Information injection-pump assembly

ZEXEL

104748-1650

1047481650

ISUZU

8944134490

8944134490

Rating:

Cross reference number

ZEXEL

104748-1650

1047481650

ISUZU

8944134490

8944134490

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113orSAEJ967d

1404 Test oil ISO4113orSAEJ967d

Test oil temperature

degC

45

45

50

Nozzle

105000-2010

Bosch type code

NP-DN12SD12TT

Nozzle holder

105780-2080

Opening pressure

MPa

14.7

14.7

15.19

Opening pressure

kgf/cm2

150

150

155

Injection pipe

Inside diameter - outside diameter - length (mm) mm 2-6-840

Inside diameter - outside diameter - length (mm) mm 2-6-840

Transfer pump pressure

kPa

20

20

20

Transfer pump pressure

kgf/cm2

0.2

0.2

0.2

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Pump speed

r/min

1250

1250

1250

Average injection quantity

mm3/st.

30.2

29.7

30.7

Difference in delivery

mm3/st.

2.5

Basic

*

Injection timing adjustment_02

Pump speed

r/min

2965

2965

2965

Average injection quantity

mm3/st.

11.1

9.6

12.6

Injection timing adjustment_03

Pump speed

r/min

2700

2700

2700

Average injection quantity

mm3/st.

24.6

19.6

29.6

Injection timing adjustment_04

Pump speed

r/min

2600

2600

2600

Average injection quantity

mm3/st.

27.2

25.1

29.3

Injection timing adjustment_05

Pump speed

r/min

2500

2500

2500

Average injection quantity

mm3/st.

26.8

24.8

28.8

Injection timing adjustment_06

Pump speed

r/min

2000

2000

2000

Average injection quantity

mm3/st.

28.6

26.6

30.6

Injection timing adjustment_07

Pump speed

r/min

1250

1250

1250

Average injection quantity

mm3/st.

30.2

29.2

31.2

Injection timing adjustment_08

Pump speed

r/min

600

600

600

Average injection quantity

mm3/st.

29

27

31

Injection timing adjustment_09

Pump speed

r/min

2965

2965

2965

Average injection quantity

mm3/st.

11

11

11

Remarks

Measure with the angle beta (39~41degC) adjusted to within the specifications.

Measure with the angle beta (39~41degC) adjusted to within the specifications.

Injection timing adjustment_10

Pump speed

r/min

2800

2650

2950

Average injection quantity

mm3/st.

20.9

19.9

21.9

Basic

*

Remarks

Measure with the angle beta (39~41degC) adjusted to within the specifications.

Measure with the angle beta (39~41degC) adjusted to within the specifications.

Injection timing adjustment_11

Pump speed

r/min

2700

2700

2700

Average injection quantity

mm3/st.

24.6

21.1

28.1

Remarks

Measure with the angle beta (39~41degC) adjusted to within the specifications.

Measure with the angle beta (39~41degC) adjusted to within the specifications.

Injection timing adjustment_12

Pump speed

r/min

2600

2600

2600

Average injection quantity

mm3/st.

26.8

24.7

28.9

Remarks

Measure with the angle beta (39~41degC) adjusted to within the specifications.

Measure with the angle beta (39~41degC) adjusted to within the specifications.

Injection quantity adjustment

Pump speed

r/min

2965

2965

2965

Average injection quantity

mm3/st.

11.1

10.1

12.1

Difference in delivery

mm3/st.

3.5

Basic

*

Injection quantity adjustment_02

Pump speed

r/min

2900

2900

2900

Average injection quantity

mm3/st.

4.5

Remarks

Insert a 4.5+-0.1 mm shim between the C/L and the full speed position and measure injection quantity.

Insert a 4.5+-0.1 mm shim between the C/L and the full speed position and measure injection quantity.

Governor adjustment

Pump speed

r/min

425

425

425

Average injection quantity

mm3/st.

6

5

7

Difference in delivery

mm3/st.

2

Basic

*

Governor adjustment_02

Pump speed

r/min

425

425

425

Average injection quantity

mm3/st.

6

5

7

Governor adjustment_03

Pump speed

r/min

500

500

500

Average injection quantity

mm3/st.

4

Timer adjustment

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

50

50

Basic

*

Speed control lever angle

Pump speed

r/min

425

425

425

Average injection quantity

mm3/st.

