Information injection-pump assembly

BOSCH

9 460 611 962

9460611962

ZEXEL

104745-9003

1047459003

NISSAN

167006T016

167006t016

Rating:

Components :

| 0. | INJECTION-PUMP ASSEMBLY | 104745-9003 |

| 1. | _ | |

| 2. | FUEL INJECTION PUMP | 104645-9002 |

| 3. | NUMBER PLATE | 146959-5900 |

| 4. | _ | |

| 5. | CAPSULE | |

| 6. | ADJUSTING DEVICE | |

| 7. | NOZZLE AND HOLDER ASSY | 105148-1221 |

| 8. | Nozzle and Holder | 16600-63G01 |

| 9. | Open Pre:MPa(Kqf/cm2) | 9.8{100} |

| 10. | NOZZLE-HOLDER | 105078-0050 |

| 11. | NOZZLE | 105007-1210 |

Scheme ###:

| 1/6. | [1] | 146601-0900 | PACKING RING |

| 6. | [1] | 146100-0420 | SUPPLY PUMP |

| 9. | [1] | 146103-0100 | COVER |

| 10. | [2] | 139104-0000 | FLAT-HEAD SCREW |

| 12. | [1] | 146200-0020 | DRIVE SHAFT |

| 12/1. | [1] | 146200-0000 | DRIVE SHAFT |

| 12/2. | [1] | 146201-0000 | WOODRUFF KEY |

| 12/3. | [2] | 146202-0100 | DAMPER |

| 12/4. | [1] | 146203-0000 | TOOTHED GEAR |

| 17. | [1] | 146204-0000 | PLAIN WASHER |

| 20. | [1] | 146210-2320 | ROLLER SET |

| 24. | [1] | 146303-0000 | BEARING PIN |

| 25. | [1] | 146304-0000 | BEARING PIN |

| 26. | [1] | 146305-0000 | CLAMPING BAND |

| 27. | [1] | 146205-0000 | SLOTTED WASHER |

| 29. | [1] | 146220-2120 | CAM PLATE |

| 30. | [1] | 146600-0800 | O-RING |

| 31. | [1] | 146311-5920 | PUMP PLUNGER |

| 32. | [1] | 146301-0000 | SLIDING PIECE |

| 34. | [1] | 146312-2900 | COMPRESSION SPRING |

| 34B. | [1] | 146312-3000 | COMPRESSION SPRING |

| 34C. | [1] | 146312-2800 | COMPRESSION SPRING |

| 35/1. | [1] | 146690-3200 | SHIM D11.5&9.4T0.1 |

| 35/1. | [1] | 146690-3300 | SHIM D11.5&9.4T0.2 |

| 35/1. | [1] | 146690-3400 | SHIM D11.5&9.4T0.25 |

| 35/1. | [1] | 146690-3500 | SHIM D11.5&9.4T1.0 |

| 35/1. | [1] | 146690-4100 | SHIM D11.5&9.4T2 |

| 35/1. | [1] | 146690-4200 | SHIM D11.5&9.4T0.5 |

| 35/1. | [1] | 146690-4300 | SHIM D11.5&9.4T0.75 |

| 36. | [1] | 146600-0800 | O-RING |

| 37. | [1] | 146310-4020 | COVER |

| 38. | [2] | 146620-5000 | BLEEDER SCREW |

| 39. | [1] | 146310-0100 | COVER |

| 40. | [2] | 146620-5000 | BLEEDER SCREW |

| 41. | [1] | 146312-1900 | COMPRESSION SPRING |

| 43. | [1] | 146230-0000 | SHIM |

| 44. | [1] | 146230-0100 | PLAIN WASHER |

| 45. | [1] | 146231-0001 | SLOTTED WASHER |

| 47. | [2] | 146233-0000 | SLOTTED WASHER |

| 48/1. | [1] | 146603-0100 | SHIM D17.0&5.2T0.80 |

| 48/1. | [1] | 146603-0200 | SHIM D17.0&5.2T1.00 |

| 48/1. | [1] | 146603-0300 | SHIM D17.0&5.2T1.20 |

| 48/1. | [1] | 146603-0400 | SHIM D17.0&5.2T1.50 |

| 48/1. | [1] | 146690-1400 | SHIM D17&5.2T0.9 |

| 48/1. | [1] | 146690-1500 | SHIM D17&5.2T1.1 |

| 48/1. | [1] | 146690-1600 | SHIM D17&5.2T1.3 |

| 48/1. | [1] | 146690-1700 | SHIM D17&5.2T1.4 |

