Information injection-pump assembly

ZEXEL

104748-1652

1047481652

Rating:

Cross reference number

ZEXEL

104748-1652

1047481652

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113orSAEJ967d

1404 Test oil ISO4113orSAEJ967d

Test oil temperature

degC

45

45

50

Nozzle

105000-2010

Bosch type code

NP-DN12SD12TT

Nozzle holder

105780-2080

Opening pressure

MPa

14.7

14.7

15.19

Opening pressure

kgf/cm2

150

150

155

Injection pipe

Inside diameter - outside diameter - length (mm) mm 2-6-840

Inside diameter - outside diameter - length (mm) mm 2-6-840

Transfer pump pressure

kPa

20

20

20

Transfer pump pressure

kgf/cm2

0.2

0.2

0.2

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Pump speed

r/min

1250

1250

1250

Average injection quantity

mm3/st.

31

30.5

31.5

Difference in delivery

mm3/st.

2.5

Basic

*

Oil temperature

degC

50

48

52

Injection timing adjustment_02

Pump speed

r/min

600

600

600

Average injection quantity

mm3/st.

29.5

28

31

Oil temperature

degC

50

48

52

Injection timing adjustment_03

Pump speed

r/min

1250

1250

1250

Average injection quantity

mm3/st.

31

30

32

Difference in delivery

mm3/st.

2.5

Basic

*

Oil temperature

degC

50

48

52

Injection timing adjustment_04

Pump speed

r/min

2500

2500

2500

Average injection quantity

mm3/st.

26.8

25.3

28.3

Oil temperature

degC

55

52

58

Injection timing adjustment_05

Pump speed

r/min

2600

2600

2600

Average injection quantity

mm3/st.

26.7

25.1

28.3

Oil temperature

degC

55

52

58

Injection timing adjustment_06

Pump speed

r/min

2700

2700

2700

Average injection quantity

mm3/st.

25.1

22.1

28.1

Oil temperature

degC

55

52

58

Injection quantity adjustment

Pump speed

r/min

2800

2800

2800

Average injection quantity

mm3/st.

20.8

19.8

21.8

Basic

*

Oil temperature

degC

55

52

58

Injection quantity adjustment_02

Pump speed

r/min

2900

2900

2900

Average injection quantity

mm3/st.

4

Oil temperature

degC

55

52

58

Injection quantity adjustment_03

Pump speed

r/min

2800

2800

2800

Average injection quantity

mm3/st.

20.8

19.8

21.8

Difference in delivery

mm3/st.

6.5

Oil temperature

degC

55

52

58

Governor adjustment

Pump speed

r/min

425

425

425

Average injection quantity

mm3/st.

6

5

7

Difference in delivery

mm3/st.

2

Basic

*

Oil temperature

degC

48

46

50

Governor adjustment_02

Pump speed

r/min

425

425

425

Average injection quantity

mm3/st.

6

5

7

Difference in delivery

mm3/st.

2

Oil temperature

degC

48

46

50

Timer adjustment

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

50

50

70

Basic

*

Oil temperature

degC

48

46

50

Remarks

Full

Full

Timer adjustment_02

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

50

50

Oil temperature

degC

48

46

50

Speed control lever angle

Pump speed

r/min

425

425

425

Average injection quantity

mm3/st.

0

0

0

Oil temperature

degC

48

46

50

Remarks

Magnet OFF at idling position

Magnet OFF at idling position

0000000901

Pump speed

r/min

1250

1250

1250

Overflow quantity

cm3/min

370

240

500

Oil temperature

degC

50

48

52

Stop lever angle

Pump speed

r/min

1250

1250

1250

Pressure

kPa

363

343

383

Pressure

kgf/cm2

3.7

3.5

3.9

Basic

*

Oil temperature

degC

50

48

52

Stop lever angle_02

Pump speed

r/min

1250

1250

1250

Pressure

kPa

363

343

383

Pressure

kgf/cm2

3.7

3.5

3.9

Basic

*

Oil temperature

degC

50

48

52

Stop lever angle_03

Pump speed

r/min

2000

2000

2000

Pressure

kPa

539

510

568

Pressure

kgf/cm2

5.5

5.2

5.8

Oil temperature

degC

50

48

52

Stop lever angle_04

Pump speed

r/min

2300

2300

2300

Pressure

kPa

618

589

647

Pressure

kgf/cm2

6.3

6

6.6

Oil temperature

degC

52

50

54

0000001101

Pump speed

r/min

1250

1250

1250

Timer stroke

mm

3.1

2.9

3.3

Basic

*

Oil temperature

degC

50

48

52

_02

Pump speed

r/min

620

620

620

Timer stroke

mm

0.5

0.5

0.5

Oil temperature

degC

50

48

52

_03

Pump speed

r/min

1250

1250

1250

Timer stroke

mm

3.1

2.9

3.3

Basic

*

Oil temperature

degC

50

48

52

_04

Pump speed

r/min

2000

2000

2000

Timer stroke

mm

6.1

5.7

6.5

Oil temperature

degC

50

48

52

_05

Pump speed

r/min

2300

2300

2300

Timer stroke

mm

7.4

7.1

7.8

Oil temperature

degC

52

50

54

0000001201

Max. applied voltage

V

8

8

8

Test voltage

V

13

12

14

0000001401

Pump speed

r/min

1250

1250

1250

Average injection quantity

mm3/st.

