Information injection-pump assembly

ZEXEL

104748-0140

1047480140

MAZDA

RF0213800

rf0213800

Rating:

Cross reference number

ZEXEL

104748-0140

1047480140

MAZDA

RF0213800

rf0213800

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113orSAEJ967d

1404 Test oil ISO4113orSAEJ967d

Test oil temperature

degC

45

45

50

Nozzle

105000-2010

Bosch type code

NP-DN12SD12TT

Nozzle holder

105780-2080

Opening pressure

MPa

14.7

14.7

15.19

Opening pressure

kgf/cm2

150

150

155

Injection pipe

Inside diameter - outside diameter - length (mm) mm 2-6-840

Inside diameter - outside diameter - length (mm) mm 2-6-840

Transfer pump pressure

kPa

20

20

20

Transfer pump pressure

kgf/cm2

0.2

0.2

0.2

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Pump speed

r/min

1375

1375

1375

Average injection quantity

mm3/st.

35.8

35.3

36.3

Difference in delivery

mm3/st.

2.5

Basic

*

Injection timing adjustment_02

Pump speed

r/min

2600

2600

2600

Average injection quantity

mm3/st.

11

8

14

Injection timing adjustment_03

Pump speed

r/min

2500

2500

2500

Average injection quantity

mm3/st.

21.1

18.1

24.1

Injection timing adjustment_04

Pump speed

r/min

2325

2325

2325

Average injection quantity

mm3/st.

31.7

29.7

33.7

Injection timing adjustment_05

Pump speed

r/min

1375

1375

1375

Average injection quantity

mm3/st.

35.8

34.8

36.8

Injection timing adjustment_06

Pump speed

r/min

500

500

500

Average injection quantity

mm3/st.

27.9

25.9

29.9

Injection quantity adjustment

Pump speed

r/min

2500

2500

2500

Average injection quantity

mm3/st.

21.1

19.1

23.1

Basic

*

Injection quantity adjustment_02

Pump speed

r/min

2700

2700

2700

Average injection quantity

mm3/st.

4

Governor adjustment

Pump speed

r/min

350

350

350

Average injection quantity

mm3/st.

8

6

10

Difference in delivery

mm3/st.

2

Basic

*

Governor adjustment_02

Pump speed

r/min

350

350

350

Average injection quantity

mm3/st.

8

6

10

Governor adjustment_03

Pump speed

r/min

450

450

450

Average injection quantity

mm3/st.

3

Timer adjustment

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

42

42

Basic

*

Speed control lever angle

Pump speed

r/min

350

350

350

Average injection quantity

mm3/st.

0

0

0

Remarks

Magnet OFF

Magnet OFF

0000000901

Pump speed

r/min

1375

1375

1375

Overflow quantity

cm3/min

410

278

542

Stop lever angle

Pump speed

r/min

1375

1375

1375

Pressure

kPa

460.5

431

490

Pressure

kgf/cm2

4.7

4.4

5

Basic

*

Stop lever angle_02

Pump speed

r/min

500

500

500

Pressure

kPa

215.5

186

245

Pressure

kgf/cm2

2.2

1.9

2.5

Stop lever angle_03

Pump speed

r/min

1375

1375

1375

Pressure

kPa

460.5

431

490

Pressure

kgf/cm2

4.7

4.4

5

Stop lever angle_04

Pump speed

r/min

2325

2325

2325

Pressure

kPa

706

677

735

Pressure

kgf/cm2

7.2

6.9

7.5

0000001101

Pump speed

r/min

1375

1375

1375

Timer stroke

mm

4.7

4.5

4.9

Basic

*

_02

Pump speed

r/min

1375

1375

1375

Timer stroke

mm

4.7

4.4

5

_03

Pump speed

r/min

2000

2000

2000

Timer stroke

mm

8

7.4

8.6

_04

Pump speed

r/min

2325

2325

2325

Timer stroke

mm

9.7

9.1

10.3

0000001201

Max. applied voltage

V

8

8

8

Test voltage

V

13

12

14

0000001401

Pump speed

r/min

1375

1375

1375

Average injection quantity

mm3/st.

28.2

27.2

29.2

Timer stroke TA

mm

4.1

3.9

4.3

Basic

*

_02

Pump speed

r/min

1375

1375

1375

Average injection quantity

mm3/st.

28

26.5

29.5

Timer stroke TA

mm

4.1

3.8

4.4

_03

Pump speed

r/min

1375

1375

1375

Average injection quantity

mm3/st.

