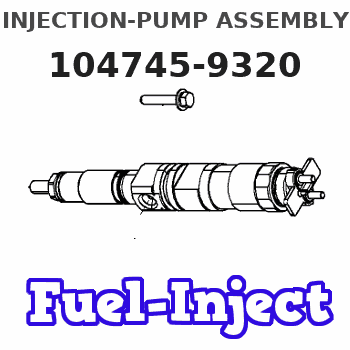

Information injection-pump assembly

ZEXEL

104745-9320

1047459320

Rating:

Cross reference number

ZEXEL

104745-9320

1047459320

Zexel num

Bosch num

Firm num

Name

104745-9320

INJECTION-PUMP ASSEMBLY

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113orSAEJ967d

1404 Test oil ISO4113orSAEJ967d

Test oil temperature

degC

45

45

50

Nozzle

105780-0060

Bosch type code

NP-DN0SD1510

Nozzle holder

105780-2150

Opening pressure

MPa

13

13

13.3

Opening pressure

kgf/cm2

133

133

136

Injection pipe

157805-7320

Injection pipe

Inside diameter - outside diameter - length (mm) mm 2-6-450

Inside diameter - outside diameter - length (mm) mm 2-6-450

Joint assembly

157641-4720

Tube assembly

157641-4020

Transfer pump pressure

kPa

20

20

20

Transfer pump pressure

kgf/cm2

0.2

0.2

0.2

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Pump speed

r/min

1100

1100

1100

Average injection quantity

mm3/st.

49.9

49.4

50.4

Difference in delivery

mm3/st.

4

Basic

*

Oil temperature

degC

50

48

52

Injection timing adjustment_02

Pump speed

r/min

500

500

500

Average injection quantity

mm3/st.

43.8

41.3

46.3

Oil temperature

degC

48

46

50

Injection timing adjustment_03

Pump speed

r/min

1100

1100

1100

Average injection quantity

mm3/st.

52.4

51.4

53.4

Difference in delivery

mm3/st.

4.5

Basic

*

Oil temperature

degC

50

48

52

Injection timing adjustment_04

Pump speed

r/min

2150

2150

2150

Average injection quantity

mm3/st.

48.8

46.3

51.3

Oil temperature

degC

52

50

54

Injection quantity adjustment

Pump speed

r/min

2550

2550

2550

Average injection quantity

mm3/st.

10.9

8.9

12.9

Difference in delivery

mm3/st.

3

Basic

*

Oil temperature

degC

55

52

58

Injection quantity adjustment_02

Pump speed

r/min

2700

2700

2700

Average injection quantity

mm3/st.

5

Oil temperature

degC

55

52

58

Injection quantity adjustment_03

Pump speed

r/min

2350

2350

2350

Average injection quantity

mm3/st.

35.6

35.6

35.6

Oil temperature

degC

52

50

54

Injection quantity adjustment_04

Pump speed

r/min

2550

2550

2550

Average injection quantity

mm3/st.

10.9

8.4

13.4

Basic

*

Oil temperature

degC

55

52

58

Governor adjustment

Pump speed

r/min

350

350

350

Average injection quantity

mm3/st.

7.7

5.7

9.7

Difference in delivery

mm3/st.

2

Basic

*

Oil temperature

degC

48

46

50

Governor adjustment_02

Pump speed

r/min

350

350

350

Average injection quantity

mm3/st.

7.7

5.2

10.2

Difference in delivery

mm3/st.

2.5

Basic

*

Oil temperature

degC

48

46

50

Timer adjustment

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

60

45

80

Basic

*

Oil temperature

degC

48

46

50

Remarks

Full

Full

Timer adjustment_02

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

60

45

80

Oil temperature

degC

48

46

50

Remarks

Full

Full

Speed control lever angle

Pump speed

r/min

350

350

350

Average injection quantity

mm3/st.

