Information injection-pump assembly

ZEXEL

104748-0130

1047480130

MAZDA

RF0113800

rf0113800

Rating:

Cross reference number

ZEXEL

104748-0130

1047480130

MAZDA

RF0113800

rf0113800

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113orSAEJ967d

1404 Test oil ISO4113orSAEJ967d

Test oil temperature

degC

45

45

50

Nozzle

105000-2010

Bosch type code

NP-DN12SD12TT

Nozzle holder

105780-2080

Opening pressure

MPa

14.7

14.7

15.19

Opening pressure

kgf/cm2

150

150

155

Injection pipe

Inside diameter - outside diameter - length (mm) mm 2-6-840

Inside diameter - outside diameter - length (mm) mm 2-6-840

Transfer pump pressure

kPa

20

20

20

Transfer pump pressure

kgf/cm2

0.2

0.2

0.2

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Pump speed

r/min

1375

1375

1375

Average injection quantity

mm3/st.

35.8

35.3

36.3

Difference in delivery

mm3/st.

2.5

Basic

*

Injection timing adjustment_02

Pump speed

r/min

2600

2600

2600

Average injection quantity

mm3/st.

11

8

14

Injection timing adjustment_03

Pump speed

r/min

2500

2500

2500

Average injection quantity

mm3/st.

21.1

18.1

24.1

Injection timing adjustment_04

Pump speed

r/min

2325

2325

2325

Average injection quantity

mm3/st.

31.7

29.7

33.7

Injection timing adjustment_05

Pump speed

r/min

1375

1375

1375

Average injection quantity

mm3/st.

35.8

34.8

36.8

Injection timing adjustment_06

Pump speed

r/min

500

500

500

Average injection quantity

mm3/st.

27.9

25.9

29.9

Injection quantity adjustment

Pump speed

r/min

2500

2500

2500

Average injection quantity

mm3/st.

21.1

19.1

23.1

Basic

*

Injection quantity adjustment_02

Pump speed

r/min

2700

2700

2700

Average injection quantity

mm3/st.

4

Governor adjustment

Pump speed

r/min

350

350

350

Average injection quantity

mm3/st.

8

6

10

Difference in delivery

mm3/st.

2

Basic

*

Governor adjustment_02

Pump speed

r/min

350

350

350

Average injection quantity

mm3/st.

8

6

10

Governor adjustment_03

Pump speed

r/min

450

450

450

Average injection quantity

mm3/st.

3

Timer adjustment

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

42

42

Basic

*

Speed control lever angle

Pump speed

r/min

350

350

350

Average injection quantity

mm3/st.

0

0

0

Remarks

Magnet OFF

Magnet OFF

0000000901

Pump speed

r/min

1375

1375

1375

Overflow quantity

cm3/min

410

278

542

Stop lever angle

Pump speed

r/min

1375

1375

1375

Pressure

kPa

460.5

431

490

Pressure

kgf/cm2

4.7

4.4

5

Basic

*

Stop lever angle_02

Pump speed

r/min

500

500

500

Pressure

kPa

215.5

186

245

Pressure

kgf/cm2

2.2

1.9

2.5

Stop lever angle_03

Pump speed

r/min

1375

1375

1375

Pressure

kPa

460.5

431

490

Pressure

kgf/cm2

4.7

4.4

5

Stop lever angle_04

Pump speed

r/min

2325

2325

2325

Pressure

kPa

706

677

735

Pressure

kgf/cm2

7.2

6.9

7.5

0000001101

Pump speed

r/min

1375

1375

1375

Timer stroke

mm

4.7

4.5

4.9

Basic

*

_02

Pump speed

r/min

1375

1375

1375

Timer stroke

mm

4.7

4.4

5

_03

Pump speed

r/min

2000

2000

2000

Timer stroke

mm

8

7.4

8.6

_04

Pump speed

r/min

2325

2325

2325

Timer stroke

mm

9.7

9.1

10.3

0000001201

Max. applied voltage

V

8

8

8

Test voltage

V

13

12

14

0000001401

Pump speed

r/min

1375

1375

1375

Average injection quantity

mm3/st.

