Information injection-pump assembly

ZEXEL

104747-7080

1047477080

KOMATSU

6273711120

6273711120

Rating:

Cross reference number

ZEXEL

104747-7080

1047477080

KOMATSU

6273711120

6273711120

Zexel num

Bosch num

Firm num

Name

104747-7080

6273711120 KOMATSU

INJECTION-PUMP ASSEMBLY

P162/CUMM

P162/CUMM

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113orSAEJ967d

1404 Test oil ISO4113orSAEJ967d

Test oil temperature

degC

45

45

50

Nozzle

105780-0060

Bosch type code

NP-DN0SD1510

Nozzle holder

105780-2150

Opening pressure

MPa

13

13

13.3

Opening pressure

kgf/cm2

133

133

136

Injection pipe

157805-7320

Injection pipe

Inside diameter - outside diameter - length (mm) mm 2-6-450

Inside diameter - outside diameter - length (mm) mm 2-6-450

Joint assembly

157641-4720

Tube assembly

157641-4020

Transfer pump pressure

kPa

20

20

20

Transfer pump pressure

kgf/cm2

0.2

0.2

0.2

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Pump speed

r/min

900

900

900

Average injection quantity

mm3/st.

67.2

66.7

67.7

Difference in delivery

mm3/st.

5

Basic

*

Oil temperature

degC

50

48

52

Injection timing adjustment_02

Pump speed

r/min

500

500

500

Average injection quantity

mm3/st.

57.8

53.3

62.3

Oil temperature

degC

48

46

50

Injection timing adjustment_03

Pump speed

r/min

800

800

800

Average injection quantity

mm3/st.

68.3

64.3

72.3

Oil temperature

degC

50

48

52

Injection timing adjustment_04

Pump speed

r/min

900

900

900

Average injection quantity

mm3/st.

67.2

65.7

68.7

Difference in delivery

mm3/st.

5.5

Basic

*

Oil temperature

degC

50

48

52

Injection timing adjustment_05

Pump speed

r/min

1050

1050

1050

Average injection quantity

mm3/st.

62.4

58.4

66.4

Oil temperature

degC

50

48

52

Injection quantity adjustment

Pump speed

r/min

1175

1175

1175

Average injection quantity

mm3/st.

33.8

30.8

36.8

Difference in delivery

mm3/st.

7

Basic

*

Oil temperature

degC

50

48

52

Injection quantity adjustment_02

Pump speed

r/min

1375

1375

1375

Average injection quantity

mm3/st.

3

Oil temperature

degC

50

48

52

Injection quantity adjustment_03

Pump speed

r/min

1175

1175

1175

Average injection quantity

mm3/st.

33.8

29.3

38.3

Basic

*

Oil temperature

degC

50

48

52

Governor adjustment

Pump speed

r/min

400

400

400

Average injection quantity

mm3/st.

8.6

6.6

10.6

Difference in delivery

mm3/st.

2

Basic

*

Oil temperature

degC

48

46

50

Governor adjustment_02

Pump speed

r/min

400

400

400

Average injection quantity

mm3/st.

8.6

6.1

11.1

Difference in delivery

mm3/st.

2.5

Basic

*

Oil temperature

degC

48

46

50

Timer adjustment

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

80

75

85

Basic

*

Oil temperature

degC

48

46

50

Remarks

IDLE

IDLE

Timer adjustment_02

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

80

75

85

Oil temperature

degC

48

46

50

Remarks

IDLE

IDLE

Speed control lever angle

Pump speed

r/min

400

400

400

Average injection quantity

mm3/st.

