Information injection-pump assembly

BOSCH

9 460 614 564

9460614564

ZEXEL

104745-9410

1047459410

NISSAN

167002H210

167002h210

Rating:

Cross reference number

BOSCH

9 460 614 564

9460614564

ZEXEL

104745-9410

1047459410

NISSAN

167002H210

167002h210

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113orSAEJ967d

1404 Test oil ISO4113orSAEJ967d

Test oil temperature

degC

45

45

50

Nozzle

105780-0060

Bosch type code

NP-DN0SD1510

Nozzle holder

105780-2150

Opening pressure

MPa

13

13

13.3

Opening pressure

kgf/cm2

133

133

136

Injection pipe

157805-7320

Injection pipe

Inside diameter - outside diameter - length (mm) mm 2-6-450

Inside diameter - outside diameter - length (mm) mm 2-6-450

Joint assembly

157641-4720

Tube assembly

157641-4020

Transfer pump pressure

kPa

20

20

20

Transfer pump pressure

kgf/cm2

0.2

0.2

0.2

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Pump speed

r/min

1100

1100

1100

Average injection quantity

mm3/st.

44.2

43.7

44.7

Difference in delivery

mm3/st.

4

Basic

*

Oil temperature

degC

50

48

52

Injection timing adjustment_02

Pump speed

r/min

500

500

500

Average injection quantity

mm3/st.

38

35

41

Oil temperature

degC

48

46

50

Injection timing adjustment_03

Pump speed

r/min

850

850

850

Average injection quantity

mm3/st.

41.2

38.7

43.7

Oil temperature

degC

50

48

52

Injection timing adjustment_04

Pump speed

r/min

1100

1100

1100

Average injection quantity

mm3/st.

44.2

43.2

45.2

Difference in delivery

mm3/st.

4.5

Basic

*

Oil temperature

degC

50

48

52

Injection timing adjustment_05

Pump speed

r/min

2150

2150

2150

Average injection quantity

mm3/st.

46

43.5

48.5

Oil temperature

degC

52

50

54

Injection quantity adjustment

Pump speed

r/min

2550

2550

2550

Average injection quantity

mm3/st.

18.5

16.5

20.5

Basic

*

Oil temperature

degC

55

52

58

Injection quantity adjustment_02

Pump speed

r/min

2800

2800

2800

Average injection quantity

mm3/st.

5

Oil temperature

degC

55

52

58

Injection quantity adjustment_03

Pump speed

r/min

2400

2400

2400

Average injection quantity

mm3/st.

37.4

32.9

41.9

Oil temperature

degC

52

50

54

Injection quantity adjustment_04

Pump speed

r/min

2550

2550

2550

Average injection quantity

mm3/st.

18.5

15.5

21.5

Basic

*

Oil temperature

degC

55

52

58

Governor adjustment

Pump speed

r/min

350

350

350

Average injection quantity

mm3/st.

8.9

6.9

10.9

Difference in delivery

mm3/st.

2

Basic

*

Oil temperature

degC

48

46

50

Governor adjustment_02

Pump speed

r/min

350

350

350

Average injection quantity

mm3/st.

8.9

6.4

11.4

Difference in delivery

mm3/st.

2.5

Basic

*

Oil temperature

degC

48

46

50

Timer adjustment

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

48.9

43.9

53.9

Basic

*

Oil temperature

degC

48

46

50

Remarks

Full

Full

Timer adjustment_02

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

48.9

43.9

53.9

Oil temperature

degC

48

46

50

Remarks

Full

Full

Speed control lever angle

Pump speed

r/min

350

350

350

Average injection quantity

mm3/st.

0

0

0

Oil temperature

degC

48

46

50

Remarks

Magnet OFF at idling position

Magnet OFF at idling position

0000000901

Pump speed

r/min

1100

1100

1100

Overflow quantity

cm3/min

390

260

520

Oil temperature

degC

50

48

52

Stop lever angle

Pump speed

r/min

1100

1100

1100

Pressure

kPa

490

461

519

Pressure

kgf/cm2

5

4.7

5.3

Basic

*

Oil temperature

degC

50

48

52

Stop lever angle_02

Pump speed

r/min

1100

1100

1100

Pressure

kPa

490

451

529

Pressure

kgf/cm2

5

4.6

5.4

Basic

*

Oil temperature

degC

50

48

52

Stop lever angle_03

Pump speed

r/min

1700

1700

1700

Pressure

kPa

637

598

676

Pressure

kgf/cm2

6.5

6.1

6.9

Oil temperature

degC

50

48

52

0000001101

Pump speed

r/min

1100

1100

1100

Timer stroke

mm

4.2

4

4.4

Basic

*

Oil temperature

degC

50

48

52

_02

Pump speed

r/min

700

700

700

Timer stroke

mm

1.9

1.5

2.3

Oil temperature

degC

50

48

52

_03

Pump speed

r/min

1100

1100

1100

Timer stroke

mm

4.2

3.9

4.5

Basic

*

Oil temperature

degC

50

48

52

_04

Pump speed

r/min

1700

1700

1700

Timer stroke

mm

7.3

6.8

7.8

Oil temperature

degC

50

48

52

_05

Pump speed

r/min

2200

2200

2200

Timer stroke

mm

9

8.5

9.4

Oil temperature

degC

52

50

54

0000001201

Max. applied voltage

V

8

8

8

Test voltage

V

13

12

14

0000001401

Pump speed

r/min

1100

1100

1100

Average injection quantity

mm3/st.

