Information injection-pump assembly

ZEXEL

104748-1640

1047481640

ISUZU

8941698032

8941698032

Rating:

Cross reference number

ZEXEL

104748-1640

1047481640

ISUZU

8941698032

8941698032

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113orSAEJ967d

1404 Test oil ISO4113orSAEJ967d

Test oil temperature

degC

45

45

50

Nozzle

105000-2010

Bosch type code

NP-DN12SD12TT

Nozzle holder

105780-2080

Opening pressure

MPa

14.7

14.7

15.19

Opening pressure

kgf/cm2

150

150

155

Injection pipe

Inside diameter - outside diameter - length (mm) mm 2-6-840

Inside diameter - outside diameter - length (mm) mm 2-6-840

Transfer pump pressure

kPa

20

20

20

Transfer pump pressure

kgf/cm2

0.2

0.2

0.2

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Pump speed

r/min

1250

1250

1250

Average injection quantity

mm3/st.

30

29.5

30.5

Difference in delivery

mm3/st.

2.5

Basic

*

Oil temperature

degC

50

48

52

Injection timing adjustment_02

Pump speed

r/min

600

600

600

Average injection quantity

mm3/st.

28.8

27.3

30.3

Oil temperature

degC

50

48

52

Injection timing adjustment_03

Pump speed

r/min

1250

1250

1250

Average injection quantity

mm3/st.

30

29

31

Difference in delivery

mm3/st.

2.5

Basic

*

Oil temperature

degC

50

48

52

Injection timing adjustment_04

Pump speed

r/min

2500

2500

2500

Average injection quantity

mm3/st.

26.6

25.1

28.1

Oil temperature

degC

55

52

58

Injection timing adjustment_05

Pump speed

r/min

2600

2600

2600

Average injection quantity

mm3/st.

27

25.4

28.6

Difference in delivery

mm3/st.

3.5

Oil temperature

degC

55

52

58

Injection timing adjustment_06

Pump speed

r/min

2700

2700

2700

Average injection quantity

mm3/st.

23

20

26

Oil temperature

degC

55

52

58

Injection quantity adjustment

Pump speed

r/min

2965

2965

2965

Average injection quantity

mm3/st.

11

8

14

Difference in delivery

mm3/st.

3.5

Basic

*

Oil temperature

degC

55

52

58

Injection quantity adjustment_02

Pump speed

r/min

2965

2965

2965

Average injection quantity

mm3/st.

11

8

14

Difference in delivery

mm3/st.

3.5

Oil temperature

degC

55

52

58

Governor adjustment

Pump speed

r/min

375

375

375

Average injection quantity

mm3/st.

6

4

8

Difference in delivery

mm3/st.

2

Basic

*

Oil temperature

degC

48

46

50

Governor adjustment_02

Pump speed

r/min

375

375

375

Average injection quantity

mm3/st.

6

4

8

Difference in delivery

mm3/st.

2

Oil temperature

degC

48

46

50

Timer adjustment

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

50

50

Basic

*

Oil temperature

degC

48

46

50

Remarks

Full

Full

Timer adjustment_02

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

50

50

Oil temperature

degC

48

46

50

Speed control lever angle

Pump speed

r/min

375

375

375

Average injection quantity

mm3/st.