| 48/1. | [1] | 146690-1800 | SHIM D17&5.2T1.6 |

| 49. | [2] | 146234-0500 | GUIDE PIN |

| 50. | [1] | 146401-3720 | HYDRAULIC HEAD |

| 50. | [1] | 146401-3720 | HYDRAULIC HEAD |

| 50. | [1] | 146401-3720 | HYDRAULIC HEAD |

| 51. | [1] | 146600-0000 | O-RING |

| 52/1. | [1] | 146420-0700 | SHIM D9.5&3.0T2.04 |

| 52/1. | [1] | 146420-0800 | SHIM D9.5&3.0T2.06 |

| 52/1. | [1] | 146420-0900 | SHIM D9.5&3.0T2.08 |

| 52/1. | [1] | 146420-1000 | SHIM D9.5&3.0T2.10 |

| 52/1. | [1] | 146420-1100 | SHIM D9.5&3.0T2.12 |

| 52/1. | [1] | 146420-1200 | SHIM D9.5&3.0T2.14 |

| 52/1. | [1] | 146420-1300 | SHIM D9.5&3.0T2.16 |

| 52/1. | [1] | 146420-1400 | SHIM D9.5&3.0T2.18 |

| 52/1. | [1] | 146420-1500 | SHIM D9.5&3.0T2.20 |

| 52/1. | [1] | 146420-1600 | SHIM D9.5&3.0T2.22 |

| 52/1. | [1] | 146420-1700 | SHIM D9.5&3.0T2.24 |

| 52/1. | [1] | 146420-1800 | SHIM D9.5&3.0T2.26 |

| 52/1. | [1] | 146420-1900 | SHIM D9.5&3.0T2.28 |

| 52/1. | [1] | 146420-2000 | SHIM D9.5&3.0T2.30 |

| 52/1. | [1] | 146420-2100 | SHIM D9.5&3.0T2.32 |

| 52/1. | [1] | 146420-2200 | SHIM D9.5&3.0T2.34 |

| 52/1. | [1] | 146420-2400 | SHIM D9.5&3.0T2.38 |

| 52/1. | [1] | 146420-2500 | SHIM D9.5&3.0T2.40 |

| 52/1. | [1] | 146420-2600 | SHIM D9.5&3.0T2.42 |

| 52/1. | [1] | 146420-2700 | SHIM D9.5&3.0T2.44 |

| 52/1. | [1] | 146420-2800 | SHIM D9.5&3.0T2.46 |

| 52/1. | [1] | 146420-2900 | SHIM D9.5&3.0T2.48 |

| 52/1. | [1] | 146420-3000 | SHIM D9.5&3.0T2.50 |

| 52/1. | [1] | 146420-3100 | SHIM D9.5&3.0T2.52 |

| 52/1. | [1] | 146420-3200 | SHIM D9.5&3.0T2.54 |

| 52/1. | [1] | 146420-3300 | SHIM D9.5&3.0T2.56 |

| 52/1. | [1] | 146420-3400 | SHIM D9.5&3.0T2.58 |

| 52/1. | [1] | 146420-3500 | SHIM D9.5&3.0T2.60 |

| 52/1. | [1] | 146420-3600 | SHIM D9.5&3.0T2.62 |

| 52/1. | [1] | 146420-3700 | SHIM D9.5&3.0T2.64 |

| 52/1. | [1] | 146420-3800 | SHIM D9.5&3.0T2.66 |

| 52/1. | [1] | 146420-3900 | SHIM D9.5&3.0T2.68 |

| 52/1. | [1] | 146420-4000 | SHIM D9.5&3.0T2.70 |

| 52/1. | [1] | 146420-4100 | SHIM D9.5&3.0T2.72 |

| 54. | [4] | 146433-0100 | GASKET |

| 55. | [4] | 146430-0320 | DELIVERY-VALVE ASSEMBLY VE4 |

| 56. | [4] | 146432-0000 | COMPRESSION SPRING |

| 58. | [4] | 146440-0220 | FITTING |

| 60. | [3] | 139106-0100 | FLAT-HEAD SCREW |

| 66. | [1] | 146600-0100 | O-RING |

| 67. | [1] | 146503-2220 | GOVERNOR COVER |

| 67/1. | [1] | 146508-2221 | GOVERNOR COVER |

| 67/13. | [1] | 146621-3100 | UNION NUT |

| 67/14. | [1] | 146621-1700 | UNION NUT |

| 67/15. | [1] | 146526-6400 | BLEEDER SCREW |

| 67/16. | [1] | 146526-3400 | BLEEDER SCREW |

| 67/78. | [1] | 146600-4400 | SEAL RING |

| 67/200. | [1] | 139308-0300 | PLAIN WASHER |

| 67/201. | [1] | 146545-3400 | THREADED PIN L53.00 |

| 67/201B. | [1] | 146545-3500 | THREADED PIN L55.00 |

