Information injection-pump assembly

BOSCH

9 460 612 571

9460612571

ZEXEL

104748-0420

1047480420

Rating:

Components :

| 0. | INJECTION-PUMP ASSEMBLY | 104748-0420 |

| 1. | _ | |

| 2. | FUEL INJECTION PUMP | 104648-0223 |

| 3. | NUMBER PLATE | 146960-7300 |

| 4. | _ | |

| 5. | CAPSULE | |

| 6. | ADJUSTING DEVICE | |

| 7. | NOZZLE AND HOLDER ASSY | 105141-2240 |

| 8. | Nozzle and Holder | |

| 9. | Open Pre:MPa(Kqf/cm2) | 13.2{135} |

| 10. | NOZZLE-HOLDER | 105071-1530 |

| 11. | NOZZLE | 105000-1740 |

Scheme ###:

| 1/6. | [1] | 146601-0700 | PACKING RING |

| 6. | [1] | 146100-0120 | SUPPLY PUMP |

| 9. | [1] | 146103-0000 | COVER |

| 10. | [2] | 139104-0000 | FLAT-HEAD SCREW |

| 12. | [1] | 146200-0320 | DRIVE SHAFT |

| 12/1. | [1] | 146200-0300 | DRIVE SHAFT |

| 12/2. | [1] | 146201-0000 | WOODRUFF KEY |

| 12/3. | [2] | 146202-0100 | DAMPER |

| 12/4. | [1] | 146203-0000 | TOOTHED GEAR |

| 17. | [1] | 146204-0000 | PLAIN WASHER |

| 20. | [1] | 146210-3920 | ROLLER SET |

| 24. | [1] | 146303-0100 | BEARING PIN |

| 25. | [1] | 146304-0000 | BEARING PIN |

| 26. | [1] | 146305-0000 | CLAMPING BAND |

| 27. | [1] | 146205-0000 | SLOTTED WASHER |

| 29. | [1] | 146220-0220 | CAM PLATE |

| 30. | [1] | 146600-0800 | O-RING |

| 31. | [1] | 146300-2400 | PUMP PLUNGER |

| 32. | [1] | 146301-0200 | SLIDING PIECE |

| 33. | [1] | 146603-0700 | SHIM D17.5&7.5T0.60 |

| 34. | [1] | 146302-3600 | COMPRESSION SPRING |

| 35/1. | [0] | 146603-0700 | SHIM D17.5&7.5T0.60 |

| 35/1. | [0] | 146603-0800 | SHIM D17.5&7.5T0.70 |

| 35/1. | [0] | 146603-0900 | SHIM D17.5&7.5T0.90 |

| 35/1. | [0] | 146603-1000 | SHIM D17.5&7.5T1.00 |

| 35/1. | [0] | 146603-1100 | SHIM D17.5&7.5T1.20 |

| 35/1. | [0] | 146603-3600 | SHIM D17.5&7.5T2.40 |

| 36. | [1] | 146600-0800 | O-RING |

| 37. | [1] | 146310-0700 | COVER |

| 38. | [2] | 146620-5000 | BLEEDER SCREW |

| 39. | [1] | 146310-0100 | COVER |

| 40. | [2] | 146620-5000 | BLEEDER SCREW |

| 43. | [1] | 146230-0000 | SHIM |

| 44. | [1] | 146230-0100 | PLAIN WASHER |

| 45. | [1] | 146231-0001 | SLOTTED WASHER |

| 47. | [2] | 146233-0000 | SLOTTED WASHER |

| 48/1. | [1] | 146603-0000 | SHIM D17.0&5.2T0.50 |

| 48/1. | [1] | 146603-0100 | SHIM D17.0&5.2T0.80 |

| 48/1. | [1] | 146603-0200 | SHIM D17.0&5.2T1.00 |

| 48/1. | [1] | 146603-0300 | SHIM D17.0&5.2T1.20 |

| 48/1. | [1] | 146603-0400 | SHIM D17.0&5.2T1.50 |

| 48/1. | [1] | 146603-0500 | SHIM D17.0&5.2T1.80 |

| 48/1. | [1] | 146603-0600 | SHIM D17.0&5.2T2.00 |

| 48/1. | [1] | 146690-1400 | SHIM D17&5.2T0.9 |

| 48/1. | [1] | 146690-1500 | SHIM D17&5.2T1.1 |

| 48/1. | [1] | 146690-1600 | SHIM D17&5.2T1.3 |

| 48/1. | [1] | 146690-1700 | SHIM D17&5.2T1.4 |

