Information injection-pump assembly

ZEXEL

104747-7060

1047477060

KOMATSU

6273711110

6273711110

Rating:

Cross reference number

ZEXEL

104747-7060

1047477060

KOMATSU

6273711110

6273711110

Zexel num

Bosch num

Firm num

Name

104747-7060

6273711110 KOMATSU

INJECTION-PUMP ASSEMBLY

P162/CUMM

P162/CUMM

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113orSAEJ967d

1404 Test oil ISO4113orSAEJ967d

Test oil temperature

degC

45

45

50

Nozzle

105780-0060

Bosch type code

NP-DN0SD1510

Nozzle holder

105780-2150

Opening pressure

MPa

13

13

13.3

Opening pressure

kgf/cm2

133

133

136

Injection pipe

157805-7320

Injection pipe

Inside diameter - outside diameter - length (mm) mm 2-6-450

Inside diameter - outside diameter - length (mm) mm 2-6-450

Joint assembly

157641-4720

Tube assembly

157641-4020

Transfer pump pressure

kPa

20

20

20

Transfer pump pressure

kgf/cm2

0.2

0.2

0.2

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Pump speed

r/min

900

900

900

Average injection quantity

mm3/st.

61.8

61.3

62.3

Difference in delivery

mm3/st.

5

Basic

*

Oil temperature

degC

50

48

52

Injection timing adjustment_02

Pump speed

r/min

500

500

500

Average injection quantity

mm3/st.

52.6

48.1

57.1

Oil temperature

degC

48

46

50

Injection timing adjustment_03

Pump speed

r/min

800

800

800

Average injection quantity

mm3/st.

62.6

58.6

66.6

Oil temperature

degC

50

48

52

Injection timing adjustment_04

Pump speed

r/min

900

900

900

Average injection quantity

mm3/st.

61.8

60.3

63.3

Difference in delivery

mm3/st.

5.5

Basic

*

Oil temperature

degC

50

48

52

Injection timing adjustment_05

Pump speed

r/min

1100

1100

1100

Average injection quantity

mm3/st.

56.6

52.6

60.6

Oil temperature

degC

50

48

52

Injection quantity adjustment

Pump speed

r/min

1225

1225

1225

Average injection quantity

mm3/st.

10.7

7.7

13.7

Difference in delivery

mm3/st.

3

Basic

*

Oil temperature

degC

50

48

52

Injection quantity adjustment_02

Pump speed

r/min

1400

1400

1400

Average injection quantity

mm3/st.

3

Oil temperature

degC

50

48

52

Injection quantity adjustment_03

Pump speed

r/min

1225

1225

1225

Average injection quantity

mm3/st.

10.7

6.2

15.2

Basic

*

Oil temperature

degC

50

48

52

Governor adjustment

Pump speed

r/min

400

400

400

Average injection quantity

mm3/st.

8.6

6.6

10.6

Difference in delivery

mm3/st.

2

Basic

*

Oil temperature

degC

48

46

50

Governor adjustment_02

Pump speed

r/min

400

400

400

Average injection quantity

mm3/st.

8.6

6.1

11.1

Difference in delivery

mm3/st.

2.5

Basic

*

Oil temperature

degC

48

46

50

Timer adjustment

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

80

75

85

Basic

*

Oil temperature

degC

48

46

50

Remarks

IDLE

IDLE

Timer adjustment_02

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

80

75

85

Oil temperature

degC

48

46

50

Remarks

IDLE

IDLE

Speed control lever angle

Pump speed

r/min

400

400

400

Average injection quantity

mm3/st.