| 67/201C. | [1] | 146545-3600 | THREADED PIN L57.00 |

| 67/202. | [1] | 139208-0900 | UNION NUT |

| 67/203. | [1] | 146600-1200 | O-RING |

| 68. | [1] | 146810-2620 | CONTROL SHAFT |

| 69. | [1] | 139310-0200 | PLAIN WASHER |

| 72. | [1] | 146537-7320 | CONTROL LEVER |

| 73. | [1] | 014110-6440 | LOCKING WASHER D12.2&6.1T1.5 |

| 75. | [1] | 146621-0700 | UNION NUT |

| 95. | [1] | 146861-4820 | FULCRUM LEVER |

| 104. | [2] | 146568-0000 | SLOTTED SPRING PIN |

| 105. | [2] | 026508-1140 | GASKET D11.4&8.2T1.0 |

| 106. | [2] | 146588-0500 | COILED SPRING |

| 107. | [1] | 146569-0300 | UNION NUT |

| 108. | [1] | 146570-0420 | GOVERNOR SHAFT |

| 109. | [1] | 146600-0400 | O-RING |

| 110/1. | [1] | 146571-0000 | SHIM D20.2&8.3T1.05 |

| 110/1. | [1] | 146571-0100 | SHIM D20.2&8.3T1.25 |

| 110/1. | [1] | 146571-0200 | SHIM D20.2&8.3T1.45 |

| 110/1. | [1] | 146571-0300 | SHIM D20.2&8.3T1.65 |

| 110/1. | [1] | 146571-0400 | SHIM D20.2&8.3T1.85 |

| 111. | [1] | 146602-0600 | PLAIN WASHER |

| 112. | [1] | 146572-0020 | FLYWEIGHT ASSEMBLY |

| 114. | [1] | 146602-0500 | PLAIN WASHER |

| 115. | [1] | 146975-6600 | SLIDING SLEEVE |

| 116. | [1] | 146576-0200 | CAP |

| 117/1. | [1] | 146577-2400 | PLUG L3.30 |

| 117/1. | [1] | 146577-2500 | PLUG L3.50 |

| 117/1. | [1] | 146577-2600 | PLUG L3.70 |

| 117/1. | [1] | 146577-2700 | PLUG L3.90 |

| 117/1. | [1] | 146577-2800 | PLUG L4.10 |

| 117/1. | [1] | 146577-2900 | PLUG L4.30 |

| 117/1. | [1] | 146577-3000 | PLUG L4.50 |

| 117/1. | [1] | 146577-3100 | PLUG L4.70 |

| 117/1. | [1] | 146577-7200 | PLUG L3.2 |

| 117/1. | [1] | 146577-7300 | PLUG L3.4 |

| 117/1. | [1] | 146577-7400 | PLUG L3.6 |

| 117/1. | [1] | 146577-7500 | PLUG L3.8 |

| 117/1. | [1] | 146577-7600 | PLUG L4.0 |

| 117/1. | [1] | 146577-7700 | PLUG L4.2 |

| 117/1. | [1] | 146577-7800 | PLUG L4.4 |

| 117/1. | [1] | 146577-7900 | PLUG L4.6 |

| 117/1. | [1] | 146577-8000 | PLUG L4.8 |

| 123. | [4] | 139106-0200 | FLAT-HEAD SCREW |

| 130. | [1] | 146421-0020 | CAPSULE |

| 130/2. | [1] | 026508-1140 | GASKET D11.4&8.2T1.0 |

| 130/3. | [1] | 146422-0000 | BLEEDER SCREW |

| 130/4. | [1] | 146600-0500 | O-RING |

| 133. | [1] | 146600-0600 | O-RING |

| 134. | [1] | 146600-0700 | O-RING |

| 135. | [1] | 146110-0220 | CONTROL VALVE STAMP 02 |

| 135/5. | [1] | 146114-0000 | SPRING WASHER |

| 136. | [1] | 146120-0020 | OVER FLOW VALVE |

| 200. | [1] | 146206-0100 | COILED SPRING |

| 217. | [1] | 146541-3100 | SLOTTED WASHER |

| 218. | [1] | 146587-9900 | COILED SPRING |

| 219. | [1] | 146541-3000 | BUSHING |

| 220. | [1] | 146587-8000 | COILED SPRING |

| 221. | [1] | 146926-9100 | BRACKET |

| 222. | [2] | 139006-4600 | BLEEDER SCREW |

| 230. | [1] | 146926-8220 | BRACKET |