18

17.5

18.5

Timer stroke TA

mm

2.3

2.3

2.3

Timer stroke variation dT

mm

0.8

0.6

1

Basic

*

Oil temperature

degC

50

48

52

_02

Pump speed

r/min

1250

1250

1250

Average injection quantity

mm3/st.

18

17

19

Timer stroke variation dT

mm

0.8

0.4

1.2

Oil temperature

degC

50

48

52

_03

Pump speed

r/min

1250

1250

1250

Average injection quantity

mm3/st.

9

9

9

Timer stroke variation dT

mm

2.2

2.2

2.2

Oil temperature

degC

50

48

52

_04

Pump speed

r/min

1250

1250

1250

Average injection quantity

mm3/st.

7

6

8

Timer stroke variation dT

mm

2.2

1.6

2.8

Oil temperature

degC

50

48

52

Timing setting

K dimension

mm

3.3

3.2

3.4

KF dimension

mm

5.8

5.7

5.9

MS dimension

mm

1.6

1.5

1.7

Control lever angle alpha

deg.

20

16

24

Control lever angle beta

deg.

40

39

41

Test data Ex:

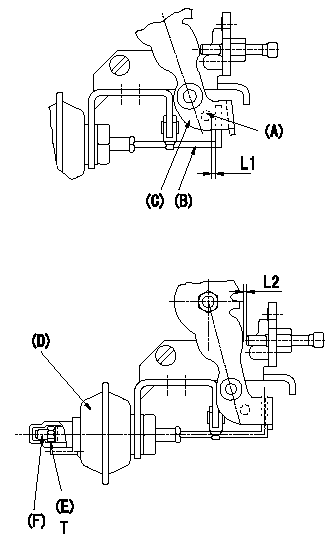

0000001801 V-FICD ADJUSTMENT

Adjustment of the V-FICD (perform with W-FICD released)

1. Adjust to obtain L1.

2. Confirm that L2 is obtained when negative pressure P1 (kPa) {P2 (mmHg)} is applied to the actuator.

Adjust the stroke using the actuator stroke adjusting screw (F).

(A): Pin

(B): Actuator shaft

(C): Control lever

(D): Actuator

(E): Lock nut (torque T)

----------

L1=1+1mm L2=1.45+-0.1mm P1=-53.3kPa P2=-400mmHg

----------

L1=1+1mm L2=1.45+-0.1mm T=1.2~1.5N-m{0.12~0.15kgf-m}

----------

L1=1+1mm L2=1.45+-0.1mm P1=-53.3kPa P2=-400mmHg

----------

L1=1+1mm L2=1.45+-0.1mm T=1.2~1.5N-m{0.12~0.15kgf-m}

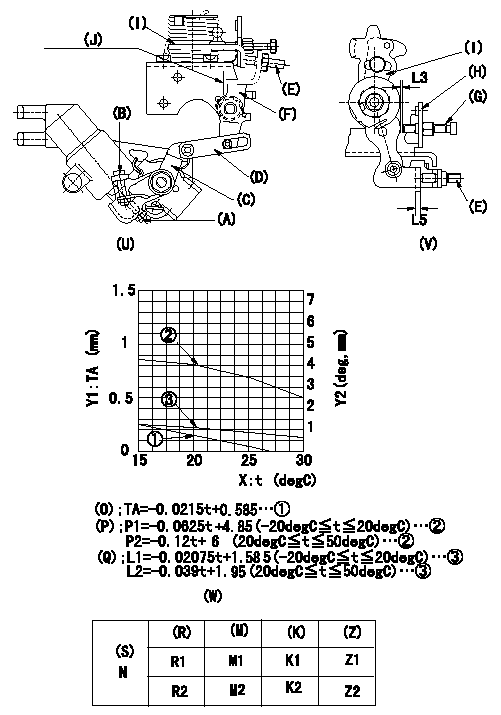

0000001901 W-CSD ADJUSTMENT

Adjustment of the W-CSD

1. Adjustment of the timer stroke

Adjust using screw (A) so that the timer stroke is the value determined using the graph (W). [(K), (M)]

2. Adjustment of the position of the intermediate lever.

With a shim L5 inserted between the control lever (I) and the FICD set screw (E), insert a shim (L3) between (I) and the idle screw (G).