28.2

27.2

29.2

Timer stroke TA

mm

4.1

3.9

4.3

Basic

*

_02

Pump speed

r/min

1375

1375

1375

Average injection quantity

mm3/st.

28

26.5

29.5

Timer stroke TA

mm

4.1

3.8

4.4

_03

Pump speed

r/min

1375

1375

1375

Average injection quantity

mm3/st.

16

14.5

17.5

Timer stroke TA

mm

2.9

2.2

3.6

Timing setting

K dimension

mm

3.3

3.2

3.4

KF dimension

mm

5.8

5.7

5.9

MS dimension

mm

1.5

1.4

1.6

Control lever angle alpha

deg.

30

26

34

Control lever angle beta

deg.

45

40

50

Test data Ex:

0000001801 M-CSD ADJUSTMENT

M-CSD adjustment

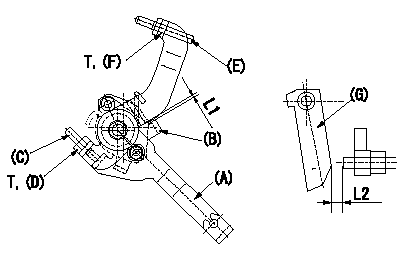

1. Fixing the M-CSD

(1)At roller holder advance angle a adjust the lever shaft ball pin so that it contacts the roller holder.

(2)At this time, adjust the position of the M-CSD lever (A) using adjusting screw (C) so that the clearance between the M-CSD lever (A) and the stopper (B) becomes L1. Then fix using nut (D).

2. M-FICD adjustment

(1)Move the CSD lever (A) through its full stroke.

(2)Adjust screw (E) so that the control lever (G)'s position is b (the clearance between the control lever and the idling set screw is L2). Then fix using the nut (F).

----------

L1=0.5+2mm L2=4.8+-1mm a=0deg b=7deg

----------

L1=0.5+2mm L2=4.8+-1mm T=-N-m(-kgf-m) b=7deg

----------

L1=0.5+2mm L2=4.8+-1mm a=0deg b=7deg

----------

L1=0.5+2mm L2=4.8+-1mm T=-N-m(-kgf-m) b=7deg

Information:

ELC cooling systems can withstand contamination of up to ten percent of conventional HD coolant/antifreeze. If the contamination exceeds ten percent of the total system capacity, perform either one of the following two procedures:* Drain the cooling system. Flush the system with clean water. Refill the system with ELC.* Maintain the cooling system as if the system is filled with conventional HD coolant/antifreeze.Commercial Extended Life Coolant

If Caterpillar extended life coolant is not used, select a commercial extended life coolant that meets the Caterpillar EC-1 specification. Do not use a product that is labeled as an extended life coolant but does not meet the Caterpillar EC-1 specification. Follow the coolant maintenance guidelines of the commercial extended life coolant supplier. In all cases, use distilled or deionized water or use water that has the properties listed in the Caterpillar Water Quality Limits chart.Caterpillar Diesel Engine Antifreeze/Coolant (DEAC)

For cooling systems using conventional HD coolant, Caterpillar recommends the use of Caterpillar Diesel Engine Antifreeze/Coolant (DEAC). DEAC is an alkaline type, single-phase, ethylene glycol-based antifreeze/coolant. DEAC contains inorganic corrosion inhibitors and anti-foaming agents.Contact your Caterpillar dealer for part numbers and available container sizes.Caterpillar DEAC is available premixed with distilled water in a 50/50 concentration. If DEAC concentrate is used, Caterpillar recommends mixing the concentrate with distilled or deionized water. If distilled or deionized water is not available, use water that has the properties listed in the Caterpillar Water Quality Limits chart.Caterpillar Supplemental Coolant Additive (SCA)

Caterpillar Supplemental Coolant Additive (SCA) is effective in preventing corrosion on all metals. Caterpillar SCA also prevents the formation of mineral deposits, prevents liner cavitation, and eliminates coolant foaming.Caterpillar DEAC is formulated with the correct level of Caterpillar SCA. Additional SCA is NOT needed when the cooling system is initially filled with DEAC.Contact your Caterpillar dealer for part numbers and available container sizes.Commercial Heavy Duty (HD) Coolant/Antifreeze and SCA