| 231. | [1] | 139006-4600 | BLEEDER SCREW |

| 236. | [1] | 139006-4800 | BLEEDER SCREW |

| 237. | [1] | 146620-0200 | HEX-SOCKET-HEAD CAP SCREW |

| 240. | [1] | 146650-0720 | PULLING ELECTROMAGNET |

| 240/8. | [1] | 146600-1700 | O-RING |

| 242. | [1] | 146658-6720 | WIRE |

| 243. | [0] | 146621-1000 | |

| 243. | [1] | 146621-4901 | UNION NUT |

| 246. | [1] | 027412-2440 | EYE BOLT |

| 310. | [1] | 146673-8421 | POTENTCIOMETER |

| 310/2. | [1] | 146925-8220 | BRACKET |

| 310/3. | [2] | 139104-0400 | FLAT-HEAD SCREW |

| 310/4. | [1] | 146620-2900 | FLAT-HEAD SCREW |

| 310/5. | [1] | 146621-0500 | UNION NUT |

| 310/6. | [1] | 146614-2300 | JOINT CONNECTION |

| 310/7. | [1] | 139006-5700 | BLEEDER SCREW |

| 310/8. | [2] | 010206-1040 | HEX-SOCKET-HEAD CAP SCREW |

| 329. | [1] | 146541-4900 | PLAIN WASHER |

| 351. | [1] | 146125-0101 | FILTER |

| 352. | [1] | 146125-0200 | COILED SPRING |

| 800S. | [1] | 146019-9920 | PUMP HOUSING |

| 800S/1/6. | [1] | 146601-0900 | PACKING RING |

| 800S/1/6. | [1] | 146601-0900 | PACKING RING |

| 804S. | [1] | 146232-0320 | COMPRESSION SPRING |

| 805S. | [1] | 146574-0120 | PARTS SET |

| 810S. | [1] | 146600-1120 | REPAIR SET |

| 821S. | [1] | 146210-5720 | ROLLER SET |

| 835S. | [1] | 146598-1000 | CAP |

| 836S/1. | [1] | 146598-0600 | CAP L18 |

| 836S/1. | [1] | 146598-0700 | CAP L21 |

| 836S/1. | [1] | 146598-0800 | CAP L24 |

| 836S/1. | [1] | 146598-0900 | CAP L27 |

| 906. | [1] | 146959-5900 | NAMEPLATE |

Include in #2:

104745-9003

as INJECTION-PUMP ASSEMBLY

Cross reference number

BOSCH

9 460 611 962

9460611962

ZEXEL

104745-9003

1047459003

NISSAN

167006T016

167006t016

Zexel num

Bosch num

Firm num

Name

104745-9003

9 460 611 962

167006T016 NISSAN

INJECTION-PUMP ASSEMBLY

TD27 K 11CJ INJECTION PUMP ASSY VE4 VE

TD27 K 11CJ INJECTION PUMP ASSY VE4 VE

104745-9003

9 460 611 962

167006T016 NISSAN-DIESEL

INJECTION-PUMP ASSEMBLY

TD27 K 11CJ INJECTION PUMP ASSY VE4 VE

TD27 K 11CJ INJECTION PUMP ASSY VE4 VE

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113orSAEJ967d

1404 Test oil ISO4113orSAEJ967d

Test oil temperature

degC

45

45

50

Nozzle

105780-0060

Bosch type code

NP-DN0SD1510

Nozzle holder

105780-2150

Opening pressure

MPa

13

13

13.3

Opening pressure

kgf/cm2

133

133

136

Injection pipe

157805-7320

Injection pipe

Inside diameter - outside diameter - length (mm) mm 2-6-450

Inside diameter - outside diameter - length (mm) mm 2-6-450

Joint assembly

157641-4720

Tube assembly

157641-4020

Transfer pump pressure

kPa

20

20

20

Transfer pump pressure

kgf/cm2

0.2

0.2

0.2

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Pump speed

r/min

1100

1100

1100

Average injection quantity

mm3/st.