0

0

0

Remarks

Magnet OFF

Magnet OFF

0000000901

Pump speed

r/min

1250

1250

1250

Overflow quantity

cm3/min

369

240

498

Stop lever angle

Pump speed

r/min

1250

1250

1250

Pressure

kPa

362.5

343

382

Pressure

kgf/cm2

3.7

3.5

3.9

Basic

*

Stop lever angle_02

Pump speed

r/min

500

500

500

Pressure

kPa

186.5

157

216

Pressure

kgf/cm2

1.9

1.6

2.2

Stop lever angle_03

Pump speed

r/min

1250

1250

1250

Pressure

kPa

362.5

343

382

Pressure

kgf/cm2

3.7

3.5

3.9

Stop lever angle_04

Pump speed

r/min

2000

2000

2000

Pressure

kPa

539.5

510

569

Pressure

kgf/cm2

5.5

5.2

5.8

Stop lever angle_05

Pump speed

r/min

2300

2300

2300

Pressure

kPa

637.5

608

667

Pressure

kgf/cm2

6.5

6.2

6.8

0000001101

Pump speed

r/min

1250

1250

1250

Timer stroke

mm

3.1

2.9

3.3

Basic

*

_02

Pump speed

r/min

1250

1250

1250

Timer stroke

mm

3.1

2.8

3.4

_03

Pump speed

r/min

2000

2000

2000

Timer stroke

mm

6.1

5.5

6.7

_04

Pump speed

r/min

2300

2300

2300

Timer stroke

mm

7.4

7

7.8

0000001201

Max. applied voltage

V

8

8

8

Test voltage

V

13

12

14

0000001401

Pump speed

r/min

1250

1250

1250

Average injection quantity

mm3/st.

18.1

17.9

18.3

Timer stroke variation dT

mm

0.8

0.7

0.9

Basic

*

_02

Pump speed

r/min

1250

1250

1250

Average injection quantity

mm3/st.

18.1

17.4

18.8

Timer stroke variation dT

mm

0.8

0.6

1

_03

Pump speed

r/min

1250

1250

1250

Average injection quantity

mm3/st.

7

5.5

8.5

Timer stroke variation dT

mm

2.2

1.7

2.7

Timing setting

K dimension

mm

3.3

3.2

3.4

KF dimension

mm

5.8

5.7

5.9

MS dimension

mm

1.6

1.5

1.7

Control lever angle alpha

deg.

20

16

24

Control lever angle beta

deg.

40

37

43

Test data Ex:

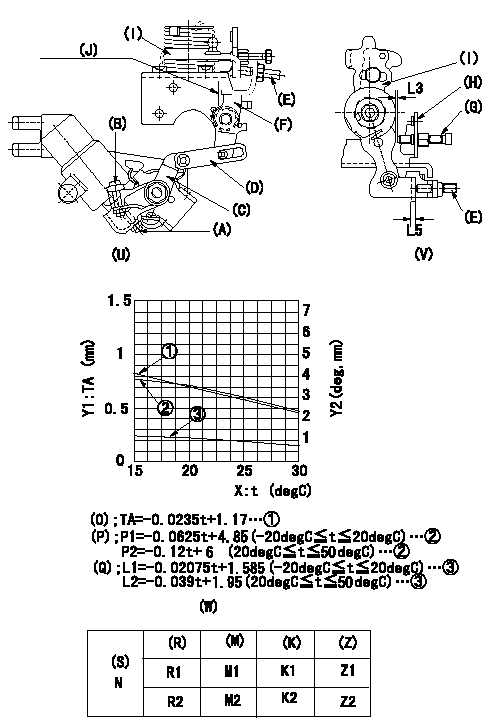

0000001801 W-CSD ADJUSTMENT

Adjustment of the W-CSD

1. Adjustment of the timer stroke

Adjust using screw (A) so that the timer stroke is the value determined using the graph (W). [(K), (M)]

2. Adjustment of the position of the intermediate lever.

With a shim L5 inserted between the control lever (I) and the FICD set screw (E), insert a shim (L3) between (I) and the idle screw (G).

Align the intermediate lever (F) with the aligning mark (J) and then fix the intermediate lever adjusting screw (E) so that (E) contacts the shim between (E) and (I). [(U), (V)]

3. Adjustment of the FICD

Insert the shim (L4) between the control lever (I) and the idle set screw (G).

Use adjusting screw (B) to fix the CSD lever (C) in the position where it operates the intermediate lever (F) via the rod (D). [(U), (V)]

However, set with a shim L5 inserted. [(U), (V), (W)]

(O) Timer stroke adjustment (mm)

(P): lever angle (deg)

(Q): lever angle (deg)

The (Q) indicates the clearance between the control lever and the idle set screw.

X:Temperature t (deg C)

Y1:Timer stroke TA (mm)

Y2:Control lever position at theta L (deg, mm)

(R): cooling water temperature (deg C)

(S): cooling water temperature: increase direction

N:Pump speed

(M): timer piston stroke (mm)

(K): colored ring

(Z): lever position (mm)

----------

L3=1.2+-0.05mm L4=L3+-0.05mm

----------

L3=1.2+-0.05mm L4=L+-0.05mm L5=-mm R1=- R2=- M1=- M2=- K1=- K2=- Z1=- Z2=-

----------

L3=1.2+-0.05mm L4=L3+-0.05mm

----------

L3=1.2+-0.05mm L4=L+-0.05mm L5=-mm R1=- R2=- M1=- M2=- K1=- K2=- Z1=- Z2=-

Information:

ACTIVE Diagnostic Codes

Diagnostic codes are used by the PEEC III system to warn the vehicle operator of a problem and indicate to the service technician the nature of the problem. Some codes are used only to record an event, and do not indicate problems.An ACTIVE Diagnostic code represents a problem that should be investigated and corrected AS SOON AS POSSIBLE. Repairing the cause of an ACTIVE code will cause the code to be cleared from the ACTIVE Diagnostic Code screen.When an ACTIVE code is generated, the PEEC III lamp will turn ON and remain ON, blinking every five seconds. If the condition generating the fault occurs only for a brief moment, the lamp will go OFF after five seconds and the fault will be LOGGED. After a problem has been investigated and corrected, the related diagnostic code should be cleared from memory.ACTIVE codes may be viewed using either of the electronic service tools (ECAP or DDT), and may also be viewed using the diagnostic lamp and cruise control switches. The diagnostic lamp should not be confused with the warning lamp which is used with PEEC III engine protection.Using The ECAP Or DDT To Display ACTIVE Codes

A. With key OFF, install an ECAP or DDT into the PEEC III system.B. Turn key ON (engine does not need to be started to view codes).C. Refer to the Operating Manual and Special Instructions for the service tool (listed under PEEC III Service Tools) to read the code(s). On the ECAP, the display menu will direct you to the proper screen to display diagnostic messages similar to the example below.Using The Cruise Control Switches To Display ACTIVE Codes:

A. Turn key ON (engine does not need to be started to view codes).B. The PEEC III Diagnostic Lamp will turn ON for five seconds, blink OFF for 1/10 second, turn ON again for five seconds, then OFF for five seconds. At the end of that time, the lamp will begin to flash the first number of the two-digit code (count the flashes). After two seconds OFF, then it will flash the second digit. If two or more codes are present, they will follow the first after a few seconds and be displayed in the same manner.C. Active Diagnostic codes may be displayed at any time by using cruise control switches. With key ON or engine running, turn the cruise control ON/OFF switch to OFF, and move the SET/RESUME switch to RESUME position. Once the codes begin to flash the switch may be released. The PEEC III Diagnostic Lamp will flash out all the codes that are currently active, or intermittent codes that have occurred since the key was turned on. LOGGED Diagnostic Codes

When an ECM generates a diagnostic code, it usually logs the code in permanent memory within the ECM. The time the code occurred (in hours on the internal diagnostic clock) is logged along with the code. The logged codes can then be later retrieved or erased using an ECAP or DDT service

Diagnostic codes are used by the PEEC III system to warn the vehicle operator of a problem and indicate to the service technician the nature of the problem. Some codes are used only to record an event, and do not indicate problems.An ACTIVE Diagnostic code represents a problem that should be investigated and corrected AS SOON AS POSSIBLE. Repairing the cause of an ACTIVE code will cause the code to be cleared from the ACTIVE Diagnostic Code screen.When an ACTIVE code is generated, the PEEC III lamp will turn ON and remain ON, blinking every five seconds. If the condition generating the fault occurs only for a brief moment, the lamp will go OFF after five seconds and the fault will be LOGGED. After a problem has been investigated and corrected, the related diagnostic code should be cleared from memory.ACTIVE codes may be viewed using either of the electronic service tools (ECAP or DDT), and may also be viewed using the diagnostic lamp and cruise control switches. The diagnostic lamp should not be confused with the warning lamp which is used with PEEC III engine protection.Using The ECAP Or DDT To Display ACTIVE Codes

A. With key OFF, install an ECAP or DDT into the PEEC III system.B. Turn key ON (engine does not need to be started to view codes).C. Refer to the Operating Manual and Special Instructions for the service tool (listed under PEEC III Service Tools) to read the code(s). On the ECAP, the display menu will direct you to the proper screen to display diagnostic messages similar to the example below.Using The Cruise Control Switches To Display ACTIVE Codes:

A. Turn key ON (engine does not need to be started to view codes).B. The PEEC III Diagnostic Lamp will turn ON for five seconds, blink OFF for 1/10 second, turn ON again for five seconds, then OFF for five seconds. At the end of that time, the lamp will begin to flash the first number of the two-digit code (count the flashes). After two seconds OFF, then it will flash the second digit. If two or more codes are present, they will follow the first after a few seconds and be displayed in the same manner.C. Active Diagnostic codes may be displayed at any time by using cruise control switches. With key ON or engine running, turn the cruise control ON/OFF switch to OFF, and move the SET/RESUME switch to RESUME position. Once the codes begin to flash the switch may be released. The PEEC III Diagnostic Lamp will flash out all the codes that are currently active, or intermittent codes that have occurred since the key was turned on. LOGGED Diagnostic Codes

When an ECM generates a diagnostic code, it usually logs the code in permanent memory within the ECM. The time the code occurred (in hours on the internal diagnostic clock) is logged along with the code. The logged codes can then be later retrieved or erased using an ECAP or DDT service