Information injection-pump assembly

ZEXEL

104747-7090

1047477090

KOMATSU

6273711220

6273711220

Rating:

Cross reference number

ZEXEL

104747-7090

1047477090

KOMATSU

6273711220

6273711220

Zexel num

Bosch num

Firm num

Name

104747-7090

6273711220 KOMATSU

INJECTION-PUMP ASSEMBLY

P162/CUMM

P162/CUMM

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113orSAEJ967d

1404 Test oil ISO4113orSAEJ967d

Test oil temperature

degC

45

45

50

Nozzle

105780-0060

Bosch type code

NP-DN0SD1510

Nozzle holder

105780-2150

Opening pressure

MPa

13

13

13.3

Opening pressure

kgf/cm2

133

133

136

Injection pipe

157805-7320

Injection pipe

Inside diameter - outside diameter - length (mm) mm 2-6-450

Inside diameter - outside diameter - length (mm) mm 2-6-450

Joint assembly

157641-4720

Tube assembly

157641-4020

Transfer pump pressure

kPa

20

20

20

Transfer pump pressure

kgf/cm2

0.2

0.2

0.2

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Pump speed

r/min

900

900

900

Average injection quantity

mm3/st.

67.2

66.7

67.7

Difference in delivery

mm3/st.

5

Basic

*

Oil temperature

degC

50

48

52

Injection timing adjustment_02

Pump speed

r/min

500

500

500

Average injection quantity

mm3/st.

57.8

53.3

62.3

Oil temperature

degC

48

46

50

Injection timing adjustment_03

Pump speed

r/min

800

800

800

Average injection quantity

mm3/st.

68.3

64.3

72.3

Oil temperature

degC

50

48

52

Injection timing adjustment_04

Pump speed

r/min

900

900

900

Average injection quantity

mm3/st.

67.2

65.7

68.7

Difference in delivery

mm3/st.

5.5

Basic

*

Oil temperature

degC

50

48

52

Injection timing adjustment_05

Pump speed

r/min

1050

1050

1050

Average injection quantity

mm3/st.

62.4

58.4

66.4

Oil temperature

degC

50

48

52

Injection quantity adjustment

Pump speed

r/min

1175

1175

1175

Average injection quantity

mm3/st.

33.8

30.8

36.8

Difference in delivery

mm3/st.

7

Basic

*

Oil temperature

degC

50

48

52

Injection quantity adjustment_02

Pump speed

r/min

1375

1375

1375

Average injection quantity

mm3/st.

3

Oil temperature

degC

50

48

52

Injection quantity adjustment_03

Pump speed

r/min

1175

1175

1175

Average injection quantity

mm3/st.

33.8

29.3

38.3

Basic

*

Oil temperature

degC

50

48

52

Governor adjustment

Pump speed

r/min

400

400

400

Average injection quantity

mm3/st.

8.6

6.6

10.6

Difference in delivery

mm3/st.

2

Basic

*

Oil temperature

degC

48

46

50

Governor adjustment_02

Pump speed

r/min

400

400

400

Average injection quantity

mm3/st.

8.6

6.1

11.1

Difference in delivery

mm3/st.

2.5

Basic

*

Oil temperature

degC

48

46

50

Timer adjustment

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

80

75

85

Basic

*

Oil temperature

degC

48

46

50

Remarks

IDLE

IDLE

Timer adjustment_02

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

80

75

85

Oil temperature

degC

48

46

50

Remarks

IDLE

IDLE

Speed control lever angle

Pump speed

r/min

400

400

400

Average injection quantity

mm3/st.

0

0

0

Oil temperature

degC

48

46

50

Remarks

Magnet OFF at idling position

Magnet OFF at idling position

0000000901

Pump speed

r/min

1050

1050

1050

Overflow quantity

cm3/min

410

280

540

Oil temperature

degC

50

48

52

Stop lever angle

Pump speed

r/min

1050

1050

1050

Pressure

kPa

510

490

530

Pressure

kgf/cm2

5.2

5

5.4

Basic

*

Oil temperature

degC

50

48

52

Stop lever angle_02

Pump speed

r/min

900

900

900

Pressure

kPa

451

402

500

Pressure

kgf/cm2

4.6

4.1

5.1

Oil temperature

degC

50

48

52

Stop lever angle_03

Pump speed

r/min

1000

1000

1000

Pressure

kPa

490

441

539

Pressure

kgf/cm2

5

4.5

5.5

Oil temperature

degC

50

48

52

Stop lever angle_04

Pump speed

r/min

1050

1050

1050

Pressure

kPa

510

481

539

Pressure

kgf/cm2

5.2

4.9

5.5

Basic

*

Oil temperature

degC

50

48

52

0000001101

Pump speed

r/min

1050

1050

1050

Timer stroke

mm

1.6

1.4

1.8

Basic

*

Oil temperature

degC

50

48

52

_02

Pump speed

r/min

900

900

900

Timer stroke

mm

0.4

0

0.9

Oil temperature

degC

50

48

52

_03

Pump speed

r/min

1050

1050

1050

Timer stroke

mm

1.6

1.3

1.9

Basic

*

Oil temperature

degC

50

48

52

0000001201

Max. applied voltage

V

16

16

16

Test voltage

V

25

24

26

0000001401

Pump speed

r/min

1050

1050

1050

Average injection quantity

mm3/st.

