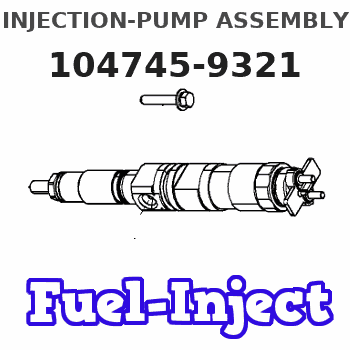

Information injection-pump assembly

BOSCH

9 460 614 560

9460614560

ZEXEL

104745-9321

1047459321

NISSAN

1670065N01

1670065n01

Rating:

Cross reference number

BOSCH

9 460 614 560

9460614560

ZEXEL

104745-9321

1047459321

NISSAN

1670065N01

1670065n01

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113orSAEJ967d

1404 Test oil ISO4113orSAEJ967d

Test oil temperature

degC

45

45

50

Nozzle

105780-0060

Bosch type code

NP-DN0SD1510

Nozzle holder

105780-2150

Opening pressure

MPa

13

13

13.3

Opening pressure

kgf/cm2

133

133

136

Injection pipe

157805-7320

Injection pipe

Inside diameter - outside diameter - length (mm) mm 2-6-450

Inside diameter - outside diameter - length (mm) mm 2-6-450

Joint assembly

157641-4720

Tube assembly

157641-4020

Transfer pump pressure

kPa

20

20

20

Transfer pump pressure

kgf/cm2

0.2

0.2

0.2

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Pump speed

r/min

1100

1100

1100

Average injection quantity

mm3/st.

52.2

51.7

52.7

Difference in delivery

mm3/st.

4

Basic

*

Oil temperature

degC

50

48

52

Injection timing adjustment_02

Pump speed

r/min

500

500

500

Average injection quantity

mm3/st.

44.6

41.6

47.6

Oil temperature

degC

48

46

50

Injection timing adjustment_03

Pump speed

r/min

850

850

850

Average injection quantity

mm3/st.

49.8

47.3

52.3

Oil temperature

degC

50

48

52

Injection timing adjustment_04

Pump speed

r/min

1100

1100

1100

Average injection quantity

mm3/st.

52.2

51.2

53.2

Difference in delivery

mm3/st.

4.5

Basic

*

Oil temperature

degC

50

48

52

Injection timing adjustment_05

Pump speed

r/min

2150

2150

2150

Average injection quantity

mm3/st.

47.2

44.7

49.7

Oil temperature

degC

52

50

54

Injection quantity adjustment

Pump speed

r/min

2550

2550

2550

Average injection quantity

mm3/st.

19.8

17.8

21.8

Basic

*

Oil temperature

degC

55

52

58

Injection quantity adjustment_02

Pump speed

r/min

2800

2800

2800

Average injection quantity

mm3/st.

5

Oil temperature

degC

55

52

58

Injection quantity adjustment_03

Pump speed

r/min

2250

2250

2250

Average injection quantity

mm3/st.

45.9

45.9

45.9

Oil temperature

degC

52

50

54

Injection quantity adjustment_04

Pump speed

r/min

2550

2550

2550

Average injection quantity

mm3/st.

19.8

17.3

22.3

Basic

*

Oil temperature

degC

55

52

58

Governor adjustment

Pump speed

r/min

350

350

350

Average injection quantity

mm3/st.

7.8

5.8

9.8

Difference in delivery

mm3/st.

2

Basic

*

Oil temperature

degC

48

46

50

Governor adjustment_02

Pump speed

r/min

350

350

350

Average injection quantity

mm3/st.

7.8

5.3

10.3

Difference in delivery

mm3/st.

2.5

Basic

*

Oil temperature

degC

48

46

50

Timer adjustment

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

75

60

95

Basic

*

Oil temperature

degC

48

46

50

Timer adjustment_02

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

75

60

95

Oil temperature

degC

48

46

50

Speed control lever angle

Pump speed

r/min

350

350

350

Average injection quantity

mm3/st.