| 48/1. | [1] | 146690-1800 | SHIM D17&5.2T1.6 |

| 48/1. | [1] | 146690-1900 | SHIM D17&5.2T1.7 |

| 48/1. | [1] | 146690-5800 | SHIM |

| 48/1. | [1] | 146690-5900 | SHIM |

| 48/1. | [1] | 146690-6000 | SHIM D17&5.2T2.3 |

| 48/1. | [1] | 146690-6100 | SHIM D17&5.2T2.4 |

| 48/1. | [1] | 146690-6200 | SHIM D17&5.2T2.5 |

| 48/1. | [1] | 146690-6300 | SHIM D17&5.2T2.6 |

| 48/1. | [1] | 146690-6400 | SHIM |

| 48/1. | [1] | 146690-6500 | SHIM |

| 48/1. | [1] | 146690-6600 | SHIM |

| 48/1. | [1] | 146690-6700 | SHIM D17&5.2T3.0 |

| 48/1. | [1] | 146690-6800 | SHIM D17&5.2T3.1 |

| 48/1. | [1] | 146690-6900 | SHIM D17&5.2T3.2 |

| 48/1. | [1] | 146690-7000 | SHIM D17&5.2T3.3 |

| 48/1. | [1] | 146690-7100 | SHIM |

| 48/1. | [1] | 146690-7200 | SHIM D17&5.2T0.4 |

| 48/1. | [1] | 146690-7300 | SHIM |

| 48/1. | [1] | 146690-7400 | SHIM |

| 48/1. | [1] | 146690-7500 | SHIM |

| 48/1. | [1] | 146690-7800 | SHIM |

| 49. | [2] | 146234-0020 | GUIDE PIN |

| 50. | [1] | 146403-1220 | HYDRAULIC HEAD |

| 50. | [1] | 146403-1220 | HYDRAULIC HEAD |

| 50. | [1] | 146403-1220 | HYDRAULIC HEAD |

| 51. | [1] | 146600-0000 | O-RING |

| 52/1. | [1] | 146420-0000 | SHIM D9.5&3.0T1.90 |

| 52/1. | [1] | 146420-0100 | SHIM D9.5&3.0T1.92 |

| 52/1. | [1] | 146420-0200 | SHIM D9.5&3.0T1.94 |

| 52/1. | [1] | 146420-0300 | SHIM D9.5&3.0T1.96 |

| 52/1. | [1] | 146420-0400 | SHIM D9.5&3.0T1.98 |

| 52/1. | [1] | 146420-0500 | SHIM D9.5&3.0T2.00 |

| 52/1. | [1] | 146420-0600 | SHIM D9.5&3.0T2.02 |

| 52/1. | [1] | 146420-0700 | SHIM D9.5&3.0T2.04 |

| 52/1. | [1] | 146420-0800 | SHIM D9.5&3.0T2.06 |

| 52/1. | [1] | 146420-0900 | SHIM D9.5&3.0T2.08 |

| 52/1. | [1] | 146420-1000 | SHIM D9.5&3.0T2.10 |

| 52/1. | [1] | 146420-1100 | SHIM D9.5&3.0T2.12 |

| 52/1. | [1] | 146420-1200 | SHIM D9.5&3.0T2.14 |

| 52/1. | [1] | 146420-1300 | SHIM D9.5&3.0T2.16 |

| 52/1. | [1] | 146420-1400 | SHIM D9.5&3.0T2.18 |

| 52/1. | [1] | 146420-1500 | SHIM D9.5&3.0T2.20 |

| 52/1. | [1] | 146420-1600 | SHIM D9.5&3.0T2.22 |

| 52/1. | [1] | 146420-1700 | SHIM D9.5&3.0T2.24 |

| 52/1. | [1] | 146420-1800 | SHIM D9.5&3.0T2.26 |

| 52/1. | [1] | 146420-1900 | SHIM D9.5&3.0T2.28 |

| 52/1. | [1] | 146420-2000 | SHIM D9.5&3.0T2.30 |

| 52/1. | [1] | 146420-2100 | SHIM D9.5&3.0T2.32 |

| 52/1. | [1] | 146420-2200 | SHIM D9.5&3.0T2.34 |

| 52/1. | [1] | 146420-2300 | SHIM D9.5&3.0T2.36 |

| 52/1. | [1] | 146420-2400 | SHIM D9.5&3.0T2.38 |

| 52/1. | [1] | 146420-2500 | SHIM D9.5&3.0T2.40 |

| 52/1. | [1] | 146420-2600 | SHIM D9.5&3.0T2.42 |

| 52/1. | [1] | 146420-2700 | SHIM D9.5&3.0T2.44 |

| 52/1. | [1] | 146420-2800 | SHIM D9.5&3.0T2.46 |

| 52/1. | [1] | 146420-2900 | SHIM D9.5&3.0T2.48 |

