Information injection-pump assembly

BOSCH

9 460 610 191

9460610191

ZEXEL

104748-0163

1047480163

Rating:

Cross reference number

BOSCH

9 460 610 191

9460610191

ZEXEL

104748-0163

1047480163

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113orSAEJ967d

1404 Test oil ISO4113orSAEJ967d

Test oil temperature

degC

45

45

50

Nozzle

105000-2010

Bosch type code

NP-DN12SD12TT

Nozzle holder

105780-2080

Opening pressure

MPa

14.7

14.7

15.19

Opening pressure

kgf/cm2

150

150

155

Injection pipe

Inside diameter - outside diameter - length (mm) mm 2-6-840

Inside diameter - outside diameter - length (mm) mm 2-6-840

Transfer pump pressure

kPa

20

20

20

Transfer pump pressure

kgf/cm2

0.2

0.2

0.2

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Pump speed

r/min

1500

1500

1500

Average injection quantity

mm3/st.

38.7

38.2

39.2

Difference in delivery

mm3/st.

2.5

Basic

*

Injection timing adjustment_02

Pump speed

r/min

2400

2400

2400

Average injection quantity

mm3/st.

13.1

10.1

16.1

Injection timing adjustment_03

Pump speed

r/min

2125

2125

2125

Average injection quantity

mm3/st.

34

32

36

Injection timing adjustment_04

Pump speed

r/min

1500

1500

1500

Average injection quantity

mm3/st.

38.7

37.7

39.7

Injection timing adjustment_05

Pump speed

r/min

500

500

500

Average injection quantity

mm3/st.

32.7

30.7

34.7

Injection quantity adjustment

Pump speed

r/min

2400

2400

2400

Average injection quantity

mm3/st.

13.1

11.1

15.1

Basic

*

Injection quantity adjustment_02

Pump speed

r/min

2550

2550

2550

Average injection quantity

mm3/st.

4

Governor adjustment

Pump speed

r/min

350

350

350

Average injection quantity

mm3/st.

8

6

10

Difference in delivery

mm3/st.

2

Basic

*

Governor adjustment_02

Pump speed

r/min

350

350

350

Average injection quantity

mm3/st.

8

6

10

Timer adjustment

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

42

42

Basic

*

Speed control lever angle

Pump speed

r/min

350

350

350

Average injection quantity

mm3/st.

0

0

0

Remarks

Magnet OFF

Magnet OFF

0000000901

Pump speed

r/min

1250

1250

1250

Overflow quantity

cm3/min

430

298

562

Stop lever angle

Pump speed

r/min

1250

1250

1250

Pressure

kPa

510

481

539

Pressure

kgf/cm2

5.2

4.9

5.5

Basic

*

Stop lever angle_02

Pump speed

r/min

500

500

500

Pressure

kPa

294.5

265

324

Pressure

kgf/cm2

3

2.7

3.3

Stop lever angle_03

Pump speed

r/min

1250

1250

1250

Pressure

kPa

510

481

539

Pressure

kgf/cm2

5.2

4.9

5.5

Stop lever angle_04

Pump speed

r/min

1500

1500

1500

Pressure

kPa

578.5

549

608

Pressure

kgf/cm2

5.9

5.6

6.2

Stop lever angle_05

Pump speed

r/min

2125

2125

2125

Pressure

kPa

745.5

716

775

Pressure

kgf/cm2

7.6

7.3

7.9

0000001101

Pump speed

r/min

1250

1250

1250

Timer stroke

mm

3.5

3.3

3.7

Basic

*

_02

Pump speed

r/min

1250

1250

1250

Timer stroke

mm

3.5

3.2

3.8

_03

Pump speed

r/min

1500

1500

1500

Timer stroke

mm

4.7

4.1

5.3

_04

Pump speed

r/min

2125

2125

2125

Timer stroke

mm

7.6

7

8.2

0000001201

Max. applied voltage

V

8

8

8

Test voltage

V

13

12

14

0000001401

Pump speed

r/min

1250

1250

1250

Average injection quantity

mm3/st.

28.2

27.2

29.2

Timer stroke TA

mm

2.7

2.5

2.9

Basic

*

_02

Pump speed

r/min

1250

1250

1250

Average injection quantity

mm3/st.

28.2

26.7

29.7

Timer stroke TA

mm

2.7

2.4

3

_03

Pump speed

r/min

1250

1250

1250

Average injection quantity

mm3/st.

18.1

16.6

19.6

Timer stroke TA

mm

1.5

0.8

2.2

Timing setting

K dimension

mm

3.3

3.2

3.4

KF dimension

mm

5.8

5.7

5.9

MS dimension

mm

1.5

1.4

1.6

Control lever angle alpha

deg.

30

28

32

Control lever angle beta

deg.

