Information injection-pump assembly

ZEXEL

104745-9350

1047459350

Rating:

Cross reference number

ZEXEL

104745-9350

1047459350

Zexel num

Bosch num

Firm num

Name

104745-9350

INJECTION-PUMP ASSEMBLY

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113orSAEJ967d

1404 Test oil ISO4113orSAEJ967d

Test oil temperature

degC

45

45

50

Nozzle

105780-0060

Bosch type code

NP-DN0SD1510

Nozzle holder

105780-2150

Opening pressure

MPa

13

13

13.3

Opening pressure

kgf/cm2

133

133

136

Injection pipe

157805-7320

Injection pipe

Inside diameter - outside diameter - length (mm) mm 2-6-450

Inside diameter - outside diameter - length (mm) mm 2-6-450

Joint assembly

157641-4720

Tube assembly

157641-4020

Transfer pump pressure

kPa

20

20

20

Transfer pump pressure

kgf/cm2

0.2

0.2

0.2

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Pump speed

r/min

1100

1100

1100

Average injection quantity

mm3/st.

49.9

49.4

50.4

Difference in delivery

mm3/st.

4

Basic

*

Oil temperature

degC

50

48

52

Injection timing adjustment_02

Pump speed

r/min

500

500

500

Average injection quantity

mm3/st.

41.3

38.8

43.8

Oil temperature

degC

48

46

50

Injection timing adjustment_03

Pump speed

r/min

1100

1100

1100

Average injection quantity

mm3/st.

49.9

48.9

50.9

Difference in delivery

mm3/st.

4.5

Basic

*

Oil temperature

degC

50

48

52

Injection timing adjustment_04

Pump speed

r/min

2150

2150

2150

Average injection quantity

mm3/st.

46.3

43.8

48.8

Oil temperature

degC

52

50

54

Injection quantity adjustment

Pump speed

r/min

2550

2550

2550

Average injection quantity

mm3/st.

10.9

8.9

12.9

Difference in delivery

mm3/st.

3

Basic

*

Oil temperature

degC

55

52

58

Injection quantity adjustment_02

Pump speed

r/min

2700

2700

2700

Average injection quantity

mm3/st.

5

Oil temperature

degC

55

52

58

Injection quantity adjustment_03

Pump speed

r/min

2350

2350

2350

Average injection quantity

mm3/st.

39.7

39.7

39.7

Oil temperature

degC

52

50

54

Injection quantity adjustment_04

Pump speed

r/min

2550

2550

2550

Average injection quantity

mm3/st.

10.9

8.4

13.4

Basic

*

Oil temperature

degC

55

52

58

Governor adjustment

Pump speed

r/min

350

350

350

Average injection quantity

mm3/st.

7.7

5.7

9.7

Difference in delivery

mm3/st.

2

Basic

*

Oil temperature

degC

48

46

50

Governor adjustment_02

Pump speed

r/min

350

350

350

Average injection quantity

mm3/st.

7.7

5.2

10.2

Difference in delivery

mm3/st.

2.5

Basic

*

Oil temperature

degC

48

46

50

Timer adjustment

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

60

45

80

Basic

*

Oil temperature

degC

48

46

50

Remarks

Full

Full

Timer adjustment_02

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

60

45

80

Oil temperature

degC

48

46

50

Remarks

Full

Full

Speed control lever angle

Pump speed

r/min

350

350

350

Average injection quantity

mm3/st.

0

0

0

Oil temperature

degC

48

46

50

Remarks

Magnet OFF at idling position

Magnet OFF at idling position

0000000901

Pump speed

r/min

1100

1100

1100

Overflow quantity with S/T ON

cm3/min

390

260

520

Oil temperature

degC

50

48

52

Remarks

With S/T O-ring; S/T ON.

With S/T O-ring; S/T ON.

_02

Pump speed

r/min

1100

1100

1100

Overflow quantity with S/T ON

cm3/min

600

470

730

Oil temperature

degC

50

48

52

Remarks

Without S/T O-ring; S/T ON.

Without S/T O-ring; S/T ON.