49.9

49.4

50.4

Difference in delivery

mm3/st.

4

Basic

*

Oil temperature

degC

50

48

52

Injection timing adjustment_02

Pump speed

r/min

500

500

500

Average injection quantity

mm3/st.

41.3

38.8

43.8

Oil temperature

degC

48

46

50

Injection timing adjustment_03

Pump speed

r/min

1100

1100

1100

Average injection quantity

mm3/st.

49.9

48.9

50.9

Difference in delivery

mm3/st.

4.5

4.5

4.5

Basic

*

Oil temperature

degC

50

48

52

Injection timing adjustment_04

Pump speed

r/min

2150

2150

2150

Average injection quantity

mm3/st.

46.3

43.8

48.8

Oil temperature

degC

52

50

54

Injection quantity adjustment

Pump speed

r/min

2550

2550

2550

Average injection quantity

mm3/st.

10.9

8.9

12.9

Basic

*

Oil temperature

degC

55

52

58

Injection quantity adjustment_02

Pump speed

r/min

2700

2700

2700

Average injection quantity

mm3/st.

5

Oil temperature

degC

55

52

58

Injection quantity adjustment_03

Pump speed

r/min

2350

2350

2350

Average injection quantity

mm3/st.

39.7

39.7

39.7

Oil temperature

degC

52

50

54

Injection quantity adjustment_04

Pump speed

r/min

2550

2550

2550

Average injection quantity

mm3/st.

10.9

8.4

13.4

Basic

*

Oil temperature

degC

55

52

58

Governor adjustment

Pump speed

r/min

350

350

350

Average injection quantity

mm3/st.

7.7

5.7

9.7

Difference in delivery

mm3/st.

2

Basic

*

Oil temperature

degC

48

46

50

Governor adjustment_02

Pump speed

r/min

350

350

350

Average injection quantity

mm3/st.

7.7

5.2

10.2

Difference in delivery

mm3/st.

2.5

Basic

*

Oil temperature

degC

48

46

50

Timer adjustment

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

60

45

80

Basic

*

Oil temperature

degC

48

46

50

Timer adjustment_02

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

60

45

80

Oil temperature

degC

48

46

50

Speed control lever angle

Pump speed

r/min

350

350

350

Average injection quantity

mm3/st.

0

0

0

Oil temperature

degC

48

46

50

Remarks

Magnet OFF at idling position

Magnet OFF at idling position

0000000901

Pump speed

r/min

1100

1100

1100

Overflow quantity

cm3/min

390

260

520

Oil temperature

degC

50

48

52

Stop lever angle

Pump speed

r/min

1300

1300

1300

Pressure

kPa

471

442

500

Pressure

kgf/cm2

4.8

4.5

5.1

Basic

*

Oil temperature

degC

50

48

52

Stop lever angle_02

Pump speed

r/min

1300

1300

1300

Pressure

kPa

471

432

510

Pressure

kgf/cm2

4.8

4.4

5.2

Basic

*

Oil temperature

degC

50

48

52

Stop lever angle_03

Pump speed

r/min

2150

2150

2150

Pressure

kPa

647

608

686

Pressure

kgf/cm2

6.6

6.2

7

Oil temperature

degC

52

50

54

0000001101

Pump speed

r/min

1300

1300

1300

Timer stroke

mm

2.1

1.9

2.3

Basic

*

Oil temperature

degC

50

48

52

_02

Pump speed

r/min

1100

1100

1100

Timer stroke

mm

1.1

0.6

1.6

Oil temperature

degC

50

48

52

_03

Pump speed

r/min

1300

1300

1300

Timer stroke

mm

2.1

1.8

2.4

Basic

*

Oil temperature

degC

50

48

52

_04

Pump speed

r/min

2150

2150

2150

Timer stroke

mm

5.6

5

6.2

Oil temperature

degC

52

50

54

_05

Pump speed

r/min

2500

2500

2500

Timer stroke

mm

6.1

5.6

6.5

Oil temperature

degC

55

52

58

0000001201

Max. applied voltage

V

8

8

8

Test voltage

V

13

12

14

0000001401

Pump speed

r/min

1300

1300

1300

Average injection quantity

mm3/st.

