Information injection-pump assembly

ZEXEL

104748-1641

1047481641

ISUZU

8941698033

8941698033

Rating:

Components :

| 0. | INJECTION-PUMP ASSEMBLY | 104748-1641 |

| 1. | _ | |

| 2. | FUEL INJECTION PUMP | |

| 3. | NUMBER PLATE | |

| 4. | _ | |

| 5. | CAPSULE | |

| 6. | ADJUSTING DEVICE | |

| 7. | NOZZLE AND HOLDER ASSY | |

| 8. | Nozzle and Holder | |

| 9. | Open Pre:MPa(Kqf/cm2) | |

| 10. | NOZZLE-HOLDER | 105088-1051 |

| 11. | NOZZLE |

Include in #2:

104748-1641

as INJECTION-PUMP ASSEMBLY

Cross reference number

ZEXEL

104748-1641

1047481641

ISUZU

8941698033

8941698033

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113orSAEJ967d

1404 Test oil ISO4113orSAEJ967d

Test oil temperature

degC

45

45

50

Nozzle

105000-2010

Bosch type code

NP-DN12SD12TT

Nozzle holder

105780-2080

Opening pressure

MPa

14.7

14.7

15.19

Opening pressure

kgf/cm2

150

150

155

Injection pipe

Inside diameter - outside diameter - length (mm) mm 2-6-840

Inside diameter - outside diameter - length (mm) mm 2-6-840

Transfer pump pressure

kPa

20

20

20

Transfer pump pressure

kgf/cm2

0.2

0.2

0.2

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Pump speed

r/min

1250

1250

1250

Average injection quantity

mm3/st.

30.2

29.7

30.7

Difference in delivery

mm3/st.

2.5

Basic

*

Injection timing adjustment_02

Pump speed

r/min

2965

2965

2965

Average injection quantity

mm3/st.

11.1

7.6

14.6

Injection timing adjustment_03

Pump speed

r/min

2700

2700

2700

Average injection quantity

mm3/st.

24.6

21.1

28.1

Injection timing adjustment_04

Pump speed

r/min

2600

2600

2600

Average injection quantity

mm3/st.

26.8

24.7

28.9

Injection timing adjustment_05

Pump speed

r/min

2500

2500

2500

Average injection quantity

mm3/st.

26.8

24.8

28.8

Injection timing adjustment_06

Pump speed

r/min

2000

2000

2000

Average injection quantity

mm3/st.

28.6

26.6

30.6

Injection timing adjustment_07

Pump speed

r/min

1250

1250

1250

Average injection quantity

mm3/st.

30.2

29.2

31.2

Injection timing adjustment_08

Pump speed

r/min

600

600

600

Average injection quantity

mm3/st.

28.8

26.8

30.8

Injection quantity adjustment

Pump speed

r/min

2965

2965

2965

Average injection quantity

mm3/st.

11.1

8.1

14.1

Difference in delivery

mm3/st.

3.5

Basic

*

Injection quantity adjustment_02

Pump speed

r/min

2900

2900

2900

Average injection quantity

mm3/st.

3.5

Remarks

Insert a 4.5+-0.1 mm shim between the C/L and the full speed position and measure injection quantity.

Insert a 4.5+-0.1 mm shim between the C/L and the full speed position and measure injection quantity.

Governor adjustment

Pump speed

r/min

375

375

375

Average injection quantity

mm3/st.

6

4

8

Difference in delivery

mm3/st.

2

Basic

*

Governor adjustment_02

Pump speed

r/min

375

375

375

Average injection quantity

mm3/st.

6

4

8

Governor adjustment_03

Pump speed

r/min

450

450

450

Average injection quantity

mm3/st.

2

Timer adjustment

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

60

50

70

Basic

*

Speed control lever angle

Pump speed

r/min

375

375

375

Average injection quantity

mm3/st.

