Information injection-pump assembly

ZEXEL

104748-1310

1047481310

ISUZU

8942429600

8942429600

Rating:

Cross reference number

ZEXEL

104748-1310

1047481310

ISUZU

8942429600

8942429600

Zexel num

Bosch num

Firm num

Name

104748-1310

8942429600 ISUZU

INJECTION-PUMP ASSEMBLY

4FB1 * K

4FB1 * K

Calibration Data:

Adjustment conditions

(Note)

For Japan: year/month/day (change sequence) 1983/07/01 (1)

For Japan: year/month/day (change sequence) 1983/07/01 (1)

Test oil

1404 Test oil ISO4113orSAEJ967d

1404 Test oil ISO4113orSAEJ967d

Test oil temperature

degC

45

45

50

Nozzle

105000-2010

Bosch type code

NP-DN12SD12TT

Nozzle holder

105780-2080

Opening pressure

MPa

14.7

14.7

15.19

Opening pressure

kgf/cm2

150

150

155

Injection pipe

Inside diameter - outside diameter - length (mm) mm 2-6-840

Inside diameter - outside diameter - length (mm) mm 2-6-840

Transfer pump pressure

kPa

20

20

20

Transfer pump pressure

kgf/cm2

0.2

0.2

0.2

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Pump speed

r/min

1250

1250

1250

Average injection quantity

mm3/st.

31.2

30.7

31.7

Difference in delivery

mm3/st.

2.5

Basic

*

Injection timing adjustment_02

Pump speed

r/min

2750

2750

2750

Average injection quantity

mm3/st.

16

13

19

Injection timing adjustment_03

Pump speed

r/min

2500

2500

2500

Average injection quantity

mm3/st.

30.6

29.6

31.6

Injection timing adjustment_04

Pump speed

r/min

1250

1250

1250

Average injection quantity

mm3/st.

31.2

30.2

32.2

Injection timing adjustment_05

Pump speed

r/min

600

600

600

Average injection quantity

mm3/st.

27.5

25.5

29.5

Injection timing adjustment_06

Pump speed

r/min

1250

1250

1250

Average injection quantity

mm3/st.

30.4

29.9

30.9

Difference in delivery

mm3/st.

2.5

Basic

*

Remarks

For Japan

For Japan

Injection timing adjustment_07

Pump speed

r/min

2750

2750

2750

Average injection quantity

mm3/st.

15.6

12.6

18.6

Remarks

For Japan

For Japan

Injection timing adjustment_08

Pump speed

r/min

2500

2500

2500

Average injection quantity

mm3/st.

29.8

27.8

31.8

Remarks

For Japan

For Japan

Injection timing adjustment_09

Pump speed

r/min

1250

1250

1250

Average injection quantity

mm3/st.

30.4

29.4

31.4

Remarks

For Japan

For Japan

Injection timing adjustment_10

Pump speed

r/min

600

600

600

Average injection quantity

mm3/st.

26.8

24.8

28.8

Remarks

For Japan

For Japan

Injection quantity adjustment

Pump speed

r/min

2750

2750

2750

Average injection quantity

mm3/st.

16

13

19

Basic

*

Injection quantity adjustment_02

Pump speed

r/min

3050

3050

3050

Average injection quantity

mm3/st.

4.1

Injection quantity adjustment_03

Pump speed

r/min

2750

2750

2750

Average injection quantity

mm3/st.

15.6

12.6

18.6

Basic

*

Remarks

For Japan

For Japan

Injection quantity adjustment_04

Pump speed

r/min

3050

3050

3050

Average injection quantity

mm3/st.

4

Remarks

For Japan

For Japan

Governor adjustment

Pump speed

r/min

365

365

365

Average injection quantity

mm3/st.

7.7

5.7

9.7

Difference in delivery

mm3/st.

2

Basic

*

Governor adjustment_02

Pump speed

r/min

365

365

365

Average injection quantity

mm3/st.

7.7

5.7

9.7

Governor adjustment_03

Pump speed

r/min

500

500

500

Average injection quantity

mm3/st.

0

0

0

Governor adjustment_04

Pump speed

r/min

365

365

365

Average injection quantity

mm3/st.

7.5

5.5

9.5

Difference in delivery

mm3/st.

2

Basic

*

Remarks

For Japan

For Japan

Governor adjustment_05

Pump speed

r/min

365

365

365

Average injection quantity

mm3/st.

7.5

5.5

9.5

Remarks

For Japan

For Japan

Governor adjustment_06

Pump speed

r/min

500

500

500

Average injection quantity

mm3/st.