| 52/1. | [1] | 146420-3000 | SHIM D9.5&3.0T2.50 |

| 52/1. | [1] | 146420-3100 | SHIM D9.5&3.0T2.52 |

| 52/1. | [1] | 146420-3200 | SHIM D9.5&3.0T2.54 |

| 52/1. | [1] | 146420-3300 | SHIM D9.5&3.0T2.56 |

| 52/1. | [1] | 146420-3400 | SHIM D9.5&3.0T2.58 |

| 52/1. | [1] | 146420-3500 | SHIM D9.5&3.0T2.60 |

| 52/1. | [1] | 146420-3600 | SHIM D9.5&3.0T2.62 |

| 52/1. | [1] | 146420-3700 | SHIM D9.5&3.0T2.64 |

| 52/1. | [1] | 146420-3800 | SHIM D9.5&3.0T2.66 |

| 52/1. | [1] | 146420-3900 | SHIM D9.5&3.0T2.68 |

| 52/1. | [1] | 146420-4000 | SHIM D9.5&3.0T2.70 |

| 52/1. | [1] | 146420-4100 | SHIM D9.5&3.0T2.72 |

| 52/1. | [1] | 146420-4200 | SHIM D9.5&3.0T2.74 |

| 52/1. | [1] | 146420-4300 | SHIM D9.5&3.0T2.76 |

| 52/1. | [1] | 146420-4400 | SHIM D9.5&3.0T2.78 |

| 52/1. | [1] | 146420-4500 | SHIM D9.5&3.0T2.80 |

| 52/1. | [1] | 146420-4600 | SHIM D9.5&3.0T2.82 |

| 52/1. | [1] | 146420-4700 | SHIM D9.5&3.0T2.84 |

| 52/1. | [1] | 146420-4800 | SHIM D9.5&3.0T2.86 |

| 52/1. | [1] | 146420-4900 | SHIM D9.5&3.0T2.88 |

| 52/1. | [1] | 146420-5000 | SHIM D9.5&3.0T2.90 |

| 52/1. | [1] | 146420-5100 | SHIM D9.5&3.0T1.74 |

| 52/1. | [1] | 146420-5200 | SHIM D9.5&3.0T1.76 |

| 52/1. | [1] | 146420-5300 | SHIM D9.5&3.0T1.78 |

| 52/1. | [1] | 146420-5400 | SHIM D9.5&3.0T1.80 |

| 52/1. | [1] | 146420-5500 | SHIM D9.5&3.0T1.82 |

| 52/1. | [1] | 146420-5600 | SHIM D9.5&3.0T1.84 |

| 52/1. | [1] | 146420-5700 | SHIM D9.5&3.0T1.86 |

| 52/1. | [1] | 146420-5800 | SHIM D9.5&3.0T1.88 |

| 54. | [4] | 146433-0100 | GASKET D12&6.4T1.00 |

| 55. | [4] | 146430-0020 | DELIVERY-VALVE ASSEMBLY |

| 56. | [4] | 146432-0000 | COMPRESSION SPRING |

| 58. | [4] | 146440-0220 | FITTING |

| 60. | [3] | 139106-0100 | FLAT-HEAD SCREW |

| 66. | [1] | 146600-0100 | O-RING |

| 67. | [1] | 146502-7622 | GOVERNOR COVER |

| 67/1. | [1] | 146505-5622 | GOVERNOR COVER |

| 67/14. | [1] | 146621-1700 | UNION NUT |

| 67/16. | [1] | 146526-2800 | BLEEDER SCREW |

| 67/23. | [1] | 146625-4920 | BRACKET |

| 67/78. | [1] | 146600-1000 | SEAL RING |

| 67/200. | [1] | 139308-0300 | PLAIN WASHER |

| 67/201. | [1] | 146545-3400 | THREADED PIN L53.00 |

| 67/201B. | [1] | 146545-3500 | THREADED PIN L55.00 |

| 67/201C. | [1] | 146545-3600 | THREADED PIN L57.00 |

| 67/202. | [1] | 139208-0900 | UNION NUT |

| 67/203. | [1] | 146600-1200 | O-RING |

| 68. | [1] | 146510-3220 | CONTROL SHAFT |

| 69. | [1] | 139310-0200 | PLAIN WASHER |

| 72. | [1] | 146534-4920 | CONTROL LEVER |

| 72B. | [1] | 146534-5020 | CONTROL LEVER |

| 73. | [1] | 014110-6440 | LOCKING WASHER |

| 75. | [1] | 013020-6040 | UNION NUT M6P1H5 |

| 95. | [1] | 146551-3720 | FULCRUM LEVER |

| 104. | [2] | 146568-0000 | SLOTTED SPRING PIN |