0

0

0

Oil temperature

degC

48

46

50

Remarks

Magnet OFF at idling position

Magnet OFF at idling position

0000000901

Pump speed

r/min

1100

1100

1100

Overflow quantity

cm3/min

390

260

520

Oil temperature

degC

50

48

52

Stop lever angle

Pump speed

r/min

1100

1100

1100

Pressure

kPa

431

402

460

Pressure

kgf/cm2

4.4

4.1

4.7

Basic

*

Oil temperature

degC

50

48

52

Stop lever angle_02

Pump speed

r/min

1100

1100

1100

Pressure

kPa

431

392

470

Pressure

kgf/cm2

4.4

4

4.8

Basic

*

Oil temperature

degC

50

48

52

Stop lever angle_03

Pump speed

r/min

1700

1700

1700

Pressure

kPa

559

520

598

Pressure

kgf/cm2

5.7

5.3

6.1

Oil temperature

degC

50

48

52

0000001101

Pump speed

r/min

1100

1100

1100

Timer stroke

mm

1.9

1.7

2.1

Basic

*

Oil temperature

degC

50

48

52

_02

Pump speed

r/min

850

850

850

Timer stroke

mm

0.5

0

1

Oil temperature

degC

50

48

52

_03

Pump speed

r/min

1100

1100

1100

Timer stroke

mm

1.9

1.6

2.2

Basic

*

Oil temperature

degC

50

48

52

_04

Pump speed

r/min

1700

1700

1700

Timer stroke

mm

4.4

3.9

4.9

Oil temperature

degC

50

48

52

_05

Pump speed

r/min

2300

2300

2300

Timer stroke

mm

6.1

5.6

6.5

Oil temperature

degC

52

50

54

0000001201

Max. applied voltage

V

8

8

8

Test voltage

V

13

12

14

0000001401

Pump speed

r/min

1100

1100

1100

Average injection quantity

mm3/st.

31

30.5

31.5

Timer stroke TA

mm

1.2

1

1.4

Timer stroke variation dT

mm

0.7

0.7

0.7

Basic

*

Oil temperature

degC

50

48

52

_02

Pump speed

r/min

1100

1100

1100

Average injection quantity

mm3/st.

31

30

32

Timer stroke TA

mm

1.2

0.9

1.5

Basic

*

Oil temperature

degC

50

48

52

_03

Pump speed

r/min

1100

1100

1100

Average injection quantity

mm3/st.

22

19.5

24.5

Timer stroke TA

mm

0.6

0.1

1.1

Oil temperature

degC

50

48

52

Timing setting

K dimension

mm

3.3

3.2

3.4

KF dimension

mm

5.8

5.7

5.9

MS dimension

mm

0.9

0.8

1

Pre-stroke

mm

0.1

0.08

0.12

Control lever angle alpha

deg.

25

23

27

Control lever angle beta

deg.

36

31

41

Information:

MOVING WATER SLEEVES

1. 8S6692 Water Sleeve Tool.5. Disconnect oil cooler water outlet elbow at back side of timing gear cover.6. Remove bolts securing front support to frame.7. Raise the front of the engine 1 in. (25.4 mm) and block under the engine.

Never support the engine by placing blocking under the oil pan. Damage to the oil pan or suction bell will result.

8. Remove engine front support. Remove timing gear cover retaining bolts. These bolts vary in length. Mark each bolt and its location for correct installation.9. Install two 1P7406 Lifting Eye Bolts in timing gear cover. Attach a hoist and pry timing gear cover off dowels in cylinder block. Remove the timing gear cover, the weight is approx. 85 lbs. (40 kg).

REMOVING TIMING GEAR COVER

2. Timing gear cover.Install Timing Gear Cover

1. Clean all gasket surfaces on timing gear cover and cylinder block. Clean water sleeve bores in cylinder heads and inspect and lubricate O-rings before installing.2. Install timing gear cover gasket. Install water sleeves in timing gear cover before installing cover. Replacement water sleeves are color coded to insure that new sleeves have the correct sized orifice to control coolant flow in the different engines. The 1140, 1145, and 1150 Series [4.1 in. (104.1 mm) and 4.5 in. (114.3 mm) stroke] use a silver code. The 1160 [5.0 in. (127.0 mm) stroke] uses a gold code.3. Install two 1P7406 Lifting Eye Bolts in timing gear cover. Attach hoist and position cover on engine. Make sure the oil pump gear teeth and the crankshaft gear teeth mesh.4. Install the timing gear cover retaining bolts.5. Connect oil cooler water outlet elbow to back side of timing gear cover.6. Trim the timing gear cover gasket flush with bottom face of cylinder block. Gaskets not cut square and flush with oil pan face will leak.7. Use an 8S6692 Water Sleeve Tool to slide water sleeves into cylinder heads and install clamps.8. Install front support. Remove blocking from beneath engine and lower engine into position. Install and tighten front support-to-frame mounting bolts.9. Lubricate the lip of the crankshaft front seal with clean engine oil (SAE 30). Install the crankshaft pulley.10. Install oil pump suction bell, oil pan gasket and oil pan. Tighten oil pan retaining bolts to 17 3 lb. ft. (2.4 0.4 mkg).11. Connect water temperature sending unit. Install tachometer drive housing and connect tachometer drive cable.12. Install the power steering pump, vacuum pump, alternator, radiator and all other components that were removed or disconnected.13. Fill the cooling system and lubricating system to the correct levels.

Have questions with 104745-9320?

Group cross 104745-9320 ZEXEL

104745-9320

INJECTION-PUMP ASSEMBLY