0

0

0

Oil temperature

degC

48

46

50

Remarks

Magnet OFF at idling position

Magnet OFF at idling position

0000000901

Pump speed

r/min

1100

1100

1100

Overflow quantity

cm3/min

415

285

545

Oil temperature

degC

50

48

52

Stop lever angle

Pump speed

r/min

1100

1100

1100

Pressure

kPa

520

500

540

Pressure

kgf/cm2

5.3

5.1

5.5

Basic

*

Oil temperature

degC

50

48

52

Stop lever angle_02

Pump speed

r/min

900

900

900

Pressure

kPa

441

392

490

Pressure

kgf/cm2

4.5

4

5

Oil temperature

degC

50

48

52

Stop lever angle_03

Pump speed

r/min

1000

1000

1000

Pressure

kPa

481

432

530

Pressure

kgf/cm2

4.9

4.4

5.4

Oil temperature

degC

50

48

52

Stop lever angle_04

Pump speed

r/min

1100

1100

1100

Pressure

kPa

520

491

549

Pressure

kgf/cm2

5.3

5

5.6

Basic

*

Oil temperature

degC

50

48

52

0000001101

Pump speed

r/min

1100

1100

1100

Timer stroke

mm

1.3

1.1

1.5

Basic

*

Oil temperature

degC

50

48

52

_02

Pump speed

r/min

900

900

900

Timer stroke

mm

0.5

Oil temperature

degC

50

48

52

_03

Pump speed

r/min

1100

1100

1100

Timer stroke

mm

1.3

1

1.6

Basic

*

Oil temperature

degC

50

48

52

0000001201

Max. applied voltage

V

8

8

8

Test voltage

V

13

12

14

Timing setting

K dimension

mm

3.3

3.2

3.4

KF dimension

mm

5.8

5.7

5.9

MS dimension

mm

2

1.9

2.1

Control lever angle alpha

deg.

16

12

20

Control lever angle beta

deg.

30

25

35

Test data Ex:

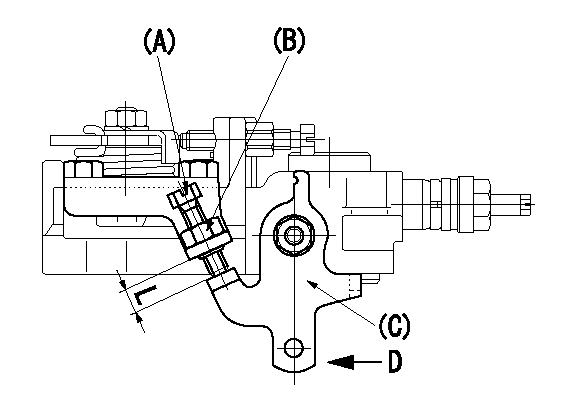

0000001801 STARTING I/Q ADJUSTMENT

Starting Q decrease lever adjustment

Adjust using the screw (A) so that the standards are satisfied, then fix using the nut (B).

Screw B protrusion: L

A = starting Q adjusting bolt

B = starting Q adjusting nut (Tightening torque T)

C = starting Q adjusting lever

D = adjust with the lever pushed in the direction of the arrow.

----------

L=6.3~10.7mm T=6~9Nm(0.6~0.9kgfm)

----------

L=6.3~10.7mm

----------

L=6.3~10.7mm T=6~9Nm(0.6~0.9kgfm)

----------

L=6.3~10.7mm

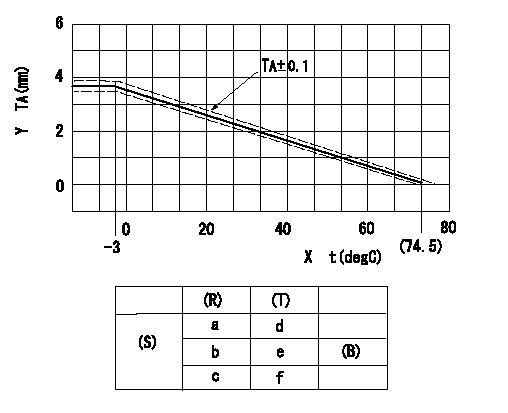

0000001901 W-CSD ADJUSTMENT

Adjustment of the W-CSD

Adjustment of the timer advance angle

1. Determine the timer advance angle using the graph (graph TA).

X:Temperature t (deg C)

Y:Timer stroke TA (mm)

(S) Cold advance

(R) Cooling water temperature (deg C)

(T) Timer piston stroke (mm)