| 105. | [2] | 026508-1140 | GASKET D11.4&8.2T1 |

| 106. | [2] | 146588-0500 | COILED SPRING |

| 107. | [1] | 146569-0300 | UNION NUT |

| 108. | [1] | 146570-0100 | GOVERNOR SHAFT |

| 109. | [1] | 146600-0400 | O-RING |

| 110/1. | [1] | 146571-0000 | SHIM D20.2&8.3T1.05 |

| 110/1. | [1] | 146571-0100 | SHIM D20.2&8.3T1.25 |

| 110/1. | [1] | 146571-0200 | SHIM D20.2&8.3T1.45 |

| 110/1. | [1] | 146571-0300 | SHIM D20.2&8.3T1.65 |

| 110/1. | [1] | 146571-0400 | SHIM D20.2&8.3T1.85 |

| 110/1. | [1] | 146571-0500 | SHIM D20.2&8.3T1.15 |

| 110/1. | [1] | 146571-0600 | SHIM D20.2&8.3T1.35 |

| 110/1. | [1] | 146571-0700 | SHIM D20.2&8.3T1.55 |

| 110/1. | [1] | 146571-0800 | SHIM D20.2&8.3T1.75 |

| 111. | [1] | 146602-0600 | PLAIN WASHER D20&8.4T1.40 |

| 112. | [1] | 146572-0020 | FLYWEIGHT ASSEMBLY |

| 114. | [1] | 146602-0500 | PLAIN WASHER D17&6.4T1.60 |

| 115. | [1] | 146575-0600 | SLIDING SLEEVE |

| 116. | [1] | 146576-0000 | SEALING CAP |

| 117/1. | [1] | 146577-0000 | PLUG L1.70 |

| 117/1. | [1] | 146577-0100 | PLUG L1.90 |

| 117/1. | [1] | 146577-0200 | PLUG L2.10 |

| 117/1. | [1] | 146577-0300 | PLUG L2.30 |

| 117/1. | [1] | 146577-0400 | PLUG L2.50 |

| 117/1. | [1] | 146577-0500 | PLUG L2.70 |

| 117/1. | [1] | 146577-0600 | PLUG L2.90 |

| 117/1. | [1] | 146577-0700 | PLUG L3.10 |

| 117/1. | [1] | 146577-0800 | PLUG L3.30 |

| 117/1. | [1] | 146577-0900 | PLUG L3.50 |

| 117/1. | [1] | 146577-1000 | PLUG L3.70 |

| 117/1. | [1] | 146577-1100 | PLUG L3.90 |

| 117/1. | [1] | 146577-1200 | PLUG L4.10 |

| 117/1. | [1] | 146577-1300 | PLUG L4.30 |

| 117/1. | [1] | 146577-1400 | PLUG L4.50 |

| 117/1. | [1] | 146577-1500 | PLUG L4.70 |

| 117/1. | [1] | 146577-1600 | PLUG L4.90 |

| 117/1. | [1] | 146577-1700 | PLUG L5.10 |

| 117/1. | [1] | 146577-5000 | PLUG L1.8 |

| 117/1. | [1] | 146577-5100 | PLUG L2.0 |

| 117/1. | [1] | 146577-5200 | PLUG L2.2 |

| 117/1. | [1] | 146577-5300 | PLUG L2.4 |

| 117/1. | [1] | 146577-5400 | PLUG L2.6 |

| 117/1. | [1] | 146577-5500 | PLUG L2.8 |

| 117/1. | [1] | 146577-5600 | PLUG L3.0 |

| 117/1. | [1] | 146577-5700 | PLUG L3.2 |

| 117/1. | [1] | 146577-5800 | PLUG L3.4 |

| 117/1. | [1] | 146577-5900 | PLUG L3.6 |

| 117/1. | [1] | 146577-6000 | PLUG L3.8 |

| 117/1. | [1] | 146577-6100 | PLUG L4.0 |

| 117/1. | [1] | 146577-6200 | PLUG L4.2 |

| 117/1. | [1] | 146577-6300 | PLUG L4.4 |

| 117/1. | [1] | 146577-6400 | PLUG L4.6 |

| 117/1. | [1] | 146577-6500 | PLUG L4.8 |

| 117/1. | [1] | 146577-6600 | PLUG L5.0 |

| 117/1. | [1] | 146877-0400 | PLUG |

| 117/1. | [1] | 146877-0500 | PLUG |

| 117/1. | [1] | 146877-0600 | PLUG |

| 117/1. | [1] | 146877-0700 | PLUG |

| 117/1. | [1] | 146877-4300 | PLUG |