0

0

0

Oil temperature

degC

48

46

50

Remarks

Magnet OFF at idling position

Magnet OFF at idling position

0000000901

Pump speed

r/min

1050

1050

1050

Overflow quantity

cm3/min

410

280

540

Oil temperature

degC

50

48

52

Stop lever angle

Pump speed

r/min

1050

1050

1050

Pressure

kPa

510

490

530

Pressure

kgf/cm2

5.2

5

5.4

Basic

*

Oil temperature

degC

50

48

52

Stop lever angle_02

Pump speed

r/min

900

900

900

Pressure

kPa

451

402

500

Pressure

kgf/cm2

4.6

4.1

5.1

Oil temperature

degC

50

48

52

Stop lever angle_03

Pump speed

r/min

1000

1000

1000

Pressure

kPa

490

441

539

Pressure

kgf/cm2

5

4.5

5.5

Oil temperature

degC

50

48

52

Stop lever angle_04

Pump speed

r/min

1050

1050

1050

Pressure

kPa

510

481

539

Pressure

kgf/cm2

5.2

4.9

5.5

Basic

*

Oil temperature

degC

50

48

52

0000001101

Pump speed

r/min

1050

1050

1050

Timer stroke

mm

1.6

1.4

1.8

Basic

*

Oil temperature

degC

50

48

52

_02

Pump speed

r/min

900

900

900

Timer stroke

mm

0.4

0

0.9

Oil temperature

degC

50

48

52

_03

Pump speed

r/min

1050

1050

1050

Timer stroke

mm

1.6

1.3

1.9

Basic

*

Oil temperature

degC

50

48

52

0000001201

Max. applied voltage

V

8

8

8

Test voltage

V

13

12

14

0000001401

Pump speed

r/min

1050

1050

1050

Average injection quantity

mm3/st.

50

49

51

Timer stroke TA

mm

1

0.8

1.2

Timer stroke variation dT

mm

0.6

0.6

0.6

Basic

*

Oil temperature

degC

50

48

52

_02

Pump speed

r/min

1050

1050

1050

Average injection quantity

mm3/st.

50

48.5

51.5

Timer stroke TA

mm

1

0.7

1.3

Timer stroke variation dT

mm

0.6

0.6

0.6

Basic

*

Oil temperature

degC

50

48

52

_03

Pump speed

r/min

1050

1050

1050

Average injection quantity

mm3/st.

40

38

42

Timer stroke TA

mm

0.4

0

0.9

Timer stroke variation dT

mm

1.2

1.2

1.2

Oil temperature

degC

50

48

52

Timing setting

K dimension

mm

3.3

3.2

3.4

KF dimension

mm

5.8

5.7

5.9

MS dimension

mm

2

1.9

2.1

Control lever angle alpha

deg.

16

12

20

Control lever angle beta

deg.

33

28

38

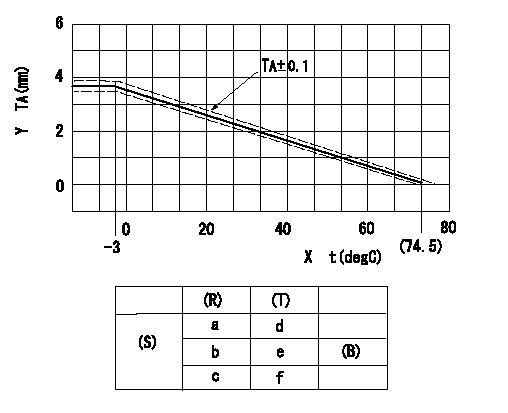

Test data Ex:

0000001801 W-CSD ADJUSTMENT

Adjustment of the W-CSD

Adjustment of the timer advance angle

1. Determine the timer advance angle using the graph (graph TA).

X:Temperature t (deg C)

Y:Timer stroke TA (mm)

(S) Cold advance

(R) Cooling water temperature (deg C)

(T) Timer piston stroke (mm)

(B) Standard point

----------

TA=-0.053t+3.881 -3degC<=t<=20degC TA=-0.0517t+3.854 20degC<=t

----------

a=76.5++degC b=20degC c=-3degC d=0mm e=2.82+-0.4mm f=4.04+-0.6mm

----------

TA=-0.053t+3.881 -3degC<=t<=20degC TA=-0.0517t+3.854 20degC<=t

----------

a=76.5++degC b=20degC c=-3degC d=0mm e=2.82+-0.4mm f=4.04+-0.6mm

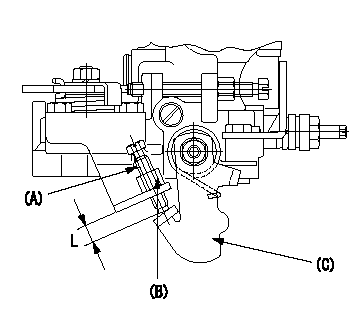

0000001901 STARTING I/Q ADJUSTMENT

Starting Q decrease lever adjustment

Adjust using the screw (A) so that the standards are satisfied, then fix using the nut (B).

