Information injection-pump assembly

ZEXEL

104748-1651

1047481651

ISUZU

8944134491

8944134491

Rating:

Cross reference number

ZEXEL

104748-1651

1047481651

ISUZU

8944134491

8944134491

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113orSAEJ967d

1404 Test oil ISO4113orSAEJ967d

Test oil temperature

degC

45

45

50

Nozzle

105000-2010

Bosch type code

NP-DN12SD12TT

Nozzle holder

105780-2080

Opening pressure

MPa

14.7

14.7

15.19

Opening pressure

kgf/cm2

150

150

155

Injection pipe

Inside diameter - outside diameter - length (mm) mm 2-6-840

Inside diameter - outside diameter - length (mm) mm 2-6-840

Transfer pump pressure

kPa

20

20

20

Transfer pump pressure

kgf/cm2

0.2

0.2

0.2

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Pump speed

r/min

1250

1250

1250

Average injection quantity

mm3/st.

30.2

29.7

30.7

Difference in delivery

mm3/st.

2.5

Basic

*

Injection timing adjustment_02

Pump speed

r/min

2965

2965

2965

Average injection quantity

mm3/st.

11.1

9.6

12.6

Injection timing adjustment_03

Pump speed

r/min

2700

2700

2700

Average injection quantity

mm3/st.

24.6

21.1

28.1

Injection timing adjustment_04

Pump speed

r/min

2600

2600

2600

Average injection quantity

mm3/st.

26.8

24.7

28.9

Injection timing adjustment_05

Pump speed

r/min

2500

2500

2500

Average injection quantity

mm3/st.

26.8

24.8

28.8

Injection timing adjustment_06

Pump speed

r/min

2000

2000

2000

Average injection quantity

mm3/st.

28.6

26.6

30.6

Injection timing adjustment_07

Pump speed

r/min

1250

1250

1250

Average injection quantity

mm3/st.

30.2

29.2

31.2

Injection timing adjustment_08

Pump speed

r/min

600

600

600

Average injection quantity

mm3/st.

28.8

26.8

30.8

Injection timing adjustment_09

Pump speed

r/min

2965

2965

2965

Average injection quantity

mm3/st.

11

11

11

Remarks

Measure with the angle beta (39~41degC) adjusted to within the specifications.

Measure with the angle beta (39~41degC) adjusted to within the specifications.

Injection timing adjustment_10

Pump speed

r/min

2800

2650

2950

Average injection quantity

mm3/st.

20.9

19.9

21.9

Basic

*

Remarks

Measure with the angle beta (39~41degC) adjusted to within the specifications.

Measure with the angle beta (39~41degC) adjusted to within the specifications.

Injection timing adjustment_11

Pump speed

r/min

2700

2700

2700

Average injection quantity

mm3/st.

24.6

21.1

28.1

Remarks

Measure with the angle beta (39~41degC) adjusted to within the specifications.

Measure with the angle beta (39~41degC) adjusted to within the specifications.

Injection timing adjustment_12

Pump speed

r/min

2600

2600

2600

Average injection quantity

mm3/st.

26.8

24.7

28.9

Remarks

Measure with the angle beta (39~41degC) adjusted to within the specifications.

Measure with the angle beta (39~41degC) adjusted to within the specifications.

Injection timing adjustment_13

Remarks

Measure with the angle beta (39~41degC) adjusted to within the specifications.

Measure with the angle beta (39~41degC) adjusted to within the specifications.

Injection quantity adjustment

Pump speed

r/min

2965

2965

2965

Average injection quantity

mm3/st.

11.1

10.1

12.1

Difference in delivery

mm3/st.

3.5

Basic

*

Injection quantity adjustment_02

Pump speed

r/min

2900

2900

2900

Average injection quantity

mm3/st.

4.5

Remarks

Insert a 4.5+-0.1 mm shim between the C/L and the full speed position and measure injection quantity.

Insert a 4.5+-0.1 mm shim between the C/L and the full speed position and measure injection quantity.

Governor adjustment

Pump speed

r/min

425

425

425

Average injection quantity

mm3/st.

6

5

7

Difference in delivery

mm3/st.

2

Basic

*

Governor adjustment_02

Pump speed

r/min

425

425

425

Average injection quantity

mm3/st.

6

5

7

Governor adjustment_03

Pump speed

r/min

500

500

500

Average injection quantity

mm3/st.

4

Governor adjustment_04

Pump speed

r/min

1200

1200

1200

Average injection quantity

mm3/st.

2

Timer adjustment

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

60

50

70

Basic

*

Speed control lever angle

Pump speed

r/min

425

425

425

Average injection quantity

mm3/st.