If Caterpillar DEAC is not used, select a low silicate commercial HD coolant/antifreeze that meets ASTM D5345 or D4985 specifications.When a commercial HD coolant/antifreeze is used, the cooling system should be treated with three to six percent Caterpillar SCA by volume. Refer to the Caterpillar SCA Requirements for Heavy Duty Coolant/Antifreeze chart. If Caterpillar SCA is not used, select a commercial SCA. The commercial SCA must provide a minimum of 1200 mg/L or 1200 ppm (70 grains/US gal) nitrites in the final coolant mixture. Follow the coolant maintenance guidelines of the commercial SCA supplier.HD coolant/antifreezes that meet ASTM D5345 or D4985 specifications DO require SCA treatment at initial fill, and on a maintenance basis.When mixing concentrated coolants, use distilled or deionized water or use water that has the properties listed in the Caterpillar Water Quality Limits chart.Heavy Duty Coolant/Antifreeze Cooling System Maintenance

Never operate an engine without thermostats in the cooling system. Thermostats maintain the engine coolant at the proper operating temperature. Cooling system problems can develop without thermostats.

Check the coolant/antifreeze solution (glycol content) frequently to ensure adequate anti-boil and anti-freeze protection. Caterpillar recommends the use of a refractometer for checking the

If Caterpillar extended life coolant is not used, select a commercial extended life coolant that meets the Caterpillar EC-1 specification. Do not use a product that is labeled as an extended life coolant but does not meet the Caterpillar EC-1 specification. Follow the coolant maintenance guidelines of the commercial extended life coolant supplier. In all cases, use distilled or deionized water or use water that has the properties listed in the Caterpillar Water Quality Limits chart.Caterpillar Diesel Engine Antifreeze/Coolant (DEAC)

For cooling systems using conventional HD coolant, Caterpillar recommends the use of Caterpillar Diesel Engine Antifreeze/Coolant (DEAC). DEAC is an alkaline type, single-phase, ethylene glycol-based antifreeze/coolant. DEAC contains inorganic corrosion inhibitors and anti-foaming agents.Contact your Caterpillar dealer for part numbers and available container sizes.Caterpillar DEAC is available premixed with distilled water in a 50/50 concentration. If DEAC concentrate is used, Caterpillar recommends mixing the concentrate with distilled or deionized water. If distilled or deionized water is not available, use water that has the properties listed in the Caterpillar Water Quality Limits chart.Caterpillar Supplemental Coolant Additive (SCA)

Caterpillar Supplemental Coolant Additive (SCA) is effective in preventing corrosion on all metals. Caterpillar SCA also prevents the formation of mineral deposits, prevents liner cavitation, and eliminates coolant foaming.Caterpillar DEAC is formulated with the correct level of Caterpillar SCA. Additional SCA is NOT needed when the cooling system is initially filled with DEAC.Contact your Caterpillar dealer for part numbers and available container sizes.Commercial Heavy Duty (HD) Coolant/Antifreeze and SCA

If Caterpillar DEAC is not used, select a low silicate commercial HD coolant/antifreeze that meets ASTM D5345 or D4985 specifications.When a commercial HD coolant/antifreeze is used, the cooling system should be treated with three to six percent Caterpillar SCA by volume. Refer to the Caterpillar SCA Requirements for Heavy Duty Coolant/Antifreeze chart. If Caterpillar SCA is not used, select a commercial SCA. The commercial SCA must provide a minimum of 1200 mg/L or 1200 ppm (70 grains/US gal) nitrites in the final coolant mixture. Follow the coolant maintenance guidelines of the commercial SCA supplier.HD coolant/antifreezes that meet ASTM D5345 or D4985 specifications DO require SCA treatment at initial fill, and on a maintenance basis.When mixing concentrated coolants, use distilled or deionized water or use water that has the properties listed in the Caterpillar Water Quality Limits chart.Heavy Duty Coolant/Antifreeze Cooling System Maintenance

Never operate an engine without thermostats in the cooling system. Thermostats maintain the engine coolant at the proper operating temperature. Cooling system problems can develop without thermostats.

Check the coolant/antifreeze solution (glycol content) frequently to ensure adequate anti-boil and anti-freeze protection. Caterpillar recommends the use of a refractometer for checking the