| 117/1. | [1] | 146877-4400 | PLUG |

| 117/1. | [1] | 146877-4500 | PLUG |

| 117/1. | [1] | 146877-4600 | PLUG |

| 123. | [4] | 139106-0200 | FLAT-HEAD SCREW |

| 130. | [1] | 146421-0020 | CAPSULE |

| 130/2. | [1] | 026508-1140 | GASKET D11.4&8.2T1 |

| 130/3. | [1] | 146422-0000 | BLEEDER SCREW |

| 130/4. | [1] | 146600-0500 | O-RING |

| 133. | [1] | 146600-0600 | O-RING |

| 134. | [1] | 146600-0700 | O-RING |

| 135. | [1] | 146110-0920 | CONTROL VALVE |

| 135/5. | [1] | 146114-0000 | SPRING WASHER |

| 136. | [1] | 146120-0020 | OVER FLOW VALVE |

| 137. | [2] | 026512-1540 | GASKET D15.4&12.2T1.50 |

| 138. | [1] | 146606-5620 | INLET UNION |

| 200. | [1] | 146206-0100 | COILED SPRING |

| 205. | [1] | 029470-4030 | WOODRUFF KEY |

| 220. | [1] | 146587-2000 | COILED SPRING |

| 221. | [1] | 146627-1020 | BRACKET |

| 235. | [1] | 146627-1120 | BRACKET |

| 236. | [1] | 139006-4800 | BLEEDER SCREW |

| 237. | [1] | 146620-0200 | HEX-SOCKET-HEAD CAP SCREW |

| 240. | [1] | 146650-4320 | PULLING ELECTROMAGNET |

| 240/8. | [1] | 146600-1700 | O-RING |

| 242. | [1] | 146658-4020 | WIRE |

| 243. | [1] | 146621-1000 | UNION NUT |

| 245. | [3] | 026512-1540 | GASKET D15.4&12.2T1.50 |

| 246. | [1] | 139812-0400 | EYE BOLT |

| 247. | [1] | 146606-8120 | INLET UNION |

| 248. | [1] | 146614-0100 | SPACER BUSHING |

| 251. | [1] | 146626-6720 | BRACKET |

| 275. | [1] | 146612-2700 | BRACKET |

| 276. | [2] | 010010-1640 | BLEEDER SCREW M10P1.5L16 4T |

| 280. | [1] | 146360-3521 | COVER |

| 281. | [1] | 146600-0800 | O-RING |

| 282. | [2] | 139106-1100 | FLAT-HEAD SCREW |

| 800S. | [1] | 146019-0820 | PUMP HOUSING |

| 800S/1/6. | [1] | 146601-0700 | PACKING RING |

| 804S. | [1] | 146232-0320 | COMPRESSION SPRING |

| 805S. | [1] | 146574-0120 | PARTS SET |

| 810S. | [1] | 146600-2420 | REPAIR SET |

| 906. | [1] | 146960-7300 | NAMEPLATE |

Include in #2:

104748-0420

as INJECTION-PUMP ASSEMBLY

Cross reference number

BOSCH

9 460 612 571

9460612571

ZEXEL

104748-0420

1047480420

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113orSAEJ967d

1404 Test oil ISO4113orSAEJ967d

Test oil temperature

degC

45

45

50

Nozzle

105000-2010

Bosch type code

NP-DN12SD12TT

Nozzle holder

105780-2080

Opening pressure

MPa

14.7

14.7

15.19

Opening pressure

kgf/cm2

150

150

155

Injection pipe

Inside diameter - outside diameter - length (mm) mm 2-6-840

Inside diameter - outside diameter - length (mm) mm 2-6-840

Transfer pump pressure

kPa

20

20

20

Transfer pump pressure

kgf/cm2

0.2

0.2

0.2

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Pump speed

r/min

1500

1500

1500

Average injection quantity

mm3/st.

