Information injection-pump assembly

ZEXEL

104745-9011

1047459011

Rating:

Cross reference number

ZEXEL

104745-9011

1047459011

Zexel num

Bosch num

Firm num

Name

104745-9011

INJECTION-PUMP ASSEMBLY

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113orSAEJ967d

1404 Test oil ISO4113orSAEJ967d

Test oil temperature

degC

45

45

50

Nozzle

105780-0060

Bosch type code

NP-DN0SD1510

Nozzle holder

105780-2150

Opening pressure

MPa

13

13

13.3

Opening pressure

kgf/cm2

133

133

136

Injection pipe

157805-7320

Injection pipe

Inside diameter - outside diameter - length (mm) mm 2-6-450

Inside diameter - outside diameter - length (mm) mm 2-6-450

Joint assembly

157641-4720

Tube assembly

157641-4020

Transfer pump pressure

kPa

20

20

20

Transfer pump pressure

kgf/cm2

0.2

0.2

0.2

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Pump speed

r/min

1100

1100

1100

Average injection quantity

mm3/st.

49.9

49.4

50.4

Difference in delivery

mm3/st.

4

Basic

*

Oil temperature

degC

50

48

52

Injection timing adjustment_02

Pump speed

r/min

500

500

500

Average injection quantity

mm3/st.

41.3

38.8

43.8

Oil temperature

degC

48

46

50

Injection timing adjustment_03

Pump speed

r/min

1100

1100

1100

Average injection quantity

mm3/st.

49.9

48.9

50.9

Difference in delivery

mm3/st.

4.5

Basic

*

Oil temperature

degC

50

48

52

Injection timing adjustment_04

Pump speed

r/min

2150

2150

2150

Average injection quantity

mm3/st.

46.3

43.8

48.8

Oil temperature

degC

52

50

54

Injection quantity adjustment

Pump speed

r/min

2550

2550

2550

Average injection quantity

mm3/st.

10.9

8.9

12.9

Difference in delivery

mm3/st.

3

Basic

*

Oil temperature

degC

55

52

58

Injection quantity adjustment_02

Pump speed

r/min

2700

2700

2700

Average injection quantity

mm3/st.

5

Oil temperature

degC

55

52

58

Injection quantity adjustment_03

Pump speed

r/min

2350

2350

2350

Average injection quantity

mm3/st.

39.7

39.7

39.7

Oil temperature

degC

52

50

54

Injection quantity adjustment_04

Pump speed

r/min

2550

2550

2550

Average injection quantity

mm3/st.

10.9

8.4

13.4

Basic

*

Oil temperature

degC

55

52

58

Governor adjustment

Pump speed

r/min

350

350

350

Average injection quantity

mm3/st.

7.7

5.7

9.7

Difference in delivery

mm3/st.

2

Basic

*

Oil temperature

degC

48

46

50

Governor adjustment_02

Pump speed

r/min

350

350

350

Average injection quantity

mm3/st.

7.7

5.2

10.2

Difference in delivery

mm3/st.

2.5

Basic

*

Oil temperature

degC

48

46

50

Timer adjustment

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

60

45

80

Basic

*

Oil temperature

degC

48

46

50

Remarks

Full

Full

Timer adjustment_02

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

60

45

80

Oil temperature

degC

48

46

50

Remarks

Full

Full

Speed control lever angle

Pump speed

r/min

350

350

350

Average injection quantity

mm3/st.