Stop lever angle

Pump speed

r/min

1100

1100

1100

Pressure with S/T ON

kPa

520

481

559

Pressure with S/T ON

kgf/cm2

5.3

4.9

5.7

Pressure with S/T OFF

kPa

431

402

460

Pressure with S/T OFF

kgf/cm2

4.4

4.1

4.7

Basic

*

Oil temperature

degC

50

48

52

Remarks

OFF

OFF

Stop lever angle_02

Pump speed

r/min

1100

1100

1100

Pressure with S/T OFF

kPa

431

392

470

Pressure with S/T OFF

kgf/cm2

4.4

4

4.8

Basic

*

Oil temperature

degC

50

48

52

Stop lever angle_03

Pump speed

r/min

1700

1700

1700

Pressure with S/T OFF

kPa

559

520

598

Pressure with S/T OFF

kgf/cm2

5.7

5.3

6.1

Oil temperature

degC

50

48

52

0000001101

Pump speed

r/min

1100

1100

1100

Timer stroke with S/T ON

mm

3.4

3

3.8

Timer stroke with S/T OFF

mm

1.9

1.7

2.1

Basic

*

Oil temperature

degC

50

48

52

Remarks

OFF

OFF

_02

Pump speed

r/min

850

850

850

Timer stroke with S/T OFF

mm

0.5

0

1

Oil temperature

degC

50

48

52

_03

Pump speed

r/min

1100

1100

1100

Timer stroke with S/T ON

mm

3.4

2.9

3.9

Timer stroke with S/T OFF

mm

1.9

1.6

2.2

Basic

*

Oil temperature

degC

50

48

52

_04

Pump speed

r/min

1700

1700

1700

Timer stroke with S/T OFF

mm

4.4

3.9

4.9

Oil temperature

degC

50

48

52

_05

Pump speed

r/min

2300

2300

2300

Timer stroke with S/T OFF

mm

6.1

5.6

6.5

Oil temperature

degC

52

50

54

0000001201

Max. applied voltage

V

8

8

8

Test voltage

V

13

12

14

0000001401

Pump speed

r/min

1100

1100

1100

Average injection quantity

mm3/st.

31

30.5

31.5

Timer stroke TA

mm

1.2

1

1.4

Timer stroke variation dT

mm

0.7

0.7

0.7

Basic

*

Oil temperature

degC

50

48

52

_02

Pump speed

r/min

1100

1100

1100

Average injection quantity

mm3/st.

31

30

32

Timer stroke TA

mm

1.2

0.9

1.5

Basic

*

Oil temperature

degC

50

48

52

_03

Pump speed

r/min

1100

1100

1100

Average injection quantity

mm3/st.

22

19.5

24.5

Timer stroke TA

mm

0.6

0.1

1.1

Oil temperature

degC

50

48

52

Timing setting

K dimension

mm

3.3

3.2

3.4

KF dimension

mm

5.8

5.7

5.9

MS dimension

mm

0.9

0.8

1

Pre-stroke

mm

0.1

0.08

0.12

Control lever angle alpha

deg.

25

23

27

Control lever angle beta

deg.

36

31

41

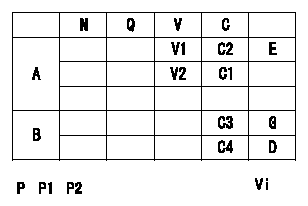

Test data Ex:

0000001801 POTENTIOMETER ADJUSTMENT

A:Potentiometer standards

B:ON, OFF switch standard

G:ON-->OFF

D:OFF-->ON

E:Adjusting point

F:Checking point

P:Boost pressure

Vi:Applied voltage

C1:Full-speed

C2:Idle

Q:Injection quantity

N:Pump speed

V:Output voltage

C:Control lever angle

----------

----------

V1=1.6+-0.03V V2=7.6+-1.1V C3=(4.9+-2.5)deg C4=(19.4+-4)deg Vi=10V P1=-kPa P2=-mmHg

----------

----------

V1=1.6+-0.03V V2=7.6+-1.1V C3=(4.9+-2.5)deg C4=(19.4+-4)deg Vi=10V P1=-kPa P2=-mmHg

Information:

Connecting Rod

Use the 2H6782 Connecting Rod Boring Machine to recondition connecting rods and to check for connecting rod distortion. The 5P2009 Rework Group is available for the 2H6782 Connecting Rod Boring Machine. To install the rework group see Special Instruction GMG02394.Press a new piston pin bushing into the connecting rod. Assemble new rod bearings and the expansion sleeve. Tighten rod bolt nuts in the following step sequence.1. Put crankcase oil on bolt threads and seating faces of cap and nut.2. Tighten both nuts to 30 3 lb. ft. (40 4 N m).3. Put a mark on each nut and cap.4. Tighten each nut 60° from the mark.Clean spindle and slide the expansion sleeve and connecting rod into place. Install and tighten nut hand tight.Adjust the carrier to the distance between center of the bores, [center-to-center distance is 7.900 .001 in. (200.66 0.03 mm)]. Position the locating rods .25 in. (6.4 mm) from the connecting rod. Install front bushing in bracket and insert locating arbor through front bushing. Slide the centering sleeve over the end of the locating arbor. Slide the locating arbor through the rear bushing, centering sleeve, and into the connecting rod. Tighten knobs until locating rods lightly contact the connecting rod. Lock the locating rods and carrier.To check connecting rod distortion, slide locating arbor in and out of rear bushing. If the locating arbor does not slide freely, recheck horizontal location. If the locating arbor still binds, loosen the carrier clamp and raise or lower the carrier until the locating arbor slides freely. Read the vernier scale and note the variation from the nominal dimension. If the variation exceeds .010 in. (0.25 mm) the rod is distorted and should be replaced. Mark replacement rods for cylinder identification on bearing tab slot side of rod and cap.With the center-to-center distance set to the nominal dimension, set tool in boring bar and insert the boring bar and front bushing. Connect boring bar to the feed mechanism and engage the feed lever. Install the hand crank or an electric drill and flexible adapter and bore the bushing. Use a slow feed rate. Check the bore size. The size is 1.5010 .0003 in. (48.125 0.008 mm). A 5P2050 Connecting Rod Checking Fixture is available for checking connecting rods. For instructions for the use of the checking fixture see Special Instruction SMHS7366.Install connecting rod into piston with boss on rod on same side as crater in piston crown.

CONNECTING ROD AND PISTONWhen installing connecting rod and piston assemblies, inspect the threads of the rod bolts and nuts for damage. The contact surface of the nuts must be flat and free from damage. Damaged parts must be replaced.

Use the 2H6782 Connecting Rod Boring Machine to recondition connecting rods and to check for connecting rod distortion. The 5P2009 Rework Group is available for the 2H6782 Connecting Rod Boring Machine. To install the rework group see Special Instruction GMG02394.Press a new piston pin bushing into the connecting rod. Assemble new rod bearings and the expansion sleeve. Tighten rod bolt nuts in the following step sequence.1. Put crankcase oil on bolt threads and seating faces of cap and nut.2. Tighten both nuts to 30 3 lb. ft. (40 4 N m).3. Put a mark on each nut and cap.4. Tighten each nut 60° from the mark.Clean spindle and slide the expansion sleeve and connecting rod into place. Install and tighten nut hand tight.Adjust the carrier to the distance between center of the bores, [center-to-center distance is 7.900 .001 in. (200.66 0.03 mm)]. Position the locating rods .25 in. (6.4 mm) from the connecting rod. Install front bushing in bracket and insert locating arbor through front bushing. Slide the centering sleeve over the end of the locating arbor. Slide the locating arbor through the rear bushing, centering sleeve, and into the connecting rod. Tighten knobs until locating rods lightly contact the connecting rod. Lock the locating rods and carrier.To check connecting rod distortion, slide locating arbor in and out of rear bushing. If the locating arbor does not slide freely, recheck horizontal location. If the locating arbor still binds, loosen the carrier clamp and raise or lower the carrier until the locating arbor slides freely. Read the vernier scale and note the variation from the nominal dimension. If the variation exceeds .010 in. (0.25 mm) the rod is distorted and should be replaced. Mark replacement rods for cylinder identification on bearing tab slot side of rod and cap.With the center-to-center distance set to the nominal dimension, set tool in boring bar and insert the boring bar and front bushing. Connect boring bar to the feed mechanism and engage the feed lever. Install the hand crank or an electric drill and flexible adapter and bore the bushing. Use a slow feed rate. Check the bore size. The size is 1.5010 .0003 in. (48.125 0.008 mm). A 5P2050 Connecting Rod Checking Fixture is available for checking connecting rods. For instructions for the use of the checking fixture see Special Instruction SMHS7366.Install connecting rod into piston with boss on rod on same side as crater in piston crown.

CONNECTING ROD AND PISTONWhen installing connecting rod and piston assemblies, inspect the threads of the rod bolts and nuts for damage. The contact surface of the nuts must be flat and free from damage. Damaged parts must be replaced.

Have questions with 104745-9350?

Group cross 104745-9350 ZEXEL

Nissan

Nissan-Diesel

Nissan

Nissan-Diesel

Nissan

Nissan-Diesel

Nissan

Nissan-Diesel

Nissan

Nissan-Diesel

Nissan

Nissan-Diesel

Nissan

Nissan-Diesel

104745-9350

INJECTION-PUMP ASSEMBLY