Information injection-pump assembly

ZEXEL

104748-0071

1047480071

Rating:

Cross reference number

ZEXEL

104748-0071

1047480071

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113orSAEJ967d

1404 Test oil ISO4113orSAEJ967d

Test oil temperature

degC

45

45

50

Nozzle

105000-2010

Bosch type code

NP-DN12SD12TT

Nozzle holder

105780-2080

Opening pressure

MPa

14.7

14.7

15.19

Opening pressure

kgf/cm2

150

150

155

Injection pipe

Inside diameter - outside diameter - length (mm) mm 2-6-840

Inside diameter - outside diameter - length (mm) mm 2-6-840

Transfer pump pressure

kPa

20

20

20

Transfer pump pressure

kgf/cm2

0.2

0.2

0.2

Direction of rotation (viewed from drive side)

Left L

Left L

Injection timing adjustment

Pump speed

r/min

1250

1250

1250

Average injection quantity

mm3/st.

39

38.5

39.5

Difference in delivery

mm3/st.

3

Basic

*

Injection timing adjustment_02

Pump speed

r/min

2400

2400

2400

Average injection quantity

mm3/st.

15.1

12.1

18.1

Injection timing adjustment_03

Pump speed

r/min

2125

2125

2125

Average injection quantity

mm3/st.

34.7

32.2

37.2

Injection timing adjustment_04

Pump speed

r/min

1250

1250

1250

Average injection quantity

mm3/st.

39

38

40

Injection timing adjustment_05

Pump speed

r/min

500

500

500

Average injection quantity

mm3/st.

34.6

32.6

36.6

Injection quantity adjustment

Pump speed

r/min

2400

2400

2400

Average injection quantity

mm3/st.

15.1

13.1

17.1

Difference in delivery

mm3/st.

4

Basic

*

Injection quantity adjustment_02

Pump speed

r/min

2500

2500

2500

Average injection quantity

mm3/st.

10

Governor adjustment

Pump speed

r/min

325

325

325

Average injection quantity

mm3/st.

7.2

5.2

9.2

Difference in delivery

mm3/st.

2

Basic

*

Governor adjustment_02

Pump speed

r/min

325

325

325

Average injection quantity

mm3/st.

7.2

5.2

9.2

Governor adjustment_03

Pump speed

r/min

470

Average injection quantity

mm3/st.

0

0

0

Timer adjustment

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

40

40

Basic

*

Speed control lever angle

Pump speed

r/min

325

325

325

Average injection quantity

mm3/st.

0

0

0

Remarks

Magnet OFF

Magnet OFF

0000000901

Pump speed

r/min

1250

1250

1250

Overflow quantity

cm3/min

441

312

570

Stop lever angle

Pump speed

r/min

1250

1250

1250

Pressure

kPa

460.5

431

490

Pressure

kgf/cm2

4.7

4.4

5

Basic

*

Stop lever angle_02

Pump speed

r/min

500

500

500

Pressure

kPa

235.5

206

265

Pressure

kgf/cm2

2.4

2.1

2.7

Stop lever angle_03

Pump speed

r/min

1250

1250

1250

Pressure

kPa

460.5

431

490

Pressure

kgf/cm2

4.7

4.4

5

Stop lever angle_04

Pump speed

r/min

2125

2125

2125

Pressure

kPa

706

677

735

Pressure

kgf/cm2

7.2

6.9

7.5

0000001101

Pump speed

r/min

1250

1250

1250

Timer stroke

mm

4.2

4

4.4

Basic

*

_02

Pump speed

r/min

1250

1250

1250

Timer stroke

mm

4.2

3.9

4.5

_03

Pump speed

r/min

2125

2125

2125

Timer stroke

mm

9.1

8.5

9.7

0000001201

Max. applied voltage

V

8

8

8

Test voltage

V

13

12

14

Timing setting

K dimension

mm

3.3

3.2

3.4

KF dimension

mm

5.8

5.7

5.9

MS dimension

mm

1.8

1.7

1.9

Control lever angle alpha

deg.

35

31

39

Control lever angle beta

deg.

50

45

55

Test data Ex:

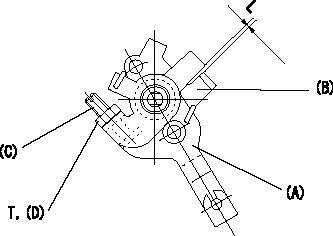

0000001801 M-CSD ADJUSTMENT

M-CSD adjustment

Fixing the M-CSD

(1)At roller holder advance angle '0' adjust the lever shaft ball pin so that it contacts the roller holder.

(2)At this time, adjust the position of the M-CSD lever (A) using adjusting screw (C) so that the clearance between the M-CSD lever (A) and the stopper (B) becomes L. Then fix using nut (D).