0

0

0

Oil temperature

degC

48

46

50

Remarks

Magnet OFF

Magnet OFF

0000000901

Pump speed

r/min

1100

1100

1100

Overflow quantity

cm3/min

390

260

520

Oil temperature

degC

50

48

52

Stop lever angle

Pump speed

r/min

1100

1100

1100

Pressure

kPa

490

461

519

Pressure

kgf/cm2

5

4.7

5.3

Basic

*

Oil temperature

degC

50

48

52

Stop lever angle_02

Pump speed

r/min

1100

1100

1100

Pressure

kPa

490

451

529

Pressure

kgf/cm2

5

4.6

5.4

Basic

*

Oil temperature

degC

50

48

52

Stop lever angle_03

Pump speed

r/min

1700

1700

1700

Pressure

kPa

637

598

676

Pressure

kgf/cm2

6.5

6.1

6.9

Oil temperature

degC

50

48

52

0000001101

Pump speed

r/min

1100

1100

1100

Timer stroke

mm

4.2

4

4.4

Basic

*

Oil temperature

degC

50

48

52

_02

Pump speed

r/min

700

700

700

Timer stroke

mm

1.9

1.4

2.4

Oil temperature

degC

50

48

52

_03

Pump speed

r/min

1100

1100

1100

Timer stroke

mm

4.2

3.9

4.5

Basic

*

Oil temperature

degC

50

48

52

_04

Pump speed

r/min

1700

1700

1700

Timer stroke

mm

7.3

6.8

7.8

Oil temperature

degC

50

48

52

_05

Pump speed

r/min

2200

2200

2200

Timer stroke

mm

9

8.5

9.4

Oil temperature

degC

52

50

54

0000001201

Max. applied voltage

V

8

8

8

Test voltage

V

13

12

14

0000001401

Pump speed

r/min

1100

1100

1100

Average injection quantity

mm3/st.

40.5

40

41

Timer stroke TA

mm

3.9

3.9

3.9

Timer stroke variation dT

mm

0.3

0.1

0.5

Basic

*

Oil temperature

degC

50

48

52

_02

Pump speed

r/min

1100

1100

1100

Average injection quantity

mm3/st.

40.5

39.5

41.5

Timer stroke variation dT

mm

0.3

0

0.6

Basic

*

Oil temperature

degC

50

48

52

_03

Pump speed

r/min

1100

1100

1100

Average injection quantity

mm3/st.

30

27.5

32.5

Timer stroke variation dT

mm

0.9

0.5

1.3

Oil temperature

degC

50

48

52

Timing setting

K dimension

mm

3.3

3.2

3.4

KF dimension

mm

6.36

6.26

6.46

MS dimension

mm

0.9

0.8

1

Control lever angle alpha

deg.

25

23

27

Control lever angle beta

deg.

36

31

41

Information:

TIMING PIN AND PULLER INSTALLED (Typical Example)

1. FT887 Timing Pin. (Fabricated Tool.) 2. 9S8520 Puller Group.5. Install the 1P2320 Puller and remove the camshaft small outer gear.

PULLING SMALL OUTER GEAR6. Remove the spacer immediately behind the gear.7. Install the 1P2321 Puller and remove the camshaft large inner gear.

PULLING LARGE INNER GEARInstall Camshaft Gears

1. Heat both gears to a maximum temperature of 600° F (315° C) before installing on camshaft.2. Align keyway of large inner gear with key in camshaft. Install large inner gear on camshaft with timing mark on gear aligned with timing mark on crankshaft gear.

TIMING MARKS3. Install the spacer and small outer gear on the camshaft.

Do not drive gears onto camshaft. Serious damage can result to camshaft or camshaft thrust pin.

4. Position the automatic timing advance unit on the fuel injection pump camshaft.5. Install the tachometer drive adapter shaft and tighten shaft retaining nut to 32 2 lb. ft. (4.4 0.3 mkg).6. Remove timing pin from fuel injection pump housing and install the plug.