Align the intermediate lever (F) with the aligning mark (J) and then fix the intermediate lever adjusting screw (E) so that (E) contacts the shim between (E) and (I). [(U), (V)]

3. Adjustment of the FICD

Insert the shim (L4) between the control lever (I) and the idle set screw (G).

Use adjusting screw (B) to fix the CSD lever (C) in the position where it operates the intermediate lever (F) via the rod (D). [(U), (V)]

However, set with a shim L5 inserted. [(U), (V), (W)]

(O) Timer stroke adjustment (mm)

(P): lever angle (deg)

(Q): lever angle (deg)

The (Q) indicates the clearance between the control lever and the idle set screw.

X:Temperature t (deg C)

Y1:Timer stroke TA (mm)

Y2:Control lever position at theta L (deg, mm)

(R): cooling water temperature (deg C)

(S): cooling water temperature: increase direction

N:Pump speed

(M): timer piston stroke (mm)

(K): colored ring

(Z): lever position (mm)

----------

L3=1.2+-0.05mm L4=L3+-0.05mm L5=-mm

----------

L3=1.2+-0.05mm L5=-mm N=500r/min R1=20deg R2=-20deg M1=0.16+-0.2mm M2=1.0+-0.4mm K1=3.6+-1deg K2=6.1+-3deg Z1=1.2+-0.3mm Z2=2+-1mm

----------

L3=1.2+-0.05mm L4=L3+-0.05mm L5=-mm

----------

L3=1.2+-0.05mm L5=-mm N=500r/min R1=20deg R2=-20deg M1=0.16+-0.2mm M2=1.0+-0.4mm K1=3.6+-1deg K2=6.1+-3deg Z1=1.2+-0.3mm Z2=2+-1mm

Information:

Example of Pulse Width Modulation SignalsRated Rack PositionA limit on rack position which provides the specified horsepower and torque curves. this value comes from maps programmed into the personality module at the factory.Rack Position SensorA linear position sensor which follows movement of the rack assembly and sends an electrical signal to the ECM.Rack Solenoid (BTM)A rotary proportional solenoid (also called a BTM) used to move the fuel rack servo spool valve.Reference VoltageA regulated voltage supplied by the ECM to a sensor. The reference voltage is used by the sensor to generate a signal voltage.Retarder Enable SignalThe Retarder Enable signal is provided by the ECM to indicate that conditions are acceptable for an engine retarder to operate. Operation of the retarder is inhibited during undesirable engine operating conditions (such as while the engine is being fueled).SensorA device used to detect and convert a change in pressure, temperature, or mechanical movement into an electrical signal.Service Program ModuleA software program on a factory programmable computer chip, designed to adapt an ECAP or DDT to a specific application.Short CircuitA condition where an electrical circuit is unintentionally connected to an undesirable point. Example: a wire which rubs against a vehicle frame until it wears off its insulation and makes electrical contact with the frame.SignalA voltage or waveform used to transmit information typically from a sensor to the ECM.Speed "burp"A sudden brief change in engine speed.Static Timing SpecificationFixed number of degrees determined by design of the fuel pump camshaft (determines injection timing with no advance). Note that the value displayed is the specification for static timing, not an electrically measured value.SubsystemAs used here, it is a part of the PEEC III System that relates to a particular function, for instance: throttle subsystem, etc.Supply VoltageA constant voltage supplied to a component to provide electrical power for its operation. It may be generated by the ECM, or it may be vehicle battery voltage supplied by the vehicle wiring."T" HarnessA test harness designed to permit normal circuit operation while measuring voltages, typically inserted between the two ends of a connector.Throttle PositionThe ECM's interpretation of the signal from the Throttle Position Sensor.Throttle Position SensorAn electronic sensor which is connected to the accelerator pedal and sends a Pulse Width Modulated signal to the ECM.Timing Position SensorA linear position sensor which follows movement of the timing advance unit and sends an electrical signal to the ECM.Timing Solenoid (BTM)A rotary proportional solenoid (also called a BTM) used to move the timing advance unit spool valve. Total TattletaleTotal number of changes to all Customer Specified Parameters.TransducerA device which converts a mechanical signal to an electrical signal.Transducer ModuleA sealed unit mounted below the rack actuator housing and contains the engine oil pressure sensor, boost pressure sensor, and protective signal conditioning circuitry.Vehicle Speed BufferA device used to condition and amplify the output of the vehicle speed sensor.Vehicle Speed SensorAn electro-magnetic pickup that measures vehicle speed from the rotation of gear teeth in the drive train of the vehicle.