TT

----------

L=0.5+2mm T=6~9Nm(0.6~0.9kgfm)

----------

L=0.5+2mm T=6~9Nm(0.6~0.9kgfm)

----------

L=0.5+2mm T=6~9Nm(0.6~0.9kgfm)

----------

L=0.5+2mm T=6~9Nm(0.6~0.9kgfm)

Information:

Literature Information

This manual contains information and instructions concerning engine safety, operation, lubrication, and maintenance. Read, study, and keep it available with other literature and engine information.Some photographs or illustrations in this publication show details or attachments that may differ from your engine. Guards and covers may have been removed for illustrative purposes. Continuing improvement and advancement of product design may have caused changes to your engine which are not included in this publication.Whenever a question arises regarding your engine, or this publication, please consult your Caterpillar dealer for the latest available information.Safety

The safety section lists basic safety precautions. In addition, this section identifies hazardous, warning situations. Read and understand the basic precautions listed in the safety section before operating or performing lubrication, maintenance and/or repair on this product.Operation

Engine operation outlined in this publication is basic. Engine operators gain knowledge of the engine through experience, developing operation skills and techniques which enhance efficient and economical engine operation.The operation section is a reference for operators. Photographs and illustrations guide operators through correct procedures of inspecting, starting, operating and stopping the engine. Discussion of gauges and engine control information is included.Maintenance

The maintenance section is a guide to engine care. The illustrated instructions are grouped by maintenance service intervals. The actual operating environment of the engine also governs the maintenance schedule. Under extremely severe, dusty, or frigid operating conditions, lubrication and maintenance checks more frequent than those specified in the Maintenance Schedule may be necessary.Maintenance Intervals

Use the amount of fuel consumed or use the service hour meter to determine service intervals. Calendar intervals shown (daily, weekly, monthly, etc.) can be used, if they provide more convenient servicing schedules and approximate the indicated service hour meter reading. Recommended service should always be performed at the interval that occurs first.We recommend that the maintenance schedules be reproduced for ease of inspection. We also recommend that ongoing maintenance records be kept to document engine service.See the Maintenance Records section of this publication for information regarding documents that are generally accepted as proof of maintenance or repair. Your Caterpillar dealer can assist you in tailoring your Maintenance Schedule to meet the needs of your operating environment.Overhaul

Major engine repair details are not covered in this manual. Major repairs are best left to trained personnel or an authorized Caterpillar dealer.If a major engine failure requiring removal of the engine occurs, numerous after-failure overhaul options available from your Caterpillar dealer. Contact your dealer for information regarding these options.Engine Description

This publication describes the 3408 and 3412 Marine Diesel Engines. These engines are designed primarily for marine propulsion.Engine Storage

For general information, refer to the Engine Lifting & Storage topic. For complete engine storage information refer to Special Instruction SEHS9031, Storage Procedure for Caterpillar Products.California

Proposition 65 Warning

Diesel engine exhaust and some of its constituents are known to the state of California to cause cancer, birth defects, and other reproductive harm.

This manual contains information and instructions concerning engine safety, operation, lubrication, and maintenance. Read, study, and keep it available with other literature and engine information.Some photographs or illustrations in this publication show details or attachments that may differ from your engine. Guards and covers may have been removed for illustrative purposes. Continuing improvement and advancement of product design may have caused changes to your engine which are not included in this publication.Whenever a question arises regarding your engine, or this publication, please consult your Caterpillar dealer for the latest available information.Safety

The safety section lists basic safety precautions. In addition, this section identifies hazardous, warning situations. Read and understand the basic precautions listed in the safety section before operating or performing lubrication, maintenance and/or repair on this product.Operation

Engine operation outlined in this publication is basic. Engine operators gain knowledge of the engine through experience, developing operation skills and techniques which enhance efficient and economical engine operation.The operation section is a reference for operators. Photographs and illustrations guide operators through correct procedures of inspecting, starting, operating and stopping the engine. Discussion of gauges and engine control information is included.Maintenance

The maintenance section is a guide to engine care. The illustrated instructions are grouped by maintenance service intervals. The actual operating environment of the engine also governs the maintenance schedule. Under extremely severe, dusty, or frigid operating conditions, lubrication and maintenance checks more frequent than those specified in the Maintenance Schedule may be necessary.Maintenance Intervals

Use the amount of fuel consumed or use the service hour meter to determine service intervals. Calendar intervals shown (daily, weekly, monthly, etc.) can be used, if they provide more convenient servicing schedules and approximate the indicated service hour meter reading. Recommended service should always be performed at the interval that occurs first.We recommend that the maintenance schedules be reproduced for ease of inspection. We also recommend that ongoing maintenance records be kept to document engine service.See the Maintenance Records section of this publication for information regarding documents that are generally accepted as proof of maintenance or repair. Your Caterpillar dealer can assist you in tailoring your Maintenance Schedule to meet the needs of your operating environment.Overhaul

Major engine repair details are not covered in this manual. Major repairs are best left to trained personnel or an authorized Caterpillar dealer.If a major engine failure requiring removal of the engine occurs, numerous after-failure overhaul options available from your Caterpillar dealer. Contact your dealer for information regarding these options.Engine Description

This publication describes the 3408 and 3412 Marine Diesel Engines. These engines are designed primarily for marine propulsion.Engine Storage

For general information, refer to the Engine Lifting & Storage topic. For complete engine storage information refer to Special Instruction SEHS9031, Storage Procedure for Caterpillar Products.California

Proposition 65 Warning

Diesel engine exhaust and some of its constituents are known to the state of California to cause cancer, birth defects, and other reproductive harm.