35.9

35.4

36.4

Difference in delivery

mm3/st.

2.5

Basic

*

Injection timing adjustment_02

Pump speed

r/min

2400

2400

2400

Average injection quantity

mm3/st.

12.85

10.1

15.6

Injection timing adjustment_03

Pump speed

r/min

2125

2125

2125

Average injection quantity

mm3/st.

32.5

30.4

34.6

Injection timing adjustment_04

Pump speed

r/min

1500

1500

1500

Average injection quantity

mm3/st.

35.9

34.9

36.9

Injection timing adjustment_05

Pump speed

r/min

500

500

500

Average injection quantity

mm3/st.

30.4

28.4

32.4

Injection quantity adjustment

Pump speed

r/min

2400

2400

2400

Average injection quantity

mm3/st.

13.1

11.1

15.1

Difference in delivery

mm3/st.

4

Basic

*

Injection quantity adjustment_02

Pump speed

r/min

2550

2550

2550

Average injection quantity

mm3/st.

4

Governor adjustment

Pump speed

r/min

350

350

350

Average injection quantity

mm3/st.

11

10

12

Difference in delivery

mm3/st.

2

Basic

*

Governor adjustment_02

Pump speed

r/min

1000

1000

1000

Average injection quantity

mm3/st.

4

Governor adjustment_03

Pump speed

r/min

450

450

450

Average injection quantity

mm3/st.

7

Governor adjustment_04

Pump speed

r/min

350

350

350

Average injection quantity

mm3/st.

11

9.5

12.5

Timer adjustment

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

42

42

Basic

*

Speed control lever angle

Pump speed

r/min

350

350

350

Average injection quantity

mm3/st.

0

0

0

Remarks

Magnet OFF

Magnet OFF

0000000901

Pump speed

r/min

1500

1500

1500

Overflow quantity

cm3/min

462

330

594

Stop lever angle

Pump speed

r/min

1500

1500

1500

Pressure

kPa

578.5

549

608

Pressure

kgf/cm2

5.9

5.6

6.2

Basic

*

Stop lever angle_02

Pump speed

r/min

1500

1500

1500

Pressure

kPa

578.5

549

608

Pressure

kgf/cm2

5.9

5.6

6.2

Stop lever angle_03

Pump speed

r/min

2125

2125

2125

Pressure

kPa

745.5

716

775

Pressure

kgf/cm2

7.6

7.3

7.9

0000001101

Pump speed

r/min

1500

1500

1500

Timer stroke

mm

4.7

4.5

4.9

Basic

*

_02

Pump speed

r/min

1250

1250

1250

Timer stroke

mm

3.5

2.9

4.1

_03

Pump speed

r/min

1500

1500

1500

Timer stroke

mm

4.7

4.4

5

_04

Pump speed

r/min

2125

2125

2125

Timer stroke

mm

7.55

7.1

8

0000001201

Max. applied voltage

V

8

8

8

Test voltage

V

13

12

14

Timing setting

K dimension

mm

3.3

3.2

3.4

KF dimension

mm

5.8

5.7

5.9

MS dimension

mm

1.5

1.4

1.6

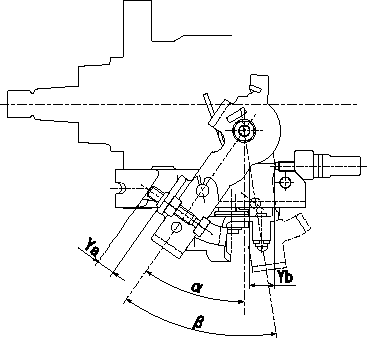

Control lever angle alpha

deg.

35

31

39

Control lever angle beta

deg.

44

39

49

Test data Ex:

0000001801 CONTROL LEVER ANGLE

Control lever angle measurement position

----------

----------

Ya=5.5~12.5mm Yb=12.2~14.8mm Alpha=31~39deg Beta=39~49deg

----------

----------

Ya=5.5~12.5mm Yb=12.2~14.8mm Alpha=31~39deg Beta=39~49deg

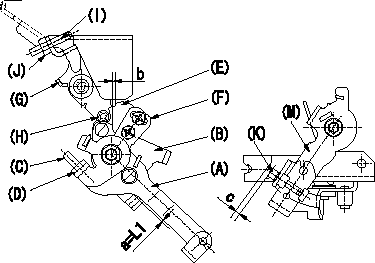

0000001901 M-CSD ADJUSTMENT

M-CSD adjustment

1. Fixing the M-CSD

(1)At roller holder advance angle o, adjust the lever shaft ball pin so that it contacts the roller holder.