0

0

0

Oil temperature

degC

48

46

50

Remarks

Magnet OFF at idling position

Magnet OFF at idling position

0000000901

Pump speed

r/min

1250

1250

1250

Overflow quantity

cm3/min

370

240

500

Oil temperature

degC

50

48

52

Stop lever angle

Pump speed

r/min

1250

1250

1250

Pressure

kPa

363

343

383

Pressure

kgf/cm2

3.7

3.5

3.9

Basic

*

Oil temperature

degC

50

48

52

Stop lever angle_02

Pump speed

r/min

1250

1250

1250

Pressure

kPa

363

343

383

Pressure

kgf/cm2

3.7

3.5

3.9

Basic

*

Oil temperature

degC

50

48

52

Stop lever angle_03

Pump speed

r/min

2000

2000

2000

Pressure

kPa

539

510

568

Pressure

kgf/cm2

5.5

5.2

5.8

Oil temperature

degC

50

48

52

Stop lever angle_04

Pump speed

r/min

2300

2300

2300

Pressure

kPa

637

608

666

Pressure

kgf/cm2

6.5

6.2

6.8

Oil temperature

degC

52

50

54

0000001101

Pump speed

r/min

1250

1250

1250

Timer stroke

mm

3.1

2.9

3.3

Basic

*

Oil temperature

degC

50

48

52

_02

Pump speed

r/min

620

520

720

Timer stroke

mm

0.5

0.5

0.5

Oil temperature

degC

50

48

52

_03

Pump speed

r/min

1250

1250

1250

Timer stroke

mm

3.1

2.9

3.3

Basic

*

Oil temperature

degC

50

48

52

_04

Pump speed

r/min

2000

2000

2000

Timer stroke

mm

6.1

5.7

6.5

Oil temperature

degC

50

48

52

_05

Pump speed

r/min

2300

2300

2300

Timer stroke

mm

7.4

7.1

7.8

Oil temperature

degC

52

50

54

0000001201

Max. applied voltage

V

8

8

8

Test voltage

V

13

12

14

0000001401

Pump speed

r/min

1250

1250

1250

Average injection quantity

mm3/st.

18

17.8

18.2

Timer stroke TA

mm

2.3

2.3

2.3

Timer stroke variation dT

mm

0.8

0.7

0.9

Basic

*

Oil temperature

degC

50

48

52

_02

Pump speed

r/min

1250

1250

1250

Average injection quantity

mm3/st.

18

17

19

Timer stroke variation dT

mm

0.8

0.4

1.2

Basic

*

Oil temperature

degC

50

48

52

_03

Pump speed

r/min

1250

1250

1250

Average injection quantity

mm3/st.

9

8

10

Timer stroke variation dT

mm

2.2

2.2

2.2

Oil temperature

degC

50

48

52

Timing setting

K dimension

mm

3.3

3.2

3.4

KF dimension

mm

5.8

5.7

5.9

MS dimension

mm

1.6

1.5

1.7

Control lever angle alpha

deg.

20

16

24

Control lever angle beta

deg.

45

40

50

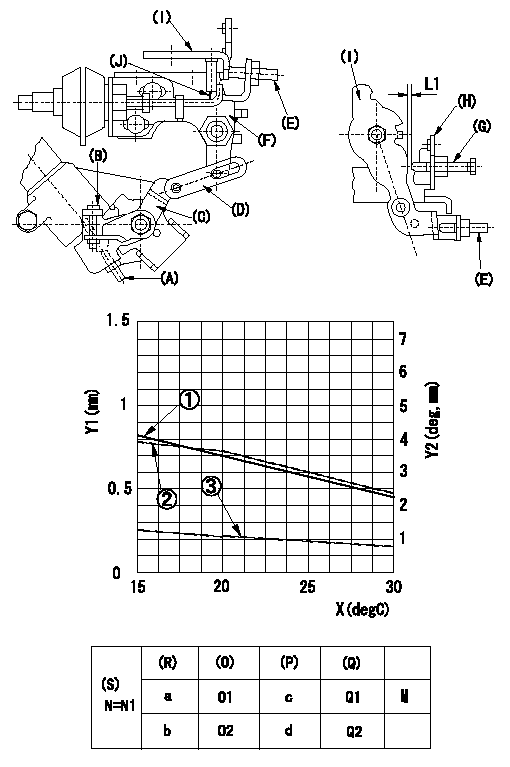

Test data Ex:

0000001801 W-CSD ADJUSTMENT

Adjustment of the W-CSD

1. Adjustment of the timer stroke

Adjust screw (A) so that the timer stroke is the value determined from the graph.

Timer stroke (mm), (1) TA=-0.0235t+1.17

Lever position (deg) (2) theta = -0.0625t+4.85 (-20 <= t <= 20)

Theta 2 = -0.12t + 6 (20 deg C <= t <= 50 deg C)

Lever position (mm) (3) L1 = -0.02075t+1.585 (-20 <= t <= 20)

L2=-0.039t+1.95 (20<=t<=50)

(3 shows the gap between the control lever and the idle set screw.)