0

0

0

Oil temperature

degC

48

46

50

Remarks

Magnet OFF at idling position

Magnet OFF at idling position

0000000901

Pump speed

r/min

1100

1100

1100

Overflow quantity with S/T ON

cm3/min

390

260

520

Oil temperature

degC

50

48

52

Remarks

With an O-ring

With an O-ring

_02

Overflow quantity with S/T ON

cm3/min

600

470

730

Oil temperature

degC

50

48

52

Remarks

Without an O-ring

Without an O-ring

Stop lever angle

Pump speed

r/min

1100

1100

1100

Pressure with S/T ON

kPa

520

481

559

Pressure with S/T ON

kgf/cm2

5.3

4.9

5.7

Pressure with S/T OFF

kPa

431

402

460

Pressure with S/T OFF

kgf/cm2

4.4

4.1

4.7

Basic

*

Oil temperature

degC

50

48

52

Remarks

OFF

OFF

Stop lever angle_02

Pump speed

r/min

1100

1100

1100

Pressure with S/T OFF

kPa

431

392

470

Pressure with S/T OFF

kgf/cm2

4.4

4

4.8

Basic

*

Oil temperature

degC

50

48

52

Stop lever angle_03

Pump speed

r/min

1700

1700

1700

Pressure with S/T OFF

kPa

559

520

598

Pressure with S/T OFF

kgf/cm2

5.7

5.3

6.1

Oil temperature

degC

50

48

52

0000001101

Pump speed

r/min

1100

1100

1100

Timer stroke with S/T ON

mm

3.4

3

3.8

Timer stroke with S/T OFF

mm

1.9

1.7

2.1

Basic

*

Oil temperature

degC

50

48

52

Remarks

OFF

OFF

_02

Pump speed

r/min

850

850

850

Timer stroke with S/T OFF

mm

0.5

0

1

Oil temperature

degC

50

48

52

_03

Pump speed

r/min

1100

1100

1100

Timer stroke with S/T ON

mm

3.4

2.9

3.9

Timer stroke with S/T OFF

mm

1.9

1.6

2.2

Basic

*

Oil temperature

degC

50

48

52

_04

Pump speed

r/min

1700

1700

1700

Timer stroke with S/T OFF

mm

4.4

3.9

4.9

Oil temperature

degC

50

48

52

_05

Pump speed

r/min

2300

2300

2300

Timer stroke with S/T OFF

mm

6.1

5.6

6.5

Oil temperature

degC

52

50

54

0000001201

Max. applied voltage

V

8

8

8

Test voltage

V

13

12

14

0000001401

Pump speed

r/min

1100

1100

1100

Average injection quantity

mm3/st.

31

30.5

31.5

Timer stroke TA

mm

1.2

1

1.4

Timer stroke variation dT

mm

0.7

0.7

0.7

Basic

*

Oil temperature

degC

50

48

52

_02

Pump speed

r/min

1100

1100

1100

Average injection quantity

mm3/st.

31

30

32

Timer stroke TA

mm

1.2

0.9

1.5

Basic

*

Oil temperature

degC

50

48

52

_03

Pump speed

r/min

1100

1100

1100

Average injection quantity

mm3/st.

22

19.5

24.5

Timer stroke TA

mm

0.6

0.1

1.1

Oil temperature

degC

50

48

52

Timing setting

K dimension

mm

3.3

3.2

3.4

KF dimension

mm

5.8

5.7

5.9

MS dimension

mm

0.9

0.8

1

Pre-stroke

mm

0.1

0.08

0.12

Control lever angle alpha

deg.

25

23

27

Control lever angle beta

deg.

36

31

41

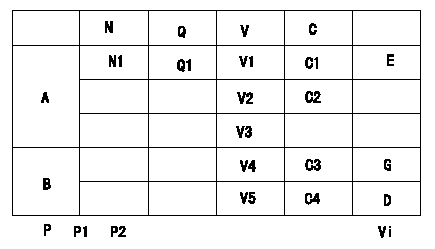

Test data Ex:

0000001801 POTENTIOMETER ADJUSTMENT

Potentiometer adjustment

1. Applied voltage: Vi

2. Boost pressure = P1kPa {P2 mmHg}

3. Set the control lever at the adjusting point. Position the dummy bolt against the lever and fix.

4. Assemble the potentiometer to obtain output voltage V1 (V) at the fixed position.

5. After mounting the potentiometer, remove the dummy bolt.

At TCV duty 100%

A:Adjusting point

B:Performance standards

C:Control lever angle

N:Pump speed

V:Output voltage

Q:Injection quantity

C1:Idle

C2:Full speed

----------

----------

N1=-r/min Q1=-cm3/1,000st V1=1.6+-0.03V V2=7.6+-1.1V V3=-V V4=-V V5=-V C3=(4.9+-2.5)deg C4=(19.4+-4)deg P1=-kPa P2=-mmHg Vi=10V