50

49

51

Timer stroke TA

mm

1

0.8

1.2

Timer stroke variation dT

mm

0.6

0.6

0.6

Basic

*

Oil temperature

degC

50

48

52

_02

Pump speed

r/min

1050

1050

1050

Average injection quantity

mm3/st.

50

48.5

51.5

Timer stroke TA

mm

1

0.7

1.3

Timer stroke variation dT

mm

0.6

0.6

0.6

Basic

*

Oil temperature

degC

50

48

52

_03

Pump speed

r/min

1050

1050

1050

Average injection quantity

mm3/st.

40

38

42

Timer stroke TA

mm

0.4

0

0.9

Timer stroke variation dT

mm

1.2

1.2

1.2

Oil temperature

degC

50

48

52

Timing setting

K dimension

mm

3.3

3.2

3.4

KF dimension

mm

5.8

5.7

5.9

MS dimension

mm

2

1.9

2.1

Control lever angle alpha

deg.

16

12

20

Control lever angle beta

deg.

33

28

38

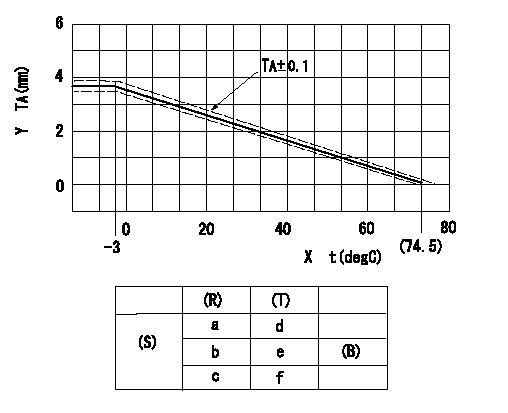

Test data Ex:

0000001801 W-CSD ADJUSTMENT

Adjustment of the W-CSD

Adjustment of the timer advance angle

1. Determine the timer advance angle using the graph (graph TA).

X:Temperature t (deg C)

Y:Timer stroke TA (mm)

(S) Cold advance

(R) Cooling water temperature (deg C)

(T) Timer piston stroke (mm)

(B) Standard point

----------

TA=-0.053t+3.881 -3degC<=t<=20degC TA=-0.0517t+3.854 20degC<=t

----------

a=76.5++degC b=20degC c=-3degC d=0mm e=2.82+-0.4mm f=4.04+-0.6mm

----------

TA=-0.053t+3.881 -3degC<=t<=20degC TA=-0.0517t+3.854 20degC<=t

----------

a=76.5++degC b=20degC c=-3degC d=0mm e=2.82+-0.4mm f=4.04+-0.6mm

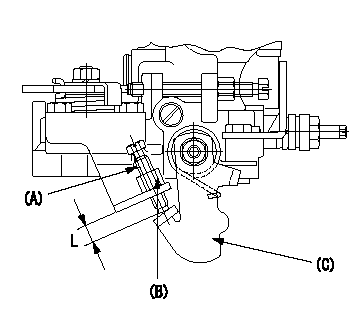

0000001901 STARTING I/Q ADJUSTMENT

Starting Q decrease lever adjustment

Adjust using the screw (A) so that the standards are satisfied, then fix using the nut (B).

Screw (A) protrusion: L

(B) Nut (SW10, T1 after completing adjustment)

(C) Stop lever

----------

L=7.4~11.1mm T1=6~9N-m(0.6~0.9kgf-m)

----------

L=7.4~11.1mm

----------

L=7.4~11.1mm T1=6~9N-m(0.6~0.9kgf-m)

----------

L=7.4~11.1mm

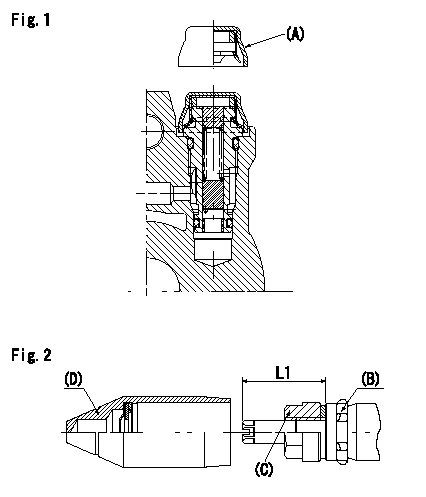

0000002001 TAMPER PROOF

Tamperproof installation procedure

A:Cap

B:Rubber vibration damper

C:Nut

D:Cap

L1:Inspection dimension

Fig. 1 Regulating valve seal

1) Insert the cap A horizontally (press fit).

2) After insertion (press-fitting), tighten the cap to torque T1, and confirm that it is not pulled out at load F1.

Fig.2 Full load adjusting screw

1) Confirm the position of the rubber vibration damper (B) and then tighten nut (C) to the torque T2.