0

0

0

Remarks

Magnet OFF

Magnet OFF

0000000901

Pump speed

r/min

1250

1250

1250

Overflow quantity

cm3/min

370

240

500

Stop lever angle

Pump speed

r/min

1250

1250

1250

Pressure

kPa

362.5

343

382

Pressure

kgf/cm2

3.7

3.5

3.9

Basic

*

Stop lever angle_02

Pump speed

r/min

500

500

500

Pressure

kPa

186.5

157

216

Pressure

kgf/cm2

1.9

1.6

2.2

Stop lever angle_03

Pump speed

r/min

1250

1250

1250

Pressure

kPa

362.5

343

382

Pressure

kgf/cm2

3.7

3.5

3.9

Stop lever angle_04

Pump speed

r/min

2000

2000

2000

Pressure

kPa

539.5

510

569

Pressure

kgf/cm2

5.5

5.2

5.8

Stop lever angle_05

Pump speed

r/min

2300

2300

2300

Pressure

kPa

617.5

588

647

Pressure

kgf/cm2

6.3

6

6.6

0000001101

Pump speed

r/min

1250

1250

1250

Timer stroke

mm

3.1

2.9

3.3

Basic

*

_02

Pump speed

r/min

1250

1250

1250

Timer stroke

mm

3.1

2.8

3.4

_03

Pump speed

r/min

2000

2000

2000

Timer stroke

mm

6.1

5.5

6.7

_04

Pump speed

r/min

2300

2300

2300

Timer stroke

mm

7.4

7

7.8

0000001201

Max. applied voltage

V

8

8

8

Test voltage

V

13

12

14

0000001401

Pump speed

r/min

1250

1250

1250

Average injection quantity

mm3/st.

18.1

17.6

18.6

Timer stroke variation dT

mm

0.8

0.6

1

Basic

*

_02

Pump speed

r/min

1250

1250

1250

Average injection quantity

mm3/st.

18.1

17.1

19.1

Timer stroke variation dT

mm

0.8

0.5

1.1

_03

Pump speed

r/min

1250

1250

1250

Average injection quantity

mm3/st.

7

5.5

8.5

Timer stroke variation dT

mm

2.2

1.7

2.7

Timing setting

K dimension

mm

3.3

3.2

3.4

KF dimension

mm

5.8

5.7

5.9

MS dimension

mm

1.6

1.5

1.7

Control lever angle alpha

deg.

20

16

24

Control lever angle beta

deg.

40

37

43

Test data Ex:

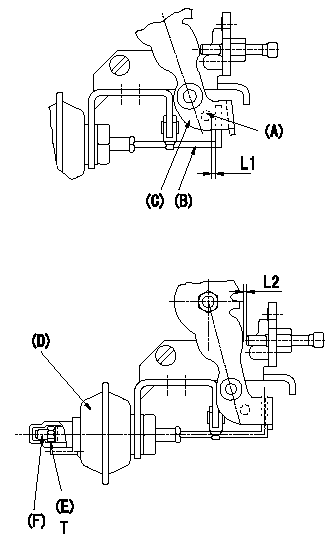

0000001801 V-FICD ADJUSTMENT

Adjustment of the V-FICD (perform with W-FICD released)

1. Adjust to obtain L1.

2. Confirm that L2 is obtained when negative pressure P1 (kPa) {P2 (mmHg)} is applied to the actuator.

Adjust the stroke using the actuator stroke adjusting screw (F).

(A): Pin

(B): Actuator shaft

(C): Control lever

(D): Actuator

(E): Lock nut (torque T)

----------

L1=1+1mm L2=1.45+-0.1mm P1=-53.3kPa P2=-400mmHg

----------

L1=1+1mm L2=1.45+-0.1mm T=1.2~1.5N-m{0.12~0.15kgf-m}

----------

L1=1+1mm L2=1.45+-0.1mm P1=-53.3kPa P2=-400mmHg

----------

L1=1+1mm L2=1.45+-0.1mm T=1.2~1.5N-m{0.12~0.15kgf-m}

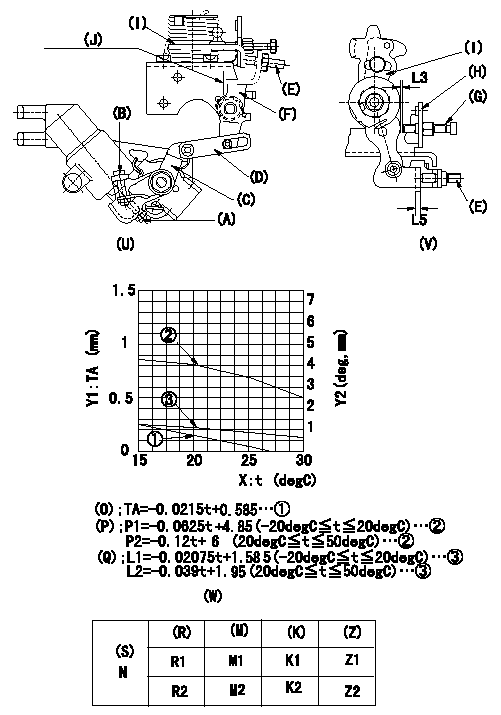

0000001901 W-CSD ADJUSTMENT

Adjustment of the W-CSD

1. Adjustment of the timer stroke

Adjust screw (A) so that the timer stroke is the value determined from the graph (W) [(V), (W)].

