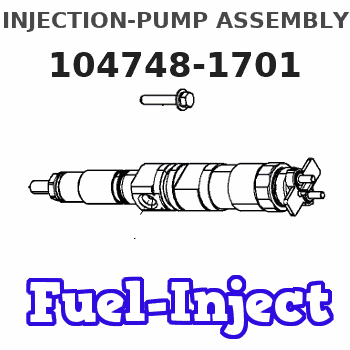

Information injection-pump assembly

ZEXEL

104748-1701

1047481701

ISUZU

8944405181

8944405181

Rating:

Cross reference number

ZEXEL

104748-1701

1047481701

ISUZU

8944405181

8944405181

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113orSAEJ967d

1404 Test oil ISO4113orSAEJ967d

Test oil temperature

degC

45

45

50

Nozzle

105000-2010

Bosch type code

NP-DN12SD12TT

Nozzle holder

105780-2080

Opening pressure

MPa

14.7

14.7

15.19

Opening pressure

kgf/cm2

150

150

155

Injection pipe

Inside diameter - outside diameter - length (mm) mm 2-6-840

Inside diameter - outside diameter - length (mm) mm 2-6-840

Transfer pump pressure

kPa

20

20

20

Transfer pump pressure

kgf/cm2

0.2

0.2

0.2

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Pump speed

r/min

1000

1000

1000

Average injection quantity

mm3/st.

23.4

22.9

23.9

Difference in delivery

mm3/st.

2

Basic

*

Injection timing adjustment_02

Pump speed

r/min

1400

1400

1400

Average injection quantity

mm3/st.

4.7

1.2

8.2

Injection timing adjustment_03

Pump speed

r/min

1300

1300

1300

Average injection quantity

mm3/st.

25.9

23.8

28

Injection timing adjustment_04

Pump speed

r/min

1000

1000

1000

Average injection quantity

mm3/st.

23.4

22.4

24.4

Injection timing adjustment_05

Pump speed

r/min

600

600

600

Average injection quantity

mm3/st.

22.3

20.3

24.3

Injection quantity adjustment

Pump speed

r/min

1400

1400

1400

Average injection quantity

mm3/st.

4.7

1.7

7.7

Difference in delivery

mm3/st.

2

Basic

*

Injection quantity adjustment_02

Pump speed

r/min

1450

1450

1450

Average injection quantity

mm3/st.

0

0

0

Governor adjustment

Pump speed

r/min

375

375

375

Average injection quantity

mm3/st.

5.3

3.3

7.3

Difference in delivery

mm3/st.

2

Basic

*

Governor adjustment_02

Pump speed

r/min

375

375

375

Average injection quantity

mm3/st.

5.3

3.3

7.3

Governor adjustment_03

Pump speed

r/min

425

425

425

Average injection quantity

mm3/st.

2

Timer adjustment

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

50

45

55

Basic

*

Remarks

Refer to additional devices.

Refer to additional devices.

Speed control lever angle

Pump speed

r/min

375

375

375

Average injection quantity

mm3/st.

0

0

0

Remarks

Magnet OFF

Magnet OFF

0000000901

Pump speed

r/min

1000

1000

1000

Overflow quantity

cm3/min

361

230

492

Stop lever angle

Pump speed

r/min

1000

1000

1000

Pressure

kPa

392.5

373

412

Pressure

kgf/cm2

4

3.8

4.2

Basic

*

Stop lever angle_02

Pump speed

r/min

600

600

600

Pressure

kPa

284.5

255

314

Pressure

kgf/cm2

2.9

2.6

3.2

Stop lever angle_03

Pump speed

r/min

1000

1000

1000

Pressure

kPa

392.5

373

412

Pressure

kgf/cm2

4

3.8

4.2

Stop lever angle_04

Pump speed

r/min

1300

1300

1300

Pressure

kPa

470.5

441

500

Pressure

kgf/cm2

4.8

4.5

5.1

0000001101

Pump speed

r/min

1000

1000

1000

Timer stroke

mm

1.1

0.9

1.3

Basic

*

_02

Pump speed

r/min

850

750

950

Timer stroke

mm

0.5

0.5

0.5

_03

Pump speed

r/min

1000

1000

1000

Timer stroke

mm

1.1

0.8

1.4

_04

Pump speed

r/min

1300

1300

1300

Timer stroke

mm

2.4

1.9

2.9

_05

Pump speed

r/min

1500

1500

1500

Timer stroke

mm

3.3

2.9

3.7

0000001201

Max. applied voltage

V

8

8

8

Test voltage

V

13

12

14

Timing setting

K dimension

mm

3.3

3.2

3.4

KF dimension

mm

5.8

5.7

5.9

MS dimension

mm

2.5

2.4

2.6

Control lever angle alpha

deg.

25

21

29

Control lever angle beta

deg.

49

44

54

Information:

Marks For Tightening Connecting Rod Bolts-7E5996 Connecting Rod Assembly(1) Bore in connecting rod for piston pin bearing ... 55.436 0.013 mm (2.1825 .0005 in) The connecting rod must be heated for installation of piston pin bearing. Do not use a torch.(2) Distance rod may be heated to 175 to 260°C (347 to 500°F) to install the piston pin bearing ... 85.0 mm (3.35 in)(3) Bore in bearing for piston pin (new) ... 50.830 0.008 mm (2.0012 .0003 in) Diameter of piston pin (new) ... 50.795 0.005 mm (1.9998 .0002 in)Thoroughly lubricate piston pin with clean engine oil prior to inserting into piston group and rod assembly.Maximum permissible clearance between bearing and piston pin (worn) ... 0.25 mm (.010 in)(4) Bearing joint must be assembled at either location on centerline through the connecting rod bore ... 5°Make reference to Special Instruction, Form No. SMHS7295 for use of pin bearing removal and installation tools and procedures.(5) Distance between center of bearings ... 261.62 0.05 mm (10.300 .002 in)(6) Bore in connecting rod for bearing with nuts tightened to specifications (8) ... 96.200 0.013 mm (3.7874 .0005 in)(7) Location for etching cylinder number on connecting rod and cap. Rods and caps are to be marked with numbers 1 through 6 on the same side of the rod as the bearing tab slots.(8) Tighten connecting rod bolts as follows: a. Before installing bolts, lubricate bolt threads and seating faces of the caps with 2P2506 Thread Lubricant.b. Tighten each bolt to ... 90 8 N m (66 6 lb ft)c. Put an alignment mark on each cap and bolt.d. Tighten each bolt an additional ... 90 5° (1/4 turn)(9) Bore in bearing for crankshaft rod journal ... 90.112 0.028 mm (3.5477 .0011 in) Clearance between bearing and crankshaft (new) ... 0.062 to 0.160 mm (.0024 to .0063 in)Maximum permissible clearance between bearing and crankshaft (worn) ... 0.20 mm (.008 in) Bearings are available in 0.63 mm (.025 in) and 1.27 mm (.050 in) smaller than original size.