----------

L1=23~28mm F1=49N(5kgf) T1=4.9N-m(0.5kgf-m) T2=7~9N-m(0.7~0.9kgf-m)

----------

L1=23~28mm

----------

L1=23~28mm F1=49N(5kgf) T1=4.9N-m(0.5kgf-m) T2=7~9N-m(0.7~0.9kgf-m)

----------

L1=23~28mm

Information:

Caterpillar Diesel Truck Engines can operate effectively in cold weather, however, engine operation in cold weather is dependent on the type of fuel used and how well the fuel moves through fuel related components. The purpose of this section is to explain some of the problems and steps that can be taken to minimize fuel problems during cold weather operation when the engine area is colder than 40°F (5°C).Fuel and the Effect from Cold Weather

The two types of diesel fuel available for your truck engine are typically grades No. 1 and No. 2. Although No. 2 diesel fuel is the most commonly used fuel, No. 1 diesel fuel or a blend of No. 1 and No. 2, is the fuel that is best suited for cold weather operation.During cold weather operation, it may be necessary for you to use No. 2 diesel fuel since quantities of No. 1 diesel fuel are limited and generally are only available during the winter months and in the colder climates.There are three major differences between No. 1 and No. 2 diesel fuel. No. 1 diesel fuel has a lower cloud point, a lower pour point and has a lower BTU (kJ) (heat content) rating per unit volume of fuel than the average No. 2 diesel fuel.When using No. 1 diesel fuel, you may notice a drop in power and fuel efficiency, but should not experience any other operating effects.The cloud point is the temperature at which a cloud or haze of wax crystals will begin to form in the fuel and cause fuel filters to plug. The pour point is the temperature which diesel fuel will begin to thicken and be more resistant to flow through fuel pumps and lines.Be aware of these fuel values when purchasing your diesel fuel and anticipate the average outside (ambient) temperature for the area your engine will be operating. Engines fueled in one climate may not operate satisfactorily if moved to another because of problems that result from cold weather.Before troubleshooting for low power or poor performance in winter months, check the type of fuel being used.The use of starting aids, engine oil pan heaters, engine coolant heaters, fuel heaters and fuel line insulation also provide a means of minimizing starting and fuel problems in cold weather when No. 2 diesel fuel is used.Fuel Related Components in Cold Weather

The 3176 electronic control module is fuel cooled. Fuel is routed from the tank, to a primary fuel filter, through the transfer pump, then through cored passages in the electronic control module housing, on to the secondary fuel filter, and finally to the injection pump.Inlet fuel temperature to the transfer pump must never exceed 149°F (65°C). Fuel temperatures in excess of this temperature reduce the life of the electronics, reduce the life of the transfer pump check valves, and reduce engine power availability.Fuel Tanks

Fuel tanks should contain some provision for draining water and sediment from the bottom of the tanks.Some fuel tanks use supply pipes that allow water

The two types of diesel fuel available for your truck engine are typically grades No. 1 and No. 2. Although No. 2 diesel fuel is the most commonly used fuel, No. 1 diesel fuel or a blend of No. 1 and No. 2, is the fuel that is best suited for cold weather operation.During cold weather operation, it may be necessary for you to use No. 2 diesel fuel since quantities of No. 1 diesel fuel are limited and generally are only available during the winter months and in the colder climates.There are three major differences between No. 1 and No. 2 diesel fuel. No. 1 diesel fuel has a lower cloud point, a lower pour point and has a lower BTU (kJ) (heat content) rating per unit volume of fuel than the average No. 2 diesel fuel.When using No. 1 diesel fuel, you may notice a drop in power and fuel efficiency, but should not experience any other operating effects.The cloud point is the temperature at which a cloud or haze of wax crystals will begin to form in the fuel and cause fuel filters to plug. The pour point is the temperature which diesel fuel will begin to thicken and be more resistant to flow through fuel pumps and lines.Be aware of these fuel values when purchasing your diesel fuel and anticipate the average outside (ambient) temperature for the area your engine will be operating. Engines fueled in one climate may not operate satisfactorily if moved to another because of problems that result from cold weather.Before troubleshooting for low power or poor performance in winter months, check the type of fuel being used.The use of starting aids, engine oil pan heaters, engine coolant heaters, fuel heaters and fuel line insulation also provide a means of minimizing starting and fuel problems in cold weather when No. 2 diesel fuel is used.Fuel Related Components in Cold Weather

The 3176 electronic control module is fuel cooled. Fuel is routed from the tank, to a primary fuel filter, through the transfer pump, then through cored passages in the electronic control module housing, on to the secondary fuel filter, and finally to the injection pump.Inlet fuel temperature to the transfer pump must never exceed 149°F (65°C). Fuel temperatures in excess of this temperature reduce the life of the electronics, reduce the life of the transfer pump check valves, and reduce engine power availability.Fuel Tanks

Fuel tanks should contain some provision for draining water and sediment from the bottom of the tanks.Some fuel tanks use supply pipes that allow water

Have questions with 104747-7090?

Group cross 104747-7090 ZEXEL

Komatsu

104747-7090

6273711220

INJECTION-PUMP ASSEMBLY

P162/CUMM

P162/CUMM