2. Adjustment of the position of the intermediate lever.

Insert a shim L3 between the control lever (I) and the idle screw (G).

Align the intermediate lever (F) with the aligning mark (J) and then fix the intermediate lever adjusting screw (E) so that (E) contacts the shim between (E) and (I). [(U), (V)]

3. Adjustment of the FICD

Insert a shim L4 between the control lever (I) and the idle set screw (G).

Use adjusting screw (B) to fix the CSD lever (C) in the position where it operates the intermediate lever (F) via the rod (D). [(U), (V), (W)]

(O) Timer stroke adjustment (mm)

(P): lever angle (deg)

(Q): lever angle (deg)

The (Q) indicates the clearance between the control lever and the idle set screw.

X:Temperature t (deg C)

Y1:Timer stroke TA (mm)

Y2:Control lever position at theta L (deg, mm)

(R): cooling water temperature (deg C)

(S): cooling water temperature: increase direction

N:Pump speed

(M): timer piston stroke (mm)

(K): colored ring

(Z): lever position (mm)

----------

L3=1.2+-0.05mm L4=L3+-0.05mm

----------

L3=1.2+-0.05mm L4=L+-0.05mm L5=-mm R1=- R2=- M1=- M2=- K1=- K2=- Z1=- Z2=-

----------

L3=1.2+-0.05mm L4=L3+-0.05mm

----------

L3=1.2+-0.05mm L4=L+-0.05mm L5=-mm R1=- R2=- M1=- M2=- K1=- K2=- Z1=- Z2=-

Information:

Location of Screwdriver While Holding BellcrankK. Rotate the timing position sensor bellcrank clock wise by inserting the No. 2 Phillips screwdriver between the arm of the bellcrank in contact with the timing position sensor until the screwdriver can be inserted into the hole in the cover to hold the bellcrank in position.

Hold Timing Position Sensor Bellcrank In PositionL. Install the gasket and timing advance housing (4).M. Remove the screwdriver to allow the bellcrank to contact the power piston.9. Check the timing sensor position calibration as described in P-531: Timing Position Sensor/Calibration.10. Install the timing solenoid (BTM). Make sure the arm of the timing solenoid is in the center groove of the control spool collar.11. Install the timing advance position sensor cover (3).P-540: Idle Shutdown Timer

System Operation

The idle shutdown timer is a feature which helps improve fuel consumption by limiting idling time. The timer may be programmed to shut down the idling engine after a period of time. This "shutdown time" is a customer specified parameter, and may be programmed for any period from 3 to 60 minutes. Programming the time to zero disables the idle shutdown timer.The timer is activated when the parking brake is set, vehicle speed is zero, and the engine is not under load. Ninety seconds before the programmed time is reached, the diagnostic lamp will begin to flash rapidly. If the driver moves the clutch pedal or brake pedal during this 90 second period, the timer will be overridden and is reset. A diagnostic code 71-00 will be set when the driver overrides the timer using the clutch or brake.If the timer is activated and allowed to shutdown the engine, then a code 71-01 will be set. Code 71-01 merely records the event and does not indicate a fault in PEEC III. If any of the codes for vehicle speed are Active, the idle shutdown timer will not operate.Diagnostic Codes

Functional Test

P-541: Multi-Torque

System Operation

Multi-Torque is an optional feature available with certain PEEC III engines. The feature is available only in certain personality modules.The 310 Multi-Torque provides an otherwise standard 310 hp PEEC III engine with two different torque curves. In all gears except top gear, the engine performs as a standard 310 hp PEEC III. In top gear, however, the engine is provided with the torque of a standard 310 hp at 1800 rpm, but with the peak torque of 350 hp at 1150 rpm (see the following illustrations).PEEC III determines whether the vehicle is in top gear by sensing the ratio of engine speed to vehicle speed. If the ratio of engine speed/vehicle speed is less than 26.6, the engine will perform like a standard 310 hp PEEC III.The 350 Multi-Torque works just like the 310Multi-Torque, except for two key differences. First, the multi-torque curve provides the engine with the standard 350 hp torque at 1800 rpm, and with the peak torque of a 400 hp at 1200 rpm (see the following illustration). Second, the multi-torque is in effect in the top two gears,