16

14.5

17.5

Timer stroke TA

mm

2.9

2.2

3.6

Timing setting

K dimension

mm

3.3

3.2

3.4

KF dimension

mm

5.8

5.7

5.9

MS dimension

mm

1.5

1.4

1.6

Control lever angle alpha

deg.

30

26

34

Control lever angle beta

deg.

45

40

50

Test data Ex:

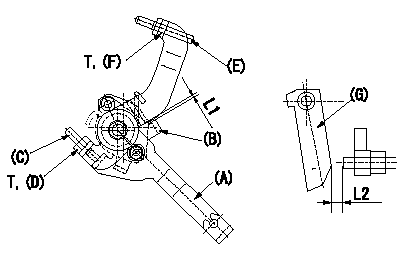

0000001801 M-CSD ADJUSTMENT

M-CSD adjustment

1. Fixing the M-CSD

(1)At roller holder advance angle a adjust the lever shaft ball pin so that it contacts the roller holder.

(2)At this time, adjust the position of the M-CSD lever (A) using adjusting screw (C) so that the clearance between the M-CSD lever (A) and the stopper (B) becomes L1. Then fix using nut (D).

2. M-FICD adjustment

(1)Move the CSD lever (A) through its full stroke.

(2)Adjust screw (E) so that the control lever (G)'s position is b (the clearance between the control lever and the idling set screw is L2). Then fix using the nut (F).

----------

L1=0.5+2mm L2=4.8+-1mm a=0deg b=7deg

----------

L1=0.5+2mm L2=4.8+-1mm T=-N-m(-kgf-m) b=7deg

----------

L1=0.5+2mm L2=4.8+-1mm a=0deg b=7deg

----------

L1=0.5+2mm L2=4.8+-1mm T=-N-m(-kgf-m) b=7deg

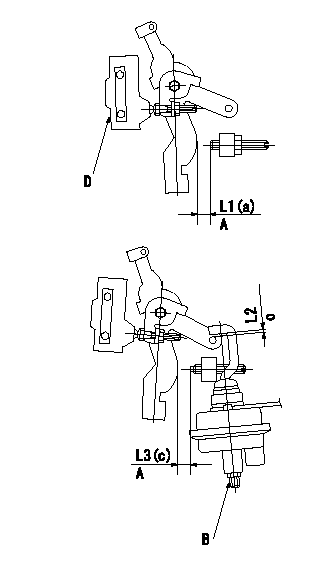

0000001901 MICROSWITCH ADJUSTMENT

Microswitch adjustment

1. Set the control lever position at a (distance from the idling setscrew is L1).

2. Adjust the lever screw so that the microswitch turns ON and fix using the nut.

Adjustment of the V-FICD

1. V-FICD installation position adjustment

(1)Maintain the control lever position b.

(2)Adjust the position of the bracket so that the clearance between the control lever's roller and the actuator's hook at initial installation is L2. Then, fix using the nut.

2. V-FICD stroke adjustment

(1)Move the actuator through its full stroke.

(2)Adjust the adjusting screw so that the control lever clearance is c (the clearance between the control lever and the idling set screw is L3), then fix using the nut.

(3)Confirm full stroke at P1 {P2}.

A = from idle

B = adjusting screw

C = gap at installation

D = microswitch

----------

a=12.5deg b=0deg c=5deg L1=8.5+-1mm L2=2+2-1mm L3=3.4+-1mm

----------

a=12.5deg c=5deg L1=8.5+-1mm L2=2+2-1mm L3=3.4+-1mm

----------

a=12.5deg b=0deg c=5deg L1=8.5+-1mm L2=2+2-1mm L3=3.4+-1mm

----------

a=12.5deg c=5deg L1=8.5+-1mm L2=2+2-1mm L3=3.4+-1mm

Information:

Cleaning Air Filter Elements

The primary element (Caterpillar air filters) can be cleaned several times before replacement. The element, when cleaned, should be thoroughly checked for rips or tears in the filter material.Replace the primary element at least every year regardless of the number of operating hours the element has accumulated.

Do not clean filter elements by bumping or tapping.Do not use filter elements with damaged pleats, gaskets or seals. Engine damage could result.