37

36.5

37.5

Timer stroke TA

mm

1.8

1.8

1.8

Timer stroke variation dT

mm

0.3

0.1

0.5

Basic

*

Oil temperature

degC

50

48

52

_02

Pump speed

r/min

1300

1300

1300

Average injection quantity

mm3/st.

37

36

38

Timer stroke variation dT

mm

0.3

0

0.6

Basic

*

Oil temperature

degC

50

48

52

_03

Pump speed

r/min

1300

1300

1300

Average injection quantity

mm3/st.

25

22.5

27.5

Timer stroke variation dT

mm

0.9

0.5

1.3

Oil temperature

degC

50

48

52

Timing setting

K dimension

mm

3.3

3.2

3.4

KF dimension

mm

5.8

5.7

5.9

MS dimension

mm

0.9

0.8

1

Pre-stroke

mm

0.1

0.08

0.12

Control lever angle alpha

deg.

25

23

27

Control lever angle beta

deg.

36

31

41

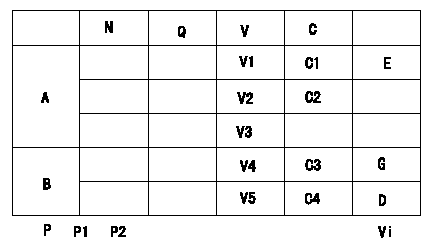

Test data Ex:

0000001801 POTENTIOMETER ADJUSTMENT

Boost pressure P1kPa {P2 mmHg}

Switch voltage is the value when the idle lever position is 0 V.

* Adjusting method of the 1 potentiometer (P/M)

Substitute the actual measurement of the angle a of each I/P in the following formula and determine the P/M output adjustment y (V).

When the angle a <= c: y = 7.23

When c < angle a < d: y = 7.23+( angle a -33) x 0.133

When d <alpha <e: y=7.97

Reference: Idle position and full speed position output voltages are V6 (idle) and V7 (full speed).

A:Potentiometer standards

B:ON, OFF switch standard

G:ON-->OFF

D:OFF-->ON

E:Adjusting point

F:Checking point

P:Boost pressure

Vi:Applied voltage

C1:Full-speed

C2:Idle

Q:Injection quantity

N:Pump speed

V:Output voltage

C:Control lever angle

----------

a=MEASURE c=33deg d=39deg e=-deg P1=-kPa P2=-mmHg V6=1.6+-0.6V V7=7.6+-0.4V

----------

V1=y+-0.03V V2=1.6+-0.6V V3=-V V4=-V V5=-V C3=0.1~10.2deg C4=(19.4)deg Vi=10V P1=-kPa P2=-mmHg

----------

a=MEASURE c=33deg d=39deg e=-deg P1=-kPa P2=-mmHg V6=1.6+-0.6V V7=7.6+-0.4V

----------

V1=y+-0.03V V2=1.6+-0.6V V3=-V V4=-V V5=-V C3=0.1~10.2deg C4=(19.4)deg Vi=10V P1=-kPa P2=-mmHg

Information:

3. Remove nuts (1) and the bearing caps. Push the rods and pistons up until the rings are out of the cylinder liners. 4. Remove pistons (2) and connecting rod from the cylinder liners.5. Do Steps 1 through 4 for the remainder of the pistons.Install Pistons

1. Put clean engine oil on piston rings, connecting rod bearings and cylinder liners.

Never install the ring compressor on the piston unless the cylinder liner is used as a guide. Damage to the piston rings can be the result.