0

0

0

Remarks

Magnet OFF

Magnet OFF

0000000901

Pump speed

r/min

1250

1250

1250

Overflow quantity

cm3/min

370

240

500

Stop lever angle

Pump speed

r/min

1250

1250

1250

Pressure

kPa

362.5

343

382

Pressure

kgf/cm2

3.7

3.5

3.9

Basic

*

Stop lever angle_02

Pump speed

r/min

500

500

500

Pressure

kPa

186.5

157

216

Pressure

kgf/cm2

1.9

1.6

2.2

Stop lever angle_03

Pump speed

r/min

1250

1250

1250

Pressure

kPa

362.5

343

382

Pressure

kgf/cm2

3.7

3.5

3.9

Stop lever angle_04

Pump speed

r/min

2000

2000

2000

Pressure

kPa

539.5

510

569

Pressure

kgf/cm2

5.5

5.2

5.8

Stop lever angle_05

Pump speed

r/min

2300

2300

2300

Pressure

kPa

617.5

588

647

Pressure

kgf/cm2

6.3

6

6.6

0000001101

Pump speed

r/min

1250

1250

1250

Timer stroke

mm

3.1

2.9

3.3

Basic

*

_02

Pump speed

r/min

1250

1250

1250

Timer stroke

mm

3.1

2.8

3.4

_03

Pump speed

r/min

2000

2000

2000

Timer stroke

mm

6.1

5.5

6.7

_04

Pump speed

r/min

2300

2300

2300

Timer stroke

mm

7.4

7

7.8

0000001201

Max. applied voltage

V

8

8

8

Test voltage

V

13

12

14

0000001401

Pump speed

r/min

1250

1250

1250

Average injection quantity

mm3/st.

18.1

17.6

18.6

Timer stroke variation dT

mm

0.8

0.6

1

Basic

*

_02

Pump speed

r/min

1250

1250

1250

Average injection quantity

mm3/st.

18.1

17.1

19.1

Timer stroke variation dT

mm

0.8

0.5

1.1

_03

Pump speed

r/min

1250

1250

1250

Average injection quantity

mm3/st.

7

5.5

8.5

Timer stroke variation dT

mm

2.2

1.7

2.7

Timing setting

K dimension

mm

3.3

3.2

3.4

KF dimension

mm

5.8

5.7

5.9

MS dimension

mm

1.6

1.5

1.7

Control lever angle alpha

deg.

20

16

24

Control lever angle beta

deg.

45

40

50

Test data Ex:

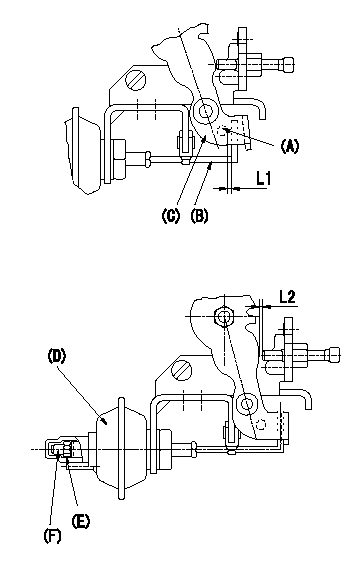

0000001801 V-FICD ADJUSTMENT

Adjustment of the V-FICD (perform with W-FICD released)

1. Adjust to obtain L1.

2. Set at L2 when negative pressure P1 is applied to the actuator.

Adjust the stroke using the actuator stroke adjusting screw (F).

(A) Pin

(B) Actuator shaft

(C) Control lever

(D) Actuator

(E) Lock nut (Torque T)

----------

L1=1+1mm L2=1.6+-0.1mm P1=-46.7kPa(-350mmHg) T=1.2~1.5N-m(0.12~0.15kgf-m)

----------

L1=1+1mm L2=1.6+-0.1mm

----------

L1=1+1mm L2=1.6+-0.1mm P1=-46.7kPa(-350mmHg) T=1.2~1.5N-m(0.12~0.15kgf-m)

----------

L1=1+1mm L2=1.6+-0.1mm

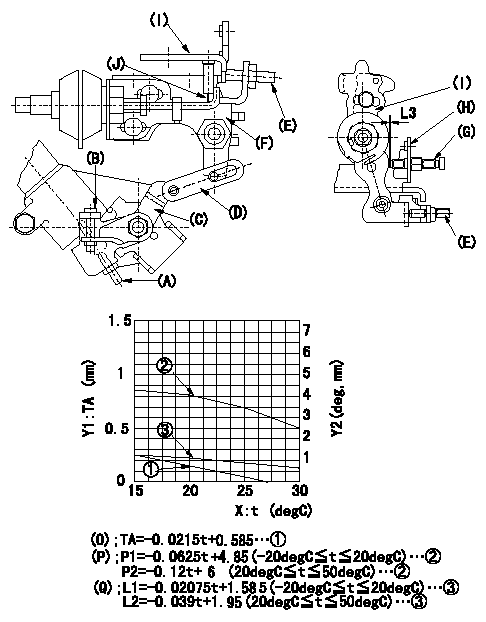

0000001901 W-CSD ADJUSTMENT

Adjustment of the W-CSD

1. Adjustment of the timer stroke

Adjust screw (A) so that the timer stroke is the value determined from the graph.