2. Adjustment of the position of the intermediate lever.

Insert a shim L1 between the control lever (I) and the idle set screw (G).

Align the intermediate lever (F) with the aligning line (J) and fix screw (E) so that it contacts the control lever.

3. Adjustment of the FICD

Insert a shim L2 between the control lever (I) and the idle set screw (G).

Use adjusting screw (B) to fix the CSD lever (C) in the position where it operates the intermediate lever via the rod (D).

X:Temperature t (deg C)

Y1:Timer stroke (mm)

Y2:Control lever position (deg)

(S) Cold advancer: cooling water temperature: increase direction

M:Standard point

N:Pump speed

(R) Cooling water temperature

(O) Timer piston stroke

(P) Lever position (deg)

(Q) lever position (mm)

----------

L1=1.2+-0.05mm L2=L1+-0.05mm

----------

L1=1.2+-0.05mm N1=100r/min a=20degC b=-20degC O1=0.7+-0.4mm O2=1.6+-0.6mm c=3.6+-1deg d=6.1+-3deg Q1=1.2+-0.3mm Q2=2+-1mm

----------

L1=1.2+-0.05mm L2=L1+-0.05mm

----------

L1=1.2+-0.05mm N1=100r/min a=20degC b=-20degC O1=0.7+-0.4mm O2=1.6+-0.6mm c=3.6+-1deg d=6.1+-3deg Q1=1.2+-0.3mm Q2=2+-1mm

Information:

1. Disconnect plug P14 from receptacle J14. The locking ring helps identify P14 from J14. Check the connections for damaged wires or pins and corrosion. Also check that the pins are at the proper height in the connector. Check that the wires and pins are tight in the connectors by pulling (slightly) on each wire of each connector (including the breakout "T").2. Install 8T8694 Adapter (five pin breakout "T") between J14 and P14. Twist the locking rings to secure the connections.3. Connect the voltmeter as shown. Check for the appropriate voltages between the lettered "T" pins as explained in Steps 4 through 7.4. Pin A (+) to pin B (ground) system voltage should be approximately 12 volts DC with key on (no accessories). Minimum voltage is 11.0 volts DC. Diagnosis - Using the truck wiring schematic, check wires A and B and connections from J14 through the truck wiring harness back to the battery for proper voltage.5. If the voltage check between pins A and B is less than 11.0 volts with the key on, check the voltage drop from pin B to the negative battery post while cranking. For this test, the common lead (black) should be connected to the negative battery post first. Then place the positive (red) lead into pin B. (Pin B is chassis ground.) Voltage should be less than .5 volts DC when cranking. Diagnosis - If the voltage drop is greater than .5 volts DC, check wire B and connections (including the battery post connections) from J14 to battery negative. Follow the truck wiring schematic to trace the electrical path from J14 Pin B to chassis ground.6. Check buffer operation. Step 6 checks the proper functioning of the truck wiring, vehicle speed sensor and vehicle speed buffer. If proper vehicle speed is present on the appropriate status screens of the 3406B (PEEC III) (7X6400) DDT or the (8T8697) ECAP service tools during road test then Step 6 is not necessary.A. Check wires and connectors for damage or corrosion from the magnetic pickup to vehicle speed buffer.B. Remove magnetic pickup (vehicle speed sensor) from transmission. If pickup has collected significant metal debris, wipe it clean. Check the magnetic pickup per the manufactures specifications. Install a properly functioning magnetic pickup to the proper depth and reconnect to the vehicle speed buffer. Check for proper system operation. The problem may reappear if transmission fluid is contaminated. Change transmission fluid if necessary.C.1. Disconnect the magnetic pickup from the vehicle speed buffer.C.2. Jumper the white vehicle speed buffer wire (input from magnetic pickup) to J14 Pin A (+ battery) at the breakout "T".* Voltage from pins D to B of breakout "T" is less than 1.0 volt DC with key on and engine off.* Voltage from pins C to B is -8.0 to -10.0 volts DC with key on.* Voltage from pins E to B is +8.0 to +10.0 volts DC with key on.C.3. Move the white input wire (jumper) to J14 Pin B (- battery)