Screw (A) protrusion: L

(B) Nut (SW10, T1 after completing adjustment)

(C) Stop lever

----------

L=7.4~11.1mm T1=6~9N-m(0.6~0.9kgf-m)

----------

L=7.4~11.1mm

----------

L=7.4~11.1mm T1=6~9N-m(0.6~0.9kgf-m)

----------

L=7.4~11.1mm

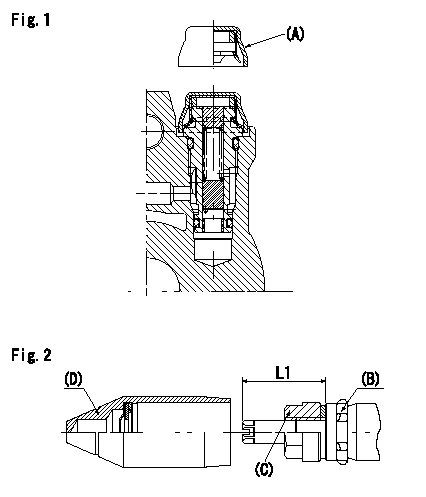

0000002001 TAMPER PROOF

Tamperproof installation procedure

A:Cap

B:Rubber vibration damper

C:Nut

D:Cap

L1:Inspection dimension

Fig. 1 Regulating valve seal

1) Insert the cap A horizontally (press fit).

2) After insertion (press-fitting), tighten the cap to torque T1, and confirm that it is not pulled out at load F1.

Fig.2 Full load adjusting screw

1) Confirm the position of the rubber vibration damper (B) and then tighten nut (C) to the torque T2.

----------

L1=23~28mm F1=49N(5kgf) T1=4.9N-m(0.5kgf-m) T2=7~9N-m(0.7~0.9kgf-m)

----------

L1=23~28mm

----------

L1=23~28mm F1=49N(5kgf) T1=4.9N-m(0.5kgf-m) T2=7~9N-m(0.7~0.9kgf-m)

----------

L1=23~28mm

Information:

Driver Techniques

The manner in which a vehicle is driven can have a dramatic effect on fuel consumption. Operators can maximize fuel economy and engine life by practicing the techniques of using minimum power and low engine rpm. The following tips can optimize fuel economy by making maximum use of the potential efficiency of the engine and vehicle.The 3176 can be programmed to ensure that the engine and vehicle are operated within specific limits for maximum fuel economy. (Refer to topic, Customer Specified Parameters, in this publication for information.)Caterpillar engines are designed to operate at lower engine rpm (speed) and have demonstrated excellent fuel savings and longer service life when operated in this manner.Starting Out

This truck engine does not require long warm-up times that waste fuel. Below 63°F (17°C), the 3176 system automatically idles at 1000 rpm. It takes just a few minutes in the summer and a bit longer in the winter to warm up the mechanical engine, and for the 3176 engine to reduce engine rpm to the programmed low idle rpm.A load can be applied to the engine after normal oil pressure is reached and the water temperature gauge begins to rise. To get the vehicle in motion, use a gear that will result in a smooth, easy start without increasing engine speed above low idle or slipping the clutch. Engage the clutch smoothly. Interrupted and jerky clutch engagement put stress on the drive train and wastes fuel.Keep engine rpm (speed) at a minimum. Use just enough rpm to pick up the next gear. This technique is called progressive shifting. It can improve fuel consumption and will not harm the engine.Progressive Shifting