0

0

0

Remarks

For Japan

For Japan

Timer adjustment

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

41

41

Basic

*

Timer adjustment_02

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

40

40

Basic

*

Remarks

For Japan

For Japan

Speed control lever angle

Pump speed

r/min

365

365

365

Average injection quantity

mm3/st.

0

0

0

Remarks

Magnet OFF

Magnet OFF

Speed control lever angle_02

Pump speed

r/min

365

365

365

Average injection quantity

mm3/st.

0

0

0

Remarks

For Japan: Magnet OFF

For Japan: Magnet OFF

0000000901

Pump speed

r/min

1400

1400

1400

Overflow quantity

cm3/min

456

324

588

_02

Pump speed

r/min

1400

1400

1400

Overflow quantity

cm3/min

480

348

612

Remarks

For Japan

For Japan

Stop lever angle

Pump speed

r/min

1400

1400

1400

Pressure

kPa

490.5

471

510

Pressure

kgf/cm2

5

4.8

5.2

Basic

*

Stop lever angle_02

Pump speed

r/min

1000

1000

1000

Pressure

kPa

382.5

353

412

Pressure

kgf/cm2

3.9

3.6

4.2

Stop lever angle_03

Pump speed

r/min

1400

1400

1400

Pressure

kPa

490.5

471

510

Pressure

kgf/cm2

5

4.8

5.2

Stop lever angle_04

Pump speed

r/min

2500

2500

2500

Pressure

kPa

764.5

735

794

Pressure

kgf/cm2

7.8

7.5

8.1

Stop lever angle_05

Pump speed

r/min

1400

1400

1400

Pressure

kPa

480.5

461

500

Pressure

kgf/cm2

4.9

4.7

5.1

Basic

*

Remarks

For Japan

For Japan

Stop lever angle_06

Pump speed

r/min

1000

1000

1000

Pressure

kPa

372.5

343

402

Pressure

kgf/cm2

3.8

3.5

4.1

Remarks

For Japan

For Japan

Stop lever angle_07

Pump speed

r/min

1400

1400

1400

Pressure

kPa

480.5

461

500

Pressure

kgf/cm2

4.9

4.7

5.1

Remarks

For Japan

For Japan

Stop lever angle_08

Pump speed

r/min

2500

2500

2500

Pressure

kPa

755.5

726

785

Pressure

kgf/cm2

7.7

7.4

8

Remarks

For Japan

For Japan

0000001101

Pump speed

r/min

1400

1400

1400

Timer stroke

mm

2.6

2.4

2.8

Basic

*

_02

Pump speed

r/min

1400

1400

1400

Timer stroke

mm

2.6

2.3

2.9

_03

Pump speed

r/min

2000

2000

2000

Timer stroke

mm

5.3

4.7

5.9

_04

Pump speed

r/min

2300

2300

2300

Timer stroke

mm

6.65

6.3

7

_05

Pump speed

r/min

1400

1400

1400

Timer stroke

mm

2.5

2.3

2.7

Basic

*

Remarks

For Japan

For Japan

_06

Pump speed

r/min

1400

1400

1400

Timer stroke

mm

2.5

2.2

2.8

Remarks

For Japan

For Japan

_07

Pump speed

r/min

2000

2000

2000

Timer stroke

mm

5.2

4.6

5.8

Remarks

For Japan

For Japan

_08

Pump speed

r/min

2300

2300

2300

Timer stroke

mm

6.55

6.1

7

Remarks

For Japan

For Japan

0000001201

Max. applied voltage

V

8

8

8

Test voltage

V

13

12

14

0000001501

Pump speed

r/min

1250

1250

1250

Atmospheric pressure difference

kPa

-21.9

-22.6

-21.2

Atmospheric pressure difference

mmHg

-164

-169

-159

Decrease qty

mm3/st.

3.1

2.6

3.6

Basic

*

_02

Pump speed

r/min

1250

1250

1250

Atmospheric pressure difference

kPa

-21.9

-22.6

-21.2

Atmospheric pressure difference

mmHg

-164

-169

-159

Decrease qty

mm3/st.

3.1

2.3

3.9

_03

Pump speed

r/min

1250

1250

1250

Atmospheric pressure difference

kPa

-21.9

-22.6

-21.2

Atmospheric pressure difference

mmHg

-164

-169

-159

Decrease qty

mm3/st.

3

2.5

3.5

Basic

*

Remarks

For Japan

For Japan

_04

Pump speed

r/min

1250

1250

1250

Atmospheric pressure difference

kPa

-21.9

-22.6

-21.2

Atmospheric pressure difference

mmHg

-164

-169

-159

Decrease qty

mm3/st.