32

31.5

32.5

Timer stroke TA

mm

2.9

2.7

3.1

Timer stroke variation dT

mm

1.3

1.3

1.3

Basic

*

Oil temperature

degC

50

48

52

_02

Pump speed

r/min

1100

1100

1100

Average injection quantity

mm3/st.

32

31

33

Timer stroke TA

mm

2.9

2.6

3.2

Basic

*

Oil temperature

degC

50

48

52

_03

Pump speed

r/min

1100

1100

1100

Average injection quantity

mm3/st.

22

19.5

24.5

Timer stroke TA

mm

1.6

1.2

2

Oil temperature

degC

50

48

52

Timing setting

K dimension

mm

3.3

3.2

3.4

KF dimension

mm

6.36

6.26

6.46

MS dimension

mm

0.9

0.8

1

Control lever angle alpha

deg.

25

23

27

Control lever angle beta

deg.

36

31

41

Test data Ex:

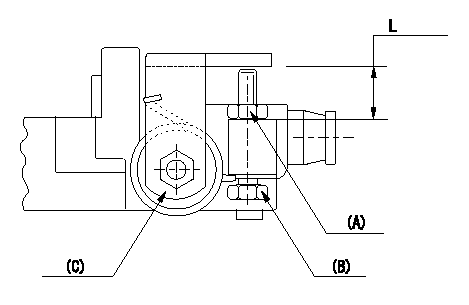

0000001801 STOP LEVER ADJUSTMENT

Adjustment of the stop lever

Adjust adjusting bolt (B) so that the starting injection quantity is within the standard.

Fix using nut.

(A) Adjusting nut

(C) Starting injection quantity adjusting lever

----------

----------

L=15.0~18.5mm

----------

----------

L=15.0~18.5mm

Information:

1. Remove the seat retaining ring (1) and pin (2). 2. Remove the seat (3), bolt (4), washers (5) and spring (6).3. Remove the sleeve and bearing assembly from the cylinder and weight assemblies. 4. Remove the retaining ring (7) from sleeve (8).5. Remove bearing (9) and races (10) from sleeve (8). 6. Remove the valve (11) from piston (12).7. Remove the cylinder-to-weight assembly retaining ring (13).8. Remove the weight assembly (14).9. Remove piston (12) and sleeve (15) from the cylinder (16).10. Remove the O-ring seal from the sleeve (15). 11. Remove the speed limiter plug (17), spring (18), and plunger (19) from the governor housing.12. Remove the high idle screw (21) and low idle screw (20). 13. Remove the lever assembly-to-shaft assembly retaining bolt (23) and lock.14. Remove the shaft assembly (22) and lever assembly (24) from governor housing.15. Remove the seal from governor housing. 16. Remove two retaining bolts (25) and lock. Remove the lever (26) and shaft (27) from idle screw housing.17. Remove two seals and bearing from idle screw housing.Assemble Governor

1. Using tool (A) install the inner seal in idle screw housing with spring side of seal facing the driver. Install bearing and outer seal with lip of the seal toward the inside of the housing. Lubricate lip of seal with clean SAE 30 engine oil.2. Position the shaft and lever in the idle screw housing. Install the retaining bolts and lock. 3. Using tool (A), install the seal in the governor housing with spring side of seal toward inside of governor housing. Lubricate lip of seal with clean SAE 30 engine oil.4. Position the lever assembly and shaft in the governor housing. Install the retaining bolt and lock.5. Install the high and low idle screws in the governor housing.6. Install the speed limiter plug, spring, and plunger in the governor housing. 7. Install the O-ring seal (3) on sleeve (4).8. Install piston (2) and sleeve (4) in the cylinder (1). 9. Position the weight assembly (6) on cylinder (7), and install retaining ring (5). 10. Install the valve (9) in piston (10).11. Install the bearing and races in sleeve. Install retaining ring. Install the sleeve and bearing assembly (8) on valve (9). 12. Position the seat (12), bolt (11), washers and spring on the valve (9). Install the retaining pin (14) and retaining ring (13).concluding step: a) connect governor to fuel injection pump housing

1. Using tool (A) install the inner seal in idle screw housing with spring side of seal facing the driver. Install bearing and outer seal with lip of the seal toward the inside of the housing. Lubricate lip of seal with clean SAE 30 engine oil.2. Position the shaft and lever in the idle screw housing. Install the retaining bolts and lock. 3. Using tool (A), install the seal in the governor housing with spring side of seal toward inside of governor housing. Lubricate lip of seal with clean SAE 30 engine oil.4. Position the lever assembly and shaft in the governor housing. Install the retaining bolt and lock.5. Install the high and low idle screws in the governor housing.6. Install the speed limiter plug, spring, and plunger in the governor housing. 7. Install the O-ring seal (3) on sleeve (4).8. Install piston (2) and sleeve (4) in the cylinder (1). 9. Position the weight assembly (6) on cylinder (7), and install retaining ring (5). 10. Install the valve (9) in piston (10).11. Install the bearing and races in sleeve. Install retaining ring. Install the sleeve and bearing assembly (8) on valve (9). 12. Position the seat (12), bolt (11), washers and spring on the valve (9). Install the retaining pin (14) and retaining ring (13).concluding step: a) connect governor to fuel injection pump housing