Drive line efficiency is best in the low to mid rpm range (1100 to 1600 rpm) of the engine due to reduced frictional losses of the engine, transmission and rear axles. When accelerating under normal level road conditions, the engine should be operated in this most efficient rpm range by using only enough power to pick up the next higher gear. This technique of upshifting at the lowest possible rpm is called progressive shifting.Progressive shifting also reduces the time to accelerate to the desired vehicle speed. Top gear is reached sooner because engine rpm does not have to fall off as far to synchronize the gears of the transmission. The key to progressive shifting is to use minimum rpm, minimum power and upshift early while accelerating the truck.The 3176 can be programmed to limit engine acceleration above pre-programmed engine rpm settings. This feature encourages the operator to practice progressive shifting techniques.Refer to Driving Techniques for Maximum Fuel Economy, form LEDT5092 for more information.Cruising Speed

It's a simple fact that the faster a vehicle is driven, the more fuel it will consume. A few miles per hour (kilometers per hour) can make a significant difference in fuel economy.Increasing cruising speed from 55 to 65 mph (88 to 104 km/h) will increase fuel consumption of a typical class 8 truck approximately 1.0 mpg (0.4 km/L). A practice of

The manner in which a vehicle is driven can have a dramatic effect on fuel consumption. Operators can maximize fuel economy and engine life by practicing the techniques of using minimum power and low engine rpm. The following tips can optimize fuel economy by making maximum use of the potential efficiency of the engine and vehicle.The 3176 can be programmed to ensure that the engine and vehicle are operated within specific limits for maximum fuel economy. (Refer to topic, Customer Specified Parameters, in this publication for information.)Caterpillar engines are designed to operate at lower engine rpm (speed) and have demonstrated excellent fuel savings and longer service life when operated in this manner.Starting Out

This truck engine does not require long warm-up times that waste fuel. Below 63°F (17°C), the 3176 system automatically idles at 1000 rpm. It takes just a few minutes in the summer and a bit longer in the winter to warm up the mechanical engine, and for the 3176 engine to reduce engine rpm to the programmed low idle rpm.A load can be applied to the engine after normal oil pressure is reached and the water temperature gauge begins to rise. To get the vehicle in motion, use a gear that will result in a smooth, easy start without increasing engine speed above low idle or slipping the clutch. Engage the clutch smoothly. Interrupted and jerky clutch engagement put stress on the drive train and wastes fuel.Keep engine rpm (speed) at a minimum. Use just enough rpm to pick up the next gear. This technique is called progressive shifting. It can improve fuel consumption and will not harm the engine.Progressive Shifting

Drive line efficiency is best in the low to mid rpm range (1100 to 1600 rpm) of the engine due to reduced frictional losses of the engine, transmission and rear axles. When accelerating under normal level road conditions, the engine should be operated in this most efficient rpm range by using only enough power to pick up the next higher gear. This technique of upshifting at the lowest possible rpm is called progressive shifting.Progressive shifting also reduces the time to accelerate to the desired vehicle speed. Top gear is reached sooner because engine rpm does not have to fall off as far to synchronize the gears of the transmission. The key to progressive shifting is to use minimum rpm, minimum power and upshift early while accelerating the truck.The 3176 can be programmed to limit engine acceleration above pre-programmed engine rpm settings. This feature encourages the operator to practice progressive shifting techniques.Refer to Driving Techniques for Maximum Fuel Economy, form LEDT5092 for more information.Cruising Speed

It's a simple fact that the faster a vehicle is driven, the more fuel it will consume. A few miles per hour (kilometers per hour) can make a significant difference in fuel economy.Increasing cruising speed from 55 to 65 mph (88 to 104 km/h) will increase fuel consumption of a typical class 8 truck approximately 1.0 mpg (0.4 km/L). A practice of

Have questions with 104747-7080?

Group cross 104747-7080 ZEXEL

Komatsu

104747-7080

6273711120

INJECTION-PUMP ASSEMBLY

P162/CUMM

P162/CUMM