2. Adjustment of the position of the intermediate lever.

Insert a shim L3 between the control lever (I) and the idle screw (G).

Align the intermediate lever (F) with the aligning mark (J) and then fix the intermediate lever adjusting screw (E) so that (E) contacts the shim between (E) and (I).

3. Adjustment of the FICD

Insert a shim L4 between the control lever (I) and the idle set screw (G).

Use adjusting screw (B) to fix the CSD lever (C) in the position where it operates the intermediate lever (F) via the rod (D). [(U), (V)]

(O) Timer stroke adjustment (mm)

(P): lever angle (deg)

(Q): lever angle (deg)

The (Q) indicates the clearance between the control lever and the idle set screw.

X:Temperature t (deg C)

Y1:Timer stroke TA (mm)

Y2:Control lever position at theta L (deg, mm)

----------

L3=1.2+-0.05mm L4=L3+-0.05mm

----------

L3=1.2+-0.05mm

----------

L3=1.2+-0.05mm L4=L3+-0.05mm

----------

L3=1.2+-0.05mm

Information:

The diagnostic lamp, on the truck dashboard, can be used to communicate status or operation problems of the electronic control system.Trucks With Cruise

The dash mounted cruise switches are used to interrogate the ECM for system status. With the cruise switch in the "off" position, hold the set/resume switch in the resume position until "check engine" light begins to flash. The sequence of flashes represents the system diagnostic message. The first sequence of flashes adds up to the first digit of the fault code. After a one second pause, a second sequence of flashes will occur which represents the second digit of the fault code. Any additional fault codes will follow, after a pause, and will be displayed in the same manner.Trucks Without Cruise

If cruise control switches are not installed or if their configuration (such as a GM type switch) does not permit their usage for checking diagnostic codes, then a push button momentary ON switch should be installed between Pin 3 of the vehicle connector P7 and engine ground.Faults With Throttle Response

The vehicle should be driven to a dealer for service ONLY if the engine oil pressure gauge indicates normal engine oil pressure and engine fuel pressure is within the normal range.Faults Without Throttle Response

If the check engine light is on and the engine does not respond to changes in throttle position, the vehicle should be driven to a dealer ONLY if the oil pressure gauge indicates normal engine oil pressure and engine fuel pressure is within the normal range.If equipped, turn on the cruise on/off switch and operate the vehicle using the set/resume cruise control switch to raise and lower the engine rpm.The cruise control mode is operational from 0 km/h (mph) up to the vehicle speed limit (VSL) when the 3406B (PEEC III) control unit does not respond to changes in throttle position. Maximum engine rpm will be the programmed engine rpm at the vehicle speed limit (VSL). Cruise control must be reselected after each gear change.

The dash mounted cruise switches are used to interrogate the ECM for system status. With the cruise switch in the "off" position, hold the set/resume switch in the resume position until "check engine" light begins to flash. The sequence of flashes represents the system diagnostic message. The first sequence of flashes adds up to the first digit of the fault code. After a one second pause, a second sequence of flashes will occur which represents the second digit of the fault code. Any additional fault codes will follow, after a pause, and will be displayed in the same manner.Trucks Without Cruise

If cruise control switches are not installed or if their configuration (such as a GM type switch) does not permit their usage for checking diagnostic codes, then a push button momentary ON switch should be installed between Pin 3 of the vehicle connector P7 and engine ground.Faults With Throttle Response

The vehicle should be driven to a dealer for service ONLY if the engine oil pressure gauge indicates normal engine oil pressure and engine fuel pressure is within the normal range.Faults Without Throttle Response

If the check engine light is on and the engine does not respond to changes in throttle position, the vehicle should be driven to a dealer ONLY if the oil pressure gauge indicates normal engine oil pressure and engine fuel pressure is within the normal range.If equipped, turn on the cruise on/off switch and operate the vehicle using the set/resume cruise control switch to raise and lower the engine rpm.The cruise control mode is operational from 0 km/h (mph) up to the vehicle speed limit (VSL) when the 3406B (PEEC III) control unit does not respond to changes in throttle position. Maximum engine rpm will be the programmed engine rpm at the vehicle speed limit (VSL). Cruise control must be reselected after each gear change.