Information injection-pump assembly

ZEXEL

104745-8800

1047458800

Rating:

Cross reference number

ZEXEL

104745-8800

1047458800

Zexel num

Bosch num

Firm num

Name

104745-8800

INJECTION-PUMP ASSEMBLY

11CJ VE4 VE

11CJ VE4 VE

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113orSAEJ967d

1404 Test oil ISO4113orSAEJ967d

Test oil temperature

degC

45

45

50

Nozzle

105780-0060

Bosch type code

NP-DN0SD1510

Nozzle holder

105780-2150

Opening pressure

MPa

13

13

13.3

Opening pressure

kgf/cm2

133

133

136

Injection pipe

157805-7320

Injection pipe

Inside diameter - outside diameter - length (mm) mm 2-6-450

Inside diameter - outside diameter - length (mm) mm 2-6-450

Joint assembly

157641-4720

Tube assembly

157641-4020

Transfer pump pressure

kPa

20

20

20

Transfer pump pressure

kgf/cm2

0.2

0.2

0.2

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Pump speed

r/min

1000

1000

1000

Average injection quantity

mm3/st.

55.4

54.9

55.9

Difference in delivery

mm3/st.

4.5

Basic

*

Oil temperature

degC

50

48

52

Injection timing adjustment_02

Pump speed

r/min

600

600

600

Average injection quantity

mm3/st.

47.7

45.2

50.2

Oil temperature

degC

48

46

50

Injection timing adjustment_03

Pump speed

r/min

1000

1000

1000

Average injection quantity

mm3/st.

55.4

54.4

56.4

Difference in delivery

mm3/st.

5

Basic

*

Oil temperature

degC

50

48

52

Injection timing adjustment_04

Pump speed

r/min

1500

1500

1500

Average injection quantity

mm3/st.

53.4

50.9

55.9

Oil temperature

degC

50

48

52

Injection timing adjustment_05

Pump speed

r/min

2000

2000

2000

Average injection quantity

mm3/st.

57

53.5

60.5

Oil temperature

degC

50

48

52

Injection quantity adjustment

Pump speed

r/min

2475

2475

2475

Average injection quantity

mm3/st.

18.5

15.5

21.5

Difference in delivery

mm3/st.

5.5

Basic

*

Oil temperature

degC

52

50

54

Injection quantity adjustment_02

Pump speed

r/min

2800

2800

2800

Average injection quantity

mm3/st.

5

Oil temperature

degC

55

52

58

Injection quantity adjustment_03

Pump speed

r/min

2475

2475

2475

Average injection quantity

mm3/st.

18.5

13.5

23.5

Difference in delivery

mm3/st.

6

Basic

*

Oil temperature

degC

52

50

54

Governor adjustment

Pump speed

r/min

350

350

350

Average injection quantity

mm3/st.

13.4

11.4

15.4

Difference in delivery

mm3/st.

2

Basic

*

Oil temperature

degC

48

46

50

Governor adjustment_02

Pump speed

r/min

350

350

350

Average injection quantity

mm3/st.

13.4

10.9

15.9

Difference in delivery

mm3/st.

2.5

Basic

*

Oil temperature

degC

48

46

50

Governor adjustment_03

Pump speed

r/min

750

750

750

Average injection quantity

mm3/st.

5

Oil temperature

degC

50

48

52

Timer adjustment

Pump speed

r/min

150

150

150

Average injection quantity

mm3/st.

46

36

56

Basic

*

Oil temperature

degC

48

46

50

Remarks

IDLE

IDLE

Timer adjustment_02

Pump speed

r/min

150

150

150

Average injection quantity

mm3/st.

46

36

56

Oil temperature

degC

48

46

50

Remarks

IDLE

IDLE

Speed control lever angle

Pump speed

r/min

350

350

350

Average injection quantity

mm3/st.

