1.3

Basic

*

Oil temperature

degC

50

48

52

_04

Pump speed

r/min

1200

1200

1200

Timer stroke

mm

2

1.7

2.3

Oil temperature

degC

50

48

52

_05

Pump speed

r/min

1500

1500

1500

Timer stroke

mm

3.3

3

3.7

Oil temperature

degC

50

48

52

0000001201

Max. applied voltage

V

8

8

8

Test voltage

V

13

12

14

Timing setting

K dimension

mm

3.3

3.2

3.4

KF dimension

mm

5.8

5.7

5.9

MS dimension

mm

2.5

2.4

2.6

Control lever angle alpha

deg.

25

21

29

Control lever angle beta

deg.

45

40

50

Information:

(1) Distance dowels extend past end surface of cylinder block ... 8.0 0.5 mm (.31 .02 in)(2) Bore diameter in cylinder block for the cylinder liners ... 138.50 0.03 mm (5.453 .001 in)(3) Distance dowels extend past end surface of cylinder block ... 8.0 0.5 mm (.31 .02 in) (4) Spacer block.(5) Height of dowels above top surface of spacer block and cylinder block ... 8.00 0.03 mm (.315 .001 in)(6) Cylinder Liner. Make reference to the procedure for checking Cylinder Liner Projection in Testing And Adjusting Section of Service Manual Form No. SENR5561.Cylinder liner projection above the top surface of the spacer block must be ... 0.12 0.08 mm (.005 .003 in)Apply 7M7260 Liquid Gasket as required to cylinder liner shoulder and cylinder block face joint of all liners. (7) Depth plug is to be installed (from end surface of cylinder block to top of plug) ... 1.25 0.25 mm (.049 .010 in)(8) Diameter of camshaft bores ... 75.000 0.025 mm (2.9530 .0010 in)(9) Oil cooling jet assembly. Tighten bolt that holds oil cooling jet to ... 25 7 N m (18 5 lb ft)(10) Width of main bearing cap ... 175.00 0.02 mm (6.8898 .0008 in) Width in cylinder block for main bearing cap ... 175.000 0.018 mm (6.8898 .0007 in)(11) Distance from centerline of crankshaft bore to top surface of cylinder block ... 265.0 mm (10.43 in)The flatness across the top contact surface of the block must be within 0.05 mm (.002 in) for any 150 mm (5.9 in) section of the surface.(12) Distance from centerline of crankshaft to bottom surface of cylinder block ... 120.0 mm (4.72 in)(13) Main bearing cap bolts. Install as follows: Main bearing caps shall be assembled with the part number towards the right side. Caps are to be identified by stamped numbers 1 through 7 located on the bottom unmachined surface.Main bearing cap bolts to be lubricated on threads and washer face with SAE 30 oil or molylube. Tighten bolts to 95 5 N m (70 4 lb ft) plus 90 5 degrees additional turn prior to machining. Tighten bolts simultaneously or tighten both bolts to 95 N m (70 lb ft) before turning the additional 90 degrees.(14) Bore in cylinder block for seven main bearings ... 108.000 0.013 mm (4.2520 .0005 in) All main bearing bore measurements are to be made before caps are disassembled.