3

2.2

3.8

Remarks

For Japan

For Japan

Timing setting

K dimension

mm

3.3

3.2

3.4

KF dimension

mm

5.8

5.7

5.9

MS dimension

mm

1.6

1.5

1.7

Control lever angle alpha

deg.

17

13

21

Control lever angle beta

deg.

36

31

41

Test data Ex:

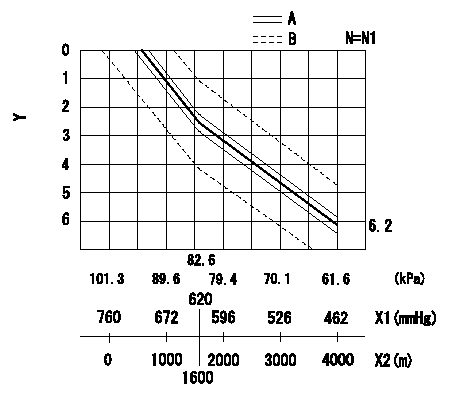

0000001501 ANEROID COMPENSATOR

ACS adjustment

Full load injection quantity at high altitudes and ACS adjusting method

1. Full load injection quantity adjustment

(1)Remove the ACS cover and remove the bellows and adjusting shim.

(2)Perform all adjustments as per the adjustment standard except for ACS adjustment.

2. ACS adjustment

(1)Assemble the ACS cover, bellows and adjusting shim.

(2)At N = N1, adjust using shims so that the decrease amount for altitude is as specified in the graph.

N:Pump speed

X1:Atmospheric pressure

X2:Altitude

Y:Decrease quantity

A:Adjustment value

B:Inspection value

----------

N1=1250r/min

----------

----------

N1=1250r/min

----------

Information:

Fuel Injection Pump

(1) Plug (timing pin hole)2. Remove plug (1) from the fuel injection pump housing.

Timing Pin Installed

(2) 6V4186 Timing Pin3. Install 6V4186 Timing Pin (2) in the fuel injection pump housing as shown. Slowly rotate the crankshaft counterclockwise (as seen from the flywheel end of the engine) until timing pin (2) goes into the slot in the fuel pump camshaft.

Timing Position Sensor Cover

(3) Cover (4) Housing (5) Timing Solenoid (BTM)4. Remove the timing position sensor cover (3) from housing (4).5. Rotate the crankshaft clockwise 15 degrees as seen from the flywheel end of the engine. Observe the motion of the timing advance power piston through housing (4).6. Rotate the crankshaft in the counterclockwise direction as seen from the rear of the engine until the timing advance power piston moves to its fully retracted position and light pressure is applied to the timing pin (2). Do not apply excessive force to rotate the engine with the timing pin installed. Excessive force will shear off the timing pin and/or cause fuel pump damage. Apply only enough force to retract the timing actuator power piston.

Install Timing Bolt

(6) 9S9082 Engine Turning Tool (7) Timing Bolt7. Put timing bolt in the timing hole in the flywheel housing. If the bolt can be installed in the timing hole in the flywheel, the static injection timing of the fuel injection pump is correct.8. If the timing bolt does not go into the timing hole in the flywheel, the timing is not correct. Perform the following steps to adjust the fuel injection pump static timing:

Automatic Timing Advance Unit

(Governor and Fuel Pump Drive Group) (8) BoltsA. Remove timing solenoid (BTM) (5).B. Remove timing advance housing (4).C. Loosen the four bolts (8) on the timing advance. With the timing pin installed in the fuel pump and the timing bolt removed, turn the engine crank shaft clockwise as viewed from the rear of the engine a minimum of 30 degrees. Make sure that the power piston of the timing advance does not move from its fully retracted position.D. Lightly tighten two of the four timing advance bolts to 2.3 N m (21 lb ft). Finger tight only so as not to bend the timing pin.E. Rotate the crankshaft counterclockwise as viewed from the rear of the engine (direction of rotation) slowly until the timing bolt can be installed in the flywheel. The number one piston is now at top dead center.F. Tighten the four timing advance bolts (8) to a torque of 10 N m (7 lb ft). Remove the timing pin from the fuel injection pump.G. Tighten the four timing advance bolts to a torque of 55 7 N m (41 5 lb ft). Remove the timing bolt from the flywheel.H. Turn the crankshaft two complete revolutions counterclockwise as viewed from the rear of the engine to make sure that the timing advance piston is in the fully retracted position. Repeat step 6 and 7 to check the timing again to see if the timing

Have questions with 104748-1310?

Group cross 104748-1310 ZEXEL

Isuzu

104748-1310

8942429600

INJECTION-PUMP ASSEMBLY

4FB1

4FB1