0

0

0

Oil temperature

degC

48

46

50

Remarks

Magnet OFF at idling position

Magnet OFF at idling position

0000000901

Pump speed

r/min

1250

1250

1250

Overflow quantity

cm3/min

800

670

930

Oil temperature

degC

50

48

52

Stop lever angle

Pump speed

r/min

1250

1250

1250

Pressure

kPa

579

559

599

Pressure

kgf/cm2

5.9

5.7

6.1

Basic

*

Oil temperature

degC

50

48

52

0000001101

Pump speed

r/min

1250

1250

1250

Timer stroke

mm

4.9

4.7

5.1

Basic

*

Oil temperature

degC

50

48

52

_02

Pump speed

r/min

700

700

700

Timer stroke

mm

2.4

1.8

3

Oil temperature

degC

50

48

52

_03

Pump speed

r/min

1250

1250

1250

Timer stroke

mm

4.9

4.5

5.3

Basic

*

Oil temperature

degC

50

48

52

_04

Pump speed

r/min

2000

2000

2000

Timer stroke

mm

7.4

6.9

7.8

Oil temperature

degC

50

48

52

0000001201

Max. applied voltage

V

8

8

8

Test voltage

V

13

12

14

0000001501

Pump speed

r/min

1000

1000

1000

Height

m

2000

2000

2000

Atmospheric pressure difference

kPa

-21.9

-21.9

-21.9

Atmospheric pressure difference

mmHg

-164

-164

-164

Average injection quantity

mm3/st.

48.8

47.3

50.3

Decrease qty

mm3/st.

6.6

6.6

6.6

Decrease rate

%

12

12

12

Basic

*

Oil temperature

degC

50

48

52

_02

Pump speed

r/min

1000

1000

1000

Height

m

0

0

0

Atmospheric pressure difference

kPa

0

0

0

Atmospheric pressure difference

mmHg

0

0

0

Average injection quantity

mm3/st.

55.4

54.4

56.4

Oil temperature

degC

50

48

52

_03

Pump speed

r/min

1000

1000

1000

Height

m

500

500

500

Atmospheric pressure difference

kPa

-5.9

-9.2

-2.6

Atmospheric pressure difference

mmHg

44

19

69

Average injection quantity

mm3/st.

55.4

55.4

55.4

Oil temperature

degC

50

48

52

_04

Pump speed

r/min

1000

1000

1000

Height

m

2000

2000

2000

Atmospheric pressure difference

kPa

-21.9

-21.9

-21.9

Atmospheric pressure difference

mmHg

-164

-164

-164

Average injection quantity

mm3/st.

48.8

46.8

50.8

Basic

*

Oil temperature

degC

50

48

52

Timing setting

K dimension

mm

3.3

3.2

3.4

KF dimension

mm

5.8

5.7

5.9

MS dimension

mm

1.1

1

1.2

Control lever angle alpha

deg.

59

55

63

Control lever angle beta

deg.

42

37

47

Test data Ex:

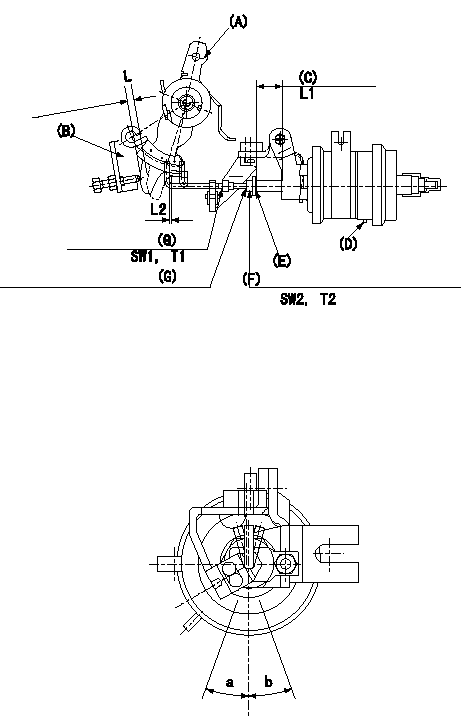

0000001801 V-FICD ADJUSTMENT

Standards for adjusting the double stage actuator

(A) Control lever

(B): Idle set bracket

(C): Actuator stroke = L1

(D): Negative pressure inlet

(E): Stroke adjusting screw

(F): Stroke adjusting nut

(G): Rod position adjusting nut

L:Thickness of the shim

Actuator adjustment

(1)Mount the actuator to the injection pump.