(2)At this time, adjust the position of the M-CSD lever (A) using adjusting screw (C) so that the clearance a between the M-CSD lever (A) and the stopper (B) becomes L1. Then fix using nut (D).

T1T1

2. Fixing CSD lever plate (E)

(1)Make the clearance between the CSD lever (A) and the stopper (B) L2.

(2)Fix the CSD lever plate (E) using the bolt (F) so that the clearance between the intermediate lever (G)'s roller (H) and the CSD lever plate is L3.

T2T2

3. Fixing the FICD screw (I)

(1)Move the CSD lever (A) through its full stroke.

(2)Adjust the intermediate lever G's FICD lever screw I position so that the control lever M's position is p (the gap between the control lever and the screw K is L4). Then fix using the nut J.

T1T1

----------

L1=0.5+2mm L2=0mm L3=4mm L4=3+-1mm o=0deg p=3.5deg T1=6~9Nm(0.6~0.9kgfm) T2=3.4~4.9Nm(0.35~0.5kgfm)

----------

a=L1=0.5+2mm b=L3=4mm c=L4=3+-1mm

----------

L1=0.5+2mm L2=0mm L3=4mm L4=3+-1mm o=0deg p=3.5deg T1=6~9Nm(0.6~0.9kgfm) T2=3.4~4.9Nm(0.35~0.5kgfm)

----------

a=L1=0.5+2mm b=L3=4mm c=L4=3+-1mm

Information:

Diagnostic Code 52 ECM or Personality Module Fault

Conditions Which Generate This Code:

The Electronic Control Module (ECM) has detected a fault in the Personality Module (PM), the ECM itself or the connector between them.System Response:

Diagnostic Code 52 is current (Diagnostic Lamp, ECAP or DDT) and is LOGGED in memory.Troubleshooting:

Refer to P-220: ECM And Personality Module Test.Diagnostic Code 53 ECM Fault

Conditions Which Generate This Code:

The ECM has detected an internal fault.System Response:

Diagnostic Code 53 is current (Diagnostic Lamp, ECAP, or DDT), and is LOGGED in memory.Troubleshooting:

The ECM must be replaced.Diagnostic Code 55 No Detected Faults

Conditions Which Generate This Code:

There are no ACTIVE Diagnostic Codes in the 3176 System.System Response:

Normal engine operation.Troubleshooting:

Diagnostic Code 55 does NOT indicate a 3176 System fault. It only shows that the system is operating correctly. The ECAP will display a Code 55 if no faults are currently ACTIVE. The Diagnostic Lamp will also flash Code 55 (on demand) if no faults have occurred since power-up.Diagnostic Code 56 Check Customer Or System Parameters

Conditions Which Generate This Code:

One or more of the Customer Specified Parameters and/or System Configuration Parameters are not correctly programmed for the system. Diagnostic Code 56 will be generated if the Electronic Control Module (ECM) has been replaced and any of the parameters have not been programmed.System Response:

1. Diagnostic Code 56 is current (Diagnostic Lamp, ECAP, or DDT), but is NOT LOGGED in memory.2. Engine power may be limited and/or the ECM may limit engine speed to low idle, depending on the parameter causing the Code 56.Troubleshooting:

1. Using an ECAP, read the parameters that triggered the code, shown along with the Diagnostic Code 56 on the " Current Diagnostic Messages" screen.2. Reprogram the displayed parameter(s). Refer to "Programming 3176 Parameters" in Section 2 of this manual.Diagnostic Code 57 Parking Brake Switch Fault

Conditions Which Generate This Code:

1. The Parking Brake Switch indicates the parking brake is ON.-AND-2. Diagnostic Code 36 (Vehicle Speed Signal Out Of Range) is NOT ACTIVE.-AND-3. The ECM reads a vehicle speed greater than 10 mph for at least five seconds.System Response:

1. Diagnostic Code 57 is current (Diagnostic Lamp, ECAP, or DDT), and IS LOGGED in memory.-AND-2. The Idle Shutdown Timer is disabled.Troubleshooting:

Follow P-216: Parking Brake Switch Test, in this manual.Diagnostic Code 63 Low Fuel Pressure Warning

Conditions Which Generate This Code:

1. The engine has been running at least 20 seconds.-AND-2. Diagnostic Code 37 (Fuel Pressure Sensor Fault) is not ACTIVE.-AND-3. Fuel pressure falls below the minimum specified for a given rpm for at least two minutes. Refer to the Chart below for minimum fuel pressure vs. rpm.System Response:

1. Diagnostic Code 63 is current (Diagnostic Lamp, ECAP, or DDT) and is LOGGED in memory.Troubleshooting:

1. Diagnostic Code 63 does NOT indicate a 3176 System fault. It only gives warning that a low fuel pressure condition exists.2. Use the procedures in the "Fuel System Inspection" and "Fuel Transfer Pump" sections of the 3176 Systems Operation Testing And Adjusting Manual, Form SENR3909, to determine the cause of the low fuel pressure condition. Diagnostic Code 72 Cylinder 1

Conditions Which Generate This Code:

The Electronic Control Module (ECM) has detected a fault in the Personality Module (PM), the ECM itself or the connector between them.System Response:

Diagnostic Code 52 is current (Diagnostic Lamp, ECAP or DDT) and is LOGGED in memory.Troubleshooting:

Refer to P-220: ECM And Personality Module Test.Diagnostic Code 53 ECM Fault

Conditions Which Generate This Code:

The ECM has detected an internal fault.System Response:

Diagnostic Code 53 is current (Diagnostic Lamp, ECAP, or DDT), and is LOGGED in memory.Troubleshooting:

The ECM must be replaced.Diagnostic Code 55 No Detected Faults

Conditions Which Generate This Code:

There are no ACTIVE Diagnostic Codes in the 3176 System.System Response:

Normal engine operation.Troubleshooting:

Diagnostic Code 55 does NOT indicate a 3176 System fault. It only shows that the system is operating correctly. The ECAP will display a Code 55 if no faults are currently ACTIVE. The Diagnostic Lamp will also flash Code 55 (on demand) if no faults have occurred since power-up.Diagnostic Code 56 Check Customer Or System Parameters

Conditions Which Generate This Code:

One or more of the Customer Specified Parameters and/or System Configuration Parameters are not correctly programmed for the system. Diagnostic Code 56 will be generated if the Electronic Control Module (ECM) has been replaced and any of the parameters have not been programmed.System Response:

1. Diagnostic Code 56 is current (Diagnostic Lamp, ECAP, or DDT), but is NOT LOGGED in memory.2. Engine power may be limited and/or the ECM may limit engine speed to low idle, depending on the parameter causing the Code 56.Troubleshooting:

1. Using an ECAP, read the parameters that triggered the code, shown along with the Diagnostic Code 56 on the " Current Diagnostic Messages" screen.2. Reprogram the displayed parameter(s). Refer to "Programming 3176 Parameters" in Section 2 of this manual.Diagnostic Code 57 Parking Brake Switch Fault

Conditions Which Generate This Code:

1. The Parking Brake Switch indicates the parking brake is ON.-AND-2. Diagnostic Code 36 (Vehicle Speed Signal Out Of Range) is NOT ACTIVE.-AND-3. The ECM reads a vehicle speed greater than 10 mph for at least five seconds.System Response:

1. Diagnostic Code 57 is current (Diagnostic Lamp, ECAP, or DDT), and IS LOGGED in memory.-AND-2. The Idle Shutdown Timer is disabled.Troubleshooting:

Follow P-216: Parking Brake Switch Test, in this manual.Diagnostic Code 63 Low Fuel Pressure Warning

Conditions Which Generate This Code:

1. The engine has been running at least 20 seconds.-AND-2. Diagnostic Code 37 (Fuel Pressure Sensor Fault) is not ACTIVE.-AND-3. Fuel pressure falls below the minimum specified for a given rpm for at least two minutes. Refer to the Chart below for minimum fuel pressure vs. rpm.System Response:

1. Diagnostic Code 63 is current (Diagnostic Lamp, ECAP, or DDT) and is LOGGED in memory.Troubleshooting:

1. Diagnostic Code 63 does NOT indicate a 3176 System fault. It only gives warning that a low fuel pressure condition exists.2. Use the procedures in the "Fuel System Inspection" and "Fuel Transfer Pump" sections of the 3176 Systems Operation Testing And Adjusting Manual, Form SENR3909, to determine the cause of the low fuel pressure condition. Diagnostic Code 72 Cylinder 1