2. Use tool (A) and install pistons (1) and connecting rods in the cylinder liner. Be sure the number on the tab groove side of the connecting rod is on the opposite side from the camshaft.3. Install the bearing caps on the connecting rods with number on side of the bearing caps on the same side and same number as on the connecting rod.4. Install the nuts and tighten to a torque of 60 6 lb.ft. (80 8 N m). Put a mark on the nuts and caps and tighten nuts an extra 120°.5. Do Steps 1 through 4 for the remainder of the pistons.end by:a) install oil pumpb) install cylinder headDisassemble And Assemble Pistons

start by:a) remove pistons 1. Remove bearings (2) from the connecting rod and connecting rod cap.2. Remove retainer ring (1). Remove piston pin (3) from the piston and connecting rod. 3. Use tool (A) to remove the piston rings (4) from the piston. 4. Heat the connecting rod to a temperature of 350 to 500°F (177 to 260°C). Put connecting rod (6) in position on the base plate of tooling (B). Put a new bearing (5) on the adapter of tooling (B). Put the adapter in position in the connecting rod and base plate of tooling (B). 5. Install the pusher adapter (8) and pusher (7) from tooling (B) on the adapter. The old bearing is pushed out by tooling (B) as the new bearing is installed.6. Use tooling (B) to push the new bearing (5) into the connecting rod (6) until the push adapter of tooling (B) makes full contact with the connecting rod surface. See USE OF PISTON PIN BEARING REMOVAL AND INSTALLATION TOOLS, SPECIAL INSTRUCTION, Form No. SMHS7295. Use tooling (C) for later type connecting rods (tapered ends).7. Check the piston pin bore diameter after the bearing is installed. The correct dimension is 2.0012 .0003 in. (50.830 0.008 mm).8. Clean the ring grooves in the piston before rings are installed. The two compression rings have marks "UP-1" and "UP-2". The rings must be installed with these marks toward the top of the piston with "UP-1" as the top ring. After installation of all three piston rings, put piston rings in position so gaps in rings are 120° apart. 9. Use tool (A) to install the piston rings on the piston. 10. Install bearings (2) in the connecting rod and connecting rod cap. Be sure the tabs in back of bearings are in the tab

1. Put clean engine oil on piston rings, connecting rod bearings and cylinder liners.

Never install the ring compressor on the piston unless the cylinder liner is used as a guide. Damage to the piston rings can be the result.

2. Use tool (A) and install pistons (1) and connecting rods in the cylinder liner. Be sure the number on the tab groove side of the connecting rod is on the opposite side from the camshaft.3. Install the bearing caps on the connecting rods with number on side of the bearing caps on the same side and same number as on the connecting rod.4. Install the nuts and tighten to a torque of 60 6 lb.ft. (80 8 N m). Put a mark on the nuts and caps and tighten nuts an extra 120°.5. Do Steps 1 through 4 for the remainder of the pistons.end by:a) install oil pumpb) install cylinder headDisassemble And Assemble Pistons

start by:a) remove pistons 1. Remove bearings (2) from the connecting rod and connecting rod cap.2. Remove retainer ring (1). Remove piston pin (3) from the piston and connecting rod. 3. Use tool (A) to remove the piston rings (4) from the piston. 4. Heat the connecting rod to a temperature of 350 to 500°F (177 to 260°C). Put connecting rod (6) in position on the base plate of tooling (B). Put a new bearing (5) on the adapter of tooling (B). Put the adapter in position in the connecting rod and base plate of tooling (B). 5. Install the pusher adapter (8) and pusher (7) from tooling (B) on the adapter. The old bearing is pushed out by tooling (B) as the new bearing is installed.6. Use tooling (B) to push the new bearing (5) into the connecting rod (6) until the push adapter of tooling (B) makes full contact with the connecting rod surface. See USE OF PISTON PIN BEARING REMOVAL AND INSTALLATION TOOLS, SPECIAL INSTRUCTION, Form No. SMHS7295. Use tooling (C) for later type connecting rods (tapered ends).7. Check the piston pin bore diameter after the bearing is installed. The correct dimension is 2.0012 .0003 in. (50.830 0.008 mm).8. Clean the ring grooves in the piston before rings are installed. The two compression rings have marks "UP-1" and "UP-2". The rings must be installed with these marks toward the top of the piston with "UP-1" as the top ring. After installation of all three piston rings, put piston rings in position so gaps in rings are 120° apart. 9. Use tool (A) to install the piston rings on the piston. 10. Install bearings (2) in the connecting rod and connecting rod cap. Be sure the tabs in back of bearings are in the tab

Have questions with 104745-9003?

Group cross 104745-9003 ZEXEL

Nissan-Diesel

Nissan-Diesel

Nissan

104745-9003

9 460 611 962

167006T016

INJECTION-PUMP ASSEMBLY

TD27

TD27

Nissan-Diesel

104745-9003

9 460 611 962

167006T016

INJECTION-PUMP ASSEMBLY

TD27

TD27