(B) Standard point

----------

TA=-0.053t+3.881 -3degC<=t<=20degC TA=-0.0517t+3.854 20degC<=t

----------

a=76.5++degC b=20degC c=-3degC d=0mm e=2.82+-0.4mm f=4.04+-0.6mm

----------

TA=-0.053t+3.881 -3degC<=t<=20degC TA=-0.0517t+3.854 20degC<=t

----------

a=76.5++degC b=20degC c=-3degC d=0mm e=2.82+-0.4mm f=4.04+-0.6mm

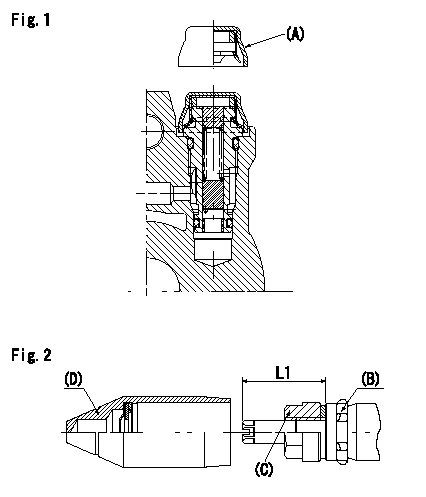

0000002001 TAMPER PROOF

Tamperproof installation procedure

A:Cap

B:Rubber vibration damper

C:Nut

D:Cap

L1:Inspection dimension

Fig. 1 Regulating valve seal

1) Insert the cap A horizontally (press fit).

2) After insertion (press-fitting), tighten the cap to torque T1, and confirm that it is not pulled out at load F1.

Fig.2 Full load adjusting screw

1) Confirm the position of the rubber vibration damper (B) and then tighten nut (C) to the torque T2.

----------

L1=23~28mm F1=49N(5kgf) T1=4.9N-m(0.5kgf-m) T2=7~9N-m(0.7~0.9kgf-m)

----------

L1=23~28mm

----------

L1=23~28mm F1=49N(5kgf) T1=4.9N-m(0.5kgf-m) T2=7~9N-m(0.7~0.9kgf-m)

----------

L1=23~28mm

Information:

PTO Mode Speed Limit (PTO)- Maximum vehicle speed at which the PTO Governor will function (between 0 and 15 mph [0 and 24 km/h]). If vehicle speed signal exceeds the programmed value, the control will exit the PTO Mode. PTO Mode RPM Limit (PTO RPM)- Maximum engine rpm attainable in the PTO Mode. The rpm limits are between 600 and 2300 rpm. PTO Engine Speed Ramp Rate- Engine rpm (speed) rate of increase. This parameter determines ACCEL, DECEL and RESUME PTO Engine rates of increase/decrease. The programmable limits are between 50 rpm/second and 500 rpm/second. Low Gears #1 RPM Limit (LoGr #1)- Engine speed is limited below Low Gear #1 Turn Off Speed. The engine will hesitate at this speed then allow slow acceleration up to Top Engine Limit (TEL). This is to encourage shifting to the next higher gear. The limits are between 1100 and 2300 rpm. Low Gears #1 Turn Off (Lo Gr Off)- The vehicle speed at which LoGr #1 RPM Limit is no longer in effect (turns off between 3 and 30 mph [5 and 48 km/h]). This parameter must be matched with Low Gear #1 RPM Limit to the specific drive train for best performance. Low Gears #2 RPM Limit (LoGr #2)- Similar to Low Gears #1 RPM Limit and typically programmed at a slightly higher rpm. The limits are between 1100 and 2300 rpm. Low Gears #2 Turn Off (LoGr TO)- Similar to Low Gears #1 Turn Off and typically programmed at a slightly higher rpm. The limits are between 5 and 50 mph [8 and 80 km/h]). High Gears RPM Limit (HiGr RPM)- The rpm limit when the vehicle speed is above High Gear Turn On Speed. This is a "hard" limit; the engine will not power above this limit to encourage shifting up into overdrive or top gear. The limits are between 1300 and 2300 rpm. High Gear Turn On Speed (HiGr On)- Vehicle speed where High Gear RPM Limit turns on. This parameter must be matched to the specific drive train for best performance. The limits are between 30 and 127 mph (48 and 204 km/h). Top Engine Limit (TEL)- Maximum allowable engine rpm when the engine is under load. The engine will still achieve Rated rpm (speed) under no load conditions. This parameter is dependent upon Rating Number, with some Rating Numbers allowing no or little variation. The limits are between 1600 and 3000 rpm. Low Engine Idle rpm- Minimum programmed engine rpm (between 600 and 750 rpm). Vehicle Speed Limit- Top vehicle speed the ECM will permit. The ECM will shut off fuel above this speed. The limits are between 30 and 127 mph (48 and 204 km/h and/or gear limit of vehicle. Engine RPM at Vehicle Speed Limit (Eng RPM at VSL)- The maximum rpm that the engine will operate when the vehicle speed signal reaches VSL, or when the ECM detects a vehicle speed signal problem (the ECM will limit engine to this rpm

Have questions with 104747-7060?

Group cross 104747-7060 ZEXEL

Komatsu

104747-7060

6273711110

INJECTION-PUMP ASSEMBLY

P162/CUMM

P162/CUMM