Filter elements can be cleaned with air pressure, 205 kPa (30 psi) maximum, or water pressure, 280 kPa (40 psi) maximum, or detergent washing. Have spare elements on hand to use while cleaning used elements.* Direct air or water along the length of the pleats inside and outside of filter element. The element can be washed in warm water and nonsudsing household detergent, such as automatic dishwasher detergent. Rinse inside and outside the pleats. The filter should then be thoroughly air dried and inspected. * Inspect the filter elements after cleaning for any rips, tears or damage. Insert a light inside of the clean, dry element. Do not use a filter element with damaged pleats, gaskets or seals. Discard the element if damaged. * Wrap and store the clean filter elements in a clean, dry place.For more information on air cleaner element cleaning, refer to SEBF8062, Guideline for Reusable Parts-Cleaning and Inspection of Air Filters.Belts

Check/Adjust

Inspect the condition and adjustment of alternator and accessory drive belts. Examine all drive belts for wear and replace if they show any signs of wear. Loose or worn pulley grooves cause belt slippage and low accessory drive speed. If belts are too loose, they vibrate enough to cause unnecessary wear on the belts and pulleys and possibly slip enough to cause overheating.If belts are too tight, unnecessary stresses are placed upon the pulley bearings and belts which might shorten the life of both.If one belt in a set requires replacement, always install a new matched set of belts. Never replace just the worn belt. If only the worn belt is replaced, the new belt will carry all the load, as it will not be stretched as much as the older belts. All the belts will fail in rapid succession.Remove the belt guard. Inspect the condition and adjustment of alternator belts and accessory drive belts (if equipped).To check the belt tension, apply 110 Newton (25 lb) force, perpendicular to the belt, midway between the driving and driven pulley. Measure the belt deflection. Correctly adjusted belts will deflect 15 to 20 mm (9/16 to 7/8 inch).If the belt does not require replacement or adjustment, install the belt guard. If the belt requires adjustment or replacement, perform the following procedure to adjust the belt tension.

Typical belt assembly mounting bolt (1) and adjusting nuts (2).1. Loosen the mounting bolt (1) and the locknut on the adjusting bolt.2. Turn the adjusting nuts (2) to increase or decrease the belt tension.3. Tighten the adjusting bolt locknut. Tighten the mounting bolts. Refer to the Torque Specifications in

The primary element (Caterpillar air filters) can be cleaned several times before replacement. The element, when cleaned, should be thoroughly checked for rips or tears in the filter material.Replace the primary element at least every year regardless of the number of operating hours the element has accumulated.

Do not clean filter elements by bumping or tapping.Do not use filter elements with damaged pleats, gaskets or seals. Engine damage could result.

Filter elements can be cleaned with air pressure, 205 kPa (30 psi) maximum, or water pressure, 280 kPa (40 psi) maximum, or detergent washing. Have spare elements on hand to use while cleaning used elements.* Direct air or water along the length of the pleats inside and outside of filter element. The element can be washed in warm water and nonsudsing household detergent, such as automatic dishwasher detergent. Rinse inside and outside the pleats. The filter should then be thoroughly air dried and inspected. * Inspect the filter elements after cleaning for any rips, tears or damage. Insert a light inside of the clean, dry element. Do not use a filter element with damaged pleats, gaskets or seals. Discard the element if damaged. * Wrap and store the clean filter elements in a clean, dry place.For more information on air cleaner element cleaning, refer to SEBF8062, Guideline for Reusable Parts-Cleaning and Inspection of Air Filters.Belts

Check/Adjust

Inspect the condition and adjustment of alternator and accessory drive belts. Examine all drive belts for wear and replace if they show any signs of wear. Loose or worn pulley grooves cause belt slippage and low accessory drive speed. If belts are too loose, they vibrate enough to cause unnecessary wear on the belts and pulleys and possibly slip enough to cause overheating.If belts are too tight, unnecessary stresses are placed upon the pulley bearings and belts which might shorten the life of both.If one belt in a set requires replacement, always install a new matched set of belts. Never replace just the worn belt. If only the worn belt is replaced, the new belt will carry all the load, as it will not be stretched as much as the older belts. All the belts will fail in rapid succession.Remove the belt guard. Inspect the condition and adjustment of alternator belts and accessory drive belts (if equipped).To check the belt tension, apply 110 Newton (25 lb) force, perpendicular to the belt, midway between the driving and driven pulley. Measure the belt deflection. Correctly adjusted belts will deflect 15 to 20 mm (9/16 to 7/8 inch).If the belt does not require replacement or adjustment, install the belt guard. If the belt requires adjustment or replacement, perform the following procedure to adjust the belt tension.

Typical belt assembly mounting bolt (1) and adjusting nuts (2).1. Loosen the mounting bolt (1) and the locknut on the adjusting bolt.2. Turn the adjusting nuts (2) to increase or decrease the belt tension.3. Tighten the adjusting bolt locknut. Tighten the mounting bolts. Refer to the Torque Specifications in