(2)Position the control lever in the idling position.

(3)Adjust with the nut (G) so that the space between the control lever and the rod is L2.

(4)Insert a shim with thickness of L between the lever (A) and the bracket (B).

(5)At that time, adjust with the screw (E) and fix with the nut (F) so that the actuator stroke (C) is the full stroke [with P applied to the negative pressure inlet port (D)].

(6)Allowable angle when adjusting the rod position: c

----------

L1=12.5(mm) L2=1+1(mm) L3=12.1+-0.05(mm) P=-66.7kPa(-500mmHg) c=+-20(deg)

----------

a=20(deg) b=20(deg) L=12.1+-0.05mm L1=12.5mm L2=1+1mm T1=1.4~2.0N-m(0.14~0.2kgf-m) T2=3.4~4.9N-m(0.35~0.5kgf-m) SW1=SW7 SW2=SW8

----------

L1=12.5(mm) L2=1+1(mm) L3=12.1+-0.05(mm) P=-66.7kPa(-500mmHg) c=+-20(deg)

----------

a=20(deg) b=20(deg) L=12.1+-0.05mm L1=12.5mm L2=1+1mm T1=1.4~2.0N-m(0.14~0.2kgf-m) T2=3.4~4.9N-m(0.35~0.5kgf-m) SW1=SW7 SW2=SW8

Information:

b. Operate vehicle at 60% of rated speed with moderate load until oil and coolant temperatures reach their normal range for operation. If there is a heavy vibration, drive shaft whip, tire bounce, etc., do not continue with dynamometer test until cause of the problem is corrected. Engines that have had new internal parts installed should be operated on a run-in schedule before operation at full load. For run-in schedule information, make reference to General Instructions section of this Service Manual.2. Put transmission in direct gear and the differential in the highest speed ratio. Operate vehicle at maximum engine speed and increase chassis dynamometer load until a speed of 50 rpm less than rated speed is reached (continuity light should be on). Maintain this speed for one minute and record the engine speed and wheel horsepower. If horsepower is low and poor maintenance is suspected, remove air cleaner or inlet piping to turbocharger and check horsepower again to see if a plugged air cleaner could be the problem.3a. If the wheel horsepower is correct, find the balance point of the engine (speed at which the rack adjustment screw just touches the torque spring or stop bar). At this point the continuity light should flicker (go off and on dimly). If the balance point is correct, then the low power complaint can not be validated. No further test or repairs are necessary.If the balance point is low, see Procedure No. 5.3b. If the wheel horsepower is below the correct value, find the balance point of the engine (speed at which the rack adjustment screw just touches the torque spring or stop bar). At this point the continuity light should flicker (go off and on dimly). If the balance point is correct, see Procedure No. 6If the balance point is low, see Procedure No. 4.4. Stop the engine. Remove the AFRC (air-fuel ratio control). Put a cover over the hole where the AFRC was installed. Start the engine and check the balance point and horsepower again. If both of these are now correct, the problem is in AFRC. Repair or replace the AFRC. If, with the AFRC removed, horsepower is now acceptable and balance point is low, the problem is still with AFRC. Repair or replace the AFRC. Then adjust balance point according to Procedure No. 5.5. If the balance point is low, the high idle will have to be increased to raise the balance point to the correct rpm (the point at which the continuity light just comes on). If the balance point is still low and high idle has been adjusted to maximum, disengage clutch while maximum throttle position is maintained. Now observe high idle rpm and, if lower than previously adjusted, check frame-to-engine-mount. A damaged or loose engine mount may put the linkage in a bind and thus prevent maximum governor position at load conditions.6. If the balance point was correct and the wheel horsepower was low, install the 4S6553 Engine Test Group and do the wheel

Have questions with 104745-8800?

Group cross 104745-8800 ZEXEL

104745-8800

INJECTION-PUMP ASSEMBLY