----------

----------

N1=-r/min Q1=-cm3/1,000st V1=1.6+-0.03V V2=7.6+-1.1V V3=-V V4=-V V5=-V C3=(4.9+-2.5)deg C4=(19.4+-4)deg P1=-kPa P2=-mmHg Vi=10V

Information:

start by: a) remove vibration damper and pulley 1. Use tooling (A) to remove the crankshaft front seal from the timing gear cover. When a replacement of the front seal is made, a replacement of the wear sleeve is to be made also. 2. Put tool (B) in position in the seal bore as shown.3. Install tool (C) between tool (B) and the wear sleeve. Turn tool (C) until the edge of the tool makes a flat place (crease) in the wear sleeve. Do this in two or more places until the wear sleeve is loose.4. Remove tool (B) and the wear sleeve by hand.5. Clean and make a preparation of the wear sleeve inside diameter and crankshaft outside diameter with 8M8060 Quick Cure Primer. Put 9S3265 Retaining Compound on the crankshaft outside diameter and wear sleeve inside diameter before the wear sleeve is installed on the crankshaft. 6. Put a small amount of clean oil on the lip of the seal. Install wear sleeve (2) and seal (1) on the crankshaft as shown with tools (D). If tools are not available, install the wear sleeve until it is .060 .020 in. (1.52 0.51 mm) (dimension "X") from the face of the crankshaft. Install the seal in the timing gear cover until the metal face of the seal is .090 .020 in. (2.29 0.51 mm) (dimension "Y") from the face of the crankshaft.end by: a) install vibration damper and pulleyRemove And Install Crankshaft Rear Seal And Wear Sleeve

start by:a) remove flywheel 1. Use tool (A) to remove crankshaft rear seal (1) from the flywheel housing. When a replacement of the rear seal is made, a replacement of the wear sleeve is to be made also.

TYPICAL EXAMPLE2. Put tool (B) in position in the seal bore as shown.3. Install tool (C) between tool (B) and the wear sleeve. Turn tool (C) until the edge of the tool makes a flat place (crease) in the wear sleeve. Do this in two or more places until the wear sleeve is loose.4. Remove tool (B) and the wear sleeve by hand.5. Clean and make a preparation of the wear sleeve inside diameter and adapter outside diameter with 8M8060 Quick Cure Primer. Put 9S3265 Retaining Compound on the adapter outside diameter and wear sleeve inside diameter before the wear sleeve is installed on the adapter. Make sure the lip of the seal is toward the inside of the engine and the outside diameter bevel of the wear sleeve is toward the outside of the engine.6. Put a small amount of clean engine oil on the lip of the seal. Install the wear sleeve and the seal on the crankshaft as shown with tools (D).end by:a) install flywheel

start by:a) remove flywheel 1. Use tool (A) to remove crankshaft rear seal (1) from the flywheel housing. When a replacement of the rear seal is made, a replacement of the wear sleeve is to be made also.

TYPICAL EXAMPLE2. Put tool (B) in position in the seal bore as shown.3. Install tool (C) between tool (B) and the wear sleeve. Turn tool (C) until the edge of the tool makes a flat place (crease) in the wear sleeve. Do this in two or more places until the wear sleeve is loose.4. Remove tool (B) and the wear sleeve by hand.5. Clean and make a preparation of the wear sleeve inside diameter and adapter outside diameter with 8M8060 Quick Cure Primer. Put 9S3265 Retaining Compound on the adapter outside diameter and wear sleeve inside diameter before the wear sleeve is installed on the adapter. Make sure the lip of the seal is toward the inside of the engine and the outside diameter bevel of the wear sleeve is toward the outside of the engine.6. Put a small amount of clean engine oil on the lip of the seal. Install the wear sleeve and the seal on the crankshaft as shown with tools (D).end by:a) install flywheel

Have questions with 104745-9011?

Group cross 104745-9011 ZEXEL

Nissan-Diesel

104745-9011

INJECTION-PUMP ASSEMBLY