45

40

50

Test data Ex:

0000001801 M-CSD ADJUSTMENT

M-CSD adjustment

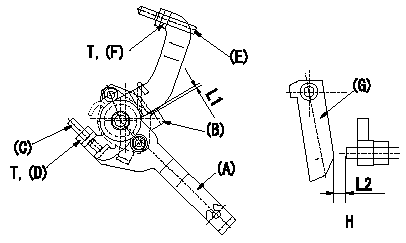

1. Fixing the M-CSD

(1)At roller holder advance angle a adjust the lever shaft ball pin so that it contacts the roller holder.

(2)At this time, adjust the position of the M-CSD lever (A) using adjusting screw (C) so that the clearance between the M-CSD lever (A) and the stopper (B) becomes L1. Then fix using nut (D).

TT

2. M-FICD adjustment

(1)Move the CSD lever (A) through its full stroke.

(2)Adjust screw (E) so that the control lever (G)'s position is b (the clearance between the control lever and the idling set screw is L2). Then fix using the nut (F).

TT

Pump speed NE

H = from idle to position b

----------

L1=0.5+2mm L2=4.8+-1mm a=0deg b=7deg T=6~9N-m(0.6~0.9kgf-m)

----------

L1=0.5+2mm L2=4.8+-1mm T=6~9N-m(0.6~0.9kgf-m) b=7deg

----------

L1=0.5+2mm L2=4.8+-1mm a=0deg b=7deg T=6~9N-m(0.6~0.9kgf-m)

----------

L1=0.5+2mm L2=4.8+-1mm T=6~9N-m(0.6~0.9kgf-m) b=7deg

0000001901 MICROSWITCH ADJUSTMENT

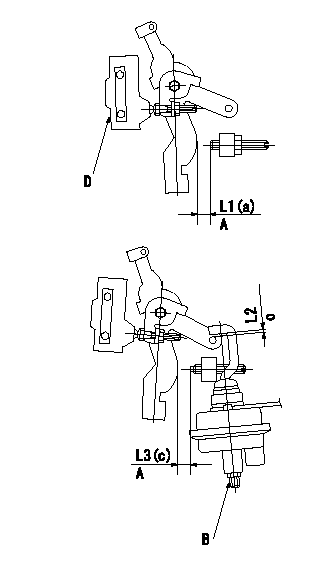

Microswitch adjustment

1. Set the control lever position at a (distance from the idling setscrew is L1).

2. Adjust the lever screw so that the microswitch turns ON and fix using the nut.

Adjustment of the V-FICD

1. V-FICD installation position adjustment

(1)Maintain the control lever position b.

(2)Adjust the position of the bracket so that the clearance between the control lever's roller and the actuator's hook at initial installation is L2. Then, fix using the nut.

2. V-FICD stroke adjustment

(1)Move the actuator through its full stroke.

(2)Adjust the adjusting screw so that the control lever clearance is c (the clearance between the control lever and the idling set screw is L3), then fix using the nut.

(3)Confirm full stroke at P1 {P2}.

A = from idle

B = adjusting screw

C = gap at installation

D = microswitch

----------

a=12.5deg b=0deg c=5deg L1=8.5+-1mm L2=2+2-1mm L3=3.4+-1mm

----------

a=12.5deg c=5deg L1=8.5+-1mm L2=2+2-1mm L3=3.4+-1mm

----------

a=12.5deg b=0deg c=5deg L1=8.5+-1mm L2=2+2-1mm L3=3.4+-1mm

----------

a=12.5deg c=5deg L1=8.5+-1mm L2=2+2-1mm L3=3.4+-1mm

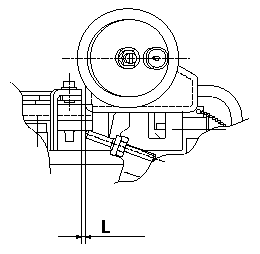

0000002001 FICD BRACKET&CONTROL LEVER

FICD bracket and control lever assembly

L = ensure at least L

----------

----------

L=3 or more mm

----------

----------

L=3 or more mm

Information:

Air Cleaner Indicator

This engine is equipped with an air cleaner mounted service indicator. A colored piston showing in the window indicates the need for servicing the air cleaner. Observe the air cleaner service indicator at regular scheduled intervals. Clean or replace the air cleaner element when the yellow diaphragm enters the red zone or the red piston locks in the visible position.If your air cleaner element becomes plugged, the air can split the element filter material. Unfiltered air will drastically accelerate internal engine wear. Excessive exhaust smoke and/or loss of power may indicate a need for air cleaner element inspection. Perform maintenance on the air cleaner as instructed in this topic.Keep spare filter elements on hand for replacement. The element should be thoroughly checked for rips or tears in the filter material, seal/gasket damage and replaced at least every year or 250 hours.Test Service Indicator

Air cleaner indicators are inexpensive but important instruments which function to show air filter element restriction as the element is progressively filled (plugged) with dust. In average dust conditions, the air cleaner indicators should be tested for proper operation Every 250 Hours . If dust is severe, the indicator should be checked Daily. To test the indicator, perform the following checks.* Check for ease of resetting; should reset in less than a maximum of three pushes.* Check the movement of the yellow core when the engine is accelerated to rated engine speed. The yellow core should latch at or very close to the highest vacuum obtained.If the indicator will NOT reset easily, or the yellow core will not latch at highest vacuum, the indicator(s) should be replaced. If the new indicator will not reset, the indicator sensor hole may be plugged.THE INDICATOR SHOULD BE REPLACED AT OVERHAUL AND/OR MAJOR ENGINE COMPONENT REPLACEMENT. THE INDICATOR MUST BE REPLACED EVERY YEAR REGARDLESS OF OPERATING CONDITIONS. When installing a new indicator, excessive tightening force may crack the top of the indicator. Tighten the indicator to a torque value of 2 N m (18 lb in). Contact your Caterpillar dealer for parts and/or assistance. Clean/Replace Air Cleaner Elements

Never service the air cleaner with the engine running since this will allow dirt to enter the engine. Check the inlet piping for leaks. Make all repairs to inlet piping immediately, as dirt and debris could enter the engine causing damage to the turbocharger and engine components.Clean or replace elements using these recommendations and/or your weather and operating conditions, or when required by the restriction indicator.

1. Remove air cleaner cover and element. Clean or discard used element. Refer to SEBF8062, Guideline for Reusable Parts-Cleaning and Inspection of Air Filters. 2. Cover air inlet opening with a clean cloth or towel to prevent dirt and debris from entering the engine. 3. Clean the inside of the air cleaner cover and body. 4. Remove cloth from air inlet opening and install clean element while noting arrows indicating air flow on the side of the element. 5. Install cover and reset service indicator.Cleaning

This engine is equipped with an air cleaner mounted service indicator. A colored piston showing in the window indicates the need for servicing the air cleaner. Observe the air cleaner service indicator at regular scheduled intervals. Clean or replace the air cleaner element when the yellow diaphragm enters the red zone or the red piston locks in the visible position.If your air cleaner element becomes plugged, the air can split the element filter material. Unfiltered air will drastically accelerate internal engine wear. Excessive exhaust smoke and/or loss of power may indicate a need for air cleaner element inspection. Perform maintenance on the air cleaner as instructed in this topic.Keep spare filter elements on hand for replacement. The element should be thoroughly checked for rips or tears in the filter material, seal/gasket damage and replaced at least every year or 250 hours.Test Service Indicator

Air cleaner indicators are inexpensive but important instruments which function to show air filter element restriction as the element is progressively filled (plugged) with dust. In average dust conditions, the air cleaner indicators should be tested for proper operation Every 250 Hours . If dust is severe, the indicator should be checked Daily. To test the indicator, perform the following checks.* Check for ease of resetting; should reset in less than a maximum of three pushes.* Check the movement of the yellow core when the engine is accelerated to rated engine speed. The yellow core should latch at or very close to the highest vacuum obtained.If the indicator will NOT reset easily, or the yellow core will not latch at highest vacuum, the indicator(s) should be replaced. If the new indicator will not reset, the indicator sensor hole may be plugged.THE INDICATOR SHOULD BE REPLACED AT OVERHAUL AND/OR MAJOR ENGINE COMPONENT REPLACEMENT. THE INDICATOR MUST BE REPLACED EVERY YEAR REGARDLESS OF OPERATING CONDITIONS. When installing a new indicator, excessive tightening force may crack the top of the indicator. Tighten the indicator to a torque value of 2 N m (18 lb in). Contact your Caterpillar dealer for parts and/or assistance. Clean/Replace Air Cleaner Elements

Never service the air cleaner with the engine running since this will allow dirt to enter the engine. Check the inlet piping for leaks. Make all repairs to inlet piping immediately, as dirt and debris could enter the engine causing damage to the turbocharger and engine components.Clean or replace elements using these recommendations and/or your weather and operating conditions, or when required by the restriction indicator.

1. Remove air cleaner cover and element. Clean or discard used element. Refer to SEBF8062, Guideline for Reusable Parts-Cleaning and Inspection of Air Filters. 2. Cover air inlet opening with a clean cloth or towel to prevent dirt and debris from entering the engine. 3. Clean the inside of the air cleaner cover and body. 4. Remove cloth from air inlet opening and install clean element while noting arrows indicating air flow on the side of the element. 